Table of contents

1. About this document.....................................................................................5

1.1 Version information.......................................................................................... 5

1.2 Documentation conventions........................................................................... 5

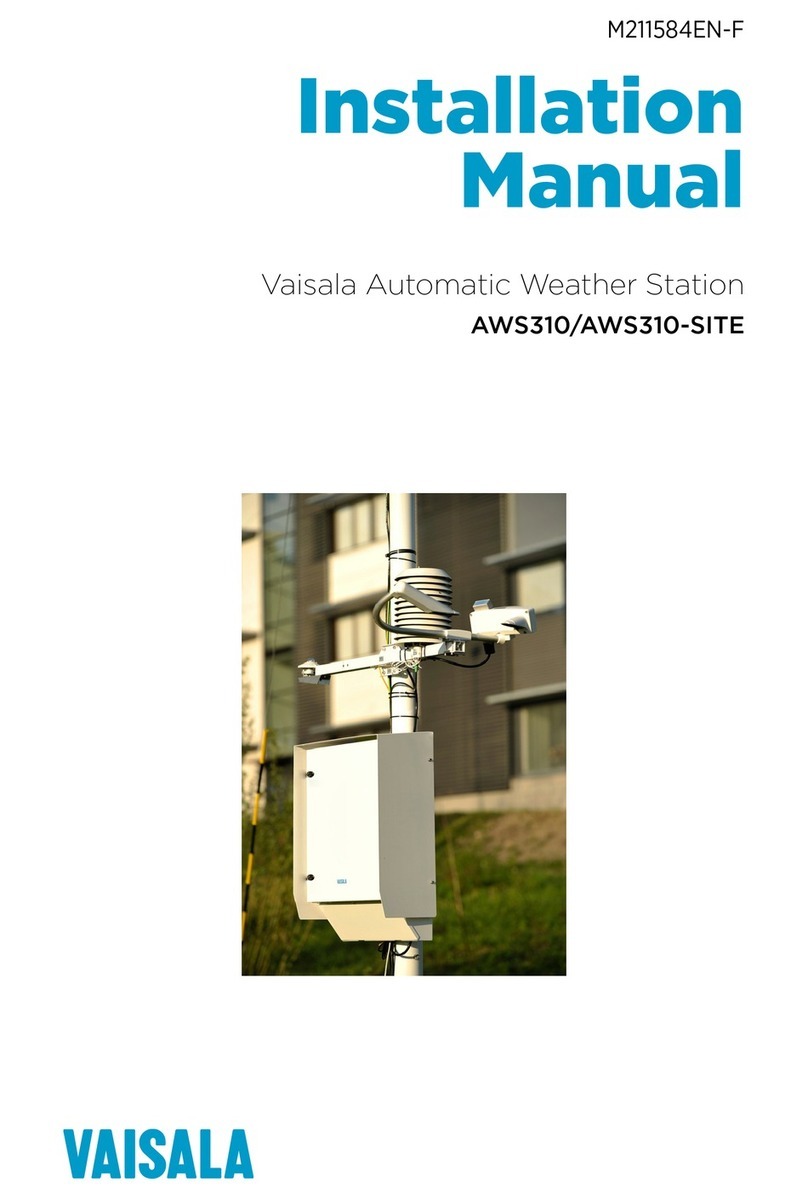

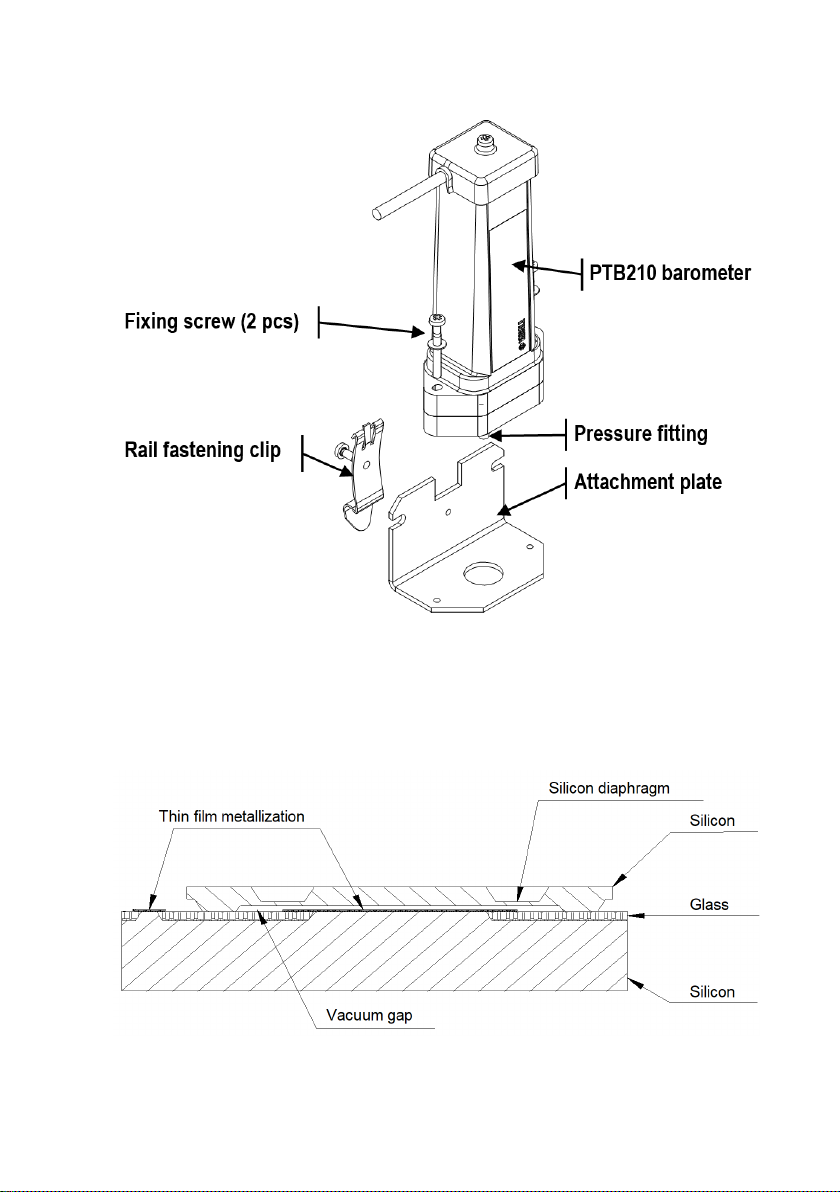

2. Product overview............................................................................................ 6

2.1 PTB210 product overview................................................................................6

2.2 Safety..................................................................................................................8

2.3 Trademarks........................................................................................................ 8

3. Installation..........................................................................................................9

3.1 Mounting PTB210..............................................................................................9

3.1.1 Static pressure head................................................................................ 10

3.2 Connections.......................................................................................................11

4. Operation..........................................................................................................14

4.1 Settings.............................................................................................................14

4.1.1 .BAUD setting baud rate......................................................................... 14

4.1.2 Setting serial communication parameters............................................ 15

4.1.3 .ID setting identification code.................................................................15

4.1.4 .PMIN / .PMAX setting pressure limits................................................... 15

4.1.5 .MPM measurements per minute............................................................16

4.1.6 .AVRG defining averaging....................................................................... 16

4.2 Operating commands..................................................................................... 16

4.2.1 .P outputting single message................................................................. 16

4.2.2 .BP continuous output............................................................................. 17

4.2.3 .UNIT selecting pressure unit.................................................................. 17

4.2.4 .FORM output with or without unit........................................................ 17

4.2.5 .RESET reset instrument..........................................................................18

4.2.6 .MPCON / MPCOFF set pressure correction on/o..............................18

4.2.7 .CALD setting calibration date................................................................18

4.2.8 .RON/ .ROFF setting RS-485 terminating resistor on/o...................18

4.3 Self-testing.......................................................................................................19

4.3.1 .? basic information of barometer settings...........................................19

5. Calibration and adjustment....................................................................... 21

5.1 Calibration and adjustment............................................................................21

5.2 Using Wizard software....................................................................................21

6. Technical Data................................................................................................25

6.1 PTB210 specifications.................................................................................... 25

Appendix A: FCC Part 15 compliance statement....................................29

Warranty.............................................................................................................31

Technical support............................................................................................. 31

Table of contents

1