Doc. # 01-04-033A

Glass Removal / Installation

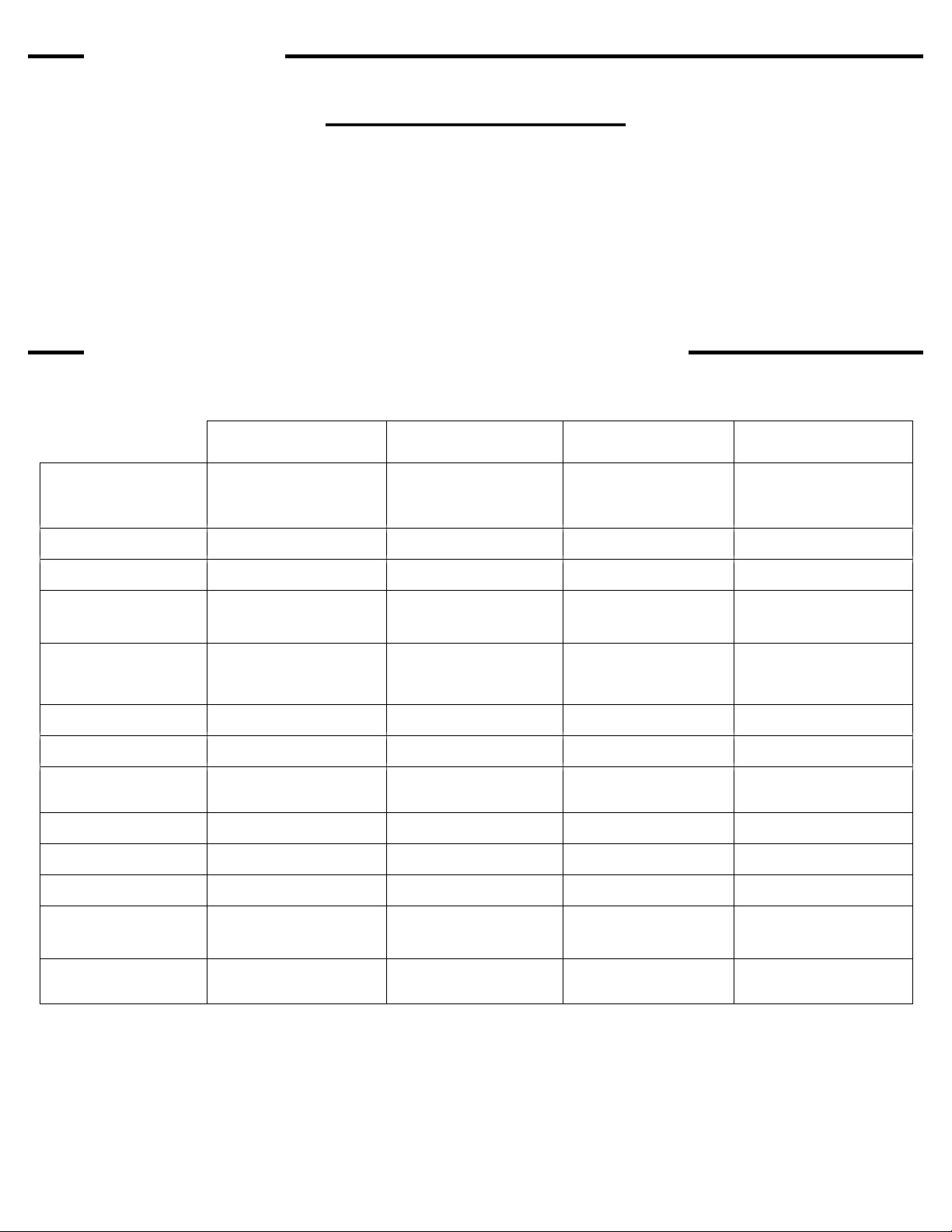

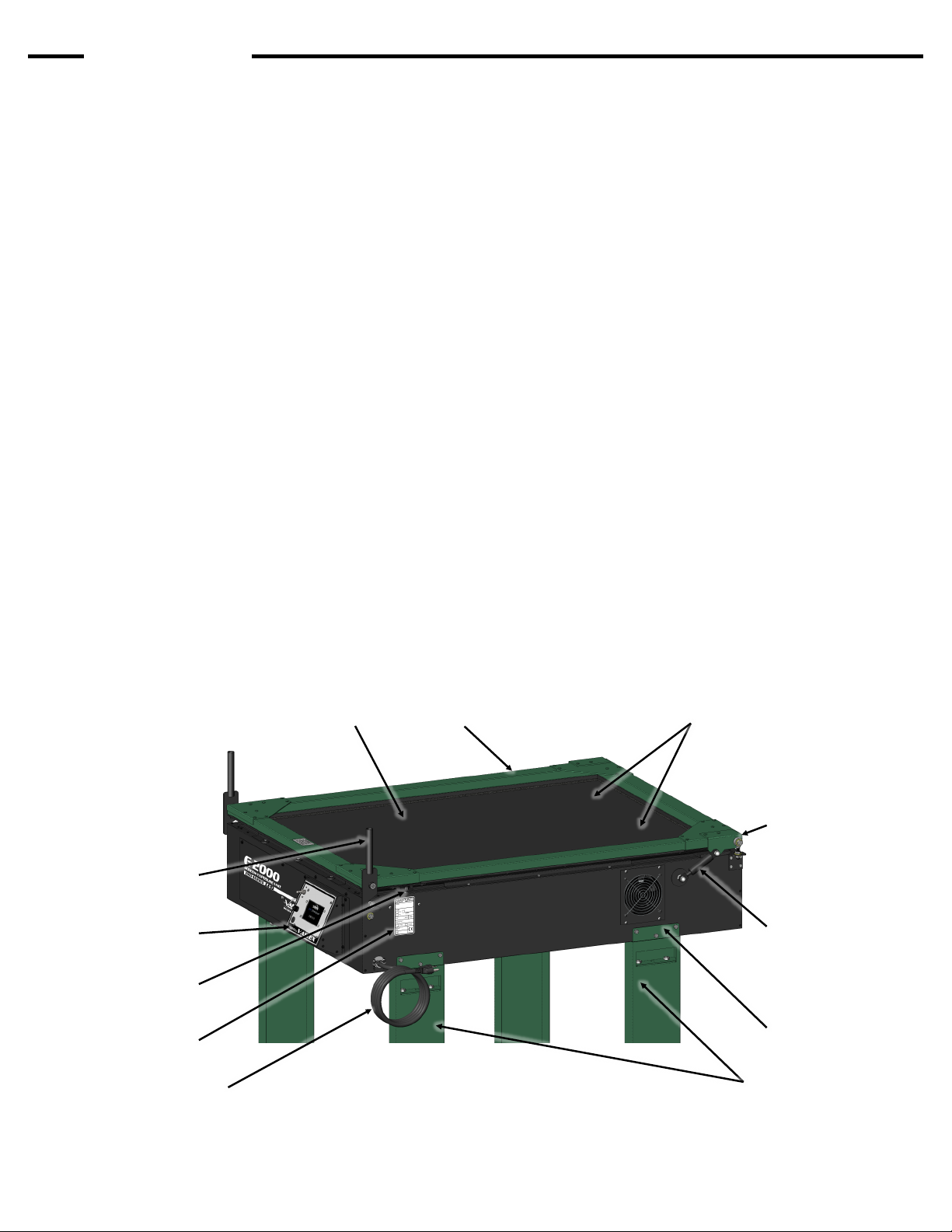

