Utilitech UT-IO-70C User manual

Purchase Date

ATTACH YOUR RECEIPT HERE

1

SM20225

Serial Number

MODEL #UT-IO-70C

Español p. 17

Questions, problems, missing parts? Before returning to your retailer, call our customer

service department at 1-866-994-4148, 8 - 8 p.m., EST, Monday - Sunday. You could also

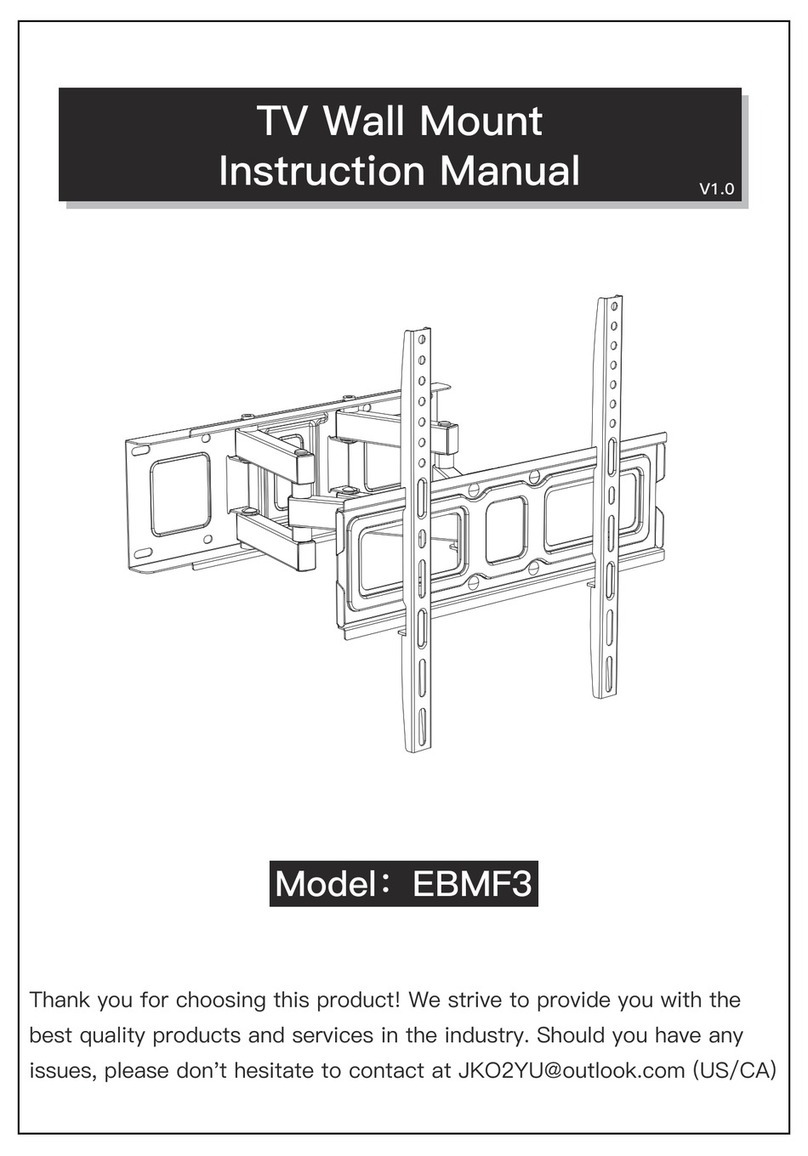

INDOOR/OUTDOOR

FULL MOTION TV MOUNT

ITEM #03850903

UTILITECH and logo design are trademarks or

registered trademarks of LF, LLC. All rights reserved.

2

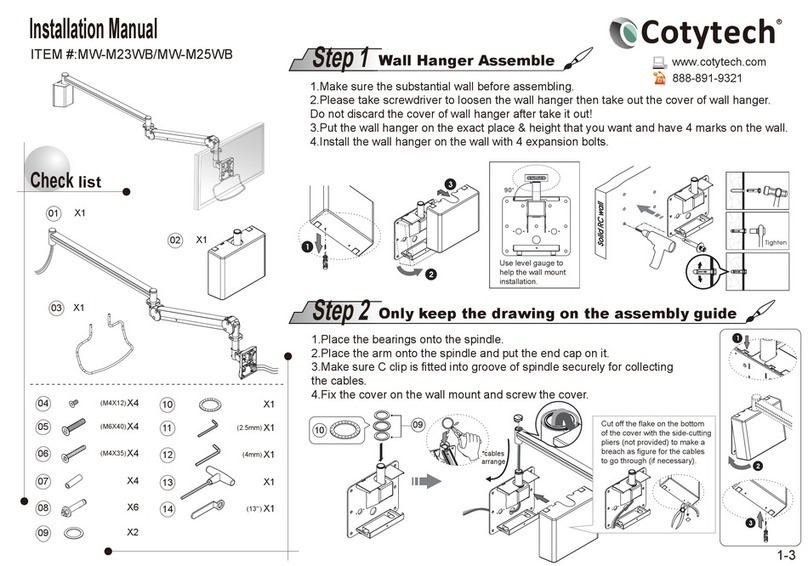

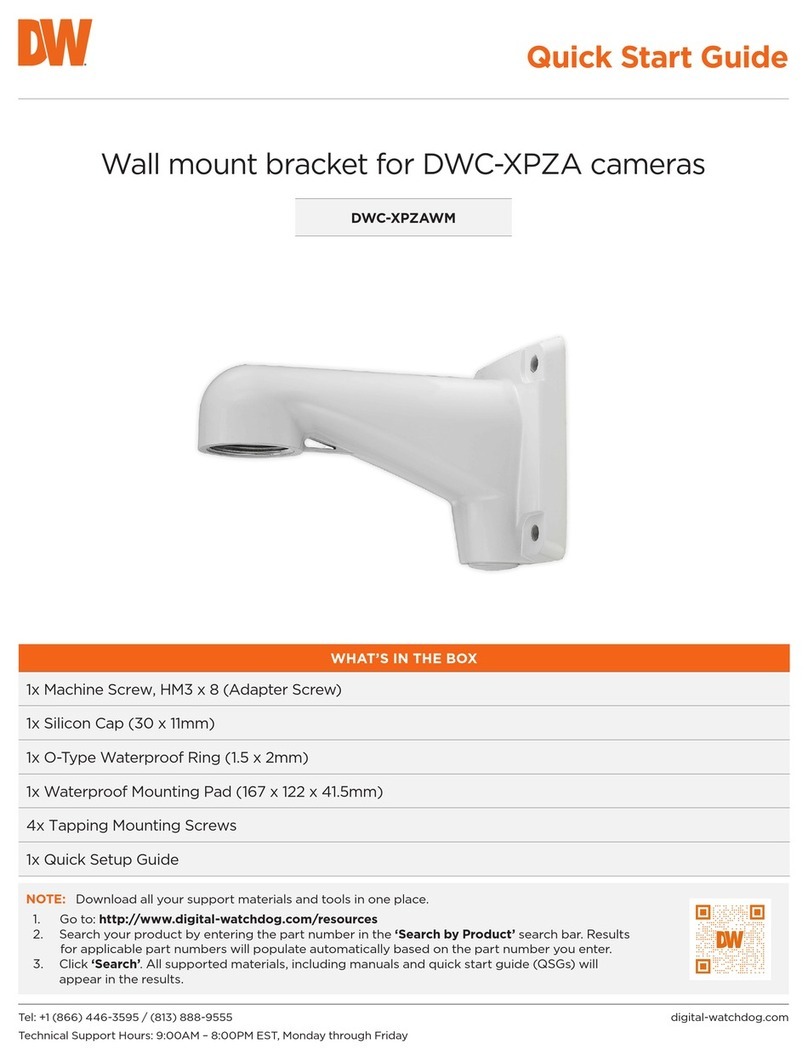

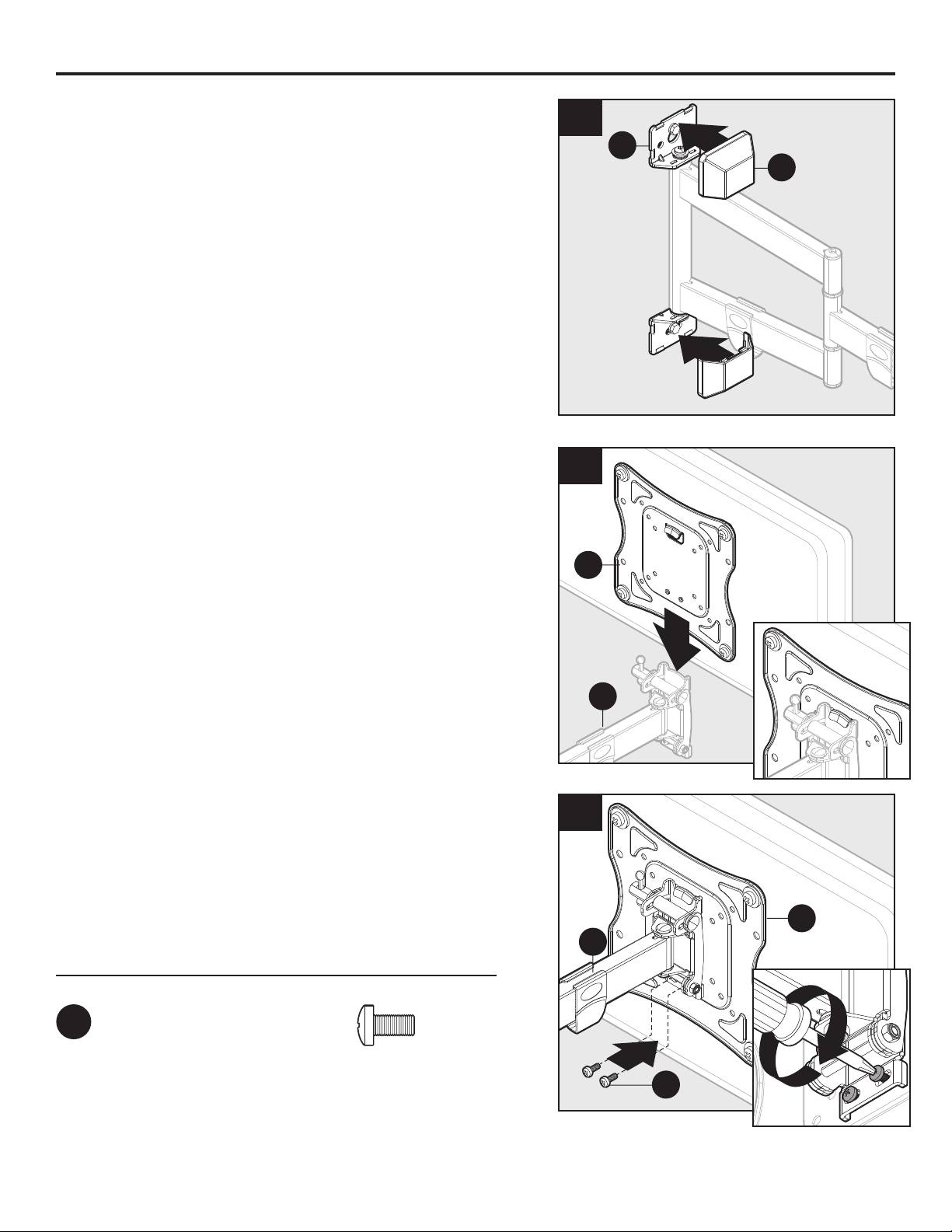

PACKAGE CONTENTS

B

B

D

C

A

C

D

E

PART DESCRIPTION QUANTITY

D Monitor adapter B 2

E Monitor plate

(pre-assembled to

Mounting arm (A))

