The installation position must be well-ventilated in accordance with the local

regulations;

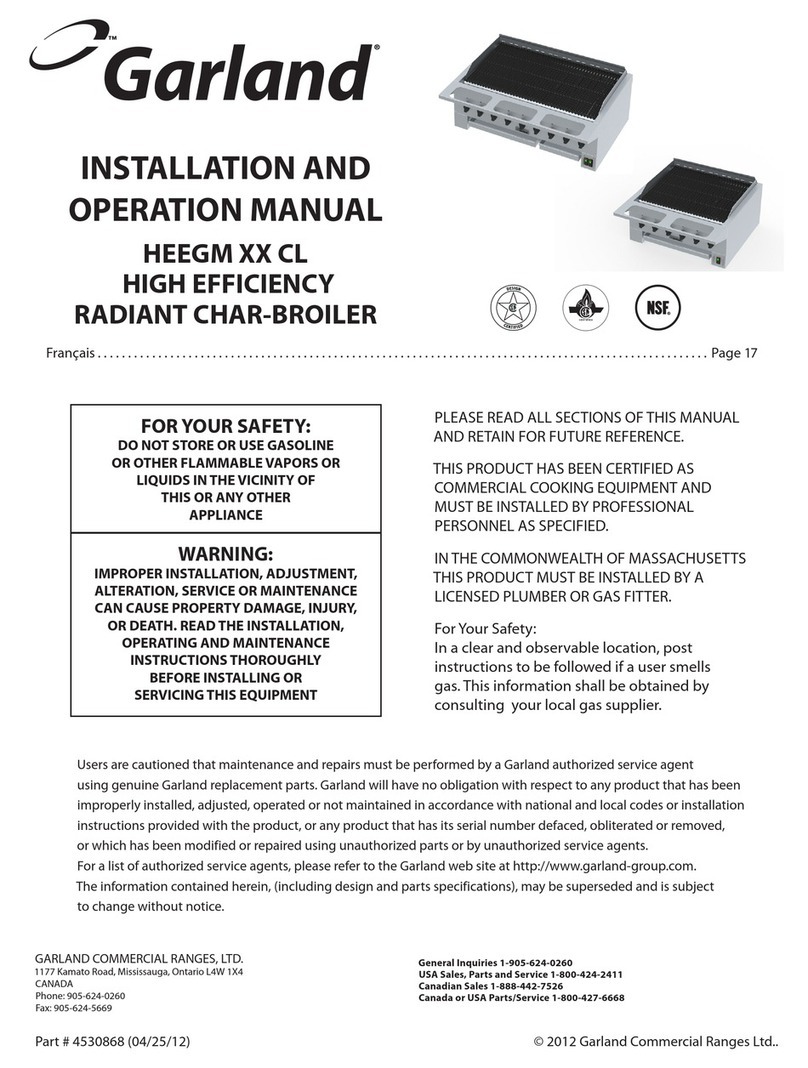

The char broiler must be installed under the matched cooking fume exhauster

according to the local regulations;

Important: Installation and ventilation laws, and codes are very different, you

should state and comply with all codes of the National Fire Protection Association

Inc. when it comes to requirements for installation of equipment;

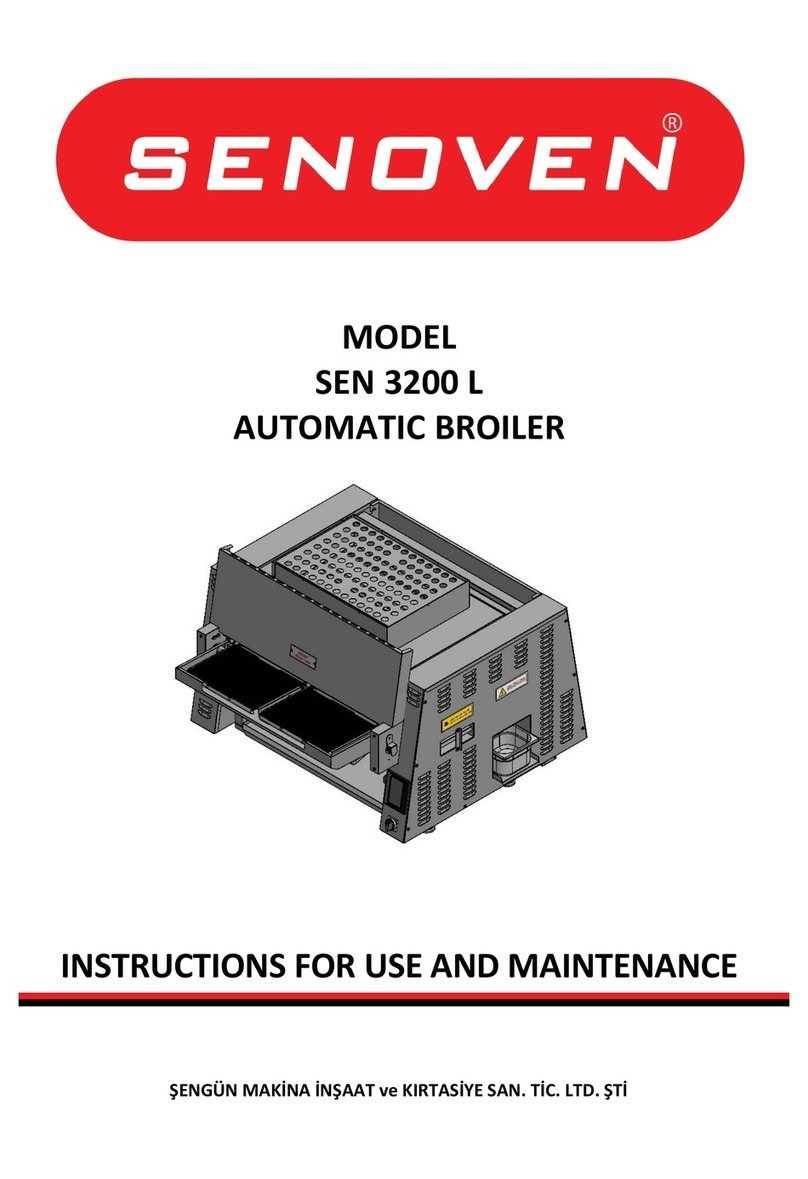

Screw four adjustable stainless steel legs in the tapping hole with four corners

of the char broiler bottom, ensure sufficient space for ventilation;

