Subject to modifications.© Vestamatic GmbH 2/10

G

HOME ∙VL-SMI-230-45

Art.-Nr.: 8900 001 GB 3117 A04 • Vestamatic GmbH • Dohrweg 27 • D-41066 Mönchengladbach • www.vestamatic.com

2. Short description

Motor 45 mm tube diameter for roller shutters

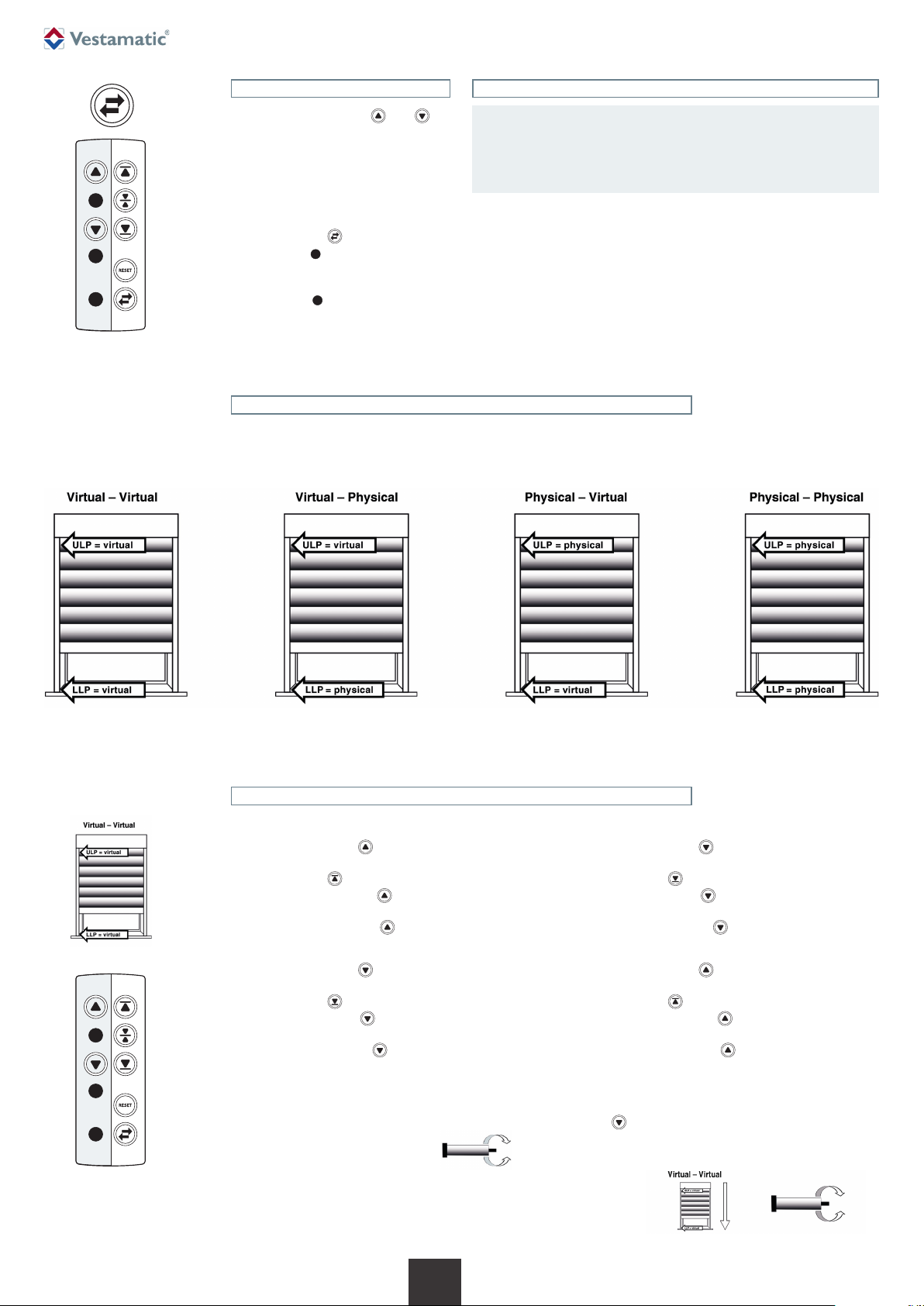

Programmable upper and lower limit position

Limit positions can be virtual or physical (upper position)

Intermediate positions storage

Parallel connection allowed

Anti-block function

Simple setting of the limit position with the “VL-Progset-ME/SMI-230”

(Art.-no.: 54185775)

Re-synchronisation of physical limit positions

Cable 2.5 m white

4. Intended use

These types of tubular motor described in these manual is intended solely

for controlling roller shutters. These types of tubular motor cannot be used

in potentially explosive area.

These types of tubular motor are designed for using in a single sunshade

system.

3. Scope of delivery

Motor 45 mm tube diameter with 2.5 m connection cable

Operating instructions

Adapter set, comprising tube adapter / adapter ring

Mounting-kit, comprising safety clip / safety cotter

ATTENTION!

Pay attention to the following European

guidelines:

– The cables must conform to the applica-

ble VDE standard.

– If installing motors with a PVC H05VV-F

cable, the cable on surface-mounted out-

door installations and recessed-mounted

installations must be protected by a cable

conduit or cable duct.

– When installing the motor an all-pole dis-

connection with a contact gap of at least

3 mm per pole must be provided.

– The up and down directions of the

switch resp. button must be electrically

or mechanically locked against each

other. The changeover time for changing

the running direction (up/ down) must be

least 0.5 sec.

Ä

ATTENTION!

– Follow the safety instructions according

to EN 60335-2-97.