1

PART DESCRIPTION QUANTITY

A Mounting arm 1

B End cap 2

CMonitor adapter A 2

3

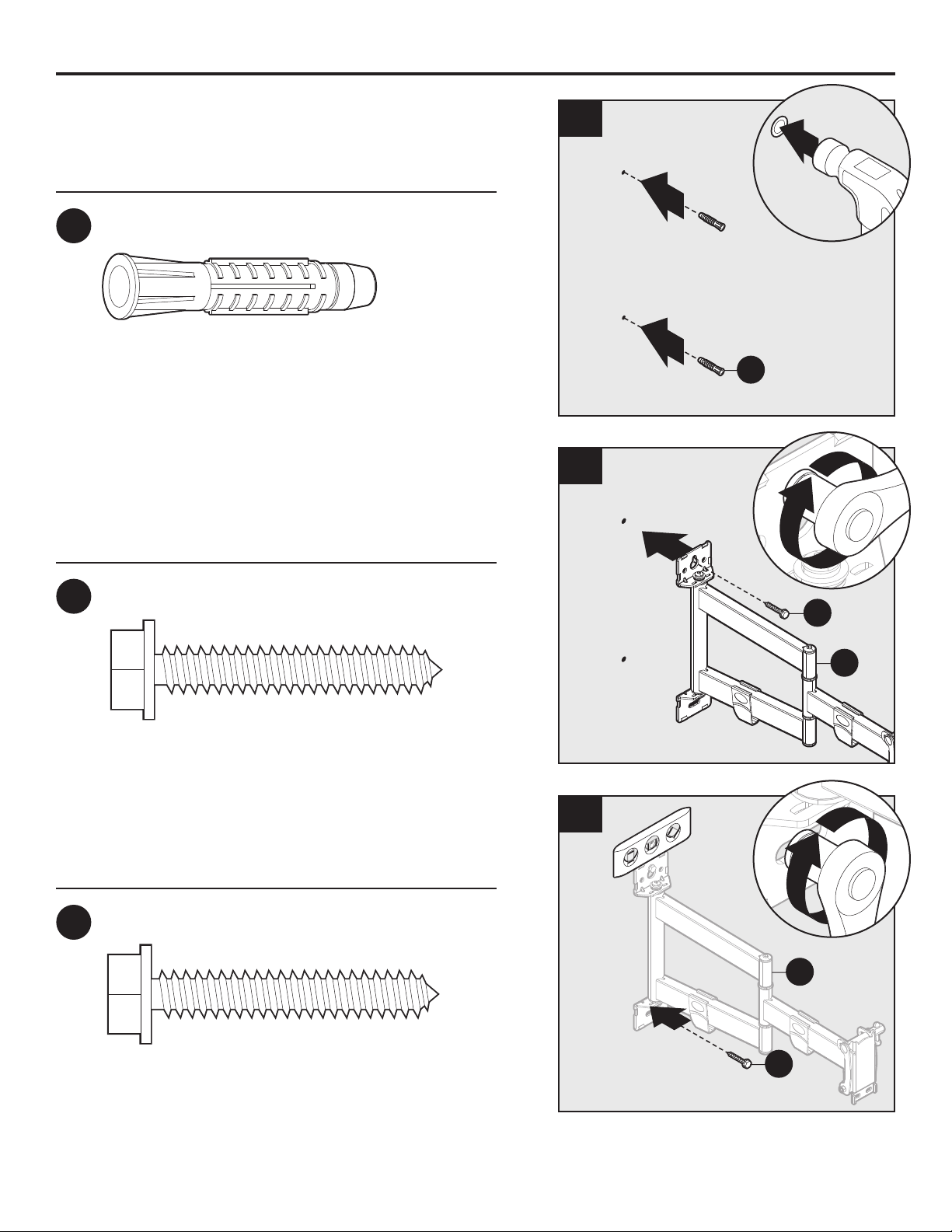

HARDWARE CONTENTS (shown actual size)

M4 x 12

Screw

Qty. 4

AA

M6 x 15

Screw

Qty. 4

CC

M8 x 15

Screw

Qty. 4

8 mm Lag bolt

Qty. 2

Anchor

Qty. 2

DD

M4 x 30

Screw

Qty. 4

EE

M6 x 30

Screw

Qty. 4

GG

M8 x 30

Screw

Qty. 4

HH

KK

5 mm

Spacer

Qty. 4

Mounting arm screw

(preassembled to

Mounting arm (A))

Qty. 2

LL

RR

PP

10 mm

Spacer

Qty. 4

MM

8 mm

Steel

washer

Qty. 8

NN

M6 x 12

Carriage Screw

Qty. 8

OO

II JJ

FF

M8 x 50

Screw

Qty. 4

M6 Nut

Qty. 8 Wrench

Qty. 1

QQ

6 mm

Steel

washer

Qty. 4

Note: All hardware is stainless steel and appropriate for outdoor use.

4

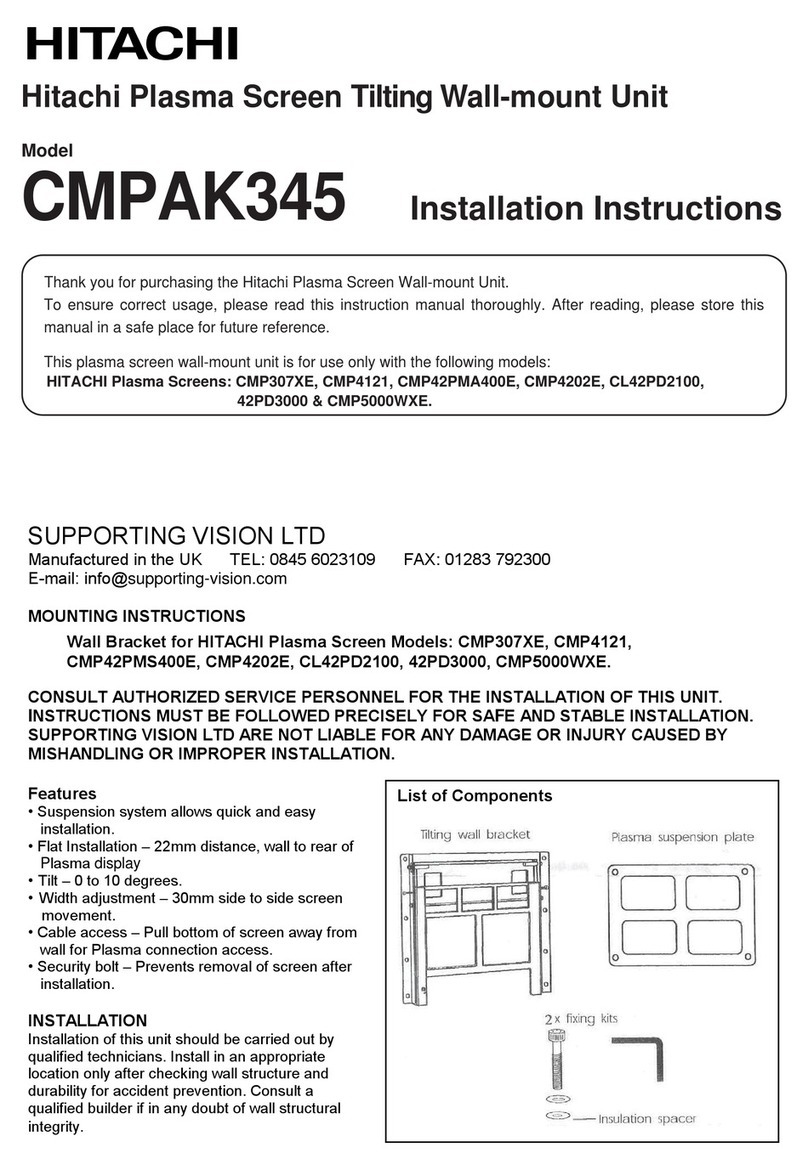

SAFETY INFORMATION

PREPARATION

Before beginning assembly of product, make sure all parts are present. Compare parts with package

contents list and hardware contents list. If any part is missing or damaged, DO NOT attempt to

assemble the product.

Estimated Assembly Time: 30 minutes

Tools Required for Assembly (not included): Drill with 7/32 in. and 3/8 in. drill bits, stud nder, socket

wrench, pencil, Phillips screwdriver, hammer, level.

Please read and understand this entire manual before attempting to assemble, operate or install the

product.

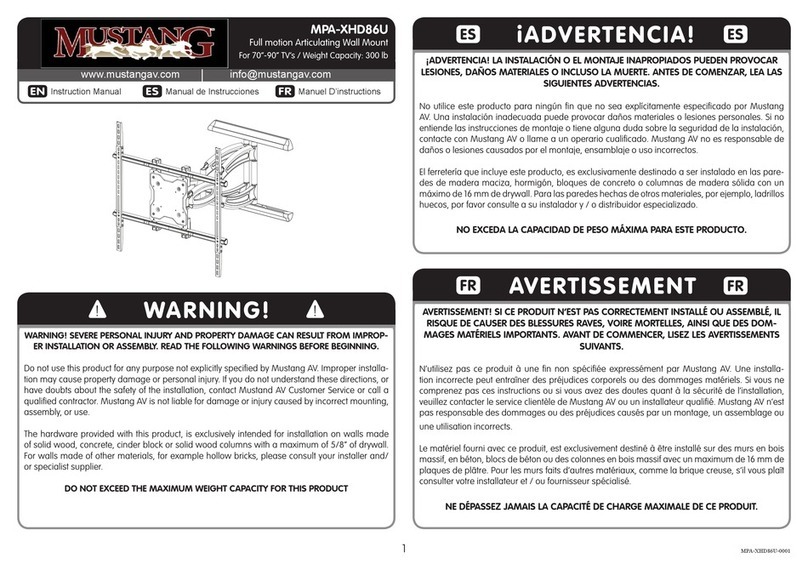

WARNING

• FAILURE TO READ, THOROUGHLY UNDERSTAND, AND FOLLOW ALL INSTRUCTIONS CAN

RESULT IN SERIOUS PERSONAL INJURY, DAMAGE TO PERSONAL PROPERTY, OR VOIDING

OF FACTORY WARRANTY.

