44 BARION®atm II Manual

0 Contents

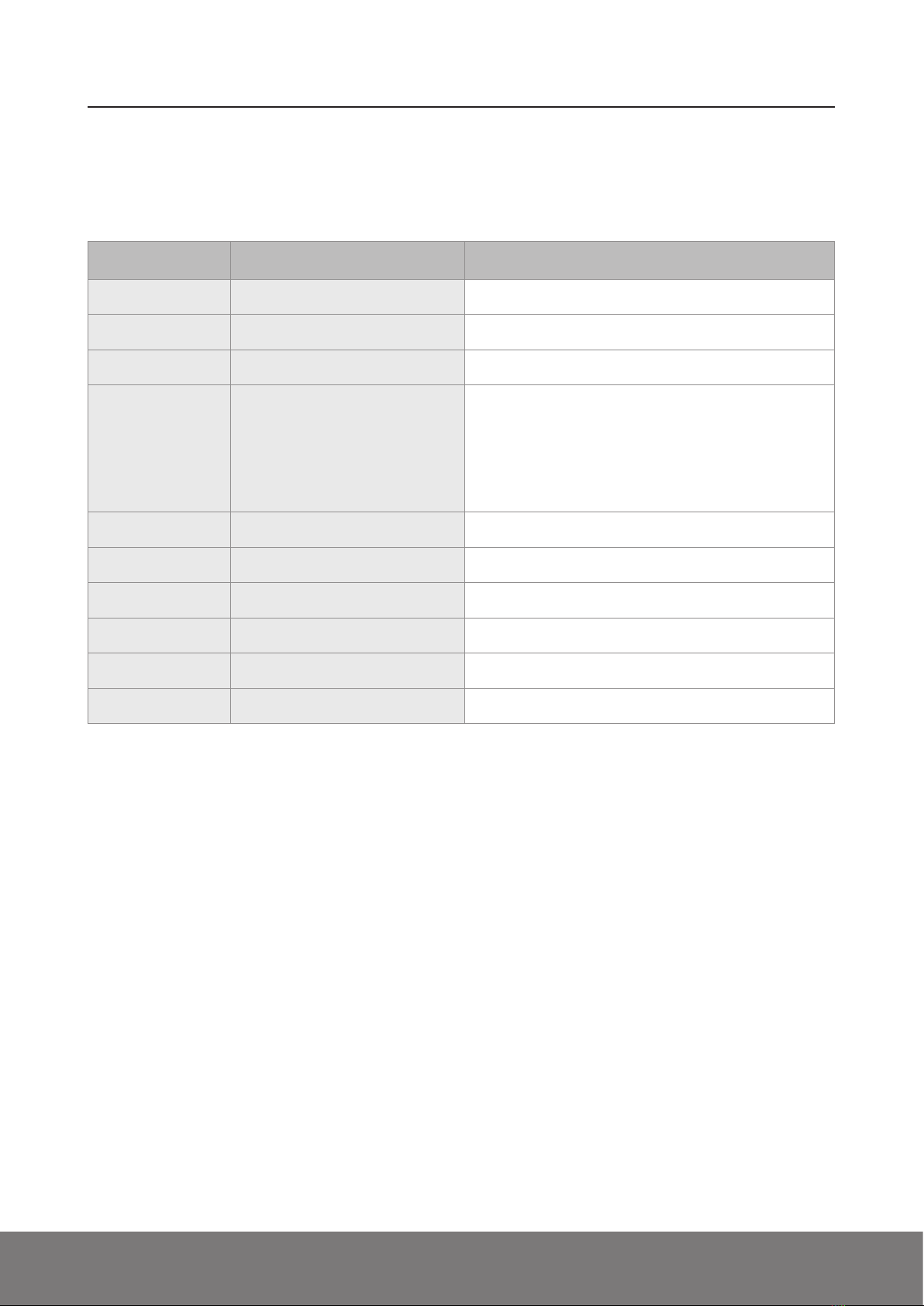

0 Table of contents.......................................................................... 4

1 General information...................................................................... 6

1.1 Product description .......................................................................................... 6

1.2 Storage ............................................................................................................ 6

1.3 General regulations and warranty ..................................................................... 6

1.4 CE-derclaration of conformity ...........................................................................6

2 Safety............................................................................................ 7

2.1 Observance of the operating instructions.......................................................... 7

2.2 Basic safety information ................................................................................... 7

2.3 Signs and symbols ........................................................................................... 7

3 Getting started ............................................................................. 8

3.1 Unpacking........................................................................................................ 8

3.1.1 Check for damage............................................................................................ 8

3.1.2 Scope of delivery.............................................................................................. 8

3.1.3 Acclimatisation ................................................................................................. 9

4 Connection and installation....................................................... 10

4.1 Description of the RS232 interface ................................................................. 10

4.2 Conversion of the voltage or current at the analogue interface........................ 10

5 Operation .................................................................................... 12

5.1 General information ........................................................................................ 12

5.1.1 Safety information .......................................................................................... 12

5.2 Adjustment..................................................................................................... 12

5.3 Setpoints........................................................................................................ 12

6 Maintenance............................................................................... 13

6.1 Cleaning and care .......................................................................................... 13

6.2 Firmware update ............................................................................................ 13

7 Troubleshooting.......................................................................... 14

8 Return / disposal ......................................................................... 15