Preparations before use

●Check the air pressure

The specified air pressure for this air tool is 0.6 MPa. If the input air

pressure surpasses this specified level, it will cause damage on the unit

or individual parts.

●Remove the drain

When moisture or impurities like rust in the pipe get into the mechanism,

it may cause malfunction. Remove accumulated drain in the compressor

before use. To secure dry air supply, install an air filter in order to prevent

moisture and any impurities.

●Use an appropriate air hoses

Please refer to Specifications for choosing an air hose of the appropriate

size for the applied air supply. If the internal diameter of the air hose is

too small, sufficient power may not be obtained as air pressure cannot

increase efficiently. It also happens when the hose is too long.

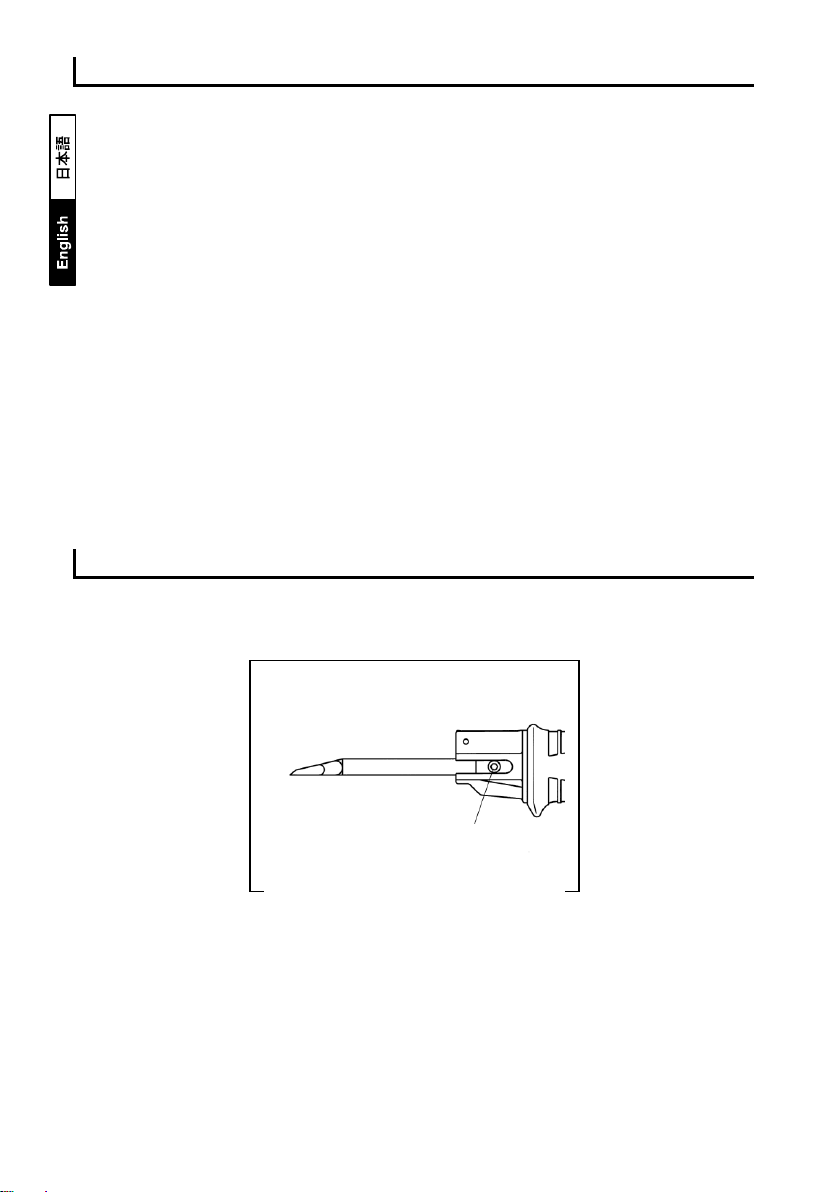

●Install the plug

Use a spanner of No.17 to holdAir Inlet Bushing

and fasten the plug.

●Air coupling

When using the air coupling included in the package, purchase a

compatible connector. When connecting a hose directly to this product,

purchase a hose connection coupling. In both cases, check the size of

the connected hoses.

●Before the first operation after purchase

Attach the scraper before connecting the air hose to the unit. When this

air tool has been newly installed or the air hose has been replaced, blow

and clean the inside of the hose and piping. Then, idle the device for a

few seconds because lubricant within the mechanism has to be blasted

out with exhaust air.