VenMill Industries

670 Douglas Street | Uxbridge, MA 01569

Toll Free: 866.864.0210 | Tel: 508.278.0091 | Fax: 508.278.0005

www.venmill.com

MAINTENANCE ... CONTINUED

Run the Splash Guard under warm water, from any sink faucet. Wipe6.

away any left over compound residue with a paper towel or cloth.

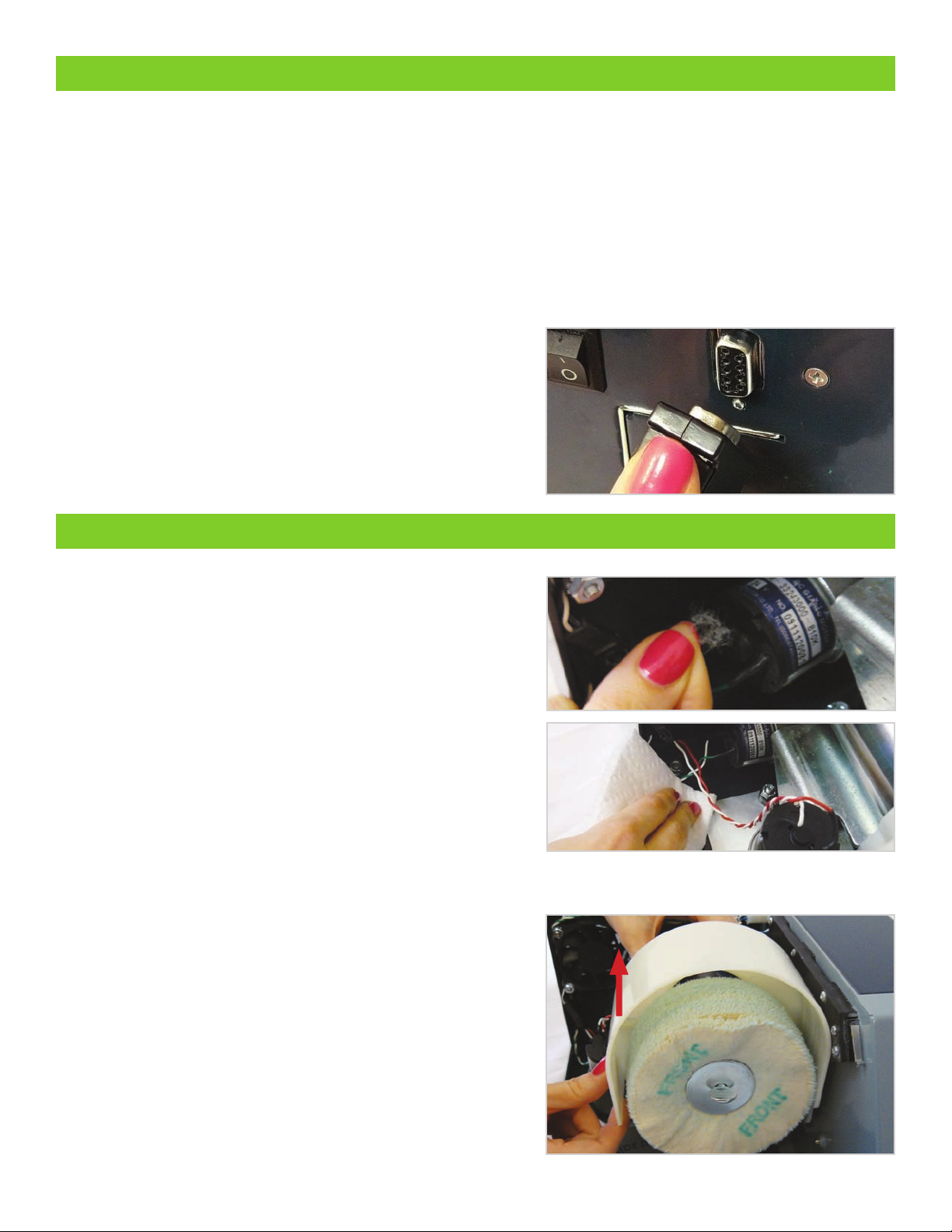

Reinstall the Splash Guard by snapping it onto the top of the7.

main motor.

Note: Pull the Splash Guard forward until it snaps into place a

second time.

Install the side panel and screw down the thumbscrews.8.

Turn on power.9.

C. How to clean the Cleaner Disc:

The Cleaner Disc must be maintained on a regular basis. You can

identify that the Cleaner Disc needs to be cleaned by seeing a heavy

buildup on the surface.

Use a“Glass Cleaner” (such as Windex) on the surface of the1.

Cleaner Disc and let it sit for a minute.

Using a paper towel, wipe the buildup o the Cleaner Disc.2.

Start from the center and work your way out.

Make sure the Cleaner Disc is dry, before use.3.

Another option is to use a plastic style bristle brush to scrub4.

the surface.

D. How to clean the Rubber Platter and why:

From time to time the Rubber Platter may become dirty. When this

happens, dust particles can become entrapped in the top surface of

the platter. This causes the surface to become slick. When the Rubber

Platter is slick discs tend to slip on the surface. In worse case scenario,

this slipping could cause a disc to break.

Take any glass cleaner (such as Windex) and spray the Rubber1.

Platter.

Let the solution sit for about a minute.2.

Wipe the rubber platter dry with a paper towel.3.

If slippage continues, replace the Rubber Platter.4.

A. Error Codes:

ES003: Magnetic Switch Sensor is not detecting that the1.

Platter is in the home position.

EC004: Lift Cam Switch is not detecting that the Lift Cam has2.

reset back to the home position.

EMC006: The machine is not detecting the proper amount of3.

amperage on the Main Motor.

RC: Replace all consumables.4.

Emergency Stop: Emergency Shutdown Mode.5.

B. How much Compound Solution should I use?

VenMill suggests that the entire optical surface of the disc

be covered with the Compound Solution. This will ensure

optimal repair capabilities. To achieve this, place one dab

North, East, South, West and then spread around.

OPERATIONS