Motor should be mounted in places protected against adverse weather conditions.

2. Safety

3. Motor assembly in a roller tube

Before starting assembling and using the device it is necessary to read the following instruction. The installer must abide by the

standards and the regulations effective in the country, where the device will be mounted and inform users on the conditions of use and

maintenance of the device. Non-compliance with the following instructions can not only present risk to life and health, but also affect the

correct operation of the entire roller shutter. This also results in the loss of warranty rights.

Torque should be suitable to the weight of the armour.

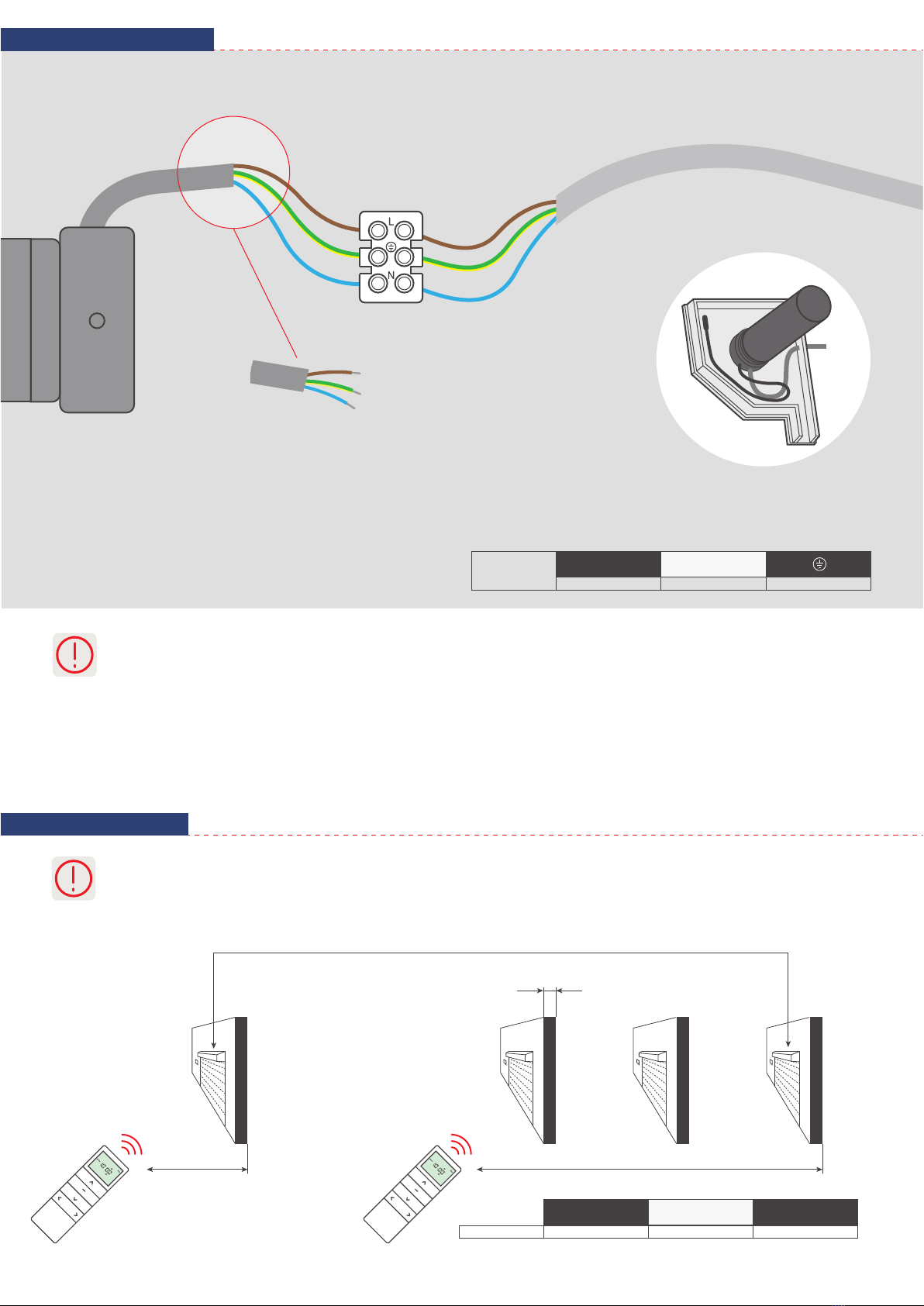

Wires of the motor should be mounted in a way to

prevent condensed water from getting inside and

so that a working roller blind does not damage them.

