INSTRUCTIONS

For

504 504T A504 A504T B504 B504T C504 C504T 0504 0504T

505 505T A505 A505T B505 B505T C505 C505T 0505 0505T

507 507T A507 A5071 C507 C5071 0507 and 0507T

Vertical Air Grinders Sanders and Wire Brush

GENERAL INSTRUCTIONS

Before placing the tool in operation, the foreman and operator is cautioned to study and FOLLOW all in-

structions with special emphasis on safety (refer to Important Safety Requirements ). The foreman and

safety director must be acquainted with and follow the requirements of the applicable Section of the A.S.A.

Safety Code B7.1latest edition.

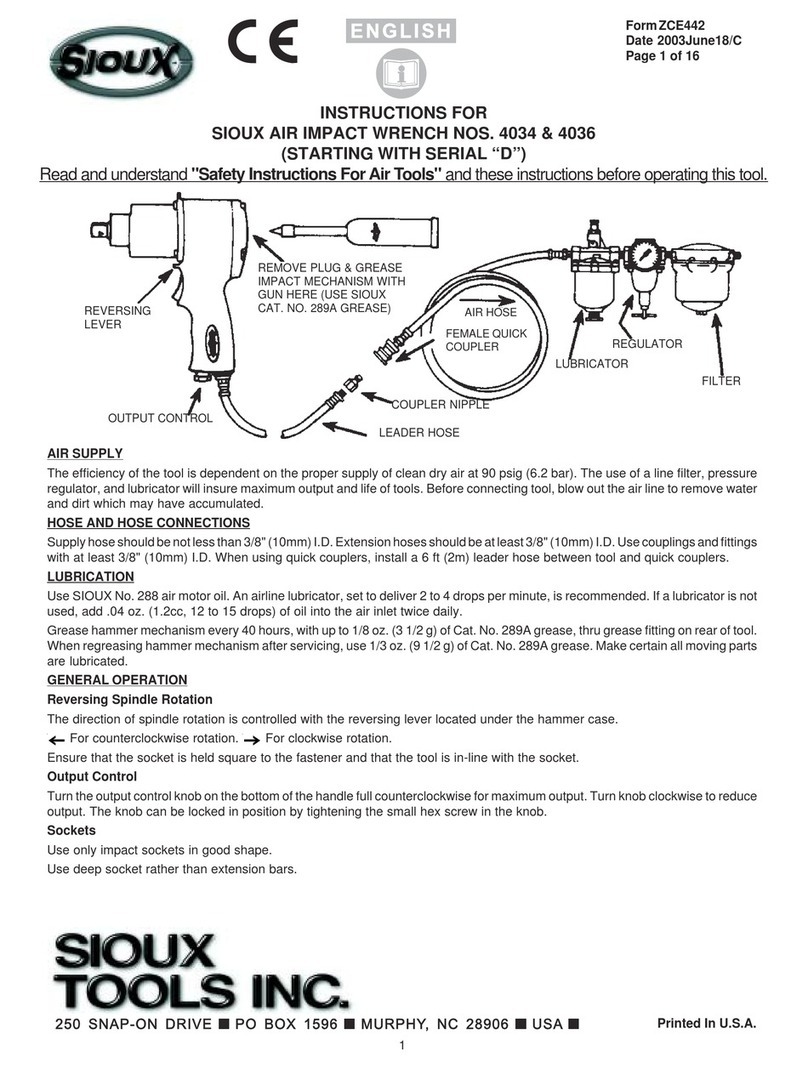

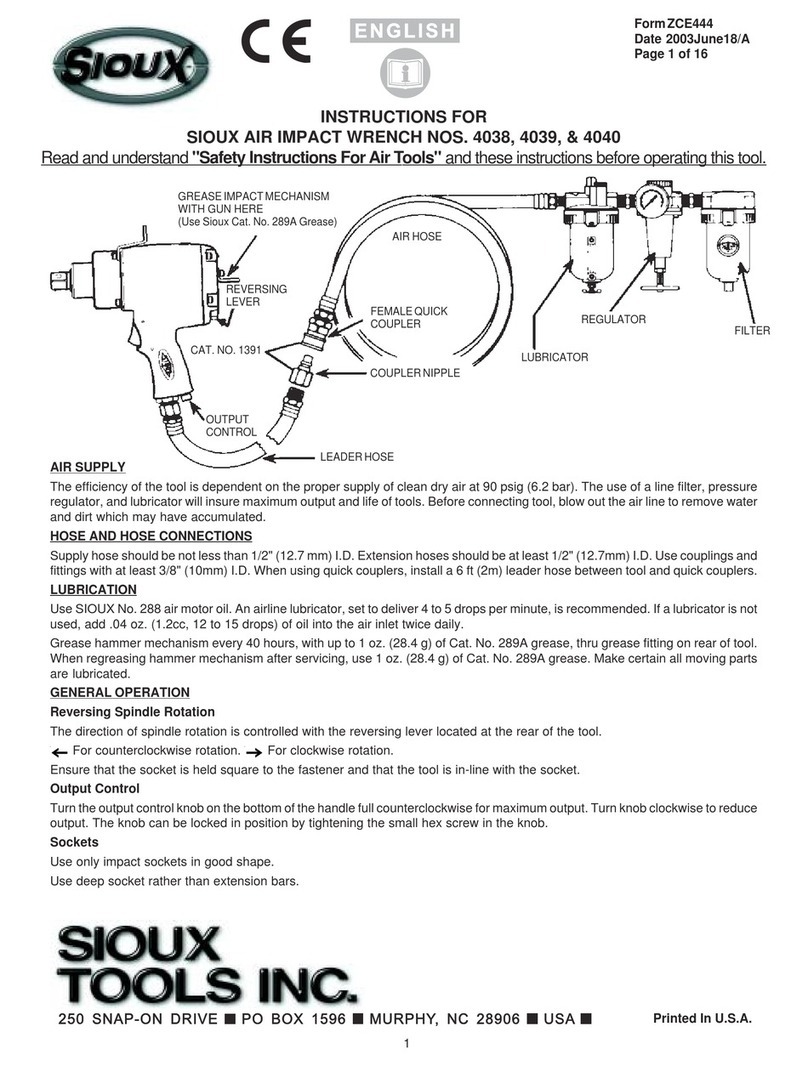

AIR SUPPLY

Grinders are designed to operate on clean moisture free air at a pressure of 90 p.s.i. at the tool with filter,

pressure regulator and lubricator in the air line. If the lubricator is eliminated, the oil chamber in the tool

must be filled daily. Air hose should not be less than

Y2

I.D. Quick couplers, if used should be

7'2

size.

Before connecting- tool, blow the air line to remove water and dirt. This is especially important for a new

line or ope which has not been sed for a time.

LUBRICATION

The air motor is lubricated with an air line lubricant designed to prevent rust and supply adequate lubrica-

tion. Our Cat. No. 288 oil is excellent. Adjust oiler to 3 to 4 drops per minute. If the air line lubricator

is not used, fill oil reservoir daily.