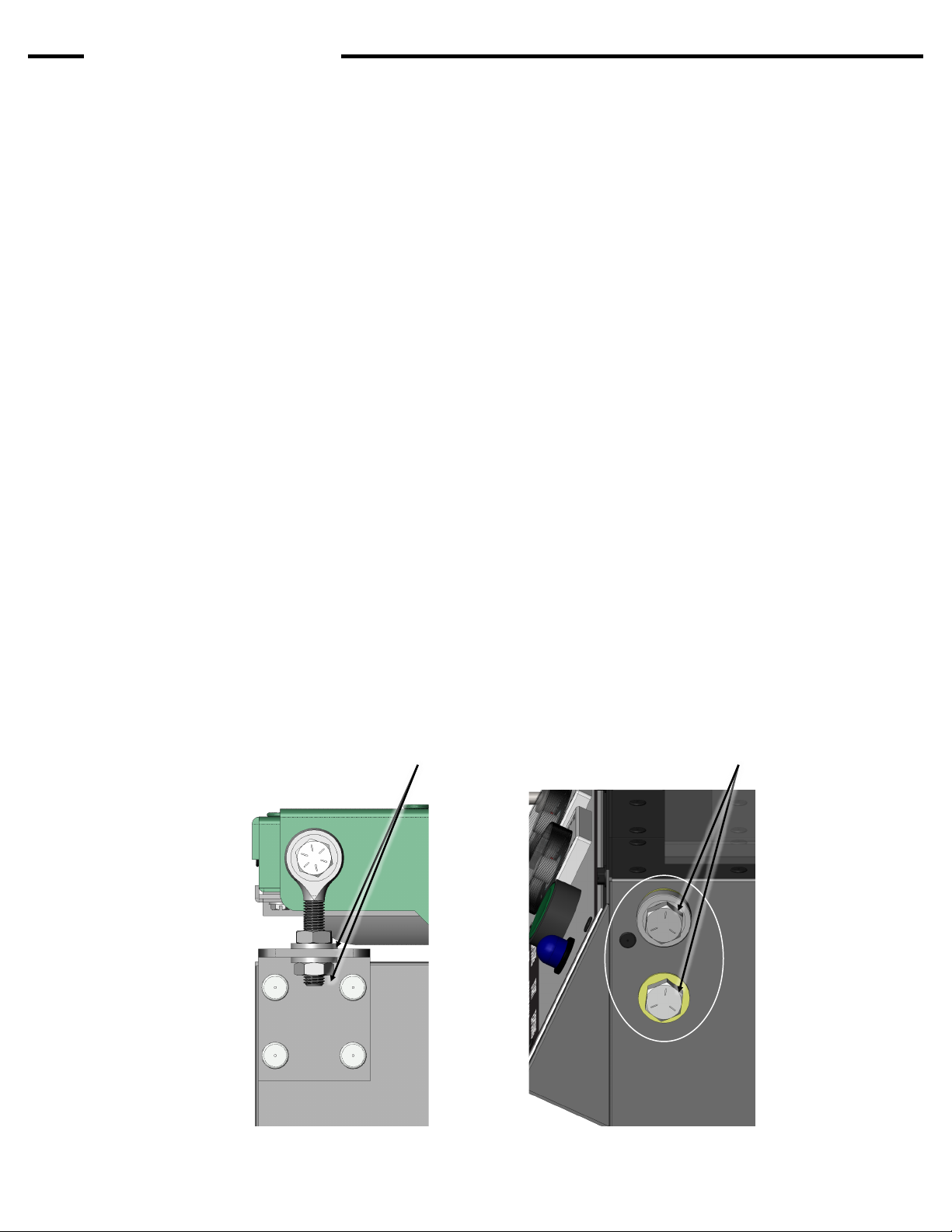

There are three glass retainers. One on each side

to square the glass to the rear seal and one in the

front with special cams. The cams are used to

gently push the glass back against the rear seal.