– Additional components for the implemen-

tation of the installation, such as adap-

tors and brackets must be chosen among

those offered by the producer. These

products are listed in the catalogue sup-

plied on request.

– When mounting the drive always use the

safest and most suitable tubular motor

and mounting bracket.

– For automatically actuated awnings a

minimum gap of 0.4 m to other parts in

the area must be maintained when the

awning is fully extended. By using as

an awning system the extended awning

must mainain a minimum height of 1.8 m.

Ä

IMPORTANT!

Any screws used to fix the rolling shutters

tube / awnings must in no way touch the

motor. Please refer to fig. 4.1 to 4.5.

Ä

WARNING!

Risk of injury due to improper installation

and commissioning.

Improper installation and commissioning may

lead to personal injury or property damage.

Therefore:

– When connecting the device, observe the

currently valid VDE standards (in particu-

lar DIN VDE 0100/0700), your local pow-

er company’s regulations and the current

accident prevention regulations.

– Connect the motor in accordance with the

wiring diagram.

– It is important for the safety of professional

electricians to follow the user instructions.

Please keep instructions for reference.

Ä

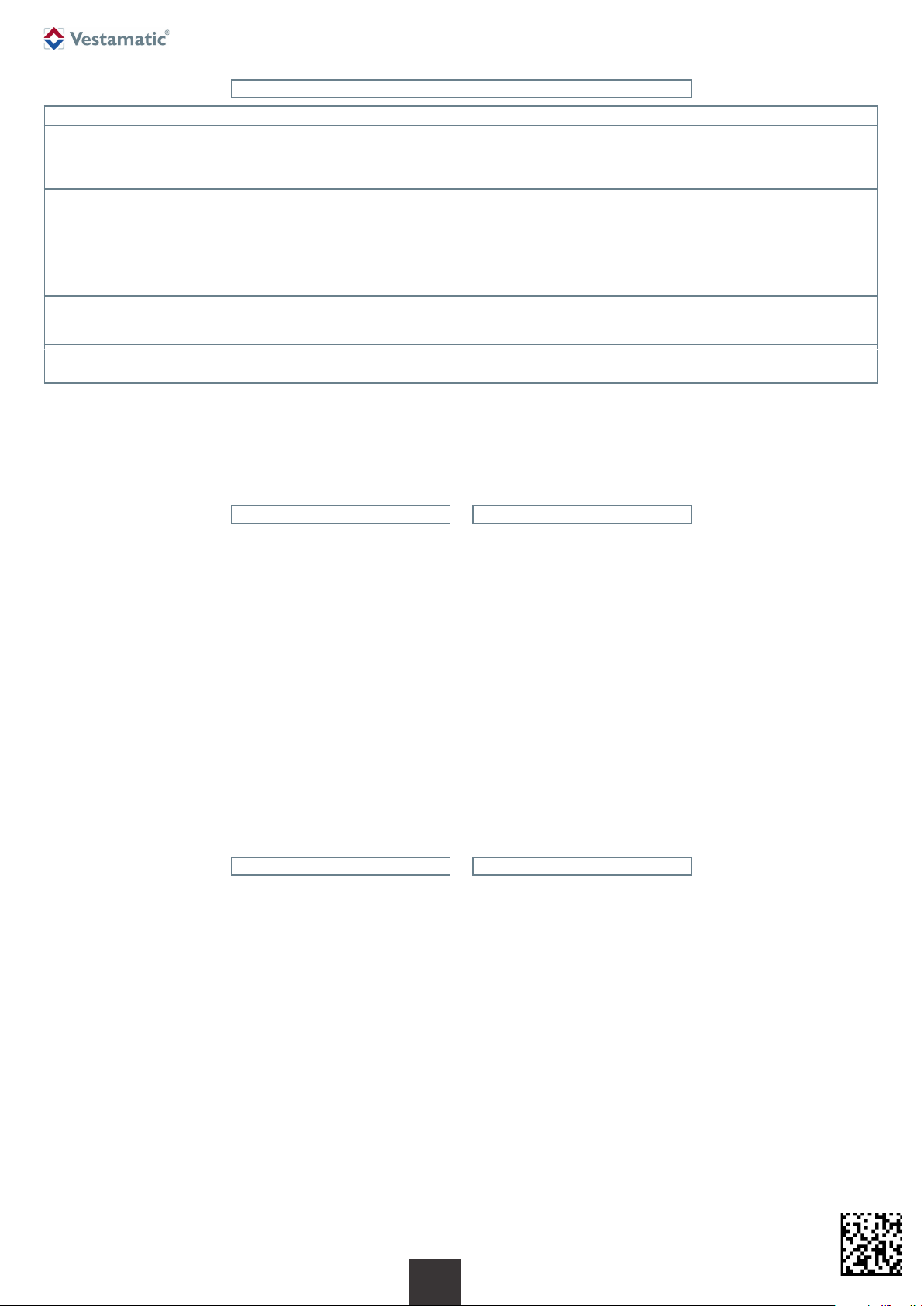

5. Technical data

Article VL-SMI-230-45/ 10Nm 20Nm 30Nm 50Nm

Art.-no.:

01066291 01066301 01066311 01066321

Torque (nominal) Nm 10 20 30 50

Output speed rpm 15 15 15 12

Tractive power kg 20 40 55 95

Supply voltage VAC 230 230 230 230

Frequency Hz 50 50 50 50

Rated power W 126 165 227 227

Rated current A 0,55 0,72 0,99 0,99

Running time Min. 4 4 4 4

Protection degree IP 44 44 44 44

Length L1 mm 461 481 522 551