4

www.ves.co.uk

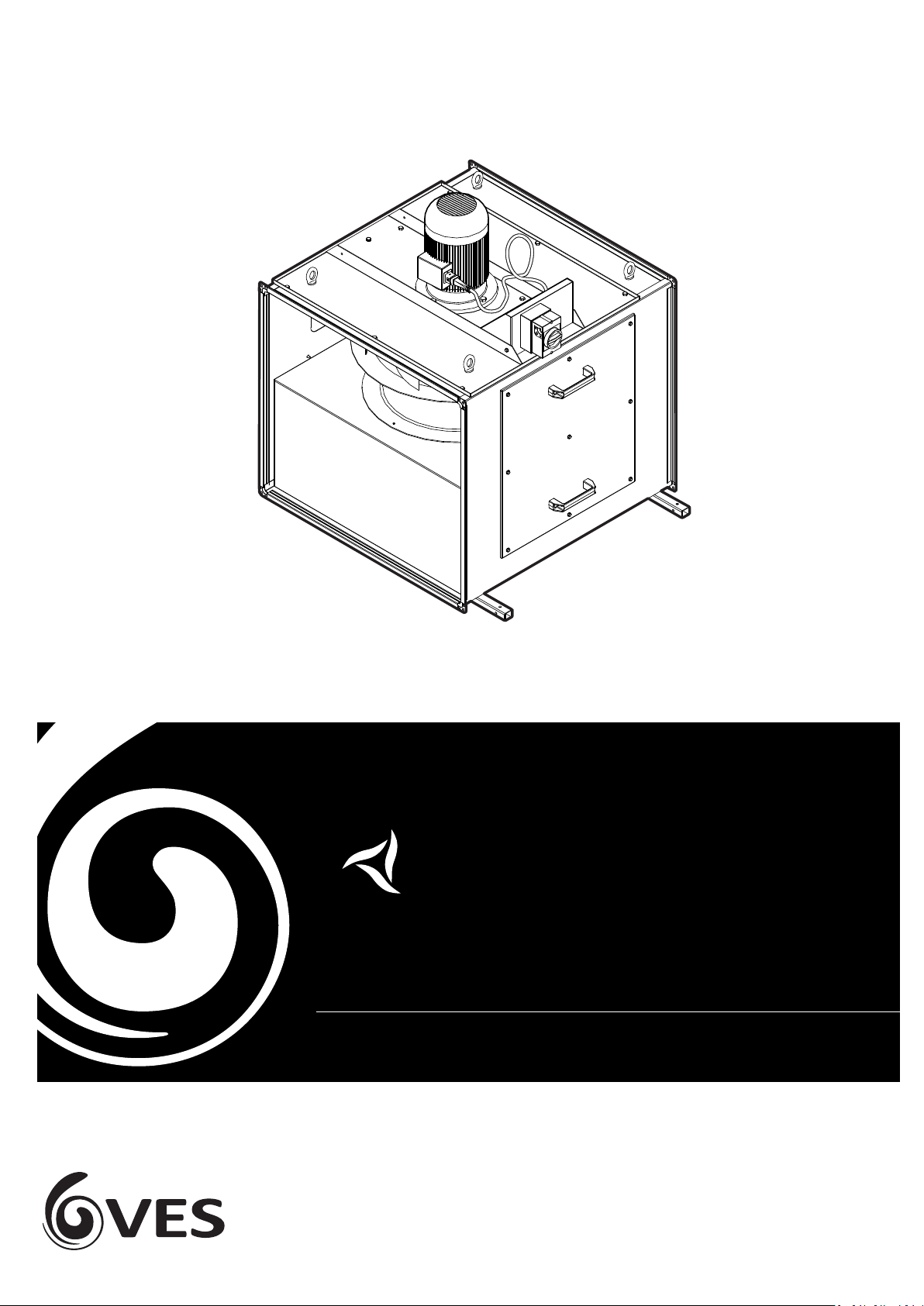

t-line Extract Units

Immediately upon receipt of goods, check for possible damage in transit. Also check to

ensure that any ancillary items are included. These will be supplied fied or taped to the

unit (in the case of small items). In the event of any damage having occurred or if any item

is found to be missing, it is essenal to inform VES Andover Ltd. within 3 working days of

delivery, quong the sale s order (SO) number, and the unit type as found on the unit

nameplate. Aer this period VES Andover Ltd. will be unable to accept any claim for

damaged or missing goods.

