4.3. TRAINING AND COMPETENCE

All personnel using or associated with the use of this equipment

must be competent and trained by Verton Australia itself or a third

party authorised to deliver training on behalf of Verton Australia.

At a minimum:

1. Read and understand this manual and all safety warnings.

2. Familiarisation with machine functions and limitations.

3. Be competent and trained in the risks of lifting equipment,

practises, and planning.

4. Know and be trained in the use of the emergency stop function

fitted to the Everest 6 (See Section 4.5)

4.4. NOISE

As the units contain moving parts, sound pressure generation

should be taken into consideration. Testing results show that a

maximum sound pressure of 78.5dBA was taken from the unit during

operation1. While this is below the requirement for ear protection,

general safety precautions such as PPE should be used to minimise

long term exposure.

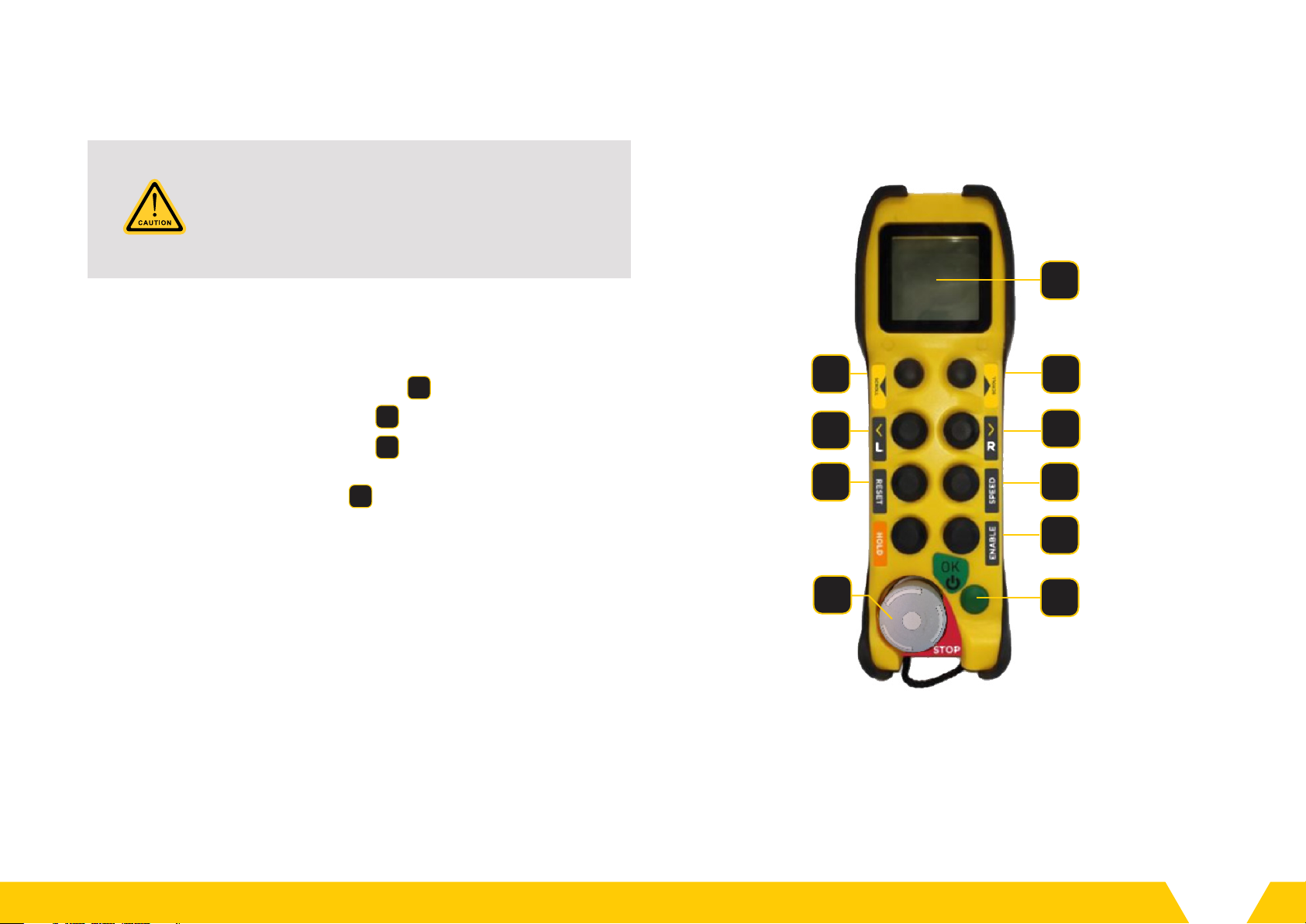

4.5. IMPORTANT NOTE ON THE EVEREST 6 STOP

FUNCTION AND LOSS OF RADIO LINK

4.6. GENERAL HAZARD REDUCTION

General hazard reduction whilst using the Everest 6 can be

accomplished by observing the following items:

• Only qualified dogmen and riggers shall use the unit.

• Operators must be trained, competent and authorised for a

specific operation.

• Inspect the unit prior to use and do not use the lifting beam

if it is damaged.

• Test operation of the unit before use. Do not use if faulty.

• Do not remove any cover panels unless authorised.

• Do not cover the air-vents while the beam is in operation as

overheating may occur.

Whilst all local laws, regulations and practises must be satisfied whilst

completing any lifting operation, additional safety considerations must

be made to reduce the general lifting operational hazards whilst using

the Everest 6. These items include:

• Observe all the normal lifting and rigging safety precautions.

• Do not exceed the SWL of the unit.

• Avoid rough landings or collisions as internal components

may be damaged.

• Cease operation immediately if the unit is damaged or faulty.

• Do not stand under the suspended unit or move the unit

over personnel.

• Avoid rotating the beam close to the ground or around

other objects.

• Avoid bodily contact with the beam, especially if the unit

is operating in a hot environment.

IMPORTANT NOTE: The Remote Shutdown / STOP button IS NOT

an Emergency Stop button in the conventional sense. The stop

function, or loss of radio communications will prevent the Verton

beam applying any torque to the lifting arrangement.

1VERT_0010 Sound Pressure Measurement

7

VERT_0014_User_Manual_04 Confidential © Verton 2021