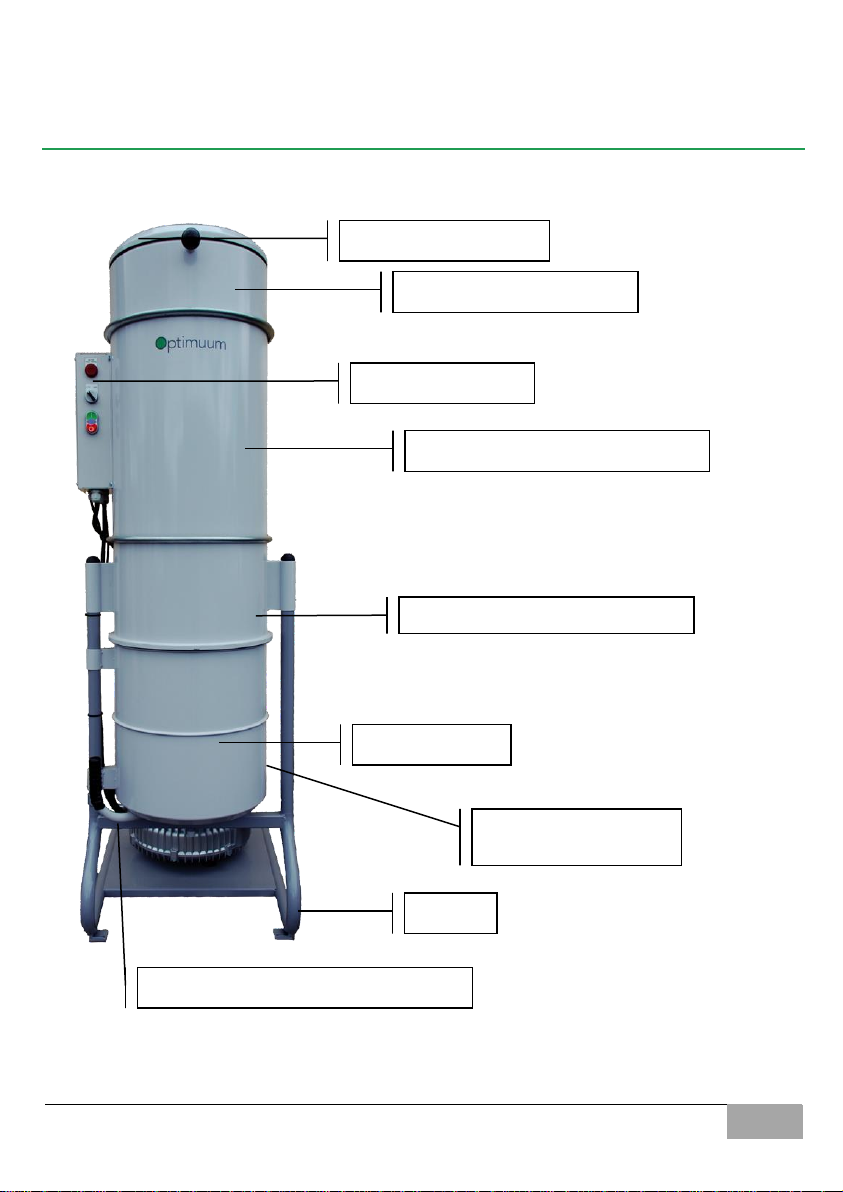

Product Description

Product designation Central vacuum cleaner

Model Optimuum 3/4/5,5 kW

Description Central vacuum cleaner consisting of a vacuum pump, an electrical cabinet, a

cyclonic separator with filter and a steel stand. Models denoted with the letter

F are also equipped with a frequency inverter.

The central vacuum cleaner is mainly made of iron and is painted with powder

coating.

The vacuum pump is made of aluminium and cast iron.

Environment A great importance has been put on the choice of material and the production

methods during the design of the central vacuum cleaner. It is worth noting

that 98% of the machine is recyclable. The remaining portion is made of

electrical components. No solvents are used during the coating, neither for

cleaning nor coat mixture.

Material

Stand Iron, quality SIS 1312

Cyclone Iron, quality SIS 1312

Vacuum pump Pump, impeller and stator of aluminium and/or cast iron.

Engine shaft of iron.

Electrical windings of copper.

Filter End plates of metal or plastic.

Filter material of cellulose or polyester.

Electrical cabinet Cabinet of iron.

Components of plastic and copper.

Plastic details Polyethylene and Bakelite.

Paint Polyester powder, TGIC-free.

Sealing Natural rubber.

Manufacturer Vacitup AB

Smedvägen 24

SE-433 61 Stenkullen

Sweden

Tel: +46 (0)31 44 32 00

Email: info@vacitup.se

www.vacitup.se