Firmware Version ???

AIR WEIGHERM

M350S Quick Setup Guide - two channel

1 2

print menutare

gross

1 2

print menuzero

net

Conguration

Calibration

System

M

E

N

U

ok

Display

Diagnostics

Alarms

Options

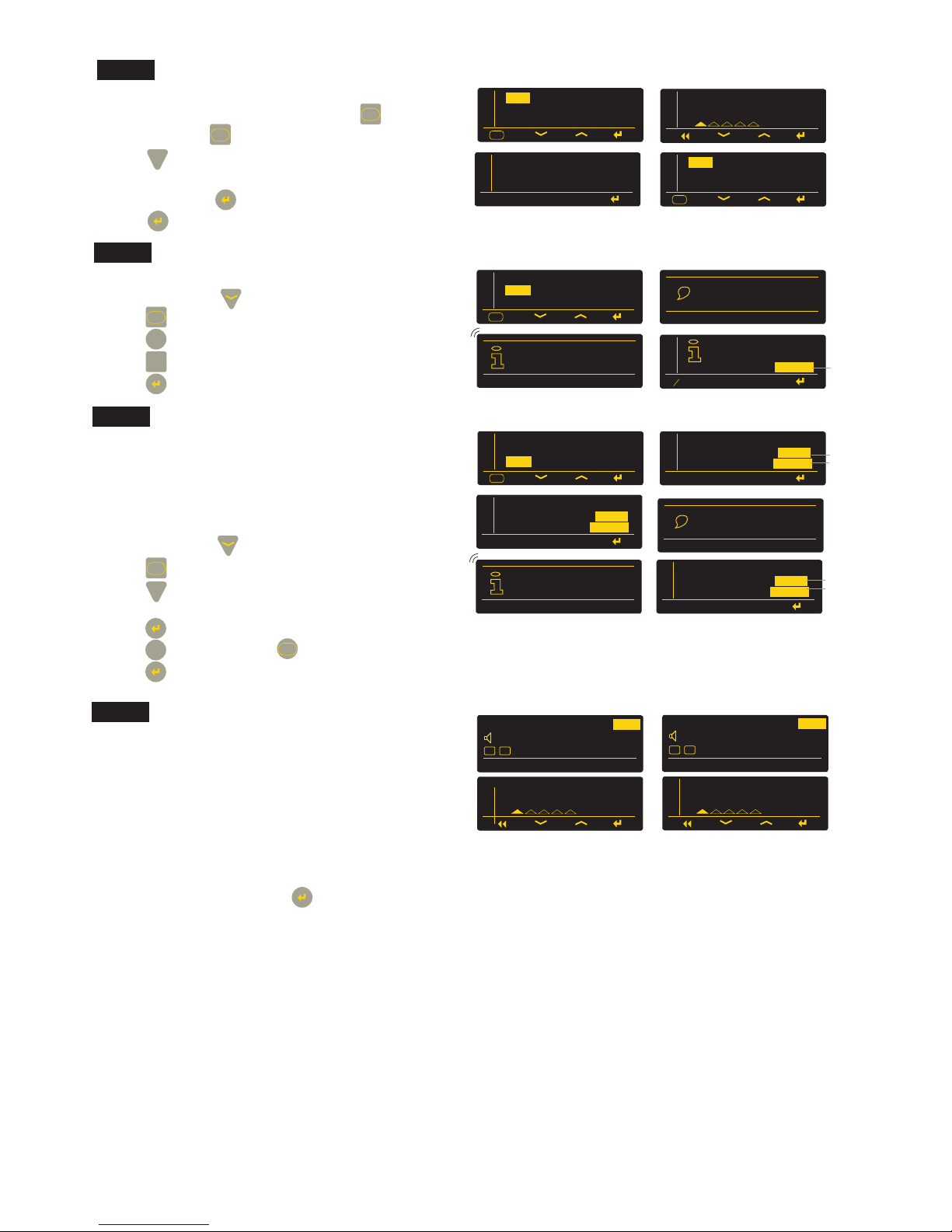

SPLIT SCREEN

Shows channel 1 front axle group

and channel 2 rear axle group

MENU

MENU with options activated

MENU

selectable options

NET

total load in body note, zero will appear

+/- 500 kg to mute alarm press any key

GROSS

total truck weight note, zero will appear

+/- 500 kg

menu

n

e

t

Channel 1

kg

n

e

t

Channel 2

kg

kg

kg

Display Changes OLED contrast to high, medium

or low. Also shows info: version & serial no.

Diagnostics Engineers screen. Shows two channel

weights and input milli-volt signals

Alarms Two alarm setpoints - PIN code required

To mute Alarm - press any key

Options Modes: Switches GROSS on & off

Load: On or off

RS232: Printer or scoreboard mode

Count by: 1, 10, 20, 50, 100, & 200 kgs

Z/Func: Allow/inhibit keyboard zero

Configuration To select 1 or 2 channels, air, oil or

fifth wheel.

Split: For split axle systems. Option for

total Ch1 + Ch2 or seperate Ch1 & Ch2

calibrations

Calibration Weighing system calibration settings

System Accesses password set and resets.

Note. for PUK (PIN unlock code) contact

service who will take you through your

PIN retrieval. Edit time and date in system

Alarm graphic - shows both alarms.

Alarm set key

Print key - prints net, gross, time & date in weighing screens

Menu key - scrolls thru’ NET, GROSS & MENU screens

Service reminder, flashes when weigher service is due

OK key - enters data

Down arrow key - scrolls down menu

Up arrow key - scrolls up menu

Back Up key - goes back a step

A

F

E

B

C

D

G

I

H

Note

GROSS or GVW (gross vehicle weight) is the total truck weight (NET + TARE)

NET ‘net load’ means the payload weight in the truck body

