17

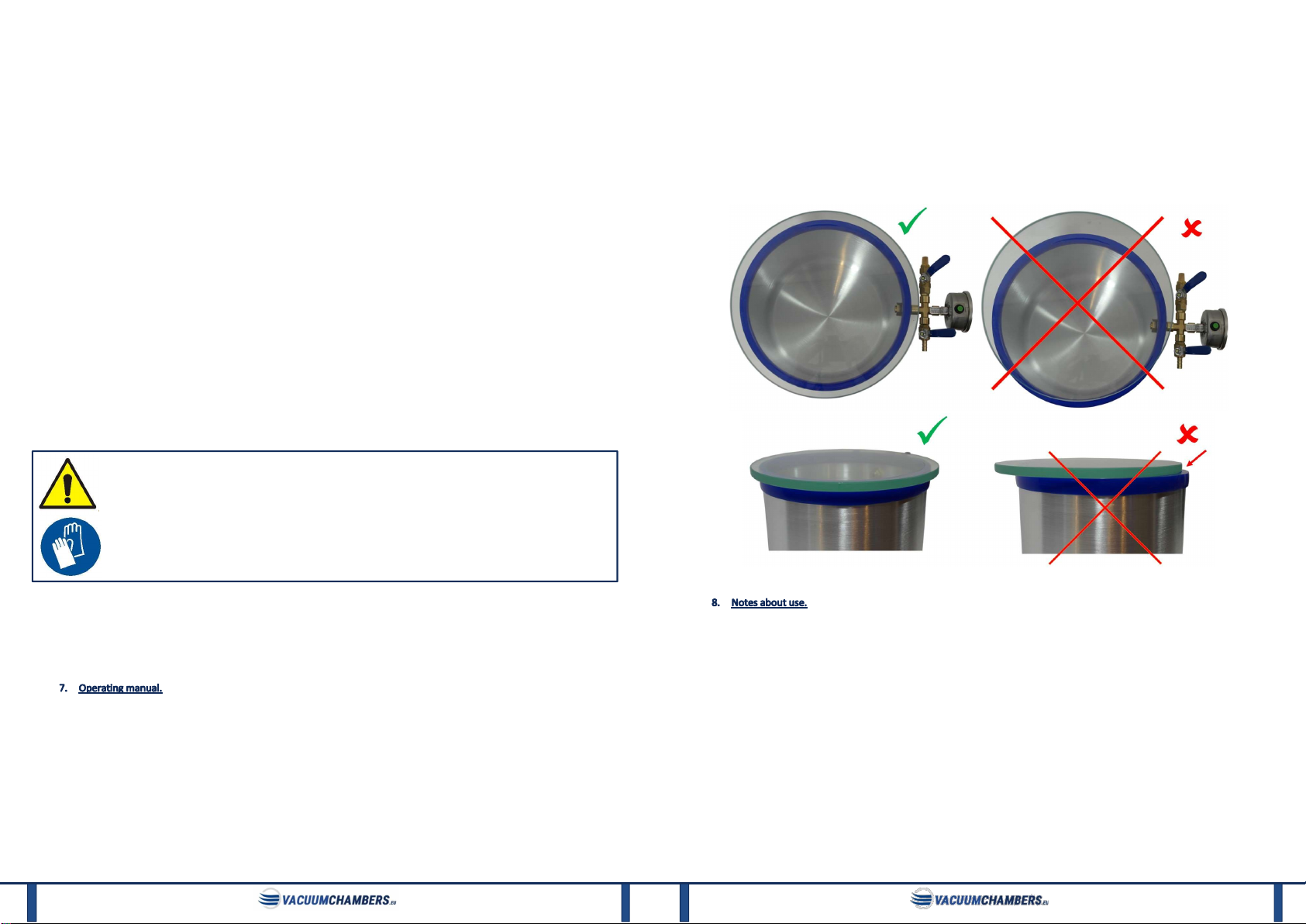

occurrence of its strong adherence to the lid. It is recommended to protect the new gasket surface, for example by technical

talc.

Chambers with polycarbonate lids are not designed for wood stabilization or to work with alcohol, ethanol, acetone and

monomers or polymers based on acrylic.

When using a vacuum chamber for degassing aggressive resins, an additional filter should be placed between the chamber

and the pump if degassing takes more than 10 minutes. Not using a filter can lead to pump damage, which is not subject to

future warranty.