Receipt of Goods

When moving the unit, handle with care and in such a manner liming damage to the

casework. Parcular care must be taken when moving weatherproof units, any damage to

the external powder coat finish may reduce the ability to resist corrosion. Units are to be

rigged and lied using spreaders, taking into account the weight of the unit, liing gear

should be arranged so as not to bear on the casework.

Installaon

Safety for the enre system must be considered when installing the unit and it is the

responsibility of the installer to ensure that all of the equipment is installed in

compliance with the manufacturer’s recommendaons, with due r egard to the current

HEALTH AND SAFETY AT WORK ACT and conform to all relevant statutory regulaons.

Precauons should be in place so that in the unlikely event of component failure the risk of

personnel injury is reduced. For opmum unit performance, careful consideraon must be

paid to the locaon of the unit in relaon to the ductwork and associated items; i.e placing

the unit directly adjacent to a bend in the ductwork will impede airflow and reduce

performance.

Duct Connecons

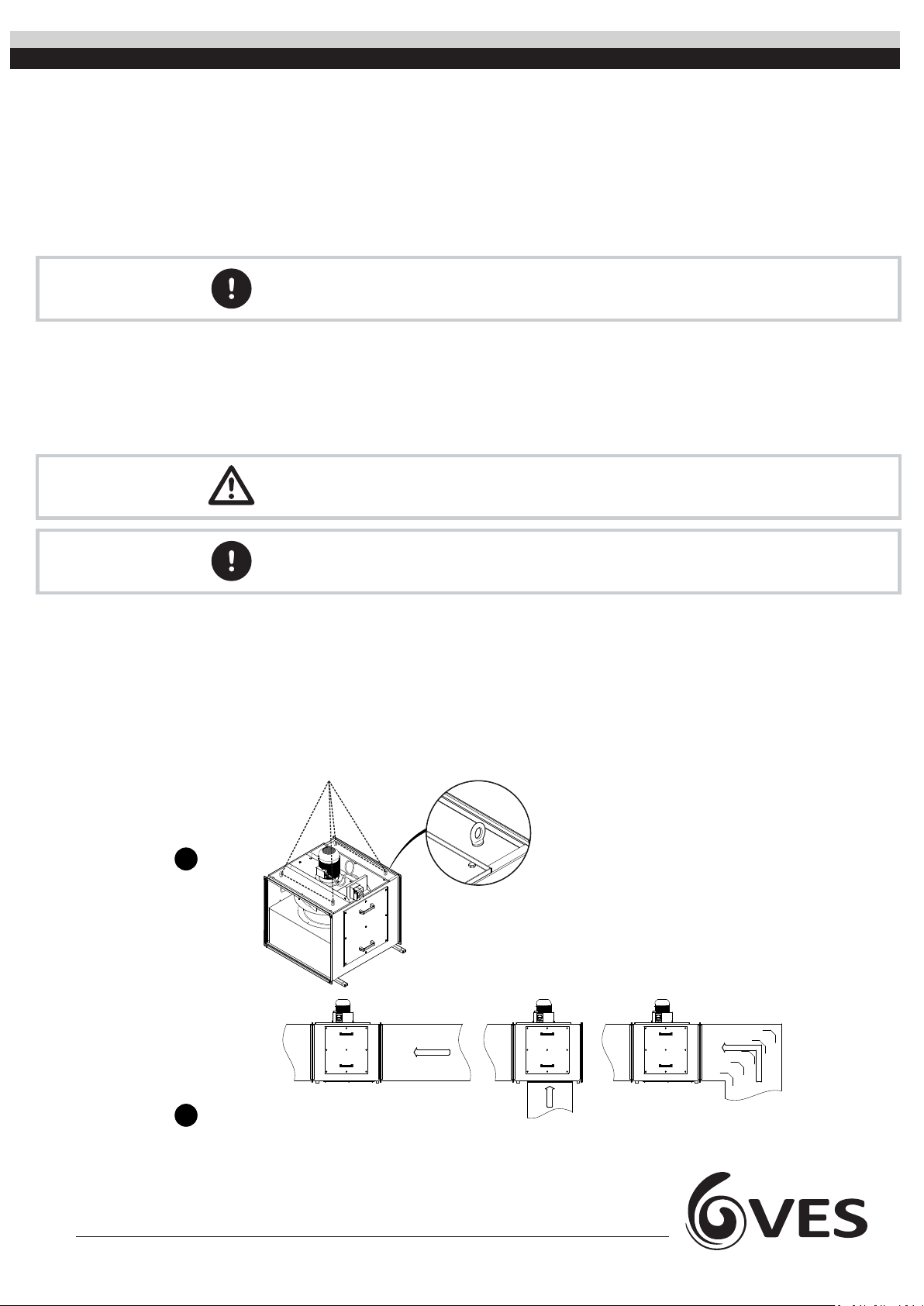

Liing and Connecng

to Duct

Cauon

3

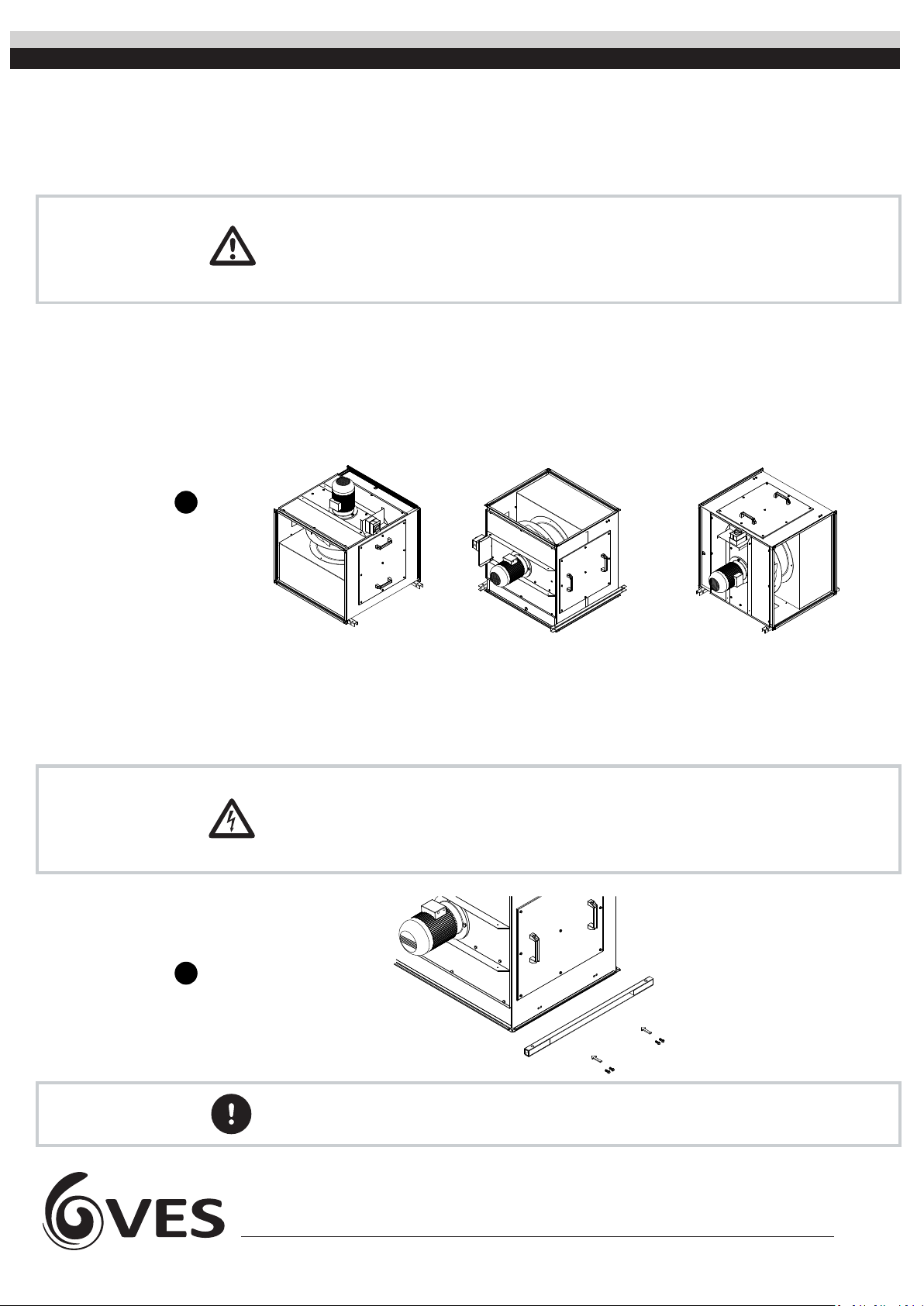

Important The unit should NOT be lied by handles, lids, housings, sha, motor or drive.

