Site Rail Target

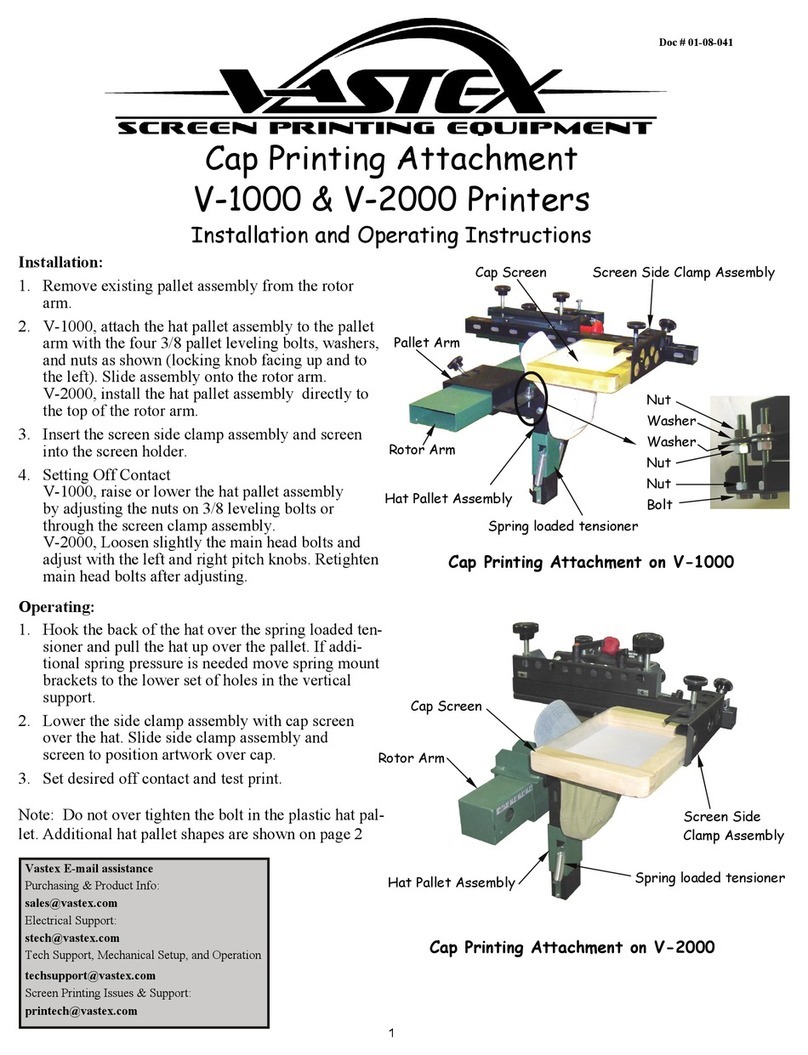

1) Loosen the two phillips head screws circled in the picture below.

2) Slide the Site Rail into the slots above the clamps

Be sure to install the correct Site and Detent Rails to match the

screen you will be using.

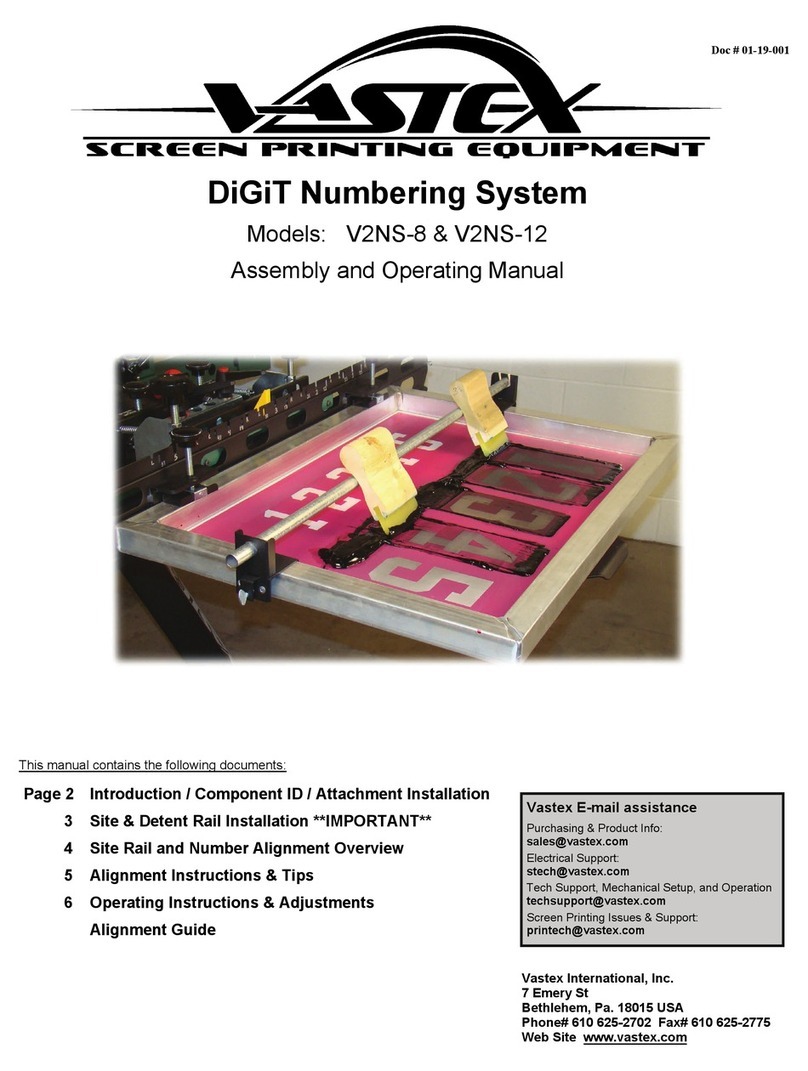

Detent Rail Installation

Note

The Site and Detent Rails can be installed

while the numbering attachment is on the

press. This is shown off the press for in-

structional purposes only.

(The picture above shows the correct

orientation of an installed Detent Rail.)

Detent Rail

3) Site Rails should be labeled from the factory as shown below.

The Site Rail is a visual aid for selecting the desired print location of the numbers.

The Detent Rail controls the location of the number. Five positions are available for each number. This is a very important step.

The grooves in the

Detent Rail engage

into a Roller Bearing,

locking the screen into

position.

1) Loosen the two philips head screws on the Detent Rail. (shown below)

2) Slide the Detent Rail onto the bottom of the Numbering Attachment and

tighten them down well. See photo (bottom right) for visual reference.

Be sure to install the correct Site and Detent Rails to match the

screen you will be using.

Roller Bearing

Important!

Detent rails must be installed as

shown below. Be sure grooves in

rail lock into the roller bearing!

Site Rail Installation

ID HOLES:

The Site and Detent rails have holes

punched in them. These should match.

8” Site/Detent : 3 ID Holes

6” Site/Detent : 2 ID Holes

4” Site/Detent : 1 ID Hole

ID Holes