• DO NOT attempt to install or assemble this product if the product or hardware is damaged or

missing. The included hardware is designed for use on vertical walls constructed of wood studs or

solid concrete. A wood stud wall is dened as consisting of a minimum of 2x4 wooden studs

(2 in. wide by 4 in. deep) with a maximum of 5/8 in. drywall. The included hardware is not designed

for use with metal studs or cinderblock walls. If you are uncertain about the construction of your

wall, please consult a qualied contractor or installer for assistance. For safe installation, the wall

selected for mounting must support 4 times the weight of the total load. If not, the surface must be

reinforced to meet this standard. The installer is responsible for verifying that the wall structure and

hardware used in any installation method will safely support the total load.

CAUTION

• The maximum loading weight is 70 lbs. Use with products heavier than the maximum weight

indicated may result in instability and possible personal injury.

• Max screen size: 65 in.

KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE.

5

SPECIFICATIONS

Dimensions and Mounting Congurations

300 mm (11.8 in.)

400 mm (15.7 in.)

300 mm (11.8 in.)

400 mm (15.7 in.)

300 mm (11.8 in.)

400 mm (15.7 in.)

400 mm (15.7 in.)

300 mm (11.8 in.)

75 mm

(3 in.)

100 mm

(3.9 in.)

200 mm

(7.9 in.)

75 mm

(3 in.)

100 mm

(3.9 in.)

200 mm

(7.9 in.)

CCD

D

D

DC

C

C

C

D

D

D

D

C

C

C

CD

D

D

DC

C

200 mm (7.9 in.)

6

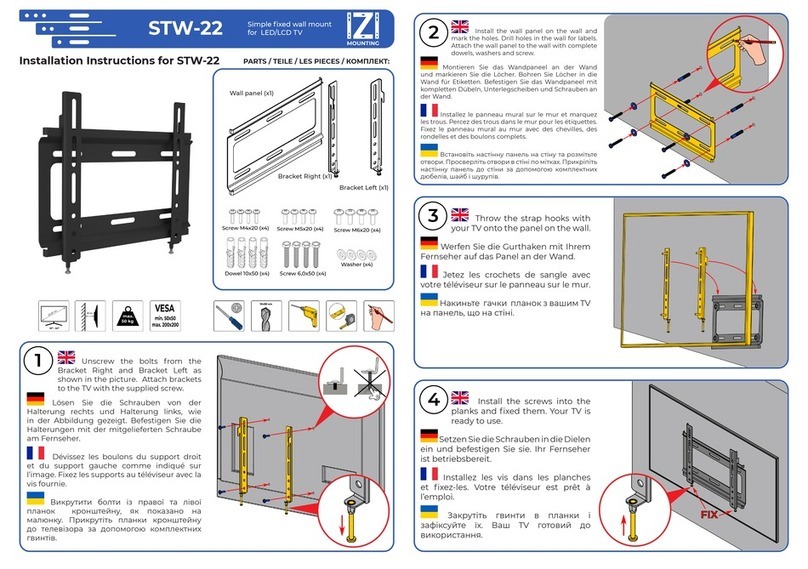

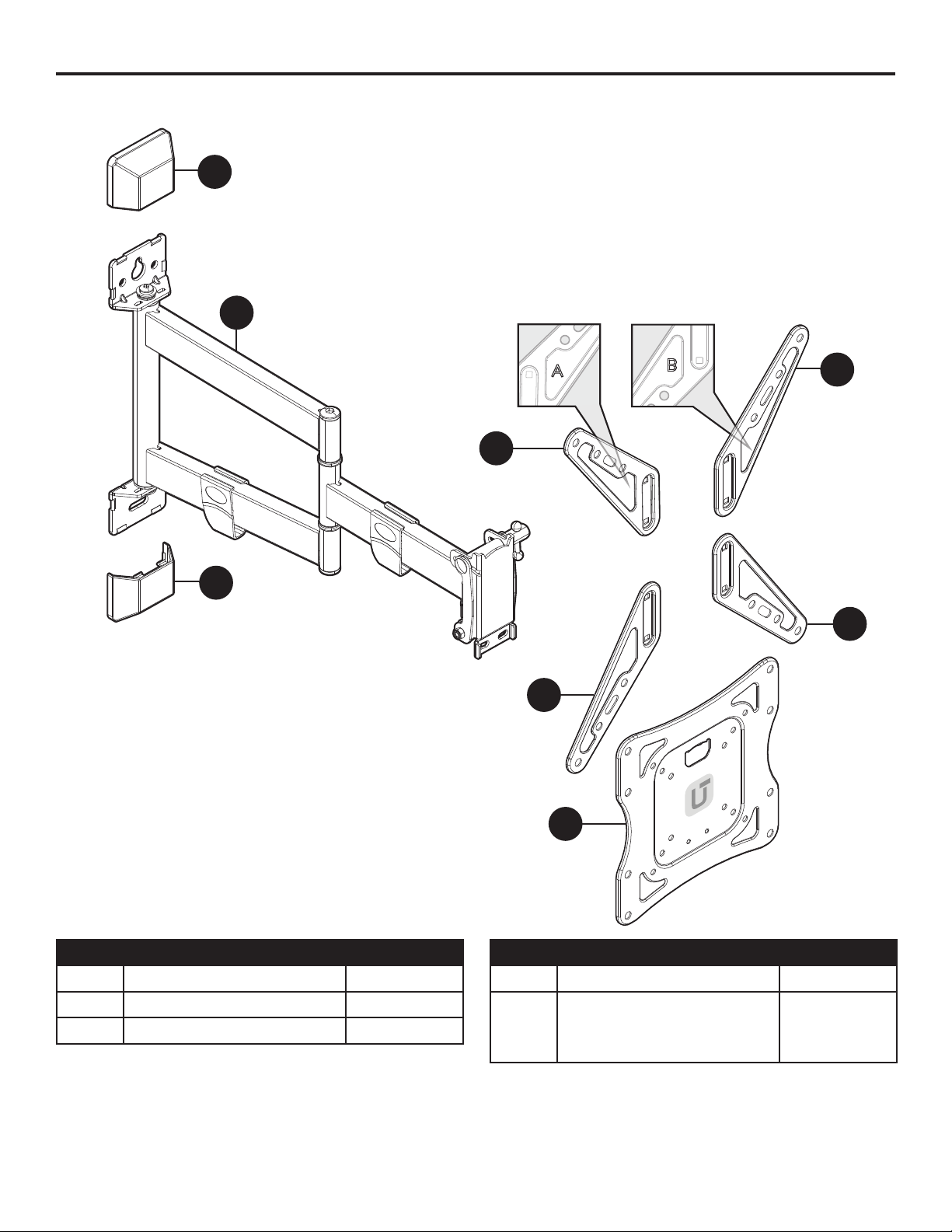

ASSEMBLY INSTRUCTIONS

3. Determine mounting conguration to use based

on the mounting hole pattern on the back of at

panel TV (not included).

2. Remove monitor plate (E) from mounting arm (A).

1. Remove two mounting arm screws (PP) from

mounting arm (A) and save them for later use.

2

E

A

11.8 in.

15.7 in.

11.8 in.

15.7 in.

11.8 in.

15.7 in.

15.7 in.

11.8 in.

3 in.

3.9 in.

7.9 in.

7.9 in.

3 in.

3.9 in.

7.9 in.

3

2

1

1

PP

A

Hardware Used

PP x 2

Mounting arm screw

M4 x 12

Screw

Qty. 4

AA

M6 x 15

Screw

Qty. 4

CC

M8 x 15

Screw

Qty. 4

8 mm Lag bolt

Qty. 2

Anchor

Qty. 2

DD

M4 x 30

Screw

Qty. 4

EE

M6 x 30

Screw

Qty. 4

GG

M8 x 30

Screw

Qty. 4

HH

KK

5 mm

Spacer

Qty. 4

Mounting arm screw

(preassembled to

Mounting arm (A))

