Table of Contents

IMPORTANT SAFETY PRECAUTIONS................................................................................. . - 2 -

Section 1 Introduction.............................................................. - 3 -

Product Overview ....................................................................................................................... - 3 -

General Features ........................................................................................................................ - 3 -

Section 2 Installation.............................................................. - 4 -

Materials Needed for Installation .............................................................................................. - 4 -

Installation Location ................................................................................................................. - 13 -

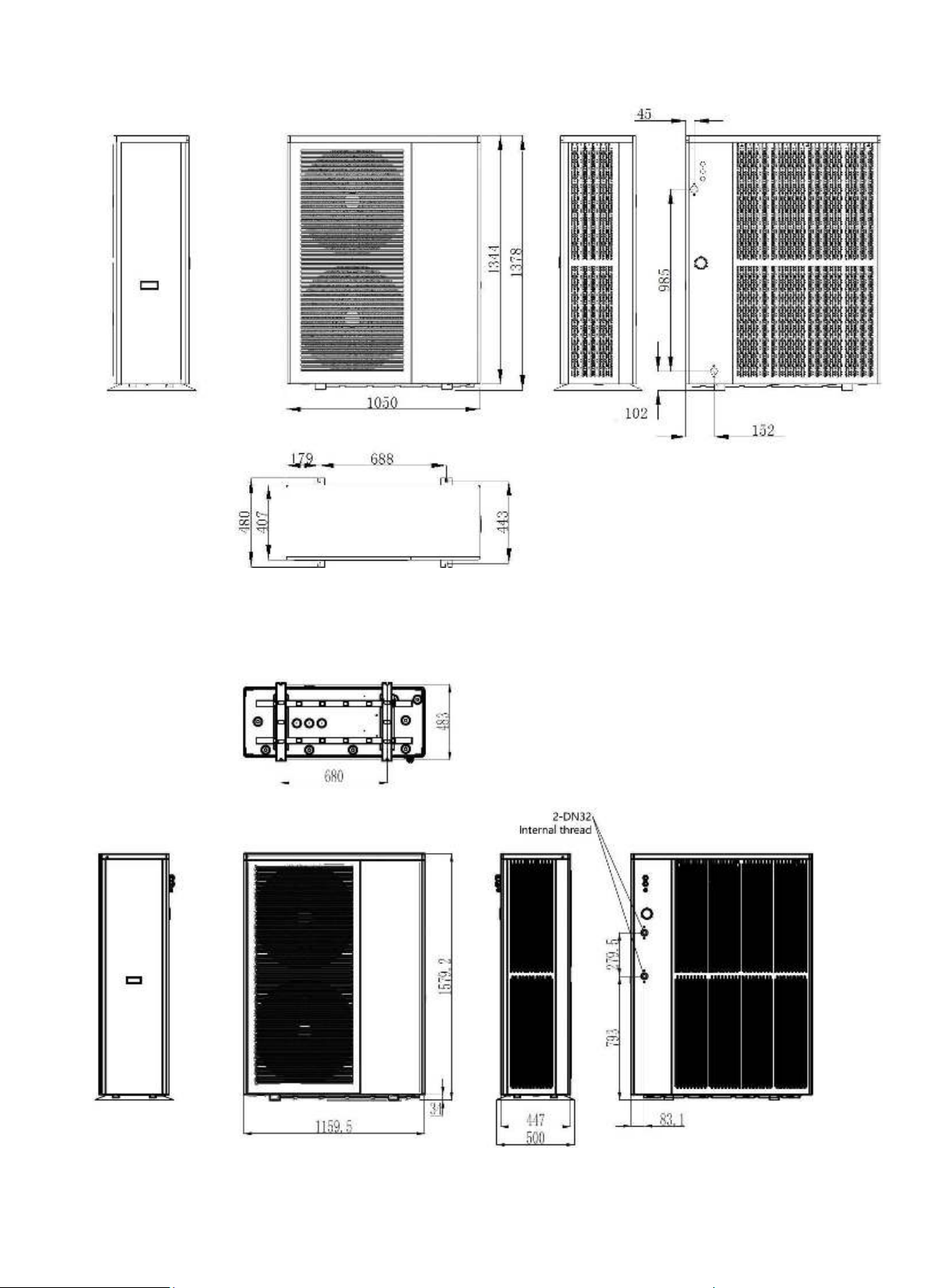

Installation Details .................................................................................................................... - 13 -

Drainage and Condensation .................................................................................................... - 14 -

Suggested Installation Methods............................................................................................. - 14 -

Water Connections................................................................................................................... - 20 -

Plumbing Installation Requirements ...................................................................................... - 20 -

Electrical Connections............................................................................................................. - 20 -

Power Supply ............................................................................................................................ - 21 -

Grounding and Over Current Protection ............................................................................... - 21 -

Electrical Wiring Diagram ........................................................................................................ - 22 -

Section 3 Operating Heat Pump.............................................................- 25 -

Controller Panel ........................................................................................................................ - 25 -

1.

Display

Icon

.....................................................................................................................................................-

25

-

2.

Definition

of

Buttons

.......................................................................................................................................-

26

-

3. Wire Controller

Operation

............................................................................................................................. - 27 -

General Operating Guide ......................................................................................................... - 35 -

Users’ Guide .............................................................................................................................. - 36 -

Section 4 General maintenance............................................................. - 37 -

Controller Error Codes ............................................................................................................. - 37 -

Owner Inspection ......................................................................................................................- 39 -

Troubleshooting........................................................................................................................- 40 -

Maintenance.............................................................................................................................. - 41 -

Common Faults and Debugging ............................................................................................. - 42 -

Section 5 WIFI Connection and Operation ................................ .................................... 43

APP Download................................................................ .......................................................................... 43

WIFI Connect Method 1: intelligent network distribution mode.................................................. 46

WIFI Connect Method 2: AP distribution network mode ............................................................... 49

Software function operation ................................................................................................................. 53