Adjustable stainless steel legs to make the equipment level, and get the same

level with other series of the same stove; Please lift the equipment rather than

drag if you need to move it;

Open the grate, and take out the support under it, and reinstall grate after you

make sure the thermal radiation plate is unmoved, and dispose the support;

Supplied gas pressure regulator is factory set at 4”Natural Gas W.C, and

10”L.P. Gas W.C;

The equipment can only be placed on a nonflammable counter top, and keep

at least 6 inches(152mm) to equipment’s both sides and back, and at least 4

inches(102mm) to the bottom;

Do not put anything around the equipment, or on the counter top and bottom,

in order to avoid influencing combustion and air circulation;

Leave enough distance in front of the equipment to take apart the control

panel. All major parts, in addition to the burner remove from the front intake-tube;

It may be necessary to adjust the balance of air input by authorized and

licensed technicians;

Pipe threading compound must be resistant to the action of liquefied

petroleum gases.

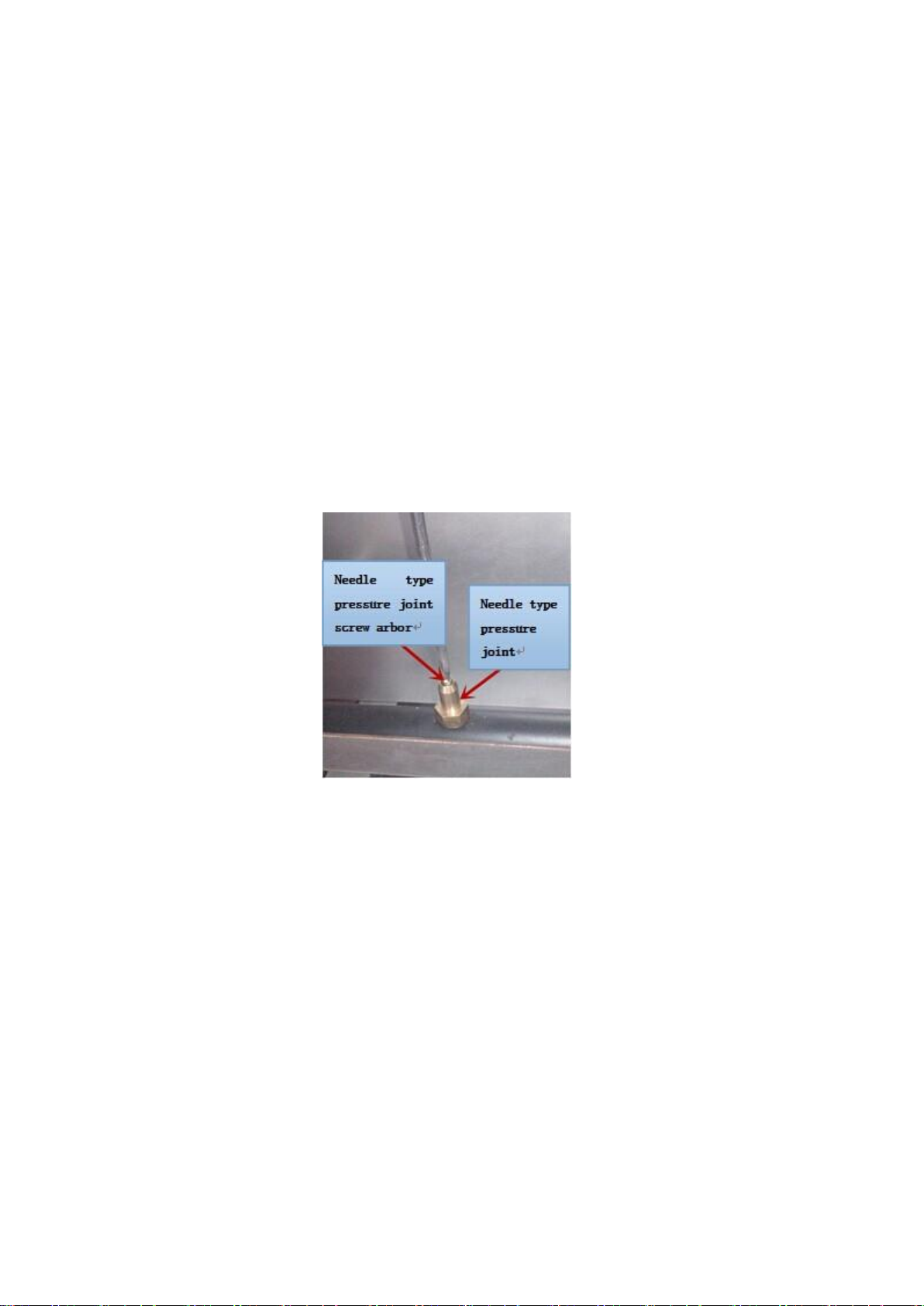

Warning! Use soap water or testing instrument to test whether piping joint

leaks before use, do not use an open flame to test!

After installing, you should check gas supply pressure. Use a pressure gauge

which is equipped with liquid (such as U-type pressure gauge, the minimum value

is 0.1mbar) or a digital pressure gauge to test.