• instruments: fuel and temperature indicator

•Instrument panel lights

• Horn

• Electric starter

• Engine stopping with emergency stop switch

• electric saddle opening button

CAUTION

TO ENSURE MAXIMUM PERFORMANCE, THE BATTERY MUST BE CHARGED BEFORE USE.

INADEQUATE CHARGING OF THE BATTERY WITH A LOW LEVEL OF ELECTROLYTE BEFORE

IT IS FIRST USED SHORTENS THE LIFE OF THE BATTERY.

CAUTION

WHEN INSTALLING THE BATTERY, ATTACH THE POSITIVE LEAD FIRST AND THEN THE NEG-

ATIVE ONE.

WARNING

BATTERY ELECTROLYTE IS TOXIC AND IT MAY CAUSE SERIOUS BURNS. IT CONTAINS SUL-

PHURIC ACID. AVOID CONTACT WITH EYES, SKIN AND CLOTHING.

IF IT ACCIDENTALLY COMES INTO CONTACT WITH YOUR EYES OR SKIN, WASH WITH ABUN-

DANT WATER FOR APPROX. 15 MIN. AND SEEK IMMEDIATE MEDICAL ATTENTION.

IF ACCIDENTALLY SWALLOWED, IMMEDIATELY DRINK LARGE QUANTITIES OF WATER OR

VEGETABLE OIL. SEEK IMMEDIATE MEDICAL ATTENTION.

BATTERIES PRODUCE EXPLOSIVE GAS; KEEP CLEAR OF NAKED FLAMES, SPARKS OR CIG-

ARETTES. VENTILATE THE AREA WHEN RECHARGING INDOORS. ALWAYS WEAR EYE PRO-

TECTION WHEN WORKING IN THE PROXIMITY OF BATTERIES.

KEEP OUT OF THE REACH OF CHILDREN.

CAUTION

NEVER USE FUSES WITH A CAPACITY HIGHER THAN THAT RECOMMENDED. USING A FUSE

OF UNSUITABLE RATING MAY SERIOUSLY DAMAGE THE VEHICLE OR EVEN CAUSE A FIRE.

Levels check

Level check:

- Hydraulic brake system liquid level

- Rear hub oil level

- Engine coolant level

- Engine oil level

Road test

Test ride:

- Cold start

- Instrument operations

- Response to throttle control

- Stability on acceleration and braking

- Front and rear brake efficiency

- Front and rear suspension efficiency

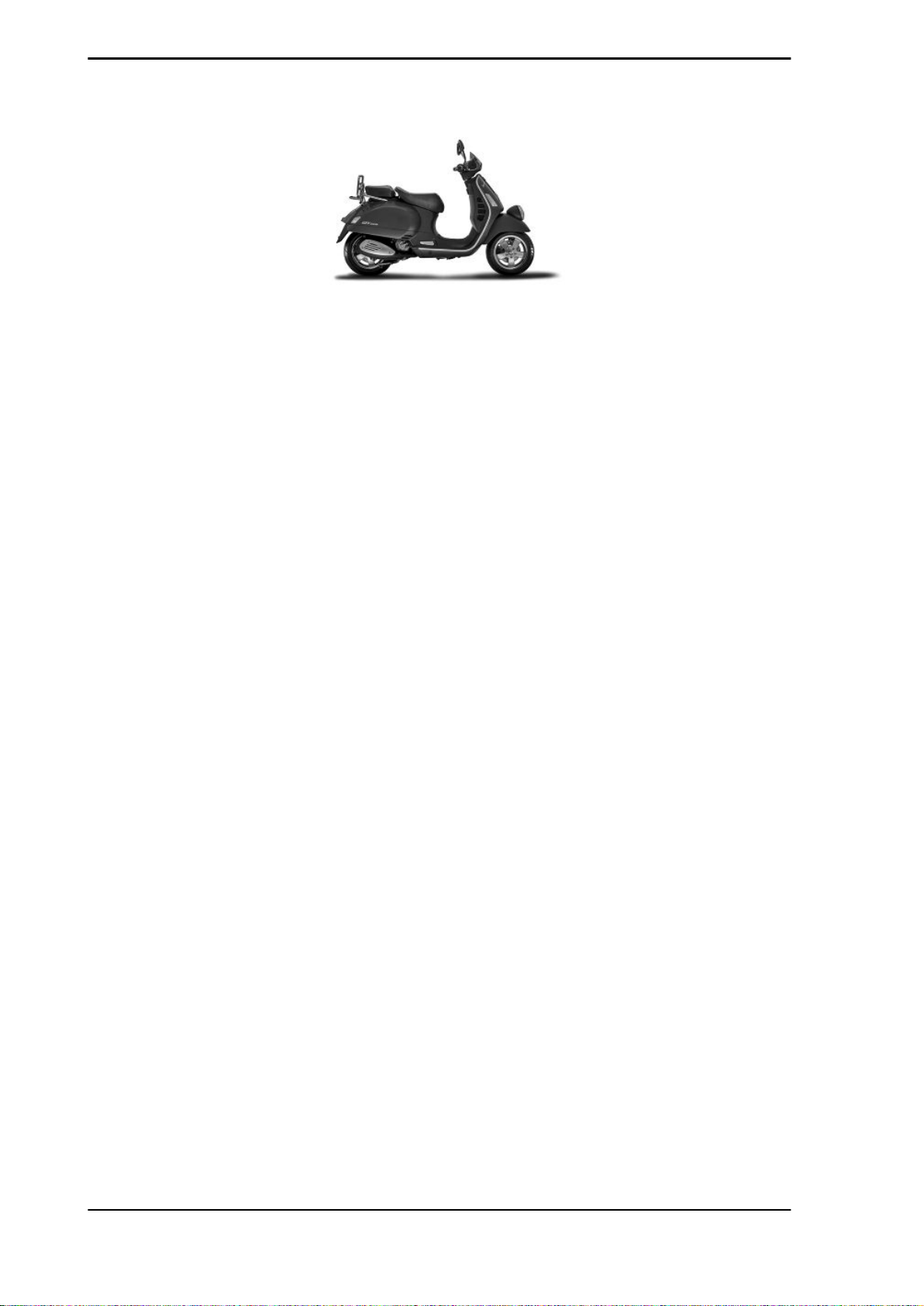

Pre-delivery Vespa GTV 250 i.e.

PRE DE - 8