Qty. 2

LL

RR

PP

10 mm

Spacer

Qty. 4

MM

8 mm

Steel

washer

Qty. 8

NN

M6 x 12

Carriage Screw

Qty. 8

OO

II JJ

FF

M8 x 50

Screw

Qty. 4

M6 Nut

Qty. 8 Wrench

Qty. 1

QQ

6 mm

Steel

washer

Qty. 4

7

ASSEMBLY INSTRUCTIONS

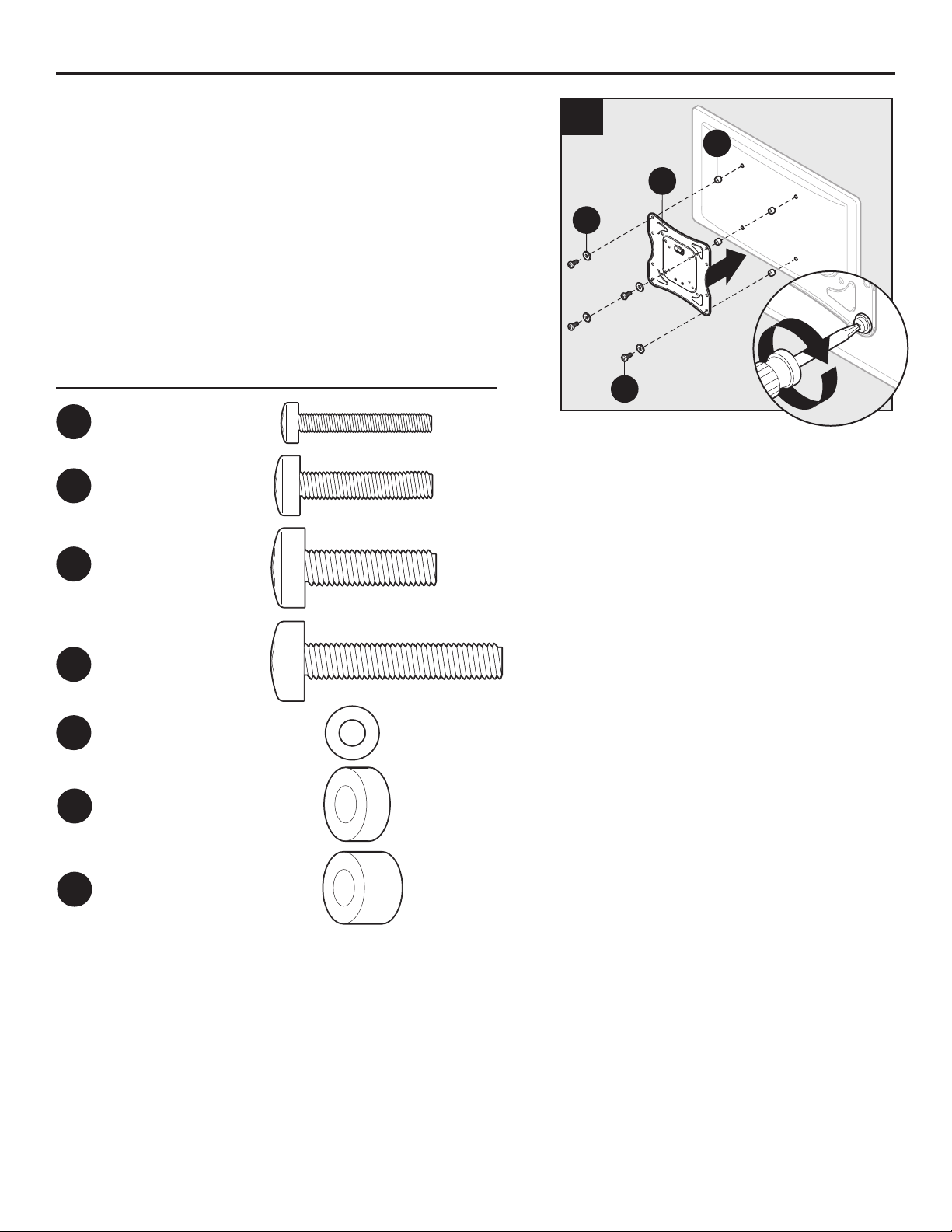

4. If needed, attach monitor adapters A (C) and

monitor adapters B (D) to monitor plate (E) in the

desired conguration using carriage screw (OO)

and nut (QQ). Secure with included wrench (RR).

5a. For at back at panel: Attach monitor plate (E)

with four steel washers (KK) and four screws (*).

*Note: Monitor plate (E) can be attached with M4 x 12

screws (AA), M6 x 15 screws (CC), or M8 x 15 screws

(DD) depending on your TV. Steel washer only for M4

and M6 screws.

1

2

4

D

D

E

C

OO

QQ

C

1

2

5a

KK

E

*

Tip: 5 mm spacers (LL) and/or

10 mm spacers (MM) can also be

used to provide clearance for cables

and connectors.

LL or

MM

Hardware Used

OO x 8

M6 x 12 Carriage screw

M4 x 12

Screw

Qty. 4

AA

M6 x 15

Screw

Qty. 4

CC

M8 x 15

Screw

Qty. 4

8 mm Lag bolt

Qty. 2

Anchor

Qty. 2

DD

M4 x 30

Screw

Qty. 4

EE

M6 x 30

Screw

Qty. 4

GG

M8 x 30

Screw

Qty. 4

HH

KK

5 mm

Spacer

Qty. 4

Mounting arm screw

(preassembled to

Mounting arm (A))

Qty. 2

LL

RR

PP

10 mm

Spacer

Qty. 4

MM

8 mm

Steel

washer

Qty. 8

NN

M6 x 12

Carriage Screw

Qty. 8

OO

II JJ

FF

M8 x 50

Screw

Qty. 4

M6 Nut

Qty. 8 Wrench

Qty. 1

QQ

6 mm

Steel

washer

Qty. 4

Hardware Used

AA

CC

DD

x 4

x 4

x 4

M4 x 12 Screw

M6 x 15 Screw

M8 x 15 Screw

M4 x 12

Screw

Qty. 4

AA

M6 x 15

Screw

Qty. 4

CC

M8 x 15

Screw

Qty. 4

8 mm Lag bolt

Qty. 2

Anchor

Qty. 2

DD

M4 x 30

Screw

Qty. 4

EE

M6 x 30

Screw

Qty. 4

GG

M8 x 30

Screw

Qty. 4

HH

KK

5 mm

Spacer

Qty. 4

Mounting arm screw

(preassembled to

Mounting arm (A))

Qty. 2

LL

RR

PP

10 mm

Spacer

Qty. 4

MM

8 mm

Steel

washer

Qty. 8

NN

M6 x 12

Carriage Screw

Qty. 8

OO

II JJ

FF

M8 x 50

Screw

Qty. 4

M6 Nut

Qty. 8 Wrench

Qty. 1

QQ

6 mm

Steel

washer

Qty. 4

KK x 4

Steel washer

M4 x 12

Screw

Qty. 4

AA

M6 x 15

Screw

Qty. 4

CC

M8 x 15

Screw

Qty. 4

8 mm Lag bolt

Qty. 2

Anchor

Qty. 2

DD

M4 x 30

Screw

Qty. 4

EE

M6 x 30

Screw

Qty. 4

GG

M8 x 30

Screw

Qty. 4

HH

KK

5 mm

Spacer

Qty. 4

Mounting arm screw

(preassembled to

Mounting arm (A))

Qty. 2

LL

RR

PP

10 mm

Spacer

Qty. 4

MM

8 mm

Steel

washer

Qty. 8

NN

M6 x 12

Carriage Screw

Qty. 8

OO

II JJ

FF

M8 x 50

Screw

Qty. 4

M6 Nut

Qty. 8 Wrench

Qty. 1

QQ

6 mm

Steel

washer

Qty. 4

M4 x 12

Screw

Qty. 4

AA

M6 x 15

Screw

Qty. 4

CC

M8 x 15

Screw

Qty. 4

8 mm Lag bolt

Qty. 2

Anchor

Qty. 2

DD

M4 x 30

Screw

Qty. 4

EE

M6 x 30

Screw

Qty. 4

GG

M8 x 30

Screw

Qty. 4

HH

KK

5 mm

Spacer

Qty. 4

Mounting arm screw

(preassembled to

Mounting arm (A))

Qty. 2

LL

RR

PP

10 mm

Spacer

Qty. 4

MM

8 mm

Steel

washer

Qty. 8

NN

M6 x 12

Carriage Screw

Qty. 8

OO

II JJ

FF

M8 x 50

Screw

Qty. 4

M6 Nut

Qty. 8 Wrench

Qty. 1

QQ

6 mm

Steel

washer

Qty. 4

M4 x 12

Screw

Qty. 4

AA

M6 x 15

Screw

Qty. 4

CC

M8 x 15

Screw

Qty. 4

8 mm Lag bolt

Qty. 2

Anchor

Qty. 2

DD

M4 x 30

Screw

Qty. 4

EE

M6 x 30

Screw

Qty. 4

GG

M8 x 30

Screw

Qty. 4

HH

KK

5 mm

Spacer

Qty. 4

Mounting arm screw

(preassembled to

Mounting arm (A))

Qty. 2

LL

RR

PP

10 mm

Spacer

Qty. 4

MM

8 mm

Steel

washer

Qty. 8

NN

M6 x 12

Carriage Screw

Qty. 8

OO

II JJ

FF

M8 x 50

Screw

Qty. 4

M6 Nut

Qty. 8 Wrench

Qty. 1

QQ

6 mm

Steel

washer

Qty. 4

QQ x 8

M6 nut

M4 x 12

Screw

Qty. 4

AA

M6 x 15

Screw

Qty. 4

CC

M8 x 15

Screw

Qty. 4

8 mm Lag bolt

Qty. 2

Anchor

Qty. 2

DD

M4 x 30

Screw

Qty. 4

EE

M6 x 30

Screw

Qty. 4

GG

M8 x 30

Screw

Qty. 4

HH

KK

5 mm

Spacer

Qty. 4

Mounting arm screw

(preassembled to

Mounting arm (A))

Qty. 2

LL

RR

PP

10 mm

Spacer

Qty. 4

MM

8 mm

Steel

washer

Qty. 8

NN

M6 x 12

Carriage Screw

Qty. 8

OO

II JJ

FF

M8 x 50

Screw

Qty. 4

M6 Nut

Qty. 8 Wrench

Qty. 1

QQ

6 mm

Steel

washer

Qty. 4

8

ASSEMBLY INSTRUCTIONS

5b. For curved back at panel: Attach monitor

plate (E) with four spacers (*), four steel

washers (KK) and four screws (**).

*Note: 5 mm spacers (LL) or 10 mm spacers (MM) can

be used depending on your TV.

**Note: Monitor plate (E) can be attached with

M4 x 30 screws (EE), M8 x 50 screws (FF), M6 x 30

screws (GG), or M8 x 30 screws (HH) depending on

your TV. Steel washer only for M4 and M6 screws.

1

2

5b

KK

E

*

**

Hardware Used

EE

KK

GG

HH

x 4

x 4

x 4

x 4

M4 x 30 Screw

Steel washer

M6 x 30 Screw

M8 x 30 Screw

M4 x 12

Screw

Qty. 4

AA

M6 x 15

Screw

Qty. 4

CC

M8 x 15

Screw

Qty. 4

8 mm Lag bolt

Qty. 2

Anchor

Qty. 2

DD

M4 x 30

Screw

Qty. 4

EE

M6 x 30

Screw

Qty. 4

GG

M8 x 30

Screw

Qty. 4

HH

KK

5 mm

Spacer

Qty. 4

Mounting arm screw

(preassembled to

Mounting arm (A))

Qty. 2

LL

RR

PP

10 mm

Spacer

Qty. 4

MM

8 mm

Steel

washer

Qty. 8

NN

M6 x 12

Carriage Screw

Qty. 8

OO

II JJ

FF

M8 x 50

Screw

Qty. 4

M6 Nut

Qty. 8 Wrench

Qty. 1

QQ

6 mm

Steel

washer

Qty. 4

M4 x 12

Screw

Qty. 4

AA

M6 x 15

Screw

Qty. 4

CC

M8 x 15

Screw

Qty. 4

8 mm Lag bolt

Qty. 2

Anchor

Qty. 2

DD

M4 x 30

Screw

Qty. 4

EE

M6 x 30

Screw

Qty. 4

GG

M8 x 30

Screw

Qty. 4

HH

KK

5 mm

Spacer

Qty. 4

Mounting arm screw

(preassembled to

Mounting arm (A))

Qty. 2

LL

RR

PP

10 mm

Spacer

Qty. 4

MM

8 mm

Steel

washer

Qty. 8

NN

M6 x 12

Carriage Screw

Qty. 8

OO

II JJ

FF

M8 x 50

Screw

Qty. 4

M6 Nut

Qty. 8 Wrench

Qty. 1

QQ

6 mm

Steel

washer

Qty. 4

FF x 4

M8 x 50 Screw

M4 x 12

Screw

Qty. 4

AA

M6 x 15

Screw

Qty. 4

CC

M8 x 15

Screw

Qty. 4

8 mm Lag bolt

Qty. 2

Anchor

Qty. 2

DD

M4 x 30

Screw

Qty. 4

EE

M6 x 30

Screw

Qty. 4

GG

M8 x 30

Screw

Qty. 4

HH

KK

5 mm

Spacer

Qty. 4

Mounting arm screw

(preassembled to

Mounting arm (A))

