PAGE 3

SECTION 2 INSTALLATION

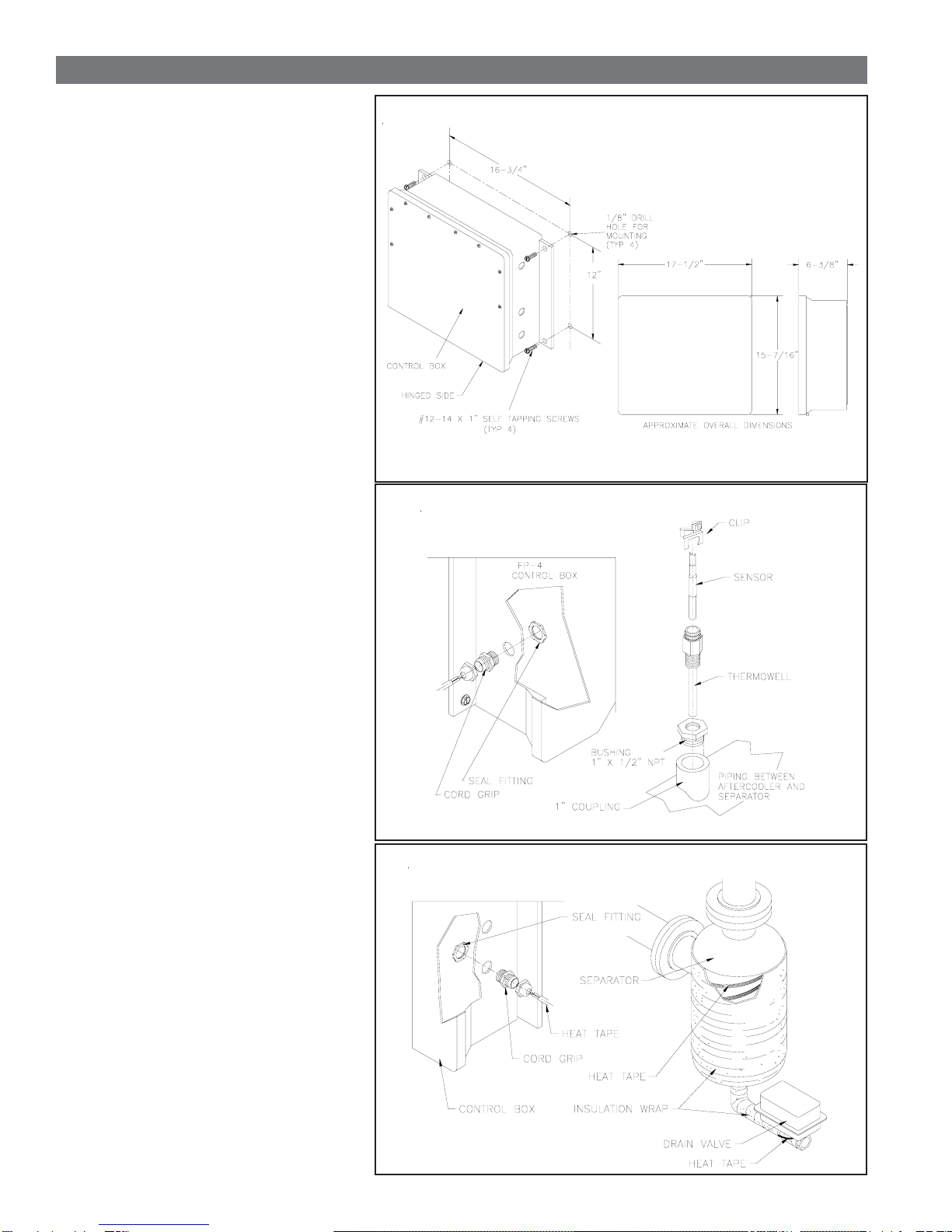

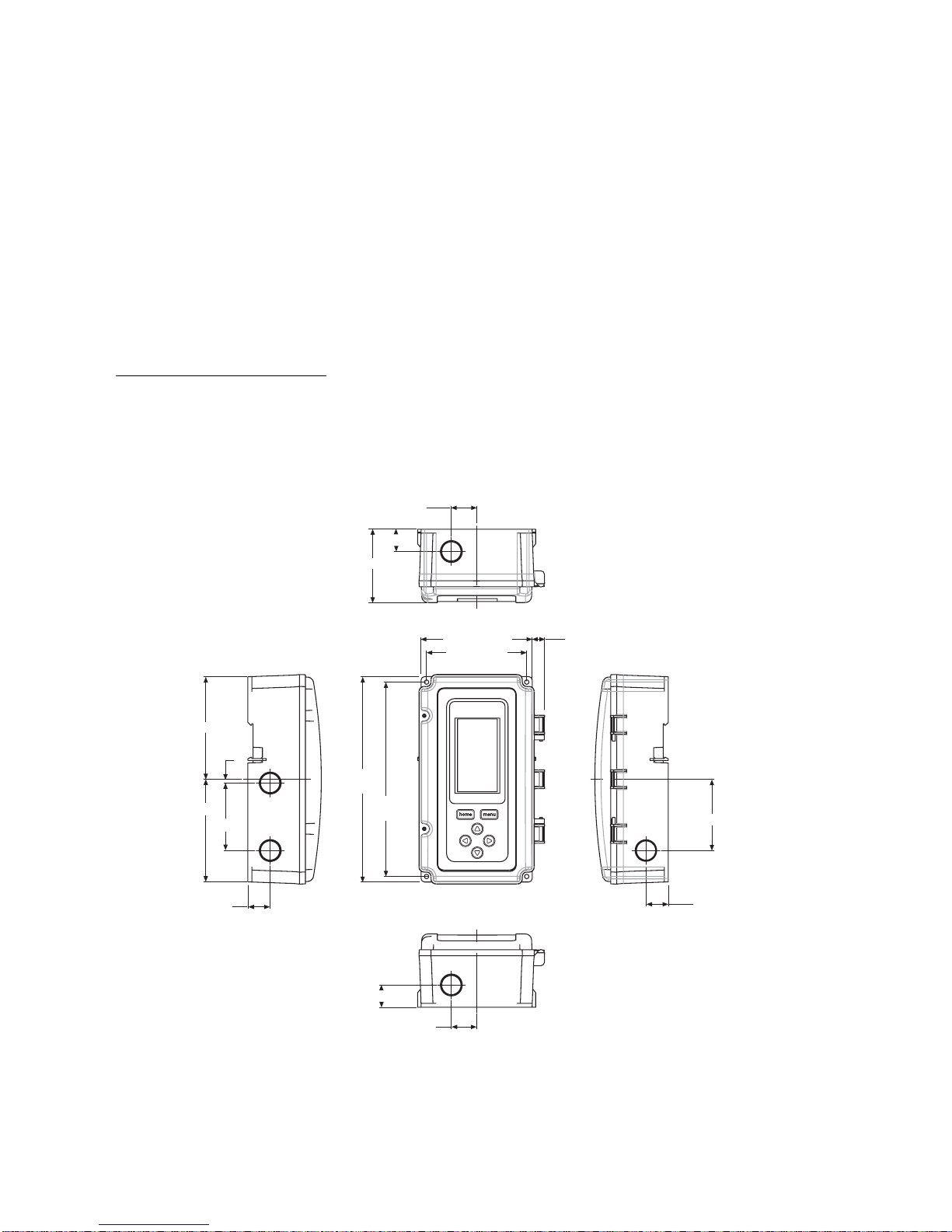

2.4 INSTALLING THE CONDUIT

Install the straight conduit connector

on the control box. Reference Figure

2-D.

The supplied conduit will be used to

run between the aftercooler and the

control box. Connect the conduit to

the straight connector.

Install the 90 degree elbow connector

on the aftercooler. Reference Figure

2-D.

FIGURE 2-D INSTALLING THE CONDUIT

2.5 INSTALLING THE TRANSFORMER JUMPERS

WARNING

BEFORE STARTING THIS PROCEDURE, TURN OFF

ELECTRICAL POWER. FAILURE TO HEED THIS

WARNING MAY RESULT IN SERIOUS PERSONAL

INJURY AND/OR DAMAGE TO THE UNIT.

