Additional Installation, Operating and Maintenance Instructions (Translation) English

Edition 07.2010 VEM-Ident-No. 73753 01en

General

Attention! Read installation, operation and maintenance instructions, connection diagram,

additional connection diagram and safety regulations before transportation, installation,

start-up, maintenance and repair. Mind the information!

The existing additional operation and maintenance manual is valid together with the already mentioned doc-

uments and the operation and maintenance manual for standard motors, where the basic specifications for

connection, installation, operation and maintenance as well as the spare parts lists are included.

This manual shall help the user to ease the secure and proper transportation, installation, start-up and

maintenance of the explosion-protected electric machine.

Observance of this manual and the conditions and methods used for installation, operation, use and mainte-

nance of the electric motor can not be monitored by the manufacturer. An improper installation can result in

property damage and thus result in personal injuries. We therefore do not accept responsibility and liability

for losses, damages or costs resulting from improper installation, improper or wrong use and maintenance or

connected with this in any kind.

Technical drawings and pictures are simplified illustrations. Due to improvements and changes it might hap-

pen that they do not correspond in detail with the supplied electric machine. We strive to improve our prod-

ucts continuously. Consequently technical data and illustrations remain subject to change without prior no-

tice. Specifications may only be considered binding after written confirmation by the supplier.

Symbols

In this manual two symbols will be used, that indicate important passages:

Security and warranty advices,

possible damage to persons included.

Warning against electric voltage, danger of life.

Advice that damages to the electrical machine and/or

the auxiliary devices can happen.

Security regulations

The security regulations, accident prevention regulations, standards and approved rules of technique must

be observed unconditionally!

The non-observance of the security advices can result in endangering people and/or damaging of the ma-

chine.

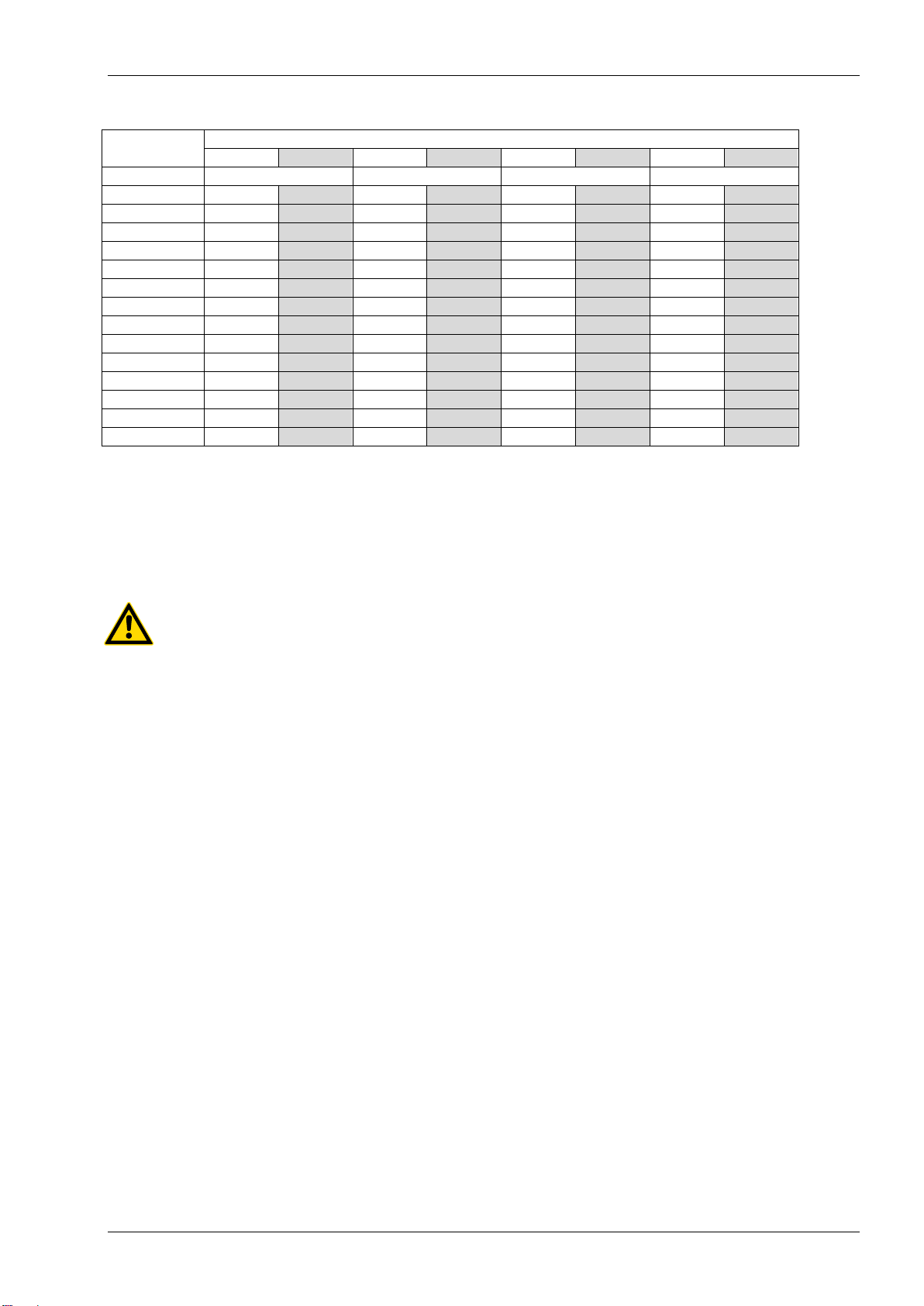

Efficiency classes

Listed are the IE-classes and the rated efficiency. The motor efficiency is determined according to EN

60034-2-1. For motors < 1kW the direct measurement method is used. For motors ≥ 1kW the individual loss

method is used. The additional losses of this method are determined from the residual losses. The type des-

ignation is extended with the efficiency class as prefix (example IE1-K11R 132 M2…).

Installation and electrical connection

At installation and start of operation the security advices that are enclosed with the motor have to be ob-

served. Installation work shall only be done by qualified personnel who is skilled because of a technical edu-

cation, expertise and schooling of knowledge about

security regulations,

accident prevention regulations,

standards and approved rules of technique

(for example VDE-regulations, standards).

The qualified personnel must have the ability to assess the assigned job, identify possible dangers and avoid

them. The qualified personnel must be authorized by the person in charge for security of the plant to carry

out the necessary work and tasks.

A careful installation of the motors on an exactly level support has to be ensured to avoid strain when tight-

ening the machine. Machines that shall be coupled must be adjusted exactly. If possible elastic couplings

shall be used.