EF1-MAN-01-07/08 3

Introduction

This manual gives instructions on the correct use of the EF1 welding unit. It is important that these instructions are

read and understood prior to use of this equipment and that they are kept with the welder for the life of this unit.

The EF1 automatically recognises the fitting when connected with the correct welding cable and applies the correct

amount of energy for a successful weld. It also checks the ambient temperature using a sensor positioned on the main

supply cable and adjusts the energy level to balance with the local environment.

The EF1 has an ON / OFF button, a weld start button and an LED display showing the weld progress and fault

indication

Safety Notes

• RISK OF EXPLOSION! - This welding unit must not be used in a gaseous atmosphere.

• RISK OF ELECTRIC SHOCK! - Do not open. No user serviceable parts inside.

• This welding unit is only to be used by trained persons, certified by PetroTechnik .

• Visually inspect welding unit, cables and connectors and replace any damaged parts prior to use.

• For use outside of hazardous areas (ATEX zones 0, 1 and 2)

• To avoid damage to the welding unit, do not interrupt the supply voltage or disconnect the output lead, while the

unit is in operation.

• Never lift or pull the welder by its cables.

• Never disconnect welding cables by pulling them always pull on the connectors.

• Keep bystanders a safe distance from welder during welding operations.

• Always use safety equipment ( Hi-visibility jacket, Safety Boots, Safety Helmut and Safety Goggles) when

operating on site.

• Always isolate welding unit from its power supply before adjusting, cleaning, un-tangling cables or leaving

unattended for any period.

• The operator is responsible for accidents or hazards occurring to other people or their property while using this

equipment (Keep the WorkArea Safe).

• Weld only in daylight or good artificial light.

• Do not weld in the rain or leave equipment outdoors while it is raining.

• Do not start welder without connecting welding cables to a properly prepared fitting assembly.

• Do not touch the fitting during the welding cycle.

• Ensure the EF1 is positioned in the environment it is to be used in prior to welding so that the temperature sensor

has opportunity to reach the ambient temperature prior to use.