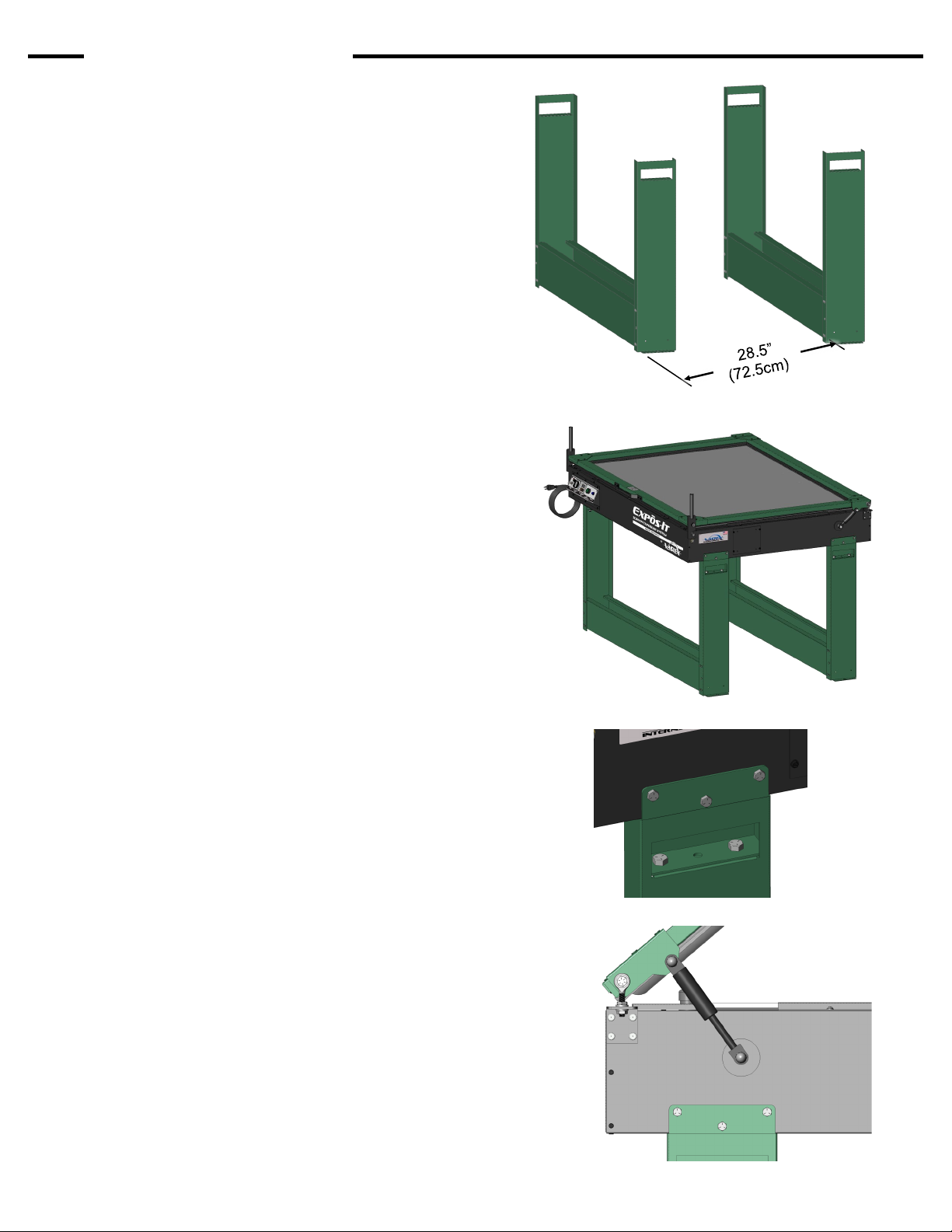

1) Remove the cams and front retainer. Slide

the glass towards the front to remove.

Carefully set glass on a flat, protected

surface. The cams are used to gently push

the glass back against the rear seal.

2) It is important to keep the inside of the

cabinet clean. Vacuum out any loose debris

from inside the cabinet. Refer to the replacing

a light bar if needed.

3) Reinstalling the glass.

Before installing the glass, switch the vacuum

pump on and off to verify it is functioning

properly. Clean both sides of the glass with

glass cleaner and a lint free rag. Vacuum

inside of cabinet. Position the glass seal side

down, blue tape towards the front, on the

front edge of the cabinet, and between the

side retainers. Slide glass back until it

contacts and it seated squarely against the

back seal. Place the front glass retainer and

the three cams against the glass front. Install

the screws but only snug the screws. Using a

1/4” flat screw driver in the cam slots, rotate

each cam to push the glass back. Do not

over tighten the cams but apply enough

pressure to make a seal. Now tighten the

center screws. If the vacuum leaks, go back

and tighten the cams a bit more.

4) Inspection of LED light bars should be

conducted monthly. See page 11, Step 1,

for instructions.

Inspection of UV Black bulbs should be

conducted bi-monthly. See page 12, Step 1,

for instructions

Note: The glass must be tight

against the back glass seal in

order to make a good vacuum.

Special cams help to apply

pressure. Do not over tighten.

Wear gloves when handling the

glass. Glass is tempered and

although strong, can shatter if the

edges are subjected to an impact.

Do Not allow objects to

contact the UV lights.

Maintenance

Side glass

retainer

(1 each side)

Rear glass seal

Front glass retainer,

with 3 cams.