2

SAFETY, HAZARD,AND MAINTENANCE INSTRUCTIONS

CAUTION:

Read the following safety warnings and all instructions in their entirety prior to installation. If you have questions or

are missing any parts, contact Mid-South Metal Products, Inc. (DBA, VersaTube Building systems) customer service

at 1-800-900-7222 before proceeding.

CAUTION:

VersaTube Building Systems designs and manufactures framing products to meet minimum load requirements in

most areas. It is the buyer’s sole responsibility to determine the specific building code requirements applicable in the

city and/or county of the state in which this product is being erected, and to ensure the product is installed with suffi-

cient materials and in such a manner as to comply with the codes.

WARNING:

Metal parts may get hot when exposed to high heat or direct sunlight. Avoid contact with skin and wear protective

gloves and clothing to prevent the possibility of burns.

WARNING:

Standing or walking on the structure could cause damage to the sheet metal panels. If you must walk on the roof,

step within 1’ of a major frame member. The structure must be properly braced to support human weight. Collapse of

the structure may cause serious injury do to weight of components.

WARNING:

Avoid installation on windy days as wind may create hazards during the installation process. Wind may blow material

or cause partially installed components to collapse prior to being secured or fully installed. The weight of the compo-

nents or structure may cause serious injury if it should collapse.

WARNING:

Metal conducts electricity and electrical shock hazards exist since the structure is made of metal. During installation

or storage, keep the structure and all components away from electrical sources. Make sure that your selected loca-

tion is away from power lines, underground cables, and any other source of

electrical power. Serious injury or even death may occur if contact is made with electrical current.

WARNING:

In the event that your structure is fully enclosed, be sure to provide proper and adequate ventilation and egress and

ingress. Hazardous, poisonous or noxious substances should not be stored in the structures absent proper ventila-

tion. Follow all warnings and instructions of the manufacturer of any substance stored in your building.

Also, proper ingress and egress should be provided to prevent persons or children from

Becoming trapped inside the structure.

WARNING:

If metal panels are selected to cover all or a portion of your structure, be careful of the sharp edges which may cause

cuts or lacerations. Wear protective work gloves and suitable clothing for protection and

always take care when handling metal parts.

NOTE:

The VersaTube Building System is an all domestically produced galvanized tubular steel framing system. Mainte-

nance is required twice annually on particular areas of the framing system i.e. ‘’weld seams” and “cut or raw ends”.

This maintenance is performed by applying any “Zinc coated” silver spray paint found at local mass merchant or paint

store to these areas twice annually or every six (6) months.

NOTE:

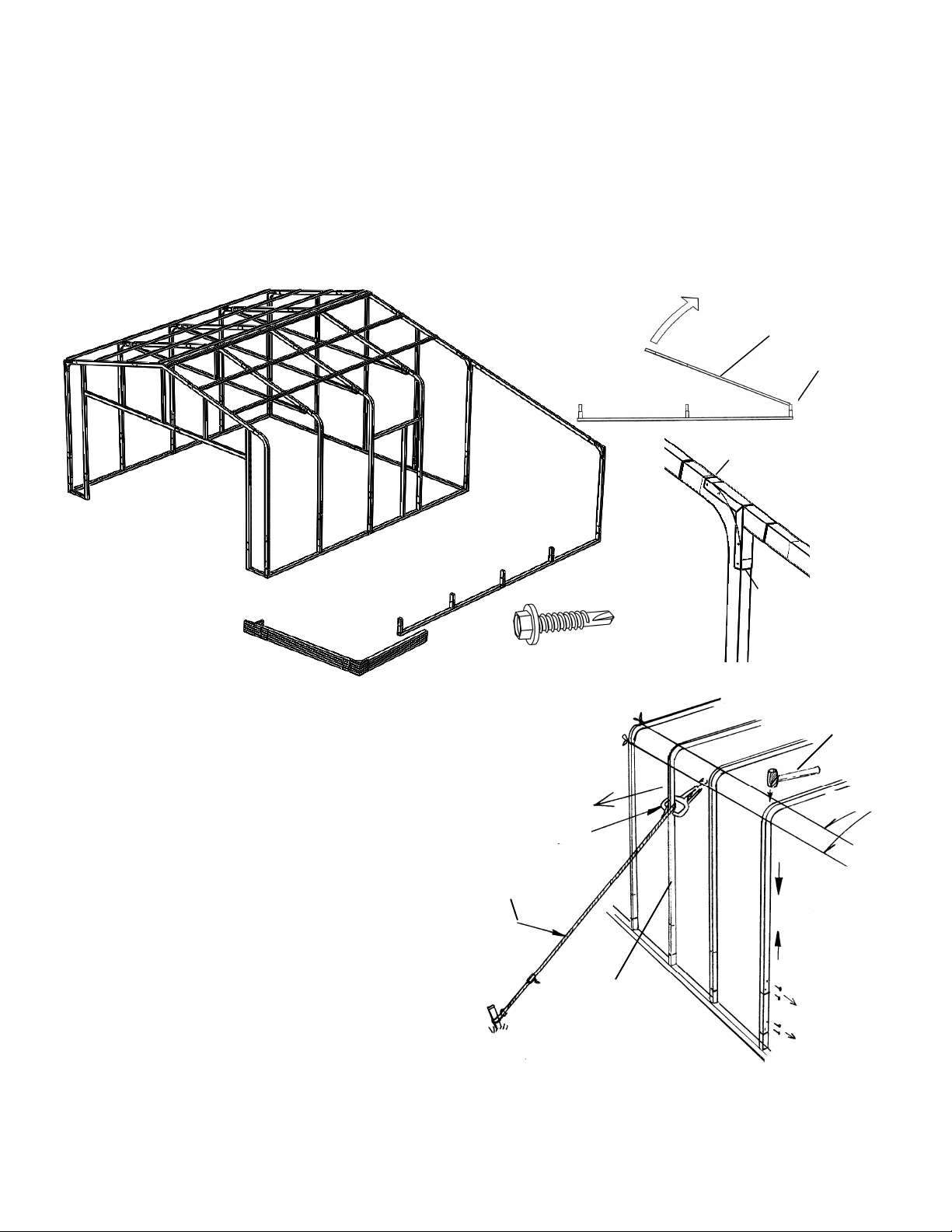

All sheet metal cladding applied to the VersaTube frame are attached with self drilling screws with a rubber washer.

These screws produce small shavings when drilling through the cladding. If the shavings are allowed to sit on the

sheet metal for an extended period, rust spots will form and promote deterioration. Metal shavings must be brushed

after installation of the sheet metal. Claims reported against rust spots will not be honored by VersaTube Building

Systems.

© MSMP INC. 11/14 © MSMP INC. 8/15 © MSMP INC. 10/15 © MSMP INC. 10/16