After 40 hours of use, inject 3 to 4 shots of grease (our Cat. No. 1232) through the grease fttings with

grease gun supplied. See maintenance'; for additional instructions.

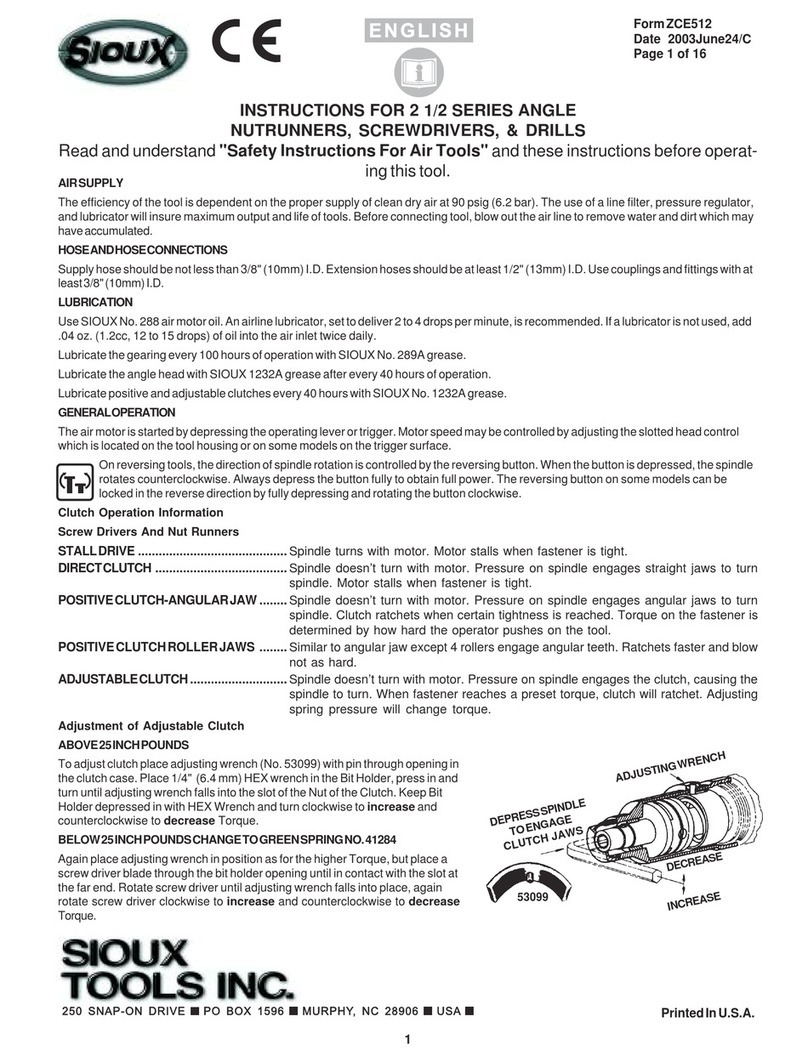

OPERATION

Grind steadily without excessive slowing down of the grinder to prevent wheel damage which could result

in breakage. Grind at as uniform load speed as possible to prevent excess wear, especially on governor

parts. A dropped or severly bumped wheel must be correctly examined before reusing. Do not drop the end

of the hose on a floor where it will pick up dirt and transport it into the tool, causing excessive wear and

governor sticking. Provide a stand for holding the grinder when not in use.

OVERS PEE DING

If overspeeding occurs, the grinder MUST BE REPAIRED and WORN PARTS REPLACED. (GRIND-

ERS MUST BE CHECKED DAILY WITH A TACHOMETER).

SAFETY

See General Instructions and Important Safety Requirements.

MAINTENANCE

Grinders must be serviced at definite intervals for safe operation and lowest operating cost. Dismantle after

100 hours of use. If little wear is shown, the time may be extended. Mechanics must be qualified, work in

clean areas, recognize worn parts and the need of moving parts to be lubricated. Pack a liberal amount of

Sioux No. 1232 grease around governor and levers. The use of Sioux Authorized Service Stations is recom-

mended.

SIOUX TOOLS INC

SIOUX

CITY IOWA U.S.A.

51102

FORM 162-10.70