HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Follow safe electrical work practices.

See NFPA 70E in the USA, or applicable local codes.

• This equipment must only be installed and serviced by qualified electrical personnel.

• Read, understand and follow the instructions before installing this product.

• Turn off all power supplying equipment before working on or inside the equipment.

• Product may use multiple voltage/power sources. Disconnect ALL sources before

servicing.

• Use a properly rated voltage sensing device to confirm that power is off.

DO NOT DEPEND ON THIS PRODUCT FOR VOLTAGE INDICATION.

• Current transformer secondaries must be shorted or connected to a burden at all times.

• Products rated only for basic insulation must be installed on insulated conductors.

• Replace all doors, covers and protective devices before powering the equipment.

Failure to follow these instructions will result in death or serious injury.

A qualied person is one who has skills and knowledge related to the construction and

operation of this electrical equipment and installations, and has received safety

training to recognize and avoid the hazards involved. NEC Article 100

No responsibility is assumed byVeris Industries for any consequences arising out of the

use of this material.

DANGER

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classied locations.

• The installer is responsible for conformance to all applicable codes.

• Mount this product inside a suitable re and electrical enclosure.

TM

Installation Guide

Current Monitoring

*The CE mark indicates RoHS2 compliance. Please refer to the CE Declaration of

Conformity for additional details.

Product Overview

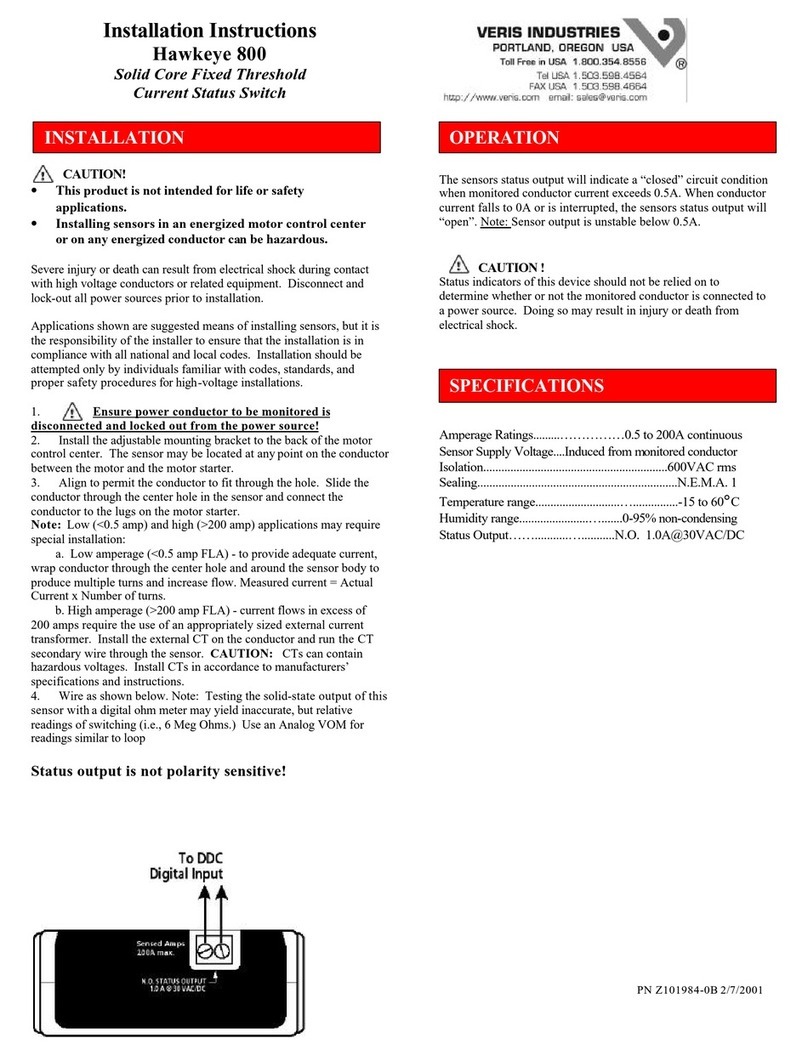

The H906 is a current-sensitive switching device that monitors current (amperage) in the conductor passing

through it. A change in amperage in the monitored conductor that crosses the switch (setpoint) threshold plus the

hysteresis value causes the resistance of the FET status output to change state, similar to the action of a mechanical

switch. In this model, the setpoint is adjustable through the action of a 20-turn potentiometer (see the Calibration

section). The status output is suitable for connection to building controllers or other appropriate data acquisition

equipment operating at up to 30 volts. The H906 requires a 5 to 30 Vdc external power supply to generate its

output.

The H906 housing offers unprecedented mounting flexibility. The mounting bracket can be attached in three

different places. Additionally, the bracket is compatible with the Veris AH01 DIN Rail clip, allowing DIN mounting.

H906

Split-Core Current Switch, Adjustable Trip Point,

N.C. Status Output

Specifications

Sensor Power 5 to 30 Vdc

Amperage Range 2.5 to 135 A continuous

Status Output Ratings N.C. 0.1 A @ 30 Vdc, polarity sensitive

Insulation Class 600 Vac RMS (UL); 300 Vac (CE)

Setpoint Adjustable, 2.5 A or less

Frequency Range 50/60 Hz

Temperature Range -15 to 60 °C (5 to 140 °F)

Humidity Range 10 to 90% RH non-condensing

Hysteresis 10% typical

Off State Leakage 34 μA @ 5 Vdc, 200 μA @ 30 Vdc

On State Voltage Drop 1.9 Vdc max. @ 0.1 A

Terminal Block Wire Size 24 to 14 AWG (0.2 to 2.1 mm2)

Terminal Block Torque 3.5 to 4.4 in-lbs (0.4 to 0.5 N-m)

COMPLIANCE INFORMATION

Agency Approvals UL508 open device listing, CE: EN61010-1

Installation Category Cat. III, pollution degree 2

The product design provides basic insulation only.

Do not use the LED indicators as evidence of applied voltage.

TM

*

www. .com information@itm.com1.800.561.8187