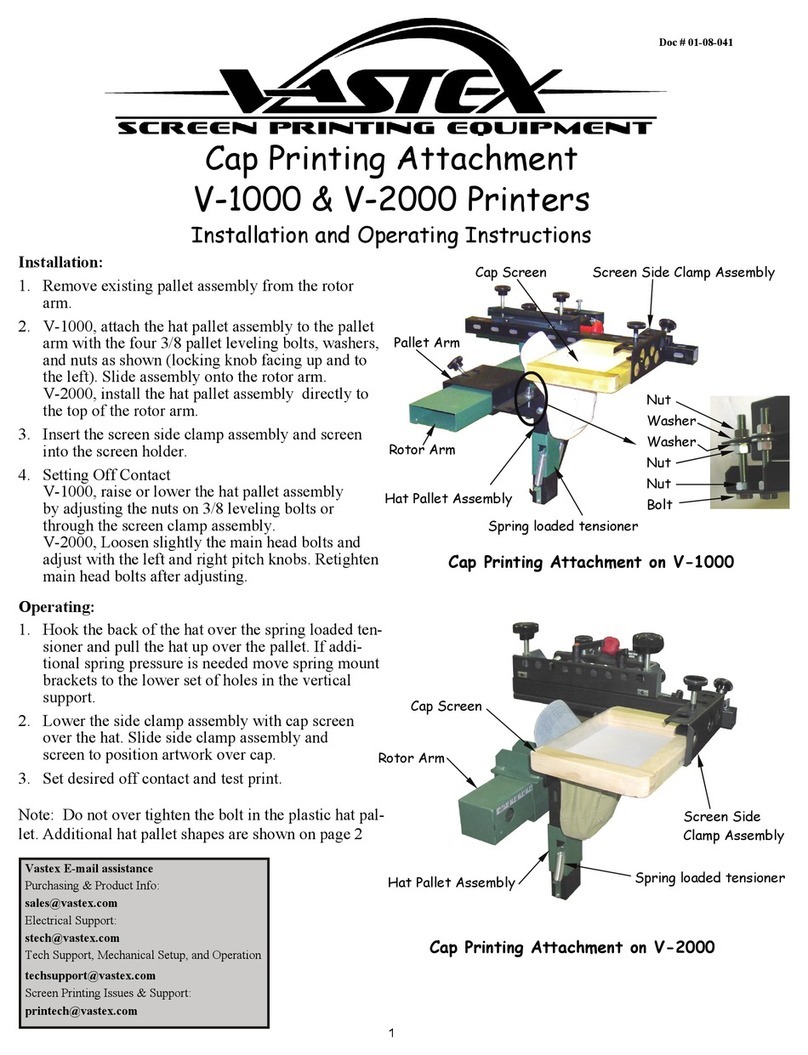

Operating Instructions

1) Install the DiGiT numbering attachments.

2) Install required Site and Detent Rails.

3) Clamp in and locate screen.

4) Be sure your screen is leveled in both directions. Set off con-

tact to 3/8” to ensure the screen locks fully into the Detent Rail.

5) Install (optional) Vastex Squeegee Rest onto screen.

6) Ink the screens with athletic ink. For athletic numbering tips,

see document (01-08-028) found at Vastex.com or contact

Vastex Sales department.

7) Use squeegees cut to proper width. See chart for sizes.

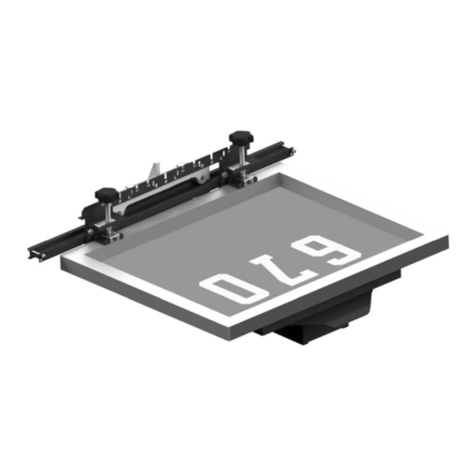

8) Tilt the screen slightly to slide to the required number. Print

position and sliding position are shown below.

Adjustments (Optional) Vastex Squeegee Rest

Print position (shown above)

Sliding position (shown above)

The spacing between the rollers, in the Roller As-

sembly, have been preset at the factory. It may be

necessary to make a slight adjustment to the roller

spacing as the rollers wear. If the screen does not

maintain level when the screen is slid to the end posi-

tions, the rollers may need to be adjusted. With the

print head lowered, center the Screen Holder Assem-

bly in the Roller Assembly. While holding down

firmly on the print head, lift up and down on the

Screen Holder Assembly. There should be no notice-

able vertical movement between the rollers and the

Screen Holder Assembly. If movement is noticed,

use two 7/16 wrenches to tighten the adjustment bolt.

Tighten no more than 1/8 turn at a time. Recheck for

vertical movement. Do NOT over tighten!! Adjust

both sets of rollers. If the rollers are adjusted too

tight it will be difficult to slide the Screen Holder

Assembly.

9) Each number has five printing positions. (Pg 3) Align the

Site Rail to the Target for the desired printing location.

When the screen is in the print position, the detent will

engage into the roller bearing. A properly set off contact is

required for this to function correctly.

10) For printing two color numbers, rotate the pallet under the

flash then proceed with the outline or drop shadow.

11) To raise the print head, center the screen and gently lift.

12) Do not lean on number screens. Damage to the mechanism

can occur and off contact will suffer.

Adjustment Bolt

2-0 1 ½”

1 1 ¼”

2-0 2 ¾”

1 2”

2-0 3 ¾”

1 2 ¾”

Recommended Squeegee width

2”

4”

6”

Check here for

vertical movement.

Screen Holder Assembly

2-0 5”

1 3 ½”

2-0 5 ¾”

1 3 ¾”

8”

10”

12” 2-0 7”

1 4 ¼”