Qty. 2

LL

RR

PP

10 mm

Spacer

Qty. 4

MM

8 mm

Steel

washer

Qty. 8

NN

M6 x 12

Carriage Screw

Qty. 8

OO

II JJ

FF

M8 x 50

Screw

Qty. 4

M6 Nut

Qty. 8 Wrench

Qty. 1

QQ

6 mm

Steel

washer

Qty. 4

M4 x 12

Screw

Qty. 4

AA

M6 x 15

Screw

Qty. 4

CC

M8 x 15

Screw

Qty. 4

8 mm Lag bolt

Qty. 2

Anchor

Qty. 2

DD

M4 x 30

Screw

Qty. 4

EE

M6 x 30

Screw

Qty. 4

GG

M8 x 30

Screw

Qty. 4

HH

KK

5 mm

Spacer

Qty. 4

Mounting arm screw

(preassembled to

Mounting arm (A))

Qty. 2

LL

RR

PP

10 mm

Spacer

Qty. 4

MM

8 mm

Steel

washer

Qty. 8

NN

M6 x 12

Carriage Screw

Qty. 8

OO

II JJ

FF

M8 x 50

Screw

Qty. 4

M6 Nut

Qty. 8 Wrench

Qty. 1

QQ

6 mm

Steel

washer

Qty. 4

M4 x 12

Screw

Qty. 4

AA

M6 x 15

Screw

Qty. 4

CC

M8 x 15

Screw

Qty. 4

8 mm Lag bolt

Qty. 2

Anchor

Qty. 2

DD

M4 x 30

Screw

Qty. 4

EE

M6 x 30

Screw

Qty. 4

GG

M8 x 30

Screw

Qty. 4

HH

KK

5 mm

Spacer

Qty. 4

Mounting arm screw

(preassembled to

Mounting arm (A))

Qty. 2

LL

RR

PP

10 mm

Spacer

Qty. 4

MM

8 mm

Steel

washer

Qty. 8

NN

M6 x 12

Carriage Screw

Qty. 8

OO

II JJ

FF

M8 x 50

Screw

Qty. 4

M6 Nut

Qty. 8 Wrench

Qty. 1

QQ

6 mm

Steel

washer

Qty. 4

LL

MM

x 4

x 4

5 mm Spacer

10 mm Spacer

M4 x 12

Screw

Qty. 4

AA

M6 x 15

Screw

Qty. 4

CC

M8 x 15

Screw

Qty. 4

8 mm Lag bolt

Qty. 2

Anchor

Qty. 2

DD

M4 x 30

Screw

Qty. 4

EE

M6 x 30

Screw

Qty. 4

GG

M8 x 30

Screw

Qty. 4

HH

KK

5 mm

Spacer

Qty. 4

Mounting arm screw

(preassembled to

Mounting arm (A))

Qty. 2

LL

RR

PP

10 mm

Spacer

Qty. 4

MM

8 mm

Steel

washer

Qty. 8

NN

M6 x 12

Carriage Screw

Qty. 8

OO

II JJ

FF

M8 x 50

Screw

Qty. 4

M6 Nut

Qty. 8 Wrench

Qty. 1

QQ

6 mm

Steel

washer

Qty. 4

M4 x 12

Screw

Qty. 4

AA

M6 x 15

Screw

Qty. 4

CC

M8 x 15

Screw

Qty. 4

8 mm Lag bolt

Qty. 2

Anchor

Qty. 2

DD

M4 x 30

Screw

Qty. 4

EE

M6 x 30

Screw

Qty. 4

GG

M8 x 30

Screw

Qty. 4

HH

KK

5 mm

Spacer

Qty. 4

Mounting arm screw

(preassembled to

Mounting arm (A))

Qty. 2

LL

RR

PP

10 mm

Spacer

Qty. 4

MM

8 mm

Steel

washer

Qty. 8

NN

M6 x 12

Carriage Screw

Qty. 8

OO

II JJ

FF

M8 x 50

Screw

Qty. 4

M6 Nut

Qty. 8 Wrench

Qty. 1

QQ

6 mm

Steel

washer

Qty. 4

9

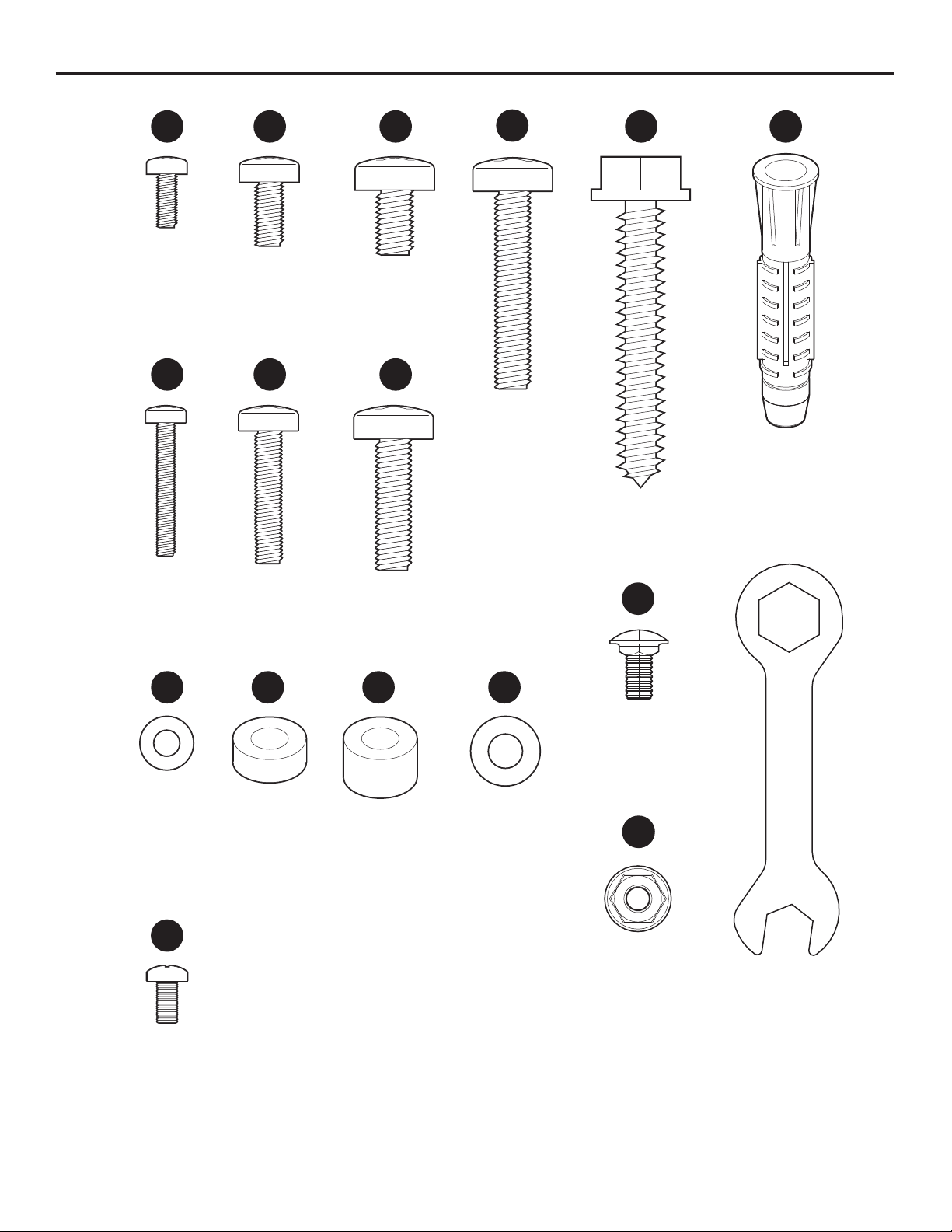

ASSEMBLY INSTRUCTIONS

6. If screws are too long, additional 5 mm spacers (LL),

10 mm spacers (MM), and steel washers (NN) may

be needed.

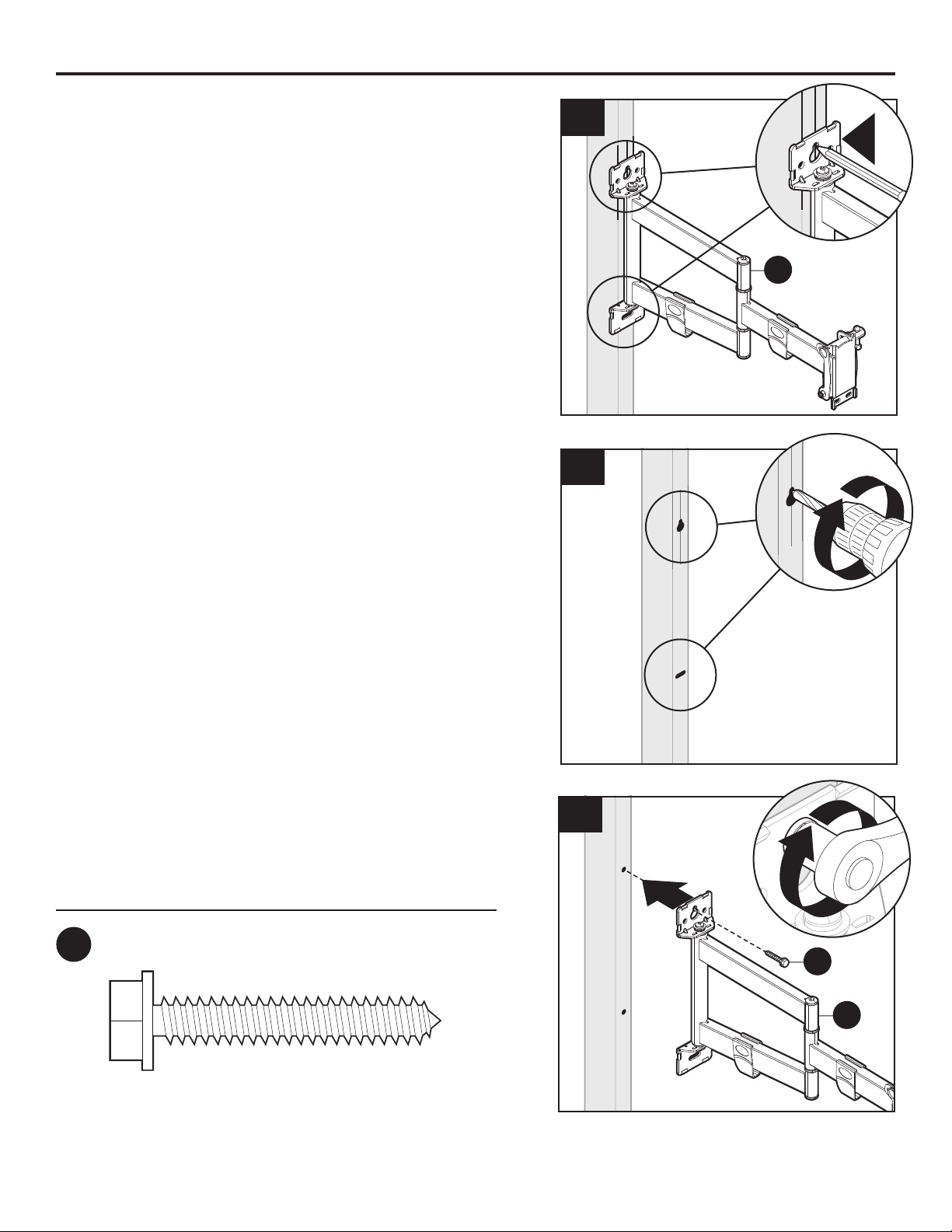

Wood Stud Installation

Note: For concrete, proceed to step 12.

