Page 2 of 8

© Ventam Systems Ltd

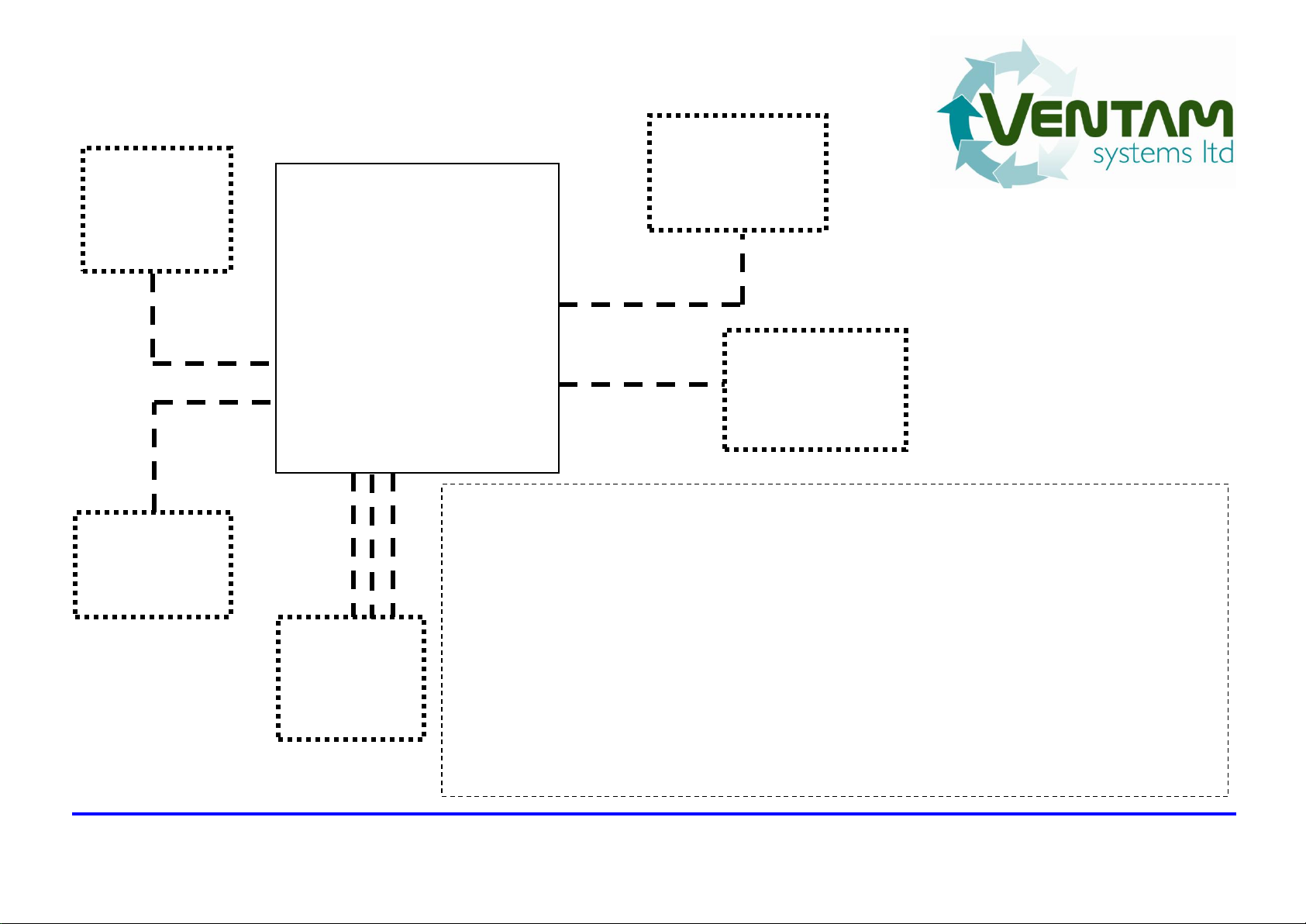

5 Additional Emergency Stop Buttons

Where there is more than one emergency exit, a normally closed emergency stop button should

be located at each exit . Additional emergency stop buttons are wired in series to terminals 11

and 12. This is a 12VDC circuit.

6 Gas Isolation Valve

The Gas Isolation Valve must only be powered from the Ventam 85 Interlock Panel, as per

supplied wiring diagrams and in accordance with Electrical and Gas Regulations.

The main gas valve is rated at 240 VAC.

The main gas valve must be fitted in an accessible location for future maintenance.

The main Gas Isolation Valve must be fitted in the kitchen equipment gas supply pipe work.

The valve is connected to the Ventam 85 Control Panel via three off THREE core cables.

(These are all Live, Neutral and Earth).

The gas isolation valve is heavy. Ensure that the gas pipe-work it is adequately supported.

7 Fan Pressure switch(es).

The Fan Pressure switch is mounted adjacent to and above the Fan.

The Fan Pressure switch is connected to the Panel by a two-core cable (12VDC).

The Fan Pressure switch is connected to the Fan ductwork by a flexible tube which is supplied

with the switch.

The Fan Pressure switch senses the airflow and sends a “Fans On” signal to the Control Panel.

The Fan pressure switch unit must be mounted vertically with tube connections at the bottom or

the side and usually within one metre of the fan and in a dry, accessible location.

The pressure switch should be located immediately above the fan. Where this is not possible,

the pressure switch must be mounted as high as practicable to allow the pressure switch tubing

to slope down from the pressure switch unit to the ductwork connector.

Pressure switch tubing must slope down continuously from the pressure switch to the ductwork

to allow condensate to naturally drain from the pipe work to prevent blockages occurring.

Twists, loops and kinks are not permitted in the pressure switch tubing.

The pressure switch unit location must allow 600mm clearance to the front and 150mm below

for access and maintenance.

DO NOT mount the pressure switch on the ductwork or transmitted vibrations may cause

unreliability and reduce the operating life of the unit.

8 Fan Pressure switch location

Consider the best location for mounting the unit AND for connecting the pipes from the pressure

switch to the ductwork

Mount the pressure switch(es). unit following above guide-lines.

The suction side of the fan is at a negative pressure. Connect this side to the –ve pressure

connection on the pressure switch. The switch will detect a differential pressure between the

ductwork negative pressure and the atmospheric pressure. This differential pressure will

close the switch.

At the pressure switch, the tube is connected to the push-fit connector on the bottom of the

pressure switch. This connector is identified with a “―“

At the ductwork, the tube is connected onto the push-fit ductwork connector supplied with

the pressure switch. Cut the tubing to the required length.

The pressure switch connection should be as close as possible to the fan.

Use a digital pressure meter in the range of 0-2mbar to check the system pressure while the

fan is running at full speed and rotate the duct connector whilst measuring the recorded

negative pressure.

The arrow direction on the duct connector should oppose the airflow direction when fitted to

the duct . This normally provides the best pressure reading possible.

Pressure switch tubing must be protected and secured to prevent damage.