LOAD means part load collected or delivered, press PRINT to print and zero the load, weight

collected is stored as an accumulation to NET

SPAN where used, means the NET weight used to calibrate the weigher

TARE weight means the weight of the empty vehicle

ALARM where fitted, an alarm sounder or flashing beacon will activate when alarm setpoint is reached

ON SITE when ‘load’ is turned on in options, on site allows logging onto site and

off site for weighing loads collected from a site with multiple bins (waste only)

TWIN means two channels are displayed and calibrated separately

DUAL means the indictor will split the weight readings between the channels

BCD

E

A

Power-up the display by either switching on the ignition (ignition live

wiring) or press the power button beneath the logo (where tted) if

the indicator is permanently wired to the vehicle supply.

to switch ON turn ignition

and/or press logo

Vehicle Weighing Solutions

Version 4D-01-16

Serial No:12B57664

For Service Tel: 0161 643 0202

M350S Welcome screen

appears for 10 seconds

Service and calibration due screen

appears for 5 seconds

Service due Jan 2010

Press key to scroll up and

down menu screens

menu

M

E

N

U

Conguration

Calibration

System

ok

Display

Diagnostics

Alarms

Options

FGH I

MENU screen

info@vwsltd.co.uk

www.vwsltd.co.uk

need help? call service

0161 643 0202

31 March 2011 by MSB

Vehicle Weighing Solutions

Unit 4a Sheepbridge Business Centre

Sheepbridge Lane, CHESTERFIELD S41 9RX

Tel: 01246 455 946

Fax: 01246 769 665

INSTALLATIONS

Vehicle Weighing Solutions

Unit 5, Southview Park, Marsack Street,

Caversham, READING RG4 5AF

T: 0118 946 1900

F: 0118 946 1862

SALES SERVICE

Vehicle Weighing Solutions (North)

United Business Centres Ltd.

4 Howarth Court, Gateway Crescent

Oldham Broadway Business Park

Oldham OL9 9XB

Tel. 0161 669 6193