7. Use a stud nder (not included) to locate wood

studs. Mark the edge and center locations.

TV

6

MM

NNLL

NN

11

2

7

Hardware Used

LL

MM

NN

x 4

x 4

x 8

5 mm Spacer

10 mm Spacer

Steel washer

M4 x 12

Screw

Qty. 4

AA

M6 x 15

Screw

Qty. 4

CC

M8 x 15

Screw

Qty. 4

8 mm Lag bolt

Qty. 2

Anchor

Qty. 2

DD

M4 x 30

Screw

Qty. 4

EE

M6 x 30

Screw

Qty. 4

GG

M8 x 30

Screw

Qty. 4

HH

KK

5 mm

Spacer

Qty. 4

Mounting arm screw

(preassembled to

Mounting arm (A))

Qty. 2

LL

RR

PP

10 mm

Spacer

Qty. 4

MM

8 mm

Steel

washer

Qty. 8

NN

M6 x 12

Carriage Screw

Qty. 8

OO

II JJ

FF

M8 x 50

Screw

Qty. 4

M6 Nut

Qty. 8 Wrench

Qty. 1

QQ

6 mm

Steel

washer

Qty. 4

M4 x 12

Screw

Qty. 4

AA

M6 x 15

Screw

Qty. 4

CC

M8 x 15

Screw

Qty. 4

8 mm Lag bolt

Qty. 2

Anchor

Qty. 2

DD

M4 x 30

Screw

Qty. 4

EE

M6 x 30

Screw

Qty. 4

GG

M8 x 30

Screw

Qty. 4

HH

KK

5 mm

Spacer

Qty. 4

Mounting arm screw

(preassembled to

Mounting arm (A))

Qty. 2

LL

RR

PP

10 mm

Spacer

Qty. 4

MM

8 mm

Steel

washer

Qty. 8

NN

M6 x 12

Carriage Screw

Qty. 8

OO

II JJ

FF

M8 x 50

Screw

Qty. 4

M6 Nut

Qty. 8 Wrench

Qty. 1

QQ

6 mm

Steel

washer

Qty. 4

M4 x 12

Screw

Qty. 4

AA

M6 x 15

Screw

Qty. 4

CC

M8 x 15

Screw

Qty. 4

8 mm Lag bolt

Qty. 2

Anchor

Qty. 2

DD

M4 x 30

Screw

Qty. 4

EE

M6 x 30

Screw

Qty. 4

GG

M8 x 30

Screw

Qty. 4

HH

KK

5 mm

Spacer

Qty. 4

Mounting arm screw

(preassembled to

Mounting arm (A))

Qty. 2

LL

RR

PP

10 mm

Spacer

Qty. 4

MM

8 mm

Steel

washer

Qty. 8

NN

M6 x 12

Carriage Screw

Qty. 8

OO

II JJ

FF

M8 x 50

Screw

Qty. 4

M6 Nut

Qty. 8 Wrench

Qty. 1

QQ

6 mm

Steel

washer

Qty. 4

10

ASSEMBLY INSTRUCTIONS

8. Use mounting arm (A) to mark two mounting hole

locations.

9. Drill two 7/32 in. pilot holes 2-1/3 in. (60 mm) deep

at the marked locations for the mounting holes.

10. Mount top of mounting arm (A) using

8 mm lag bolt (II) with a 1/2 in. socket wrench

(not included).

1

8

A

9

1

2

10

A

II

Hardware Used

II x 1

8 mm Lag bolt

M4 x 12

Screw

Qty. 4

AA

M6 x 15

Screw

Qty. 4

CC

M8 x 15

Screw

Qty. 4

8 mm Lag bolt

Qty. 2

Anchor

Qty. 2

DD

M4 x 30

Screw

Qty. 4

EE

M6 x 30

Screw

Qty. 4

GG

M8 x 30

Screw

Qty. 4

HH

KK

5 mm

Spacer

Qty. 4

Mounting arm screw

(preassembled to

Mounting arm (A))

Qty. 2

LL

RR

PP

10 mm

Spacer

Qty. 4

MM

8 mm

Steel

washer

Qty. 8

NN

M6 x 12

Carriage Screw

Qty. 8

OO

II JJ

FF

M8 x 50

Screw

Qty. 4

M6 Nut

Qty. 8 Wrench

Qty. 1

QQ

6 mm

Steel

washer

Qty. 4

11

ASSEMBLY INSTRUCTIONS

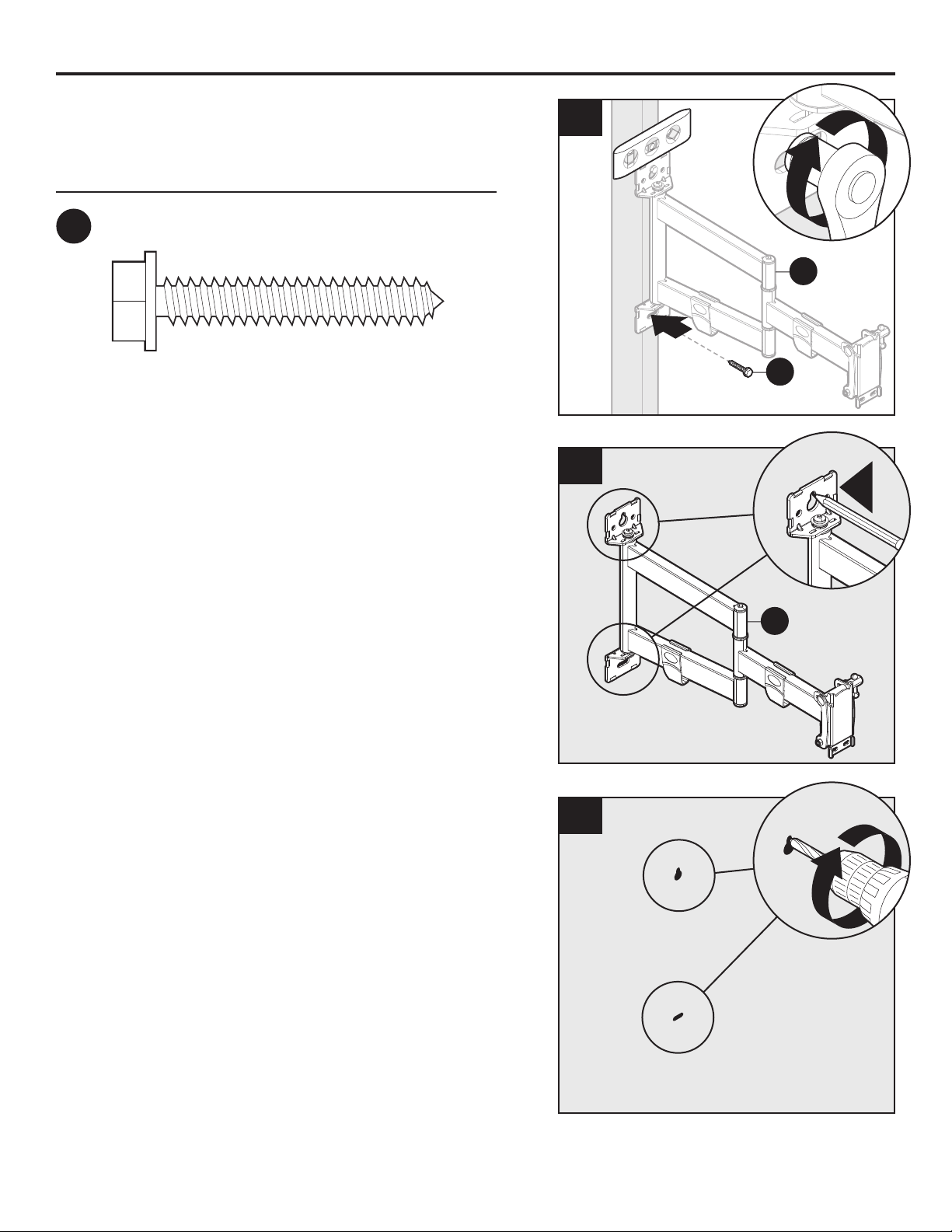

11. Make sure mounting arm (A) is level, then secure

bottom of mounting arm (A) using 8 mm lag bolt (II).

1

2

11

A

II

Hardware Used

II x 1

8 mm Lag bolt

M4 x 12

Screw

Qty. 4

AA

M6 x 15

Screw

Qty. 4

CC

M8 x 15

Screw

Qty. 4

8 mm Lag bolt

Qty. 2

Anchor

Qty. 2

DD

M4 x 30

Screw

Qty. 4

EE

M6 x 30

Screw

Qty. 4

GG

M8 x 30

Screw

Qty. 4

HH

KK

5 mm

Spacer

Qty. 4

Mounting arm screw

(preassembled to

Mounting arm (A))

Qty. 2

LL

RR

PP

10 mm

Spacer

Qty. 4

MM

8 mm

Steel

washer

Qty. 8

NN

M6 x 12

Carriage Screw

Qty. 8

OO

II JJ

FF

M8 x 50

Screw

Qty. 4

M6 Nut

Qty. 8 Wrench

Qty. 1

QQ

6 mm

Steel

washer

Qty. 4

Concrete Installation

12. Use mounting arm (A) to mark two mounting hole

locations.

13. Drill two 3/8 in. pilot holes 2-3/4 in. (70 mm) deep at

the marked locations for the mounting holes.

1

12

A

13

12

ASSEMBLY INSTRUCTIONS

14. Insert anchors (JJ) into holes. Tap with hammer (not

included) if necessary.

