-1-

Installation Instructions

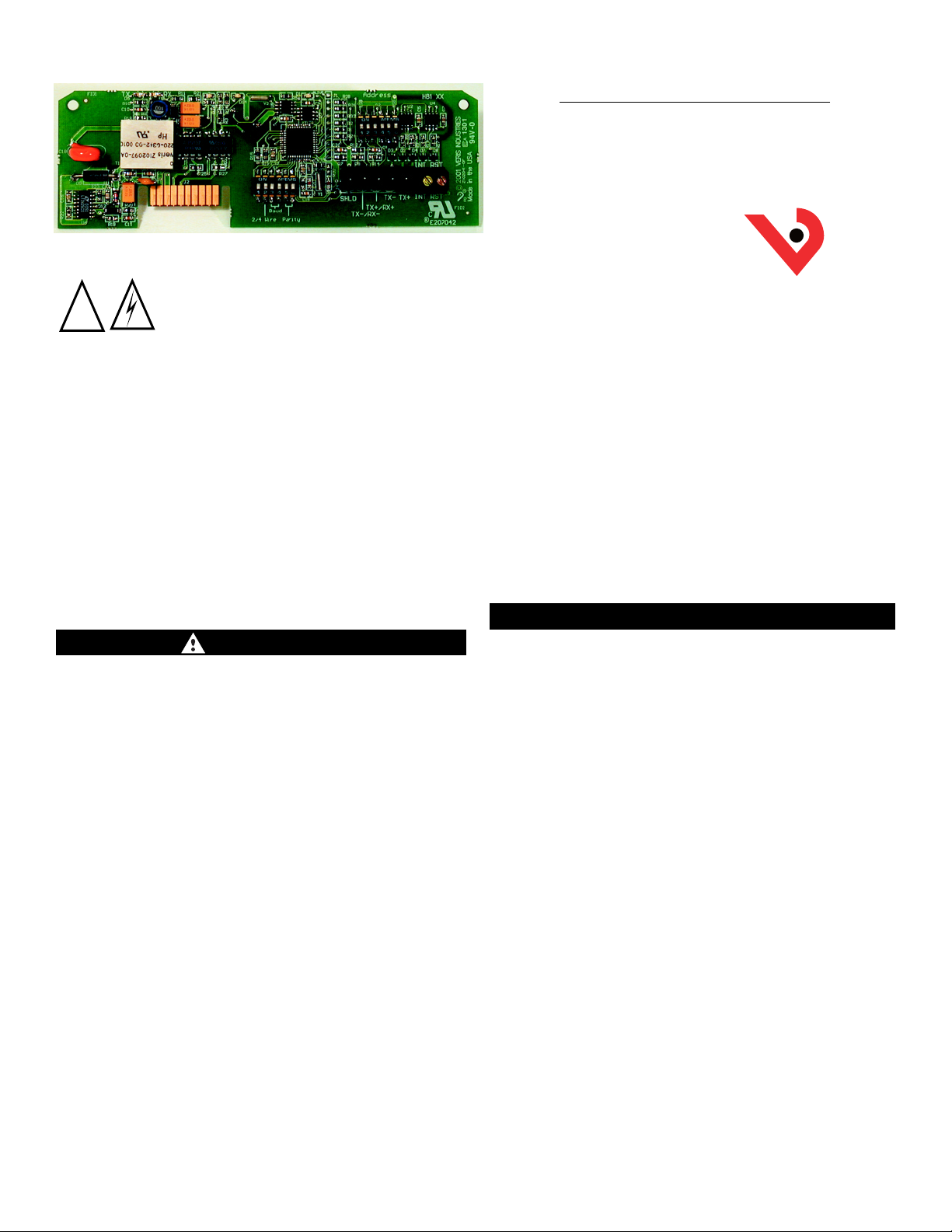

H8126-CB

Energy Meter

Communication Board, N2

DESCRIPTION

The H8126-CB Energy Meter Communication Board is an optional

field-installable board for the H8163 Energy Meter, providing N2

communications capability. The H8126-CB also enables the Energy

Meter to provide true kW & kVAR Demand information.

The easy-to-install H8126-CB provides a simple, cost-effective way to

network the Energy Meter on the N2 bus.

Applications

■Commercial tenant submetering

■Performance contracting

■Cost allocation

■Real time power monitoring via local display or through control/data

acquisition systems.

Features

■Easily network to existing systems via N2 RS-485 output

■Metasys compatible

• This product is not intended for life or safety applications.

• This product is not intended for installation in

hazardous or classified locations.

• Read instructions thoroughly before installing

this equipment.

Severe injury or death can result from electrical shock

during contact with high voltage conductors or related

equipment. Disconnect and lock-out all power sources

during installation and service. Applications shown

are suggested means of installing sensors, but it is the

responsibility of the installer to ensure that the

installation is in compliance with all national and

local codes. Installation should be attempted only by

individuals familiar with codes, standards, and proper

safety procedures for high-voltage installations.

!

VERIS INDUSTRIES

PORTLAND, OREGON USA

Toll Free in USA 1.800.354.8556

®

Tel USA 1.503.598.4564

FAX USA 1.503.598.4664

http://www.veris.com

P/N Z103167-0A

HAZARD OF ELECTRIC SHOCK, BURN OR EXPLOSION

• Only qualified workers should install this equipment. Such work

should be performed only after reading this entire set of instructions.

•NEVER work alone.

• Before performing visual inspections, tests, or maintenance on this

equipment, disconnect all sources of electric power. Assume that

all circuits are live until they have been completely de-energized,

tested, and tagged. Pay particular attention to the design of the

power system. Consider all sources of power, including the

possiblity of backfeeding.

• Turn off all power supplying the energy meter and the equipment

in which it is installed before installing the H8126-CB.

NOTE: The energy meter may be connected to multiple power

sources.

CAUTION: ESD-SENSITIVE COMPONENTS

Use an anti-static or grounding strap (customer-supplied) to

ground yourself and discharge any static charge before installing

the EMCB. Static can damage electrostatic discharge-sensitive

components in the circuit monitor and its accessories. Avoid

touching the gold plated connector points.

Failure to follow this instruction can result in equipment damage.

• Beware of potential hazards, wear personal protective equipment,

and carefully inspect the work area for tools and objects that may

have been left inside the equipment.

• The successful operation of this equipment depends upon proper

handling, installation, and operation. Neglecting fundamental

installation requirements may lead to personal injury as well as

damage to electrical equipment or other property.

Failure to observe these instructions will result in death or

serious injury.

DANGER!