07-02083A 200-230V, 200H-230V, 500-230V, 500H-230V, 1200-230V 3 VersaClean

IMPORTANT: Take care to control foaming in the

vacuum system. Excessive foam can allow moisture,

carpet fiber and other debris to be drawn through the

vacuum cutoff valve and cause damage to the vacuum

motors. Damage caused by moisture or debris will void

the product warranty. To help reduce foaming, use a

low-foam detergent. Foaming may also occur because of

residues left from previous cleanings. If this happens,

use a defoamer additive. Follow defoamer manufacturer

instructions for proper application.

2. Connect vacuum and solution hoses to machine and

attach to extraction wand or hand tool.

3. Plug power cord into a 3-pin grounded circuit. Keep

cords clear of your cleaning path. IMPORTANT:

Heated units have two cords and should be plugged

into separate 3-pin grounded circuits.

4. Switch on vacuum.

5. Switch on solution pump.

6. For heated solution (Heated units only).

7. Begin cleaning. Refer to industry-approved

procedures.

8. If equipped, solution pressure may be adjusted with

the pressure regulator knob (Fig. 2, G). Monitor the

pressure gauge to ensure pressure is adequate.

CAUTION: When the recovery tank reaches capacity,

an automatic float valve blocks vacuum intake (see

Fig. 7) and the vacuum motors will make a high

pitched noise. When this occurs, switch the machine

off immediately to prevent damage to the vacuum

motors.

9. When cleaning is completed, rinse solution tank with

clear water to ensure no detergents or rinse agents

remain in the tank.

10. Empty and rinse the waste tank thoroughly. This will

help to prevent the formation of damaging deposits

and reduce the growth of odor-causing bacteria.

11. Turn on vacuum motor and allow it to run for 15

minutes to help remove any moisture from the

vacuum motors and assure long vacuum life.

For maintenance instructions, see “Maintenance,” p. 3.

MAINTENANCE (ALL UNITS)

WARNING: Unplug machine before servicing.

Possibility of electrical shock.

WARNING: Interior components may be hot after

operation. Let unit cool completely before servicing.

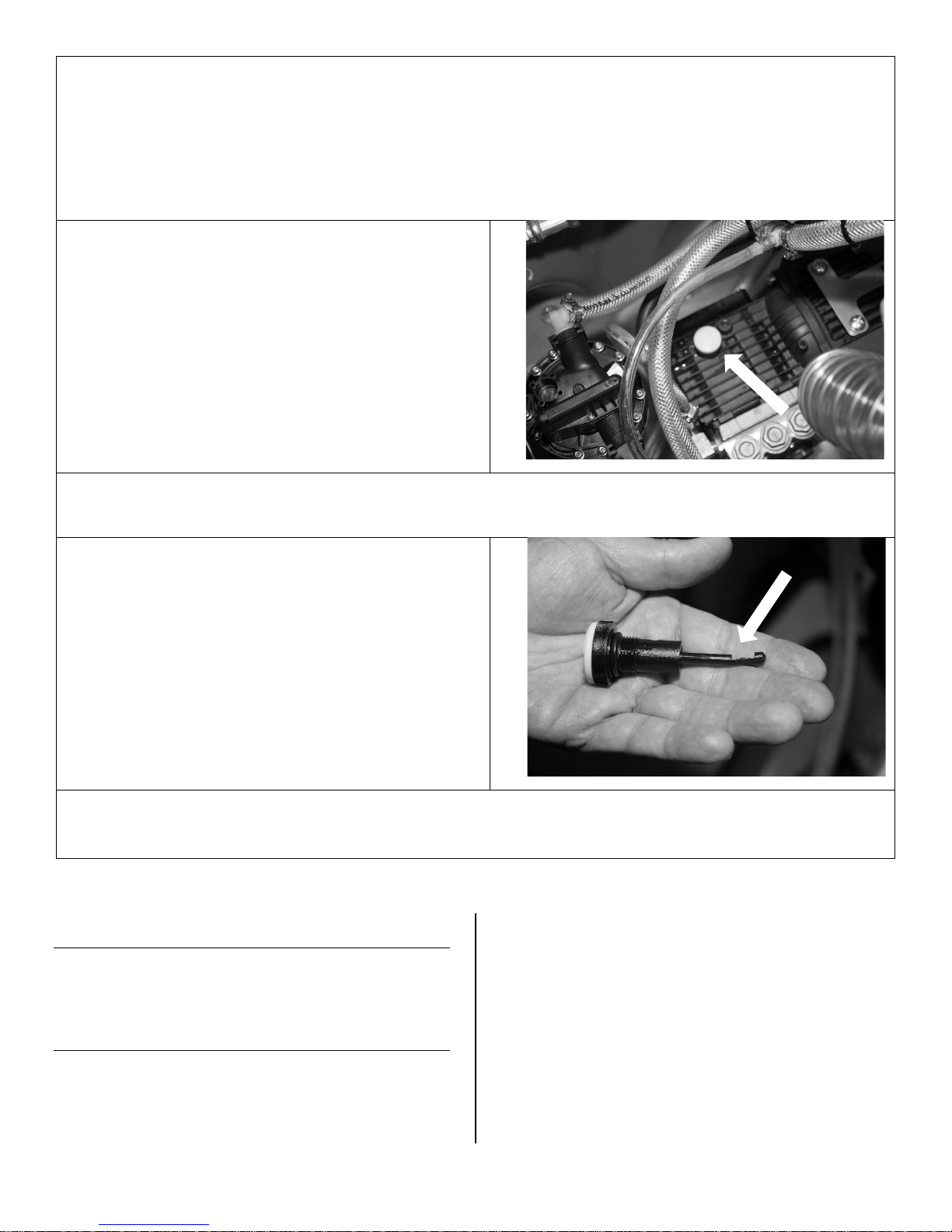

FIG. 4: Solution inlet filter cleaning

9/16 in.

nut with

wrench

and lift

open top.

filter

cap and

rinse

Power ON/OFF

Solution pressure pump ON/OFF

Solution heater ON/OFF (select models)

Pumpout ON/OFF (select models)