Check regularly the signs of wear of components

responsible for correct motor operation.

Turn off mains power before performing any activity

connected with installation or maintenance.

Keep contact of the motor with liquids to a minimum.

Do not use tools while placing the motor in a roller

tube.

Be careful not to damage the motor during assembly

of a driver.

Keep an eye on children, so that they do not play with

the motor and its control system. Mobile transmitters

should be kept away from them.

2

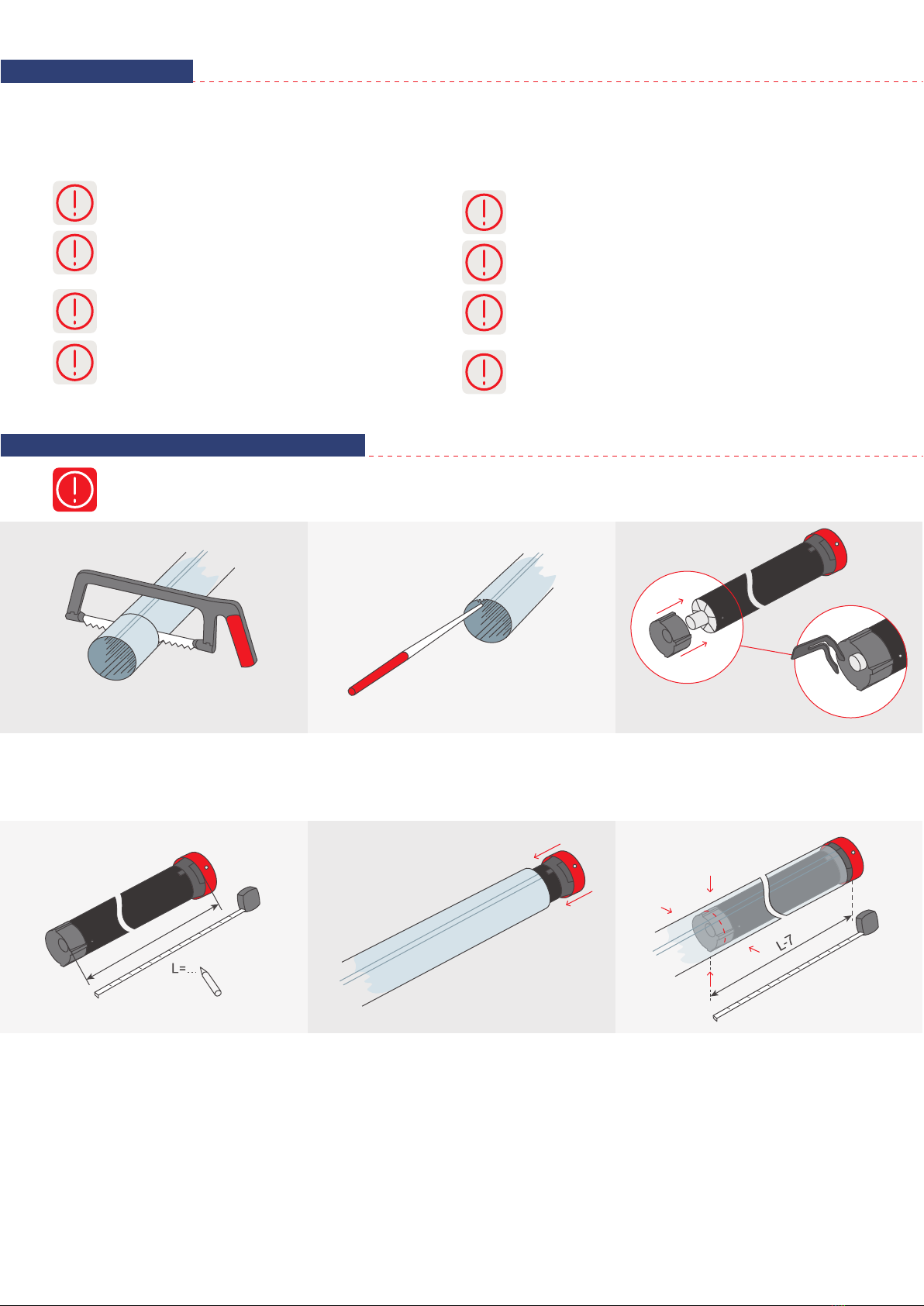