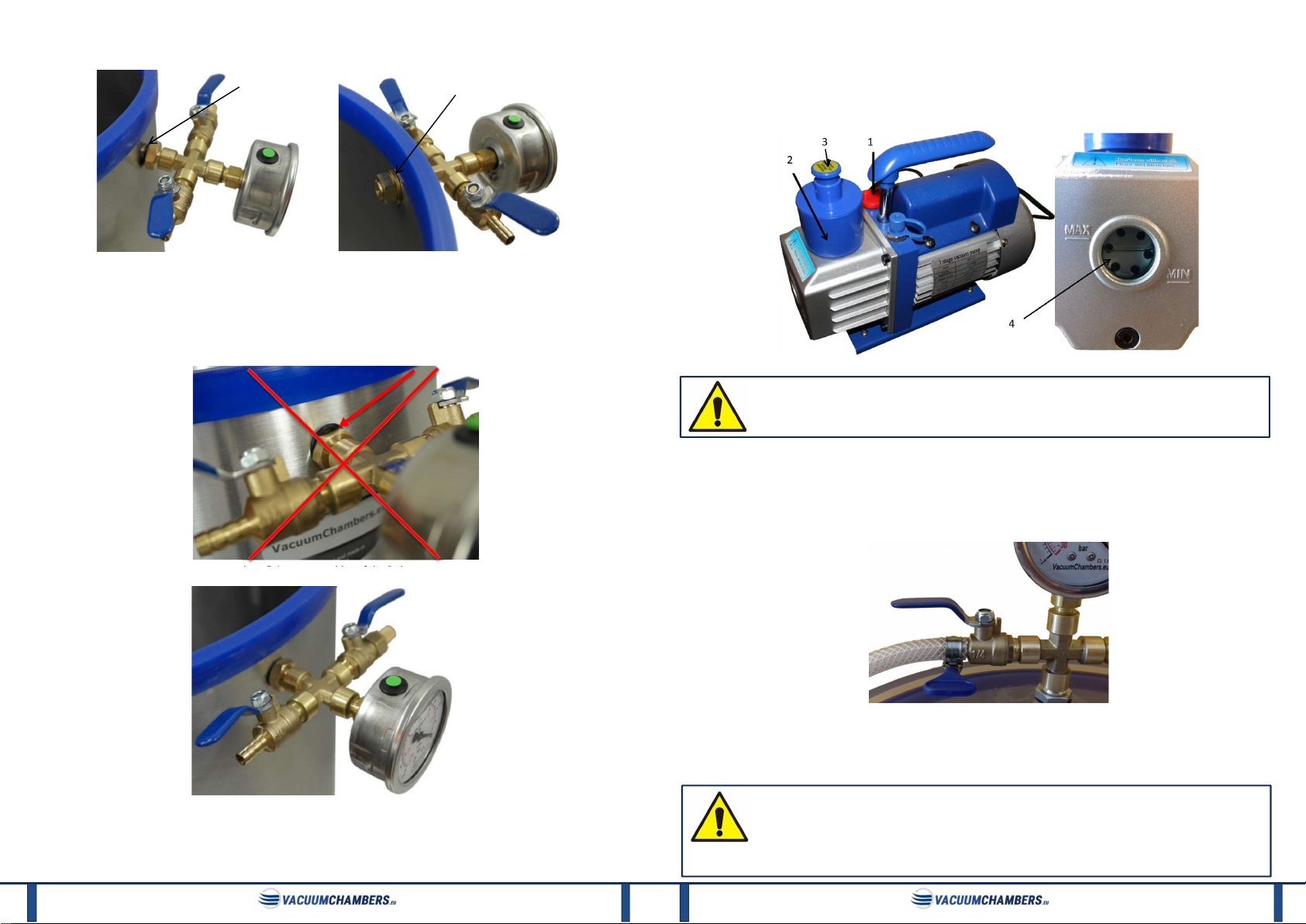

The vacuum pump must always be set below the vacuum tank.

The time of continuous operation of the vacuum pump should not exceed 15 minutes with the connected load, such as a

tank or installation.

Time of continuous operation of the vacuum pump must not exceed 30 minutes in conditions of free air circulation, without

connected load.

Do not allow the vacuum pump to overheat. Exceeding the temperature of 75°C on the motor housing significantly shortens

the life of the pump, and in some cases can lead to its complete damage.

RS series of rotary, oil sealed vacuum pumps are not designed for continuous operation. The recommended mode of use is

intermittent work S3 25%.

Oil change in the vacuum pump should be carried out every 20 work hours. One of the symptoms of the necessity to replace

oil is not reaching the maximum vacuum. Turbid or dark colour oil should be replaced with a new one.

In the case of using a vacuum set for processes that cause strong contamination of the oil, for example wood stabilization, it

is recommended to drain the oil after each process. The drained oil can be re-used as long as it has returned to its original

properties. Not following this point may cause corrosion and accelerated wear of pump mechanisms.

