1

Description, application and working principles

1.1 Description

WARNING: This manual is intended to give Important Information that must be followed

during Storage, Transportation, Installation, Operation and Maintenance of the Pump-Set.

We therefore recommend that this manual is read carefully before the Pump-Set is put into

operation. To prevent damage being caused by inappropriate or incorrect use, or by being

used outside the normal operating parameters of the Pump-set, the Instructions in this

manual must be followed. Failure to do so may lead to damage to or premature failure of the

Pump-set and may cause Injury. Any such actions will invalidate the warranty.

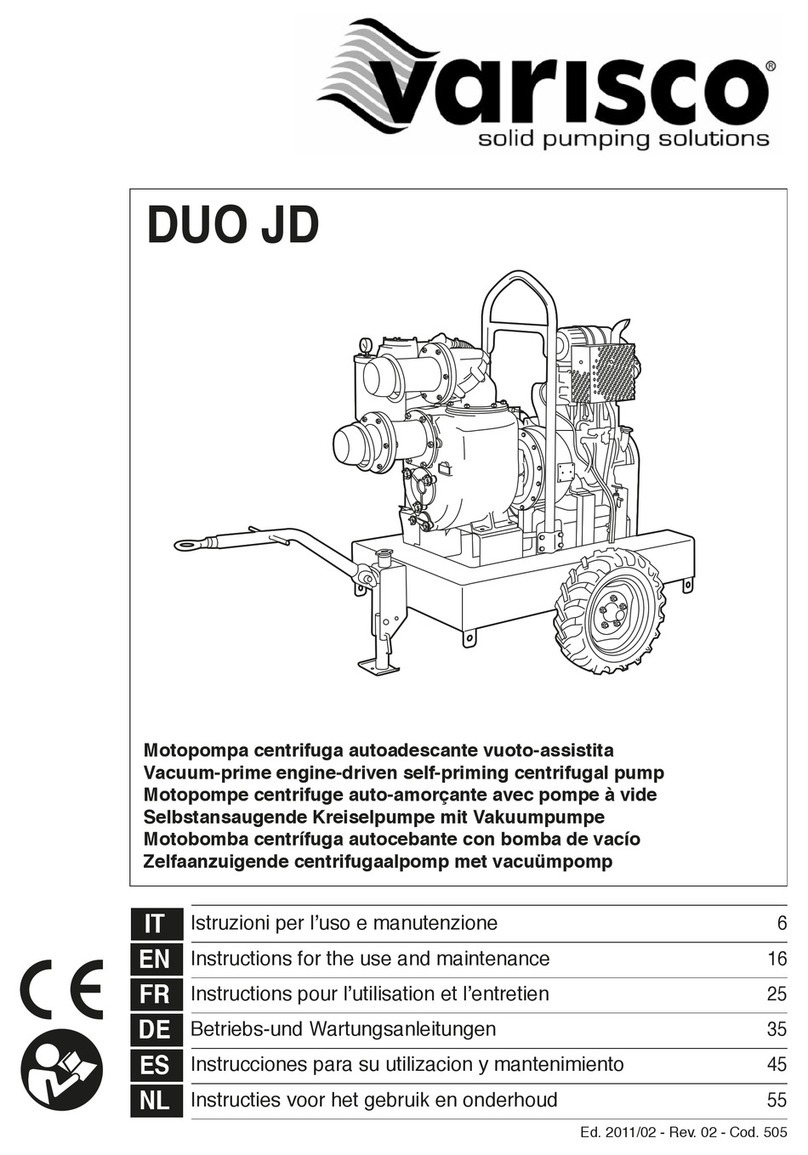

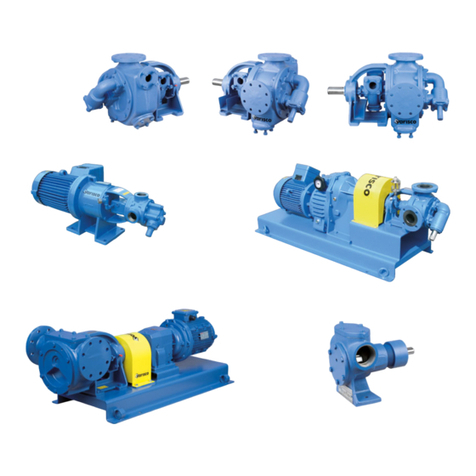

Centrifugal pump mod. J2-180 is basically a pump driven by a petrol engine, featuring an open vane

impeller to allow it to handle even liquids containing solids. This pump can also operate satisfactorily

with liquids containing dissolved gases or air. It is suitable for handling liquids of viscosity up to 50 cSt,

containing solids in suspension, and can be used in industry, civil engineering, shipbuilding, wastewater

treatment, construction and agriculture. It must not be used in a potentially explosive atmosphere.

Always quote the pump type printed on the relevant nameplate, or the serial number, when

ordering/making enquiries etc.

Self-priming principle

The air (yellow arrows) is drawn into the pump due to the negative pressure created by the moving

impeller and is emulsified with the liquid (blue arrows) contained in the pump casing. The air-liquid

emulsion is forced into the priming chamber where the lighter air is separated and leaves through the

discharge pipe; the heavier liquid drops back down into circulation. Once all of the air has beenexpelled

from the suction pipe, the pump is primed and works like a normal centrifugal pump. The pump can

also work with an air-liquid mixture