2

14

1

1

JJ

1

2

15

A

II

1

2

16

A

II

Hardware Used

JJ

x 2

Anchor

M4 x 12

Screw

Qty. 4

AA

M6 x 15

Screw

Qty. 4

CC

M8 x 15

Screw

Qty. 4

8 mm Lag bolt

Qty. 2

Anchor

Qty. 2

DD

M4 x 30

Screw

Qty. 4

EE

M6 x 30

Screw

Qty. 4

GG

M8 x 30

Screw

Qty. 4

HH

KK

5 mm

Spacer

Qty. 4

Mounting arm screw

(preassembled to

Mounting arm (A))

Qty. 2

LL

RR

PP

10 mm

Spacer

Qty. 4

MM

8 mm

Steel

washer

Qty. 8

NN

M6 x 12

Carriage Screw

Qty. 8

OO

II JJ

FF

M8 x 50

Screw

Qty. 4

M6 Nut

Qty. 8 Wrench

Qty. 1

QQ

6 mm

Steel

washer

Qty. 4

15. Mount top of mounting arm (A) using

8 mm lag bolt (II) with a 1/2 in. socket wrench

(not included).

Hardware Used

II x 1

8 mm Lag bolt

M4 x 12

Screw

Qty. 4

AA

M6 x 15

Screw

Qty. 4

CC

M8 x 15

Screw

Qty. 4

8 mm Lag bolt

Qty. 2

Anchor

Qty. 2

DD

M4 x 30

Screw

Qty. 4

EE

M6 x 30

Screw

Qty. 4

GG

M8 x 30

Screw

Qty. 4

HH

KK

5 mm

Spacer

Qty. 4

Mounting arm screw

(preassembled to

Mounting arm (A))

Qty. 2

LL

RR

PP

10 mm

Spacer

Qty. 4

MM

8 mm

Steel

washer

Qty. 8

NN

M6 x 12

Carriage Screw

Qty. 8

OO

II JJ

FF

M8 x 50

Screw

Qty. 4

M6 Nut

Qty. 8 Wrench

Qty. 1

QQ

6 mm

Steel

washer

Qty. 4

16. Make sure mounting arm (A) is level, then secure

bottom of mounting arm (A) using 8 mm lag bolt (II).

Hardware Used

II x 1

8 mm Lag bolt

M4 x 12

Screw

Qty. 4

AA

M6 x 15

Screw

Qty. 4

CC

M8 x 15

Screw

Qty. 4

8 mm Lag bolt

Qty. 2

Anchor

Qty. 2

DD

M4 x 30

Screw

Qty. 4

EE

M6 x 30

Screw

Qty. 4

GG

M8 x 30

Screw

Qty. 4

HH

KK

5 mm

Spacer

Qty. 4

Mounting arm screw

(preassembled to

Mounting arm (A))

Qty. 2

LL

RR

PP

10 mm

Spacer

Qty. 4

MM

8 mm

Steel

washer

Qty. 8

NN

M6 x 12

Carriage Screw

Qty. 8

OO

II JJ

FF

M8 x 50

Screw

Qty. 4

M6 Nut

Qty. 8 Wrench

Qty. 1

QQ

6 mm

Steel

washer

Qty. 4

13

ASSEMBLY INSTRUCTIONS

Final Installation

17. Snap end caps (B) onto top and bottom of

mounting arm (A).

18. Place mounting plate (E) onto mounting arm (A).

17

B

A

18

E

A

1

2

19

E

A

PP

Hardware Used

PP x 2

Mounting arm screw

M4 x 12

Screw

Qty. 4

AA

M6 x 15

Screw

Qty. 4

CC

M8 x 15

Screw

Qty. 4

8 mm Lag bolt

Qty. 2

Anchor

Qty. 2

DD

M4 x 30

Screw

Qty. 4

EE

M6 x 30

Screw

Qty. 4

GG

M8 x 30

Screw

Qty. 4

HH

KK

5 mm

Spacer

Qty. 4

Mounting arm screw

(preassembled to

Mounting arm (A))

Qty. 2

LL

RR

PP

10 mm

Spacer

Qty. 4

MM

8 mm

Steel

washer

Qty. 8

NN

M6 x 12

Carriage Screw

Qty. 8

OO

II JJ

FF

M8 x 50

Screw

Qty. 4

M6 Nut

Qty. 8 Wrench

Qty. 1

QQ

6 mm

Steel

washer

Qty. 4

19. Secure mounting plate (E) to mounting arm (A) with

the two previously removed mounting arm

screws (PP).

Note: DO NOT fully tighten mounting arm screws (PP).

Tighten ONLY to snug tension.

14

ASSEMBLY INSTRUCTIONS

Post Installation Level

20. If needed, at panel can be leveled +/– 3 degrees.

Note: Leveling will be difcult if mounting arm

screws (PP) are too tight.

Adjust Tilt

21. To adjust tilt, loosen tilt lever and move panel to

desired position. Tighten tilt lever to hold desired tilt.

20

± 3°

2

2

3

3

3

1

21

or

or

5 mm

1/2 in.

15

WARRANTY

Printed in China

This product is covered against defects in materials and workmanship for 5 years. The manufacturer

will repair or replace the defective component or product, at its sole discretion. Failure to follow

product care instructions from the manufacturer will void the warranty.

To obtain warranty service, contact customer service at 1-866-994-4148. You must supply a copy of

your original receipt. If your product must be shipped for inspection, you will be responsible for the

shipping charges. Replacement product shipped to you will be returned freight pre-paid.

The manufacturer disclaims any liability for modications, improper installations, installations over

the specied weight range, or failure to follow care instructions provided by the manufacturer. To

the maximum extent permitted by law, the manufacturer disclaims any other warranties, expressed

or implied, including warranties of tness for a particular purpose and warranties of merchantability.

The manufacturer will not be liable for any damages arising out of the use of, or inability to use, this

product.

This warranty gives you specic legal rights, and you may also have other rights which vary from

state to state.

Specications are subject to change without prior notice.

16

17

Número de serie Fecha de compra

ADJUNTE SU RECIBO AQUÍ

¿Preguntas, problemas, piezas faltantes? Antes de volver a la tienda, llame a nuestro

Departamento de Servicio al Cliente al 1-866-994-4148, de lunes a domingo de 8 a.m. a

8 p.m., hora estándar del Este. También puede ponerse en contacto con nosotros a través

MODELO #UT-IO-70C

ARTÍCULO #03850903

SOPORTE PARA TV

CON MOVILIDAD

COMPLETA PARA

INTERIOR/EXTERIOR

UTILITECH y el diseño del logotipo son marcas

comerciales o marcas registradas de LF, LLC. Todos

los derechos reservados.

18

CONTENIDO DEL PAQUETE

PIEZA DESCRIPCIÓN CANTIDAD

D Adaptador del monitor B 2

E Placa del monitor

(preensamblada en el

brazo de montaje [A])

1

PIEZA DESCRIPCIÓN CANTIDAD

ABrazo de montaje 1

BTapa de extremo 2

C Adaptador del monitor A 2

B

B

D

C

A

C

D

E

19

ADITAMENTOS (se muestran en tamaño real)

Tornillo

M4 x 12

Cant. 4

AA

Tornillo

M6 x 15

Cant. 4

CC

Tornillo

M8 x 15

Cant. 4

Tirafondo de 8 mm

Cant. 2

Ancla de

expansión

Cant. 2

DD

Tornillo

M4 x 30

Cant. 4

EE

Tornillo

M6 x 30

Cant. 4

GG

Tornillo

M8 x 30

Cant. 4

HH

KK

0,64 cm

Acero

arandela

Cant. 4

Espaciador

de 5 mm

Cant. 4

LL

Espaciador

de 10 mm

Cant. 4

MM

8 mm

Acero

arandela

Cant. 8

NN

II JJ

FF

Tornillo

M8 x 50

Qty. 4

M6 x 12

Tornillo con

cabeza de hongo

Qty. 8

OO

Tuerca M6

Qty. 8

Llave inglesa

Qty. 1

QQ

Tornillo del brazo

de montaje

(preensamblado en

el brazo de montaje [A])

Cant. 2

PP

Nota: todos los aditamentos son de acero inoxidable

y son aptos para usarlos en exteriores.

20

INFORMACIÓN DE SEGURIDAD

PREPARACIÓN

Antes de comenzar a ensamblar el producto, asegúrese de tener todas las piezas. Compare las

piezas con la lista del contenido del paquete y la lista de aditamentos. NO intente ensamblar

el producto si falta alguna pieza o si estas están dañadas.

Tiempo estimado de ensamblaje: 30 minutos

Herramientas necesarias para el ensamblaje (no se incluyen): taladro con brocas de 7/32 pulg. y

3/8 pulg., detector de vigas, llave de dados, lápiz, destornillador Phillips, martillo, nivel.

Lea y comprenda por completo este manual antes de intentar ensamblar, utilizar o instalar el producto.

ADVERTENCIA

• NO LEER, COMPRENDER COMPLETAMENTE O SEGUIR TODAS LAS INSTRUCCIONES

PUEDE PROVOCAR LESIONES PERSONALES GRAVES, DAÑOS A LA PROPIEDAD PERSONAL

O LA ANULACIÓN DE LA GARANTÍA DE FÁBRICA.

• NO intente instalar o ensamblar el producto si este o los aditamentos están dañados, o si falta

algún aditamento. Los aditamentos incluidos están diseñados para utilizarse en paredes verticales

construidas de vigas de madera o concreto sólido. Una pared de vigas de madera, por denición,

consiste en vigas de madera de 2x4 (2 pulg. de ancho por 4 pulg. de profundidad) como mínimo

con un panel de yeso de 5/8 pulg. como máximo. Los aditamentos incluidos no están diseñados

para utilizarse con vigas de metal o paredes de bloques de hormigón. Si no está seguro sobre la

construcción de su pared, consulte a un contratista o instalador calicado para obtener ayuda. Para

una instalación segura, la pared que escoja para colocar el montaje debe poder soportar 4 veces el

peso de la carga total. De lo contrario, se debe reforzar la supercie para cumplir con esta norma.

El instalador es responsable de vericar que la estructura de la pared y los aditamentos utilizados

en cualquier método de instalación soporten de manera segura la carga total.

PRECAUCIÓN

• La carga máxima de peso es de 31,75 kg (70 libras). El uso con productos más pesados que la

capacidad máxima indicada puede ocasionar inestabilidad o lesiones.

• Tamaño máximo de la pantalla: 165,1 cm (65 pulg.)

GUARDE ESTAS INSTRUCCIONES PARA REFERENCIA FUTURA.