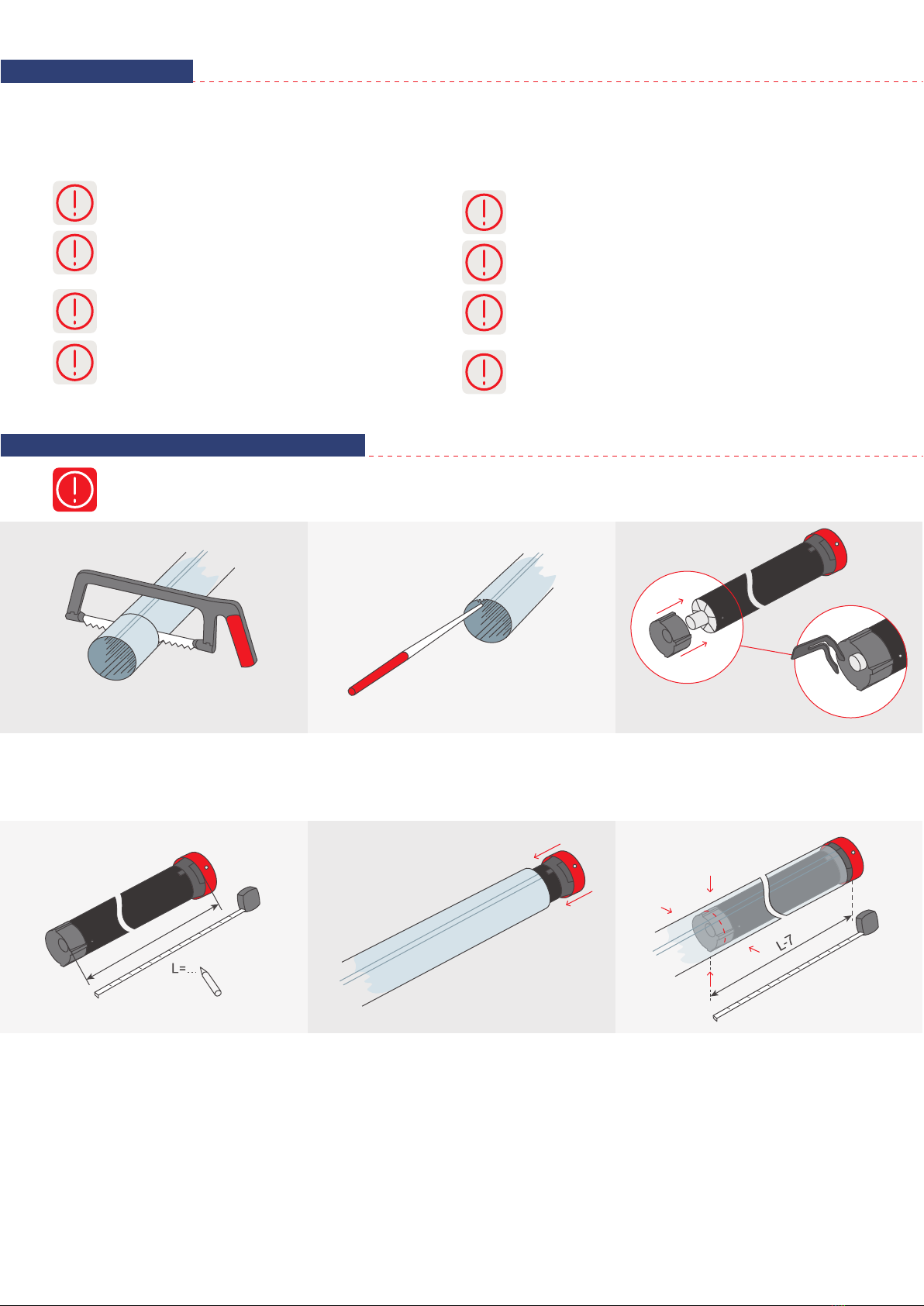

1. Cut the roller tube

to a suitable size.

2. Remove all filings and burrs

from the edges of the roller tube.

3. Mount the adaptation

on the motor.

4. Measure the length L between inner edge of

the cylinder head and the end of the driver.

5. Place the motor in the roller tube in

a way that the edge of the roller tube sticks

to the inner edge of the cylinder head.

Anchor the roller tube to the driver with four

screws or rivets, placed in a distance L-7 mm

from the inner edge of the cylinder head.