Valterra Products, LLC Mission Hills, CA91346 1-800-806-6159 www.valterra.com

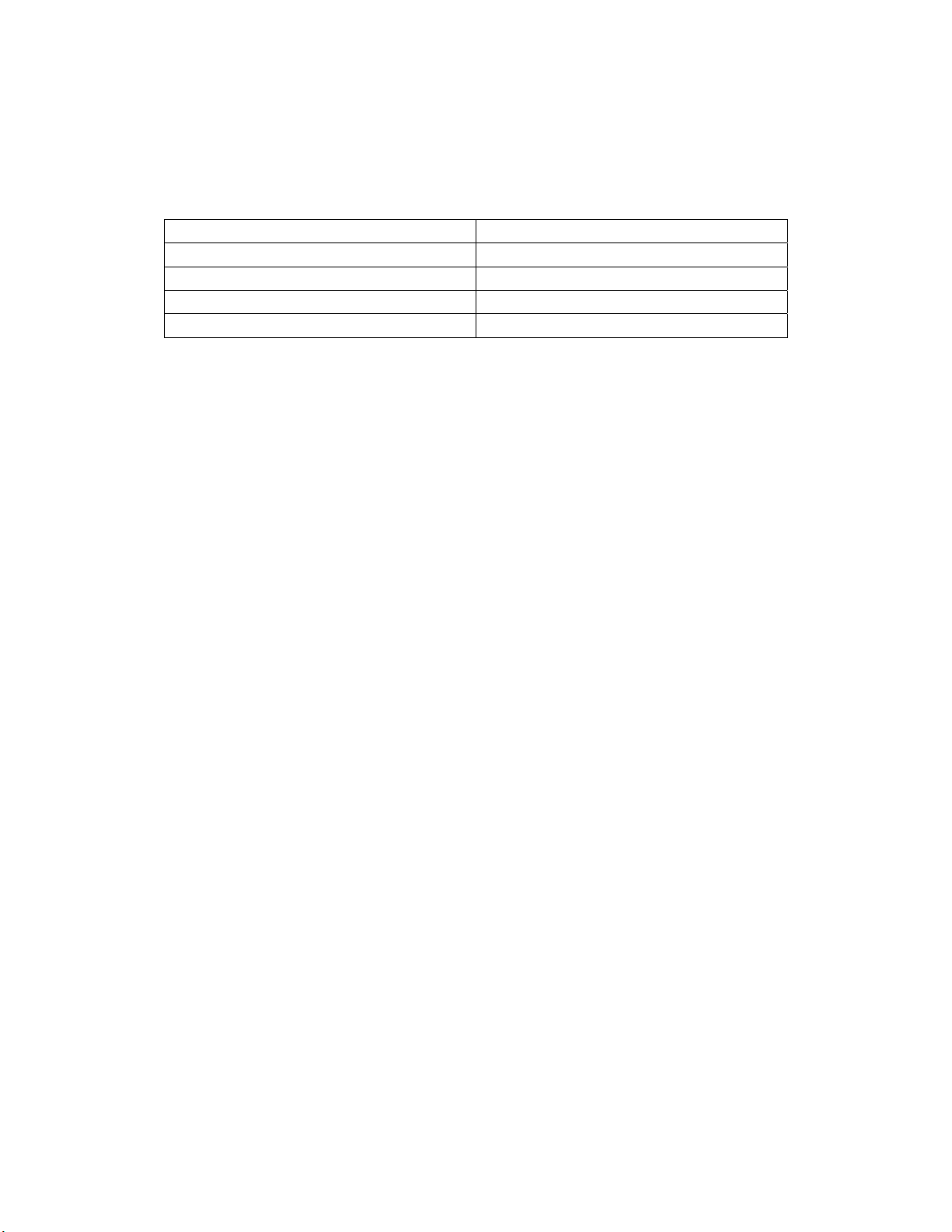

Minimum Wire Size for a 10% voltage drop on a 12VDC, 10Amp Circuit. Length is the distance

from the power source to pump and back to ground.

·The total current draw on the circuit must not exceed 15 amps. If the pump is used in conjunction

with other components, overload current protection (fuse or circuit breaker) and wire size must be

for the total amp requirements of all devices on the circuit.

Feet [Meters] AWG [mm2]

0-25 [0-7.6] 14 [2.1]

25-50 [7.6-15.2] 12 [3.3]

50-70 [15.2-21.3] 10 [5.3]

70-110 [21.3-33.5] 8 [8.4]

PLUMBING

HYDROMAX recommends at least 1ft[.3m]of 1/2"[13mm]I.D. flexible high pressure tubing to

both ports. Ideally the pump's ports/strainer should not be connected to plastic or rigid pipe. The

pump's normal oscillation may transmit through rigid plumbing causing noise, and possibly loosen

or crack components.

Installation of a 50 mesh strainer such as the HYDROMAX P25206VP is recommended to

prevent foreign debris from entering the pump. HYDROMAX P25205VP is a hex/swivel barb

fittings that provides easy removal if maintenance or access is required. The fittings are designed

with a "taper-seal", creating a water tight connection when hand-tightened. Always secure barb

tubing connections with properly sized stainless steel clamps to prevent leaks. Never use Teflon

tape or sealing compounds on threads. Sealer may enter the pumps causing a failure. Failure due

to foreign debris is not covered under warranty.

Rapid cycling may be caused by excessive back pressure created by one or more of the following

within a plumbing system: Water filters and purifiers not on separate feed lines, Flow restrictors in

faucets and shower heads, Small ID lines Pipe/tubing should be at least 1/2”(13mm) for main lines,

Restrictive fittings and connections (elbows, “T” s, feeder lines to faucets, etc). The pump with

by-pass do not need to use pressure tank.

If the pump is cycling rapidly increase the setting by turning the screw clockwise (1 1/2 turn

MAX.) until the pump operates for 1 sec. with at least 2 sec.” OFF time”.

The pump's duty cycle is: intermittently. Do not use the pump under anti-osmosis filtering system.

Continuous running under higher pressure may reduce pump life and it is not under the warranty.

Operation(only for HYDROMAX Automatic Fresh Water Pumps-42series)

This pump is designed for intermittent duty only.

The pump operates normally up to about 40-psi, where a spring-loaded by-pass valve opens,

allowing flow back from the output side to the input side, providing smooth, steady flow with

virtually no cycling, all the way down to a trickle. As a faucet is opened back up, the pressure will

drop, the by-pass will close and full flow is again obtained. This allows good flow, even with

today's restrictive showers and pullout sprayer faucets. Performance will vary, of course,

depending on the voltage to the pump; lower voltage=lower flow, higher voltage=higher flow.

Remember your electrical safety: It is always best to shut off power to the pump OFF when