Under certain conditions, the rotary oil vacuum pump may have trouble starting. This happens especially at low

temperatures which cause the oil to thicken. It is also related to the vane positioning when the pump is switched off. This is

due to the operating principle of the pump and is not a defect. In case of problems with starting the pump, the air inlet of

the pump must be unsealed, which should enable the pump to start.

It is recommended to store the rotary oil vacuum pump at room temperature. If the pump is stored at lower temperatures,

it is recommended that the pump be moved to a warm space before it is put into operation, which will enable to warm the

cold oil to room temperature. This prevents possible problems with starting the pump.

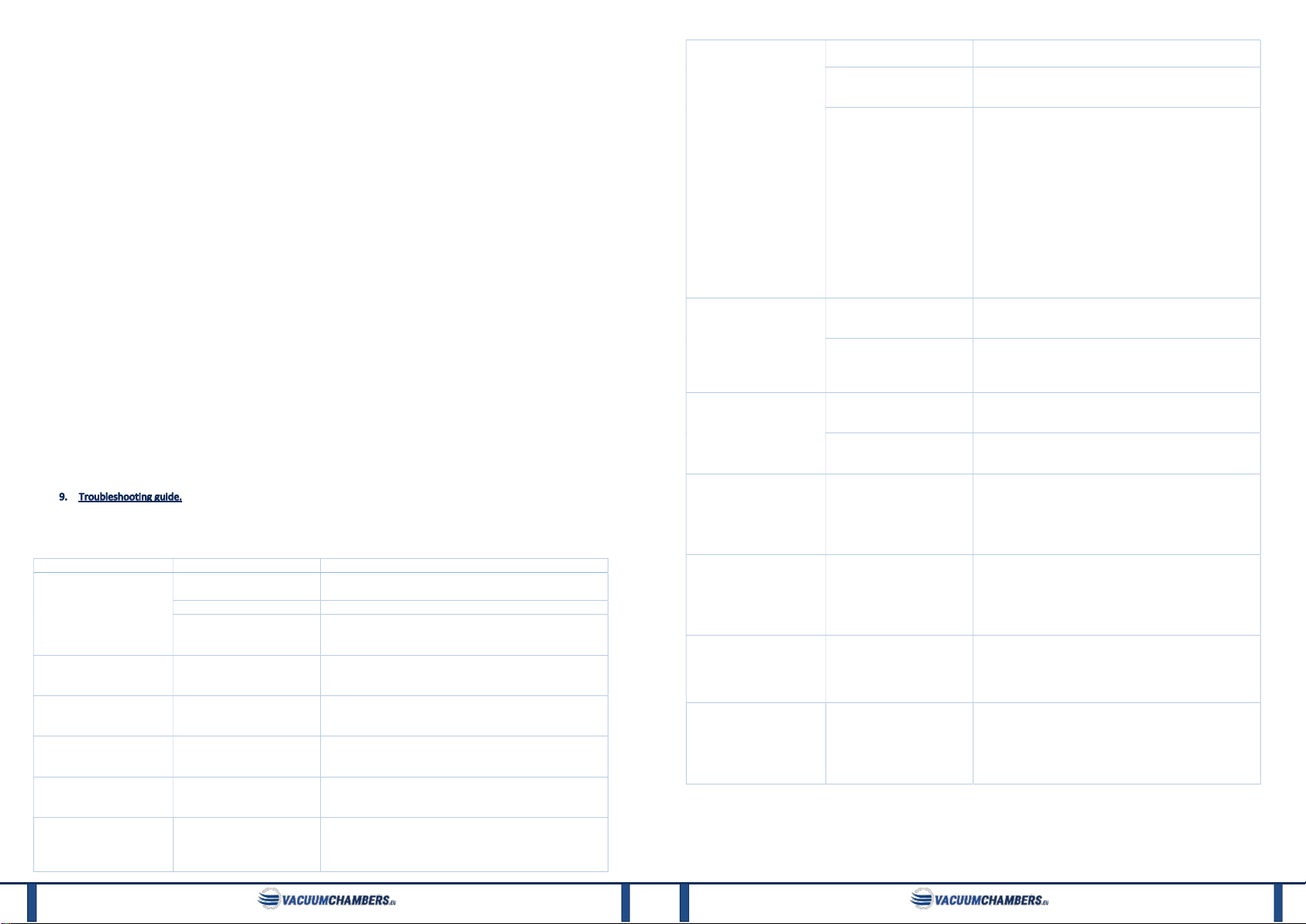

Possible and the most common failures and problems are described below, as well as recommended procedures in case of

their occurrence.