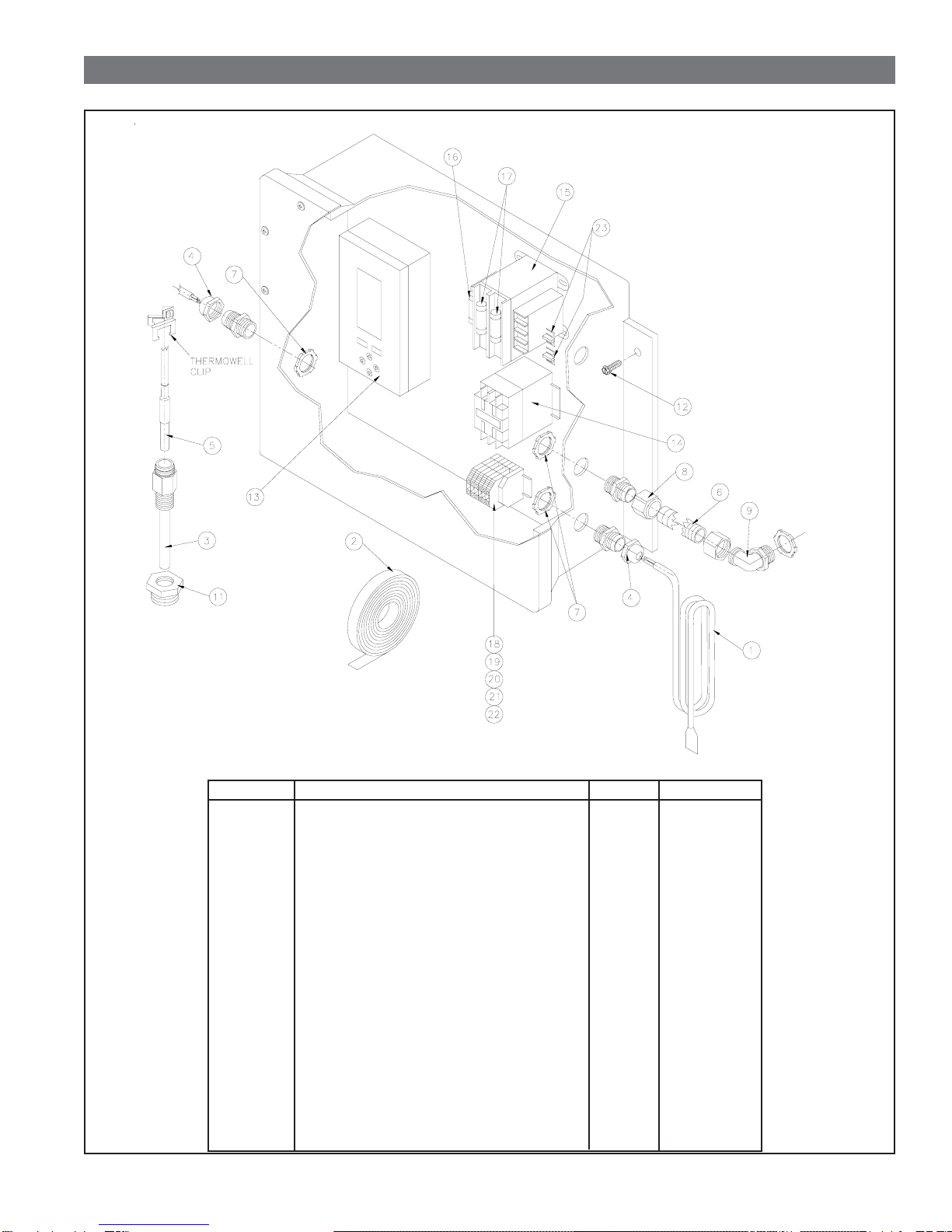

This kit was designed to operate at 230V-3PH-60Hz or

460V-3PH-60Hz. Two jumpers were shipped inside the

control box. They must be installed on the transformer

before connecting the power to the control box. Install the

jumper(s) as shown in Figure 2-E for the desired voltage.

CAUTION

It is important that this procedure be properly

completed before continuing with installation.

This kit will not operate without the jumpers.

Damage to the control box will occur if the jumpers

are improperly installed.

FIGURE 2-E INSTALLING THE TRANSFORMER JUMPERS

2.6 ELECTRICALCONNECTIONS

WARNING

BEFORE STARTING INSTALLATION PROCEDURES

OR ATTEMPTING TO MAKE ANY WIRING CHANGES,

TURN OFF ELECTRICAL POWER. FAILURE TO HEED

THIS WARNING MAY RESULT IN SERIOUS

PERSONAL INJURY AND/OR DAMAGE TO THE UNIT.

WHEN INSTALLING THIS KIT ALWAYS COMPLY WITH

THE NATIONAL ELECTRICAL CODE AND ALL OTHER

APPLICABLE FEDERAL, STATE AND LOCAL CODES.

A 7/8" hole in the top right side of the control box is provided

for incoming power conduit. The hole can be enlarged if

necessary.

The control box is designed for 230V-3PH-60Hz or 460V-

3PH-60Hz operation. The transformer jumpers must be

installed as outlined in Section 2.5 for the desired voltage.

Make the necessary wiring runs and connections for the

main power supply.

Remove the junction box cover on the aftercooler for access

to the junction box. Make the necessary wiring runs through

the conduit from the aftercooler to the control box. Fasten the

conduit to the connector on the aftercooler. Reference

FIGURE 2-D.

Make the wire connections at the junction box on the

aftercooler. Reference FIGURE 2-F. Fasten the junction box

cover to the aftercooler.

Complete the wire connections inside the controller as

shown in FIGURE 2-F.

Once all wiring connections have been properly made, the

rotation of the fan should be checked. The fan must rotate in

the proper direction for maximum performance. Reference

the operator's manual supplied with the aftercooler for the

correct rotation direction. Also, check the aftercooler for a

rotation direction label.

To check the rotation, turn on the power supply to the

aftercooler. If the fan does not rotate in the proper direction,

any two of the power leads to the motor can be switched.