This manual suits for next models

1

Table of contents

Languages:

Other Utilitech TV Mount manuals

Popular TV Mount manuals by other brands

peerless-AV

peerless-AV PLAV70-UNLP-GB Installation and assembly

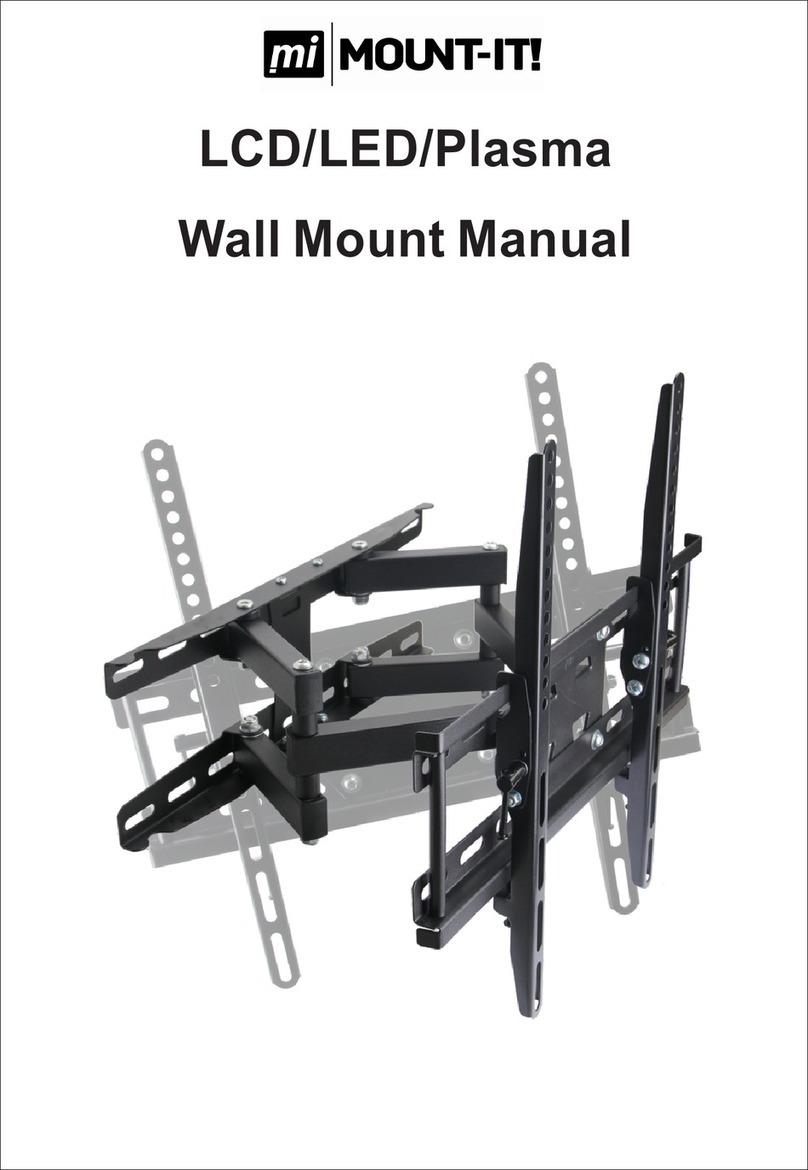

Mount-It!

Mount-It! MI-4461 manual

Kindermann

Kindermann DisplayShift2 Wings 55-78 Mounting instructions

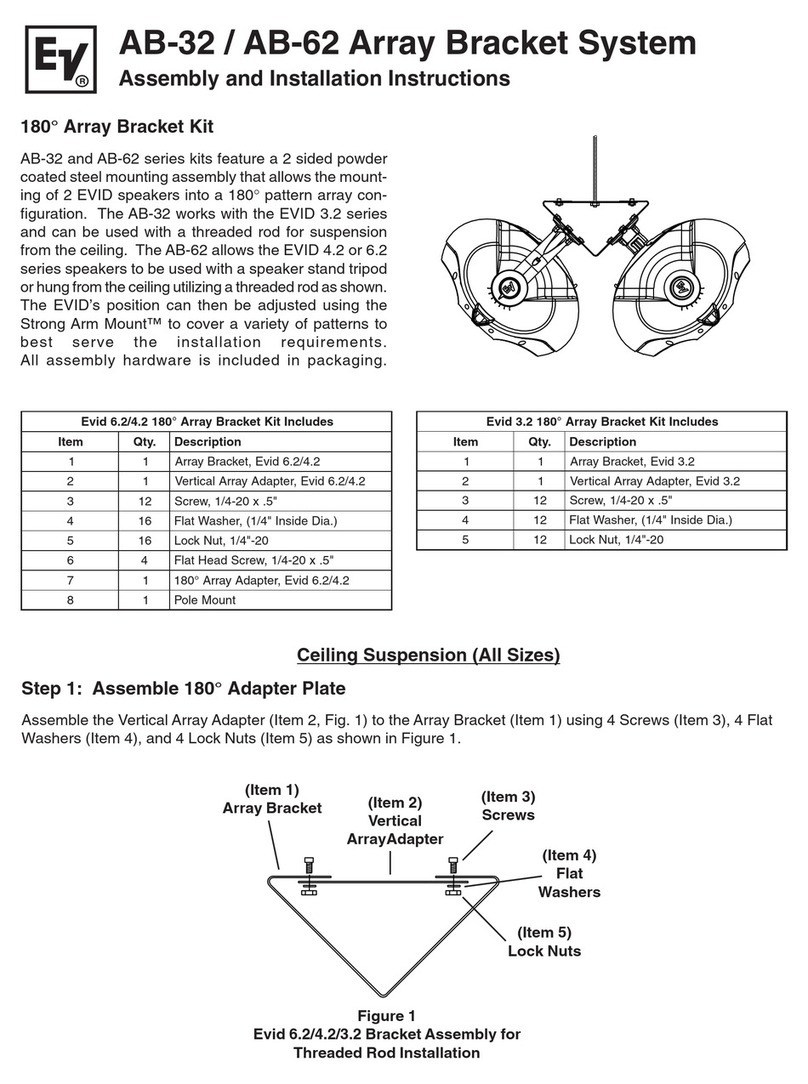

Electro-Voice

Electro-Voice AB-32 Assembly and installation instructions

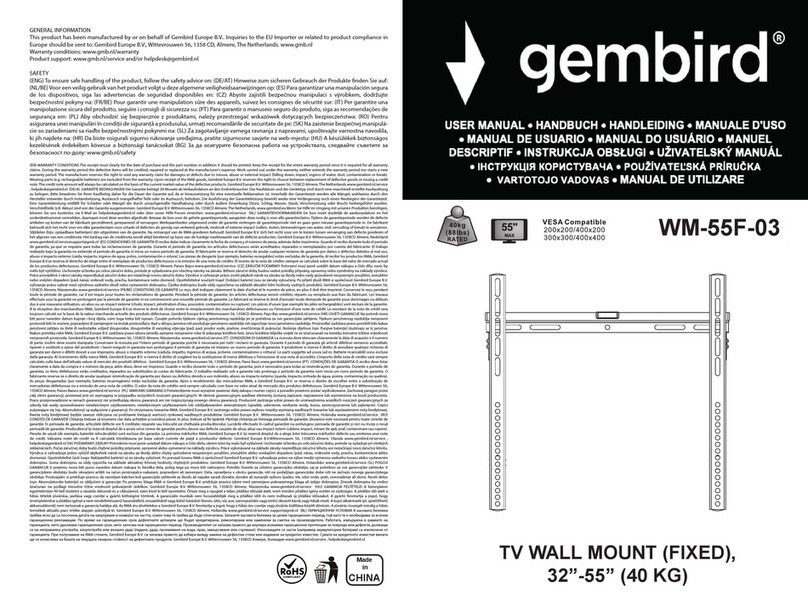

Gembird

Gembird WM-55F-03 user manual

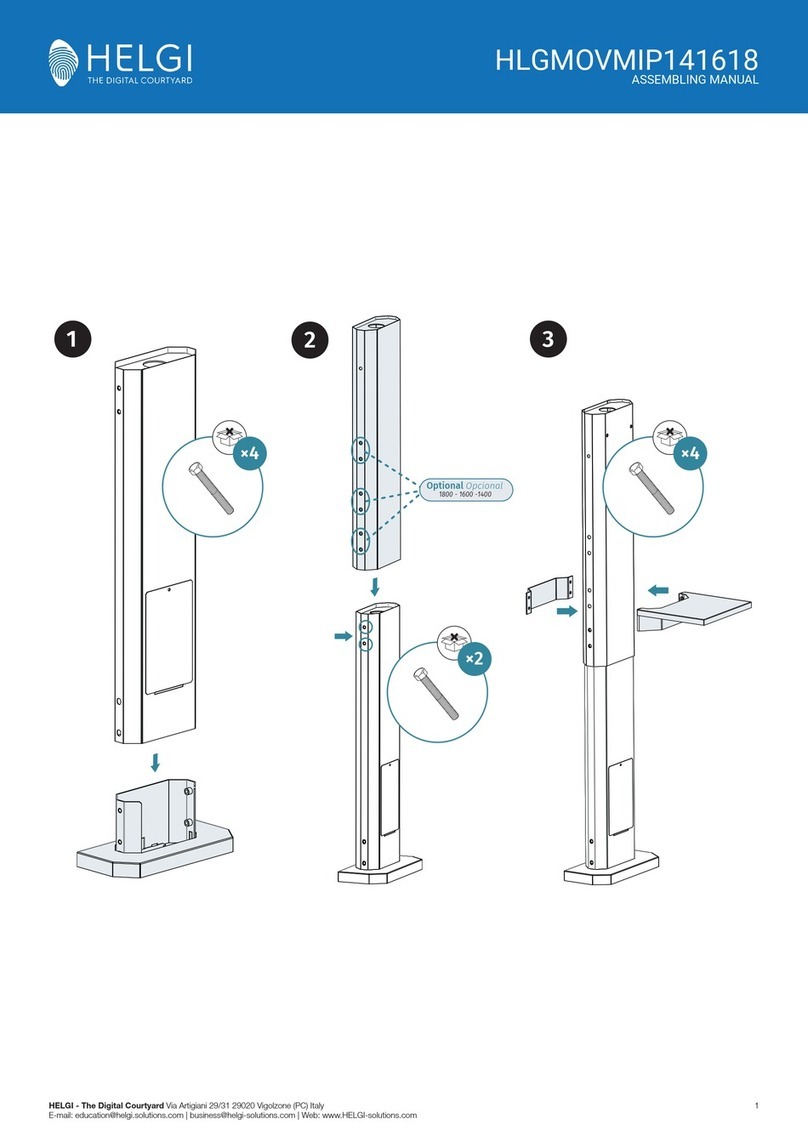

HELGI

HELGI HLGMOVMIP141618 Assembling manual