No connection to the power

supply.

Allow the pump to cool down, then try turning it

the pump causing the oil to

thicken.

Leave the pump at room temperature and wait for the pump

and oil to warm up. Try to start the pump again. Do not store

the pump in cold temperatures.

against oil return was used.

Replace the used pump with new pomp

return valve (all pumps available in the VcuumChambers.eu

offer are equipped with a non-return valve).

to a

°C.

Thermal sensor failure.

S3 25% intermittent operation

was not used.

Stop using the pump. Contact the supplier for additional

information or to perform a warranty or post-warranty

repair.

Loud, unusual vacuum pump

Stop using the pump. Contact the supplier to assess possible

damage, obtain additional information, or perform a

warranty or post-warranty repair.

The glycerin vacuum gauge

“0".

vacuum gauge.

Pull back the green plug of the vacuum gauge or remove it

completely to allow the pressure in the vacuum gauge to

equilibrate with the atmospheric pressure.

Failure to achieve the values

of the negative pressure in

vacuum chamber

Vacuum pump oil level too

low. Poor oil quality (oil is

contaminated or unsuitable

for vacuum pumps).

Check the quantity and quality of the oil in the vacuum pump

according to point 10B. “Oil change.” of this manual. A

heavily contaminated pump may require several oil changes

18

damaged.

Contact the supplier for additional information or to perform

a warranty or post-warranty repair.

by using harmful compounds

in the degassing process

Stop using the pump. Contact the supplier for additional

information or to perform a warranty or post-warranty

repair.

components of the vacuum

set.

Closing of the proper valves (see: 7. “Operating

manual.”).

Tightness of the connection of the pneumatic hose with

the chamber and the pump. make sure that a worm

clamp is used in the place where the hose and the

vacuum chamber are connected.

The elements connected by the user (especially if it is the

first start-up), including the tightness of the connection

between the air manifold and the chamber.

All other elements of the vacuum set and the vacuum

chamber (Each vacuum chamber delivered to the

customer undergoes leak tests, therefore the risk of

leakage directly in the chamber or air manifold is low.)

After the pump is turned off,

vacuum chamber and

pneumatic hose.

should be performed again. Before turning off the

pump, close the valve between the vacuum chamber and the

pneumatic hose.

ght leakage on one or more

elements of the vacuum set.

Check the vacuum set for leaks according to: " Leakage on

one or more components of the vacuum set.” in the line:

"Failure to achieve the values of the negative pressure in the

vacuum chamber declared by the manufacturer.".

The lid cannot be opened.

The lid is difficult to remove.

There is a negative pressure in

the tank.

air valve and wait for the pressure in the tank

to equilibrate with the ambient pressure. Try to remove the

lid again.

The lid sticks to the gasket.

The silicone gasket is removed

together with the lid.

The gasket can be sprinkled with a s

talc, which should reduce gasket sticking to the lid.

The polycarbonate lid goes

milky or has small scratches

Improper cleaning of the lid

(using unsuitable chemicals).

Replace the lid with a new one. Do not use

used so far. Clean the lid with a damp cloth.

If it is necessary to continue using the substances used to

clean the lid, the polycarbonate lid can be replaced with a

glass lid (but only if the glass lid is suitable for the intended

process and the substances to be used during cleaning).

ImpResin90, alcohols,

ethanol, acetone, acrylic

monomers or polymers or

other substances harmful to

the lid.

Replace the lid with a new one.

substances - the polycarbonate lid is not suitable for them. If

the customer intends to use the chamber with the listed

substances, the polycarbonate lid should be replaced with a

tempered glass lid (but only if it is suitable for the intended

process).

weakness to the vacuum set

particular: silicone gasket, lid

vacuum set or its elements.

ents. Contact the supplier to

replace damaged elements with new ones, if possible. Inform

the supplier about how the vacuum set or its elements have

been damaged for additional information and guidance that

may reduce the risk of similar damage in the future.

ss of the vacuum set

ents. In particular:

Use of unsuitable materials

when using or cleaning the

vacuum set or its elements.

ents. Verify the safety of the

substances used in the process and clean the vacuum set or

its elements. Contact the supplier to replace the damaged

elements with new ones or more suitable for the intended

process, and to obtain additional information.

If the above information did not allow to fix the problem or the problem that occurred is not described above, please

contact the supplier for additional information or to return the product for warranty repair or post-warranty service.

In the case of special vacuum sets or the use of additional equipment listed in this manual, if the problem with the vacuum

set or its element is not described above, contact the supplier for additional information, replacement of defective elements or

warranty or post-warranty repair.