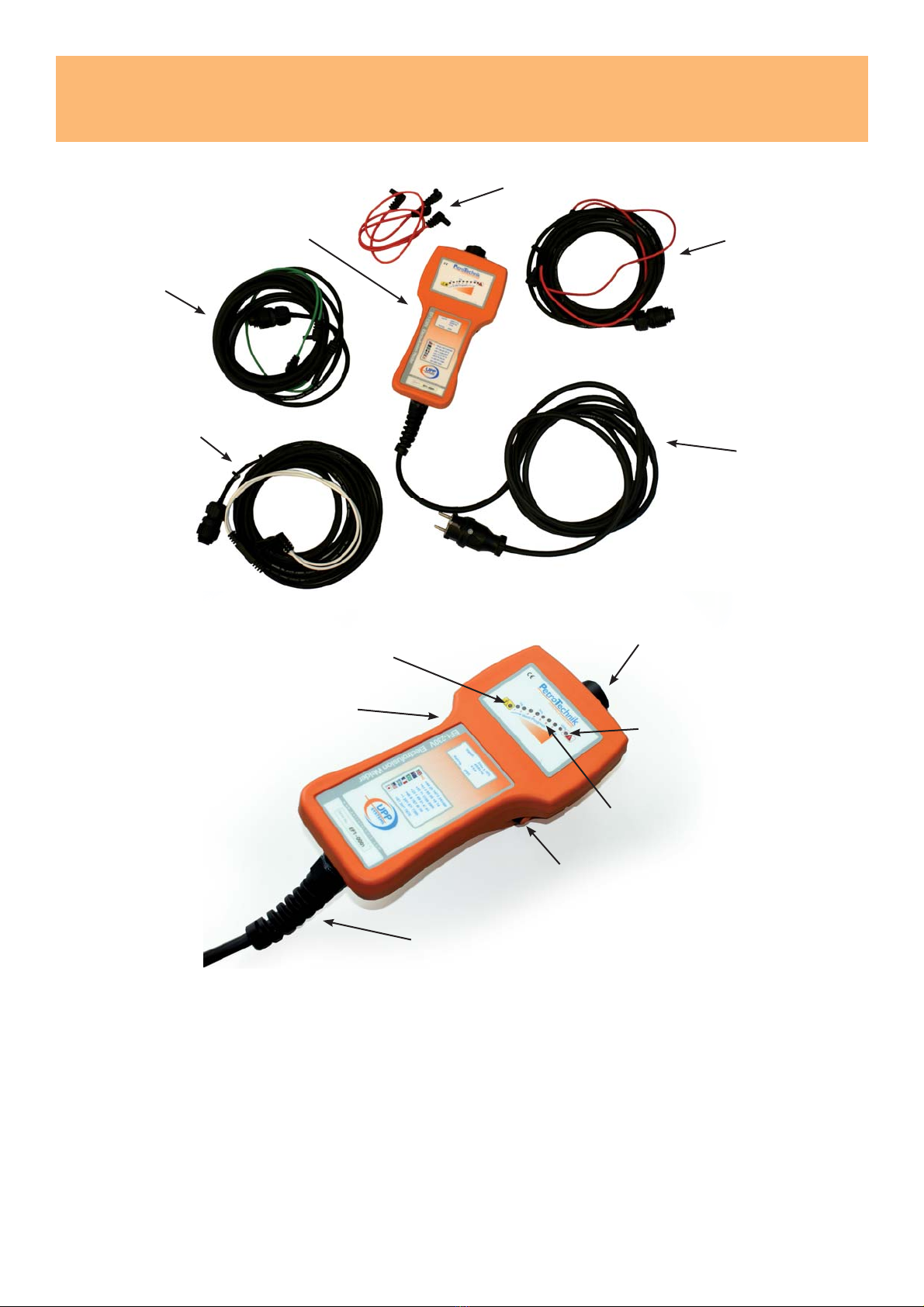

Application

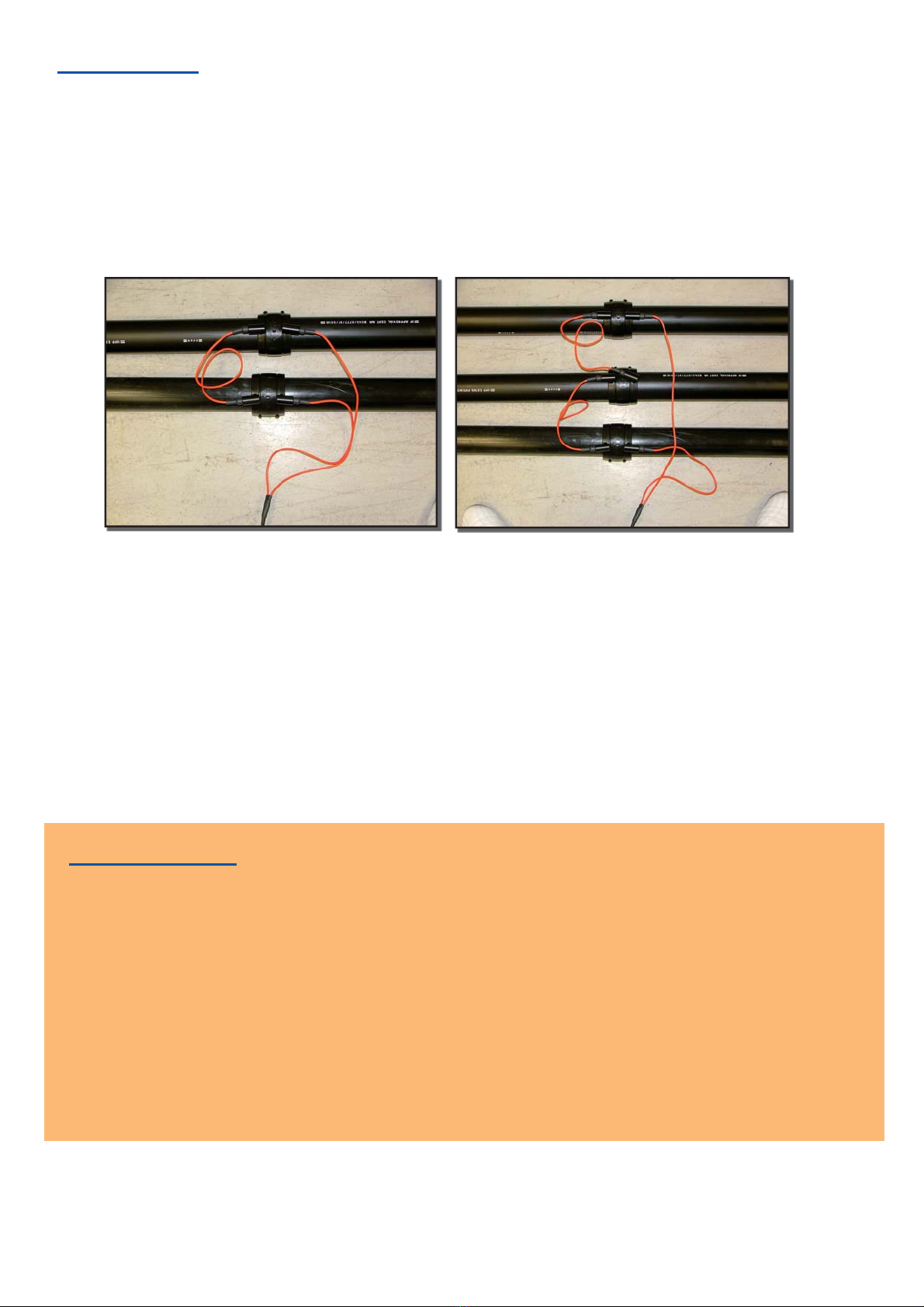

The EF1 is designed to automatically weld UPP Primary and Secondary Containment electrofusion fittings,

Electrofusion Chambers and Large diameter 10 amp fittings. This is achieved by using colour coded

welding leads as shown below.

Type of Fitting Welding Cable

Colour Size of Welding Pin

(mm) Crrent

(amps) Weld Time @ 20C

(Seconds)

Primary Red 4 4 184

Secondary Green 2 5 80

Fusion Chamber White 2.3 7 360

Large Diameter

(10 amp) Black 2 10 365

The EF1 can be used in ambient temperatures between -15°C and +45°C

Only personnel fully trained and certified in the use and installation of the UPP system should use this

equipment.