Only experienced engineers should undertake this work.

Secure liing cable through the liing lugs.

Ensure fan plate is securely in place before

liing the unit.

It is recommended that the unit is lied

using the supplied liing lugs.

(For illustraon

purposes only)

3

4

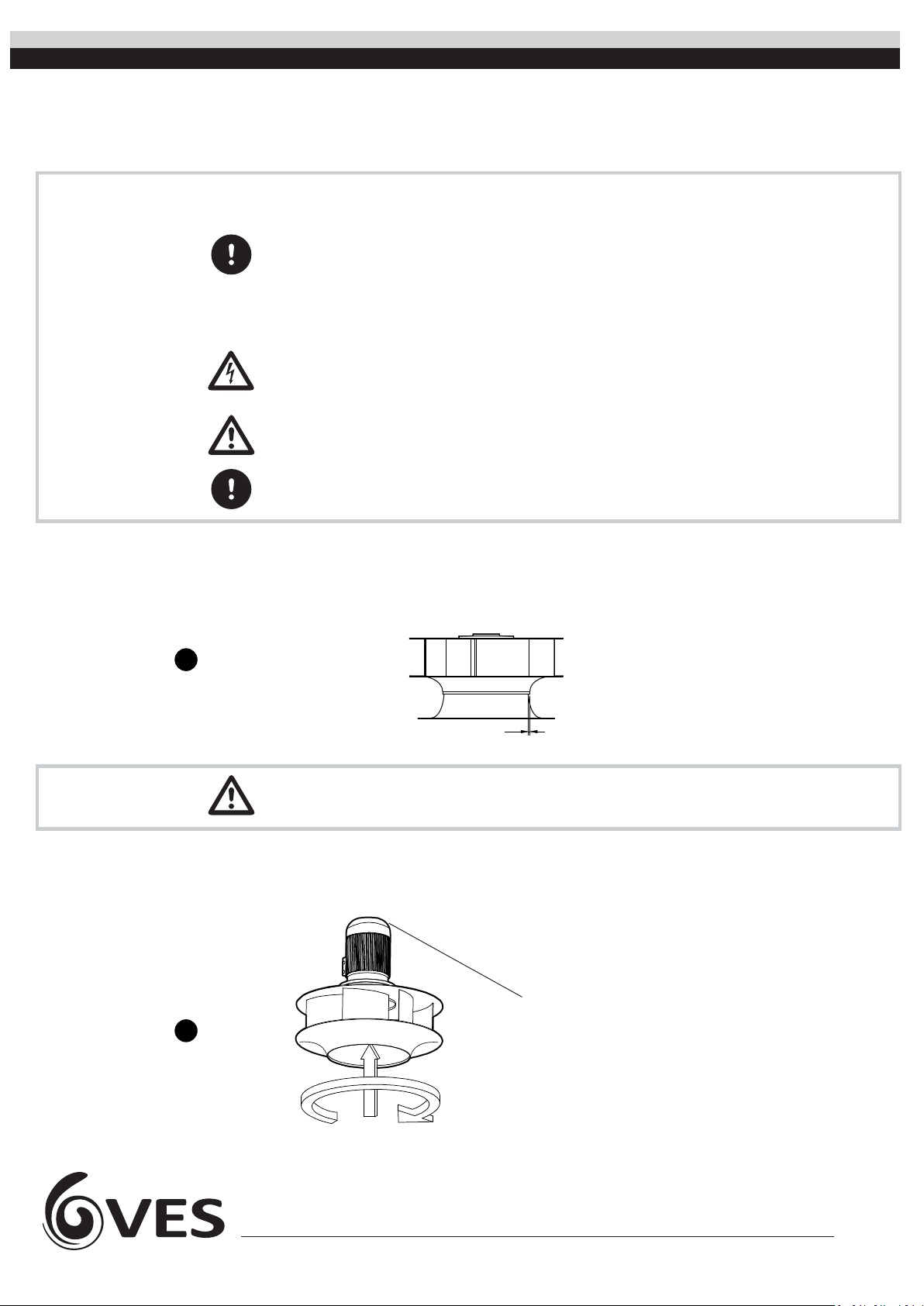

Recommended only with fied

turning vanes

RecommendedRecommended

Fig. 1

Fig. 2

Important An Inverter Speed controller is required for the operaon of this fan