3 Operating regulations

If you violate the following regulations, you may lose

your entitlement to benefits.

NOTICE

Machine damage if you violate these

regulations

If you violate the following regulations, your machine

may get damaged and/ or cause damage in the

surrounding area(s).

Thoroughly follow all instructions and information

in this section.

Intended use

The machine and the manufacturing software have

been designed for the commercial creation of dental

objects by specially trained persons. The objects

require additional work before their use on patients.

Only process materials that you can select in the

manufacturing software.

Only use the machine and manufacturing software

in a commercial environment.

Before creating jobs, verify if the objects being pre-

pared may be utilized at the place of use accord-

ing to local and/ or national regulations or other

authorized organizations or entities (e.g. pro-

fessional associations, health authorities). In par-

ticular, verify if the material is approved for the

machined object type and if the object type is

designed in accordance with applicable reg-

ulations. Neither the manufacturing software nor

the machine will inform you about possible reg-

ulatory infringements, but will execute jobs in

accordance with the preferences and materials set

by the user.

Verify that each object type and each material in

your jobs are authorized manufacturing materials.

If mandated by local or national regulations, obtain

relevant authorization from the responsible organ-

izations or entities (e.g. professional associations,

health authorities).

Only manufacture objects which correspond to

the object types that you can select in the man-

ufacturing software. While you can import/ man-

ufacture any other objects as well, neither the

manufacturing software nor the machine are

designed for these other objects and should not

be used in this way.

Do not manufacture implants or parts of objects

that are designed to have contact with implants.

These parts include parts of two-part abutments

which contain the connection geometry for the

implant. Do not manipulate the connection geo-

metry of prefabricated abutments (“prefab abut-

ments”) and you must always check finished

objects for accurate connection geometries (i.e.

that connection geometries of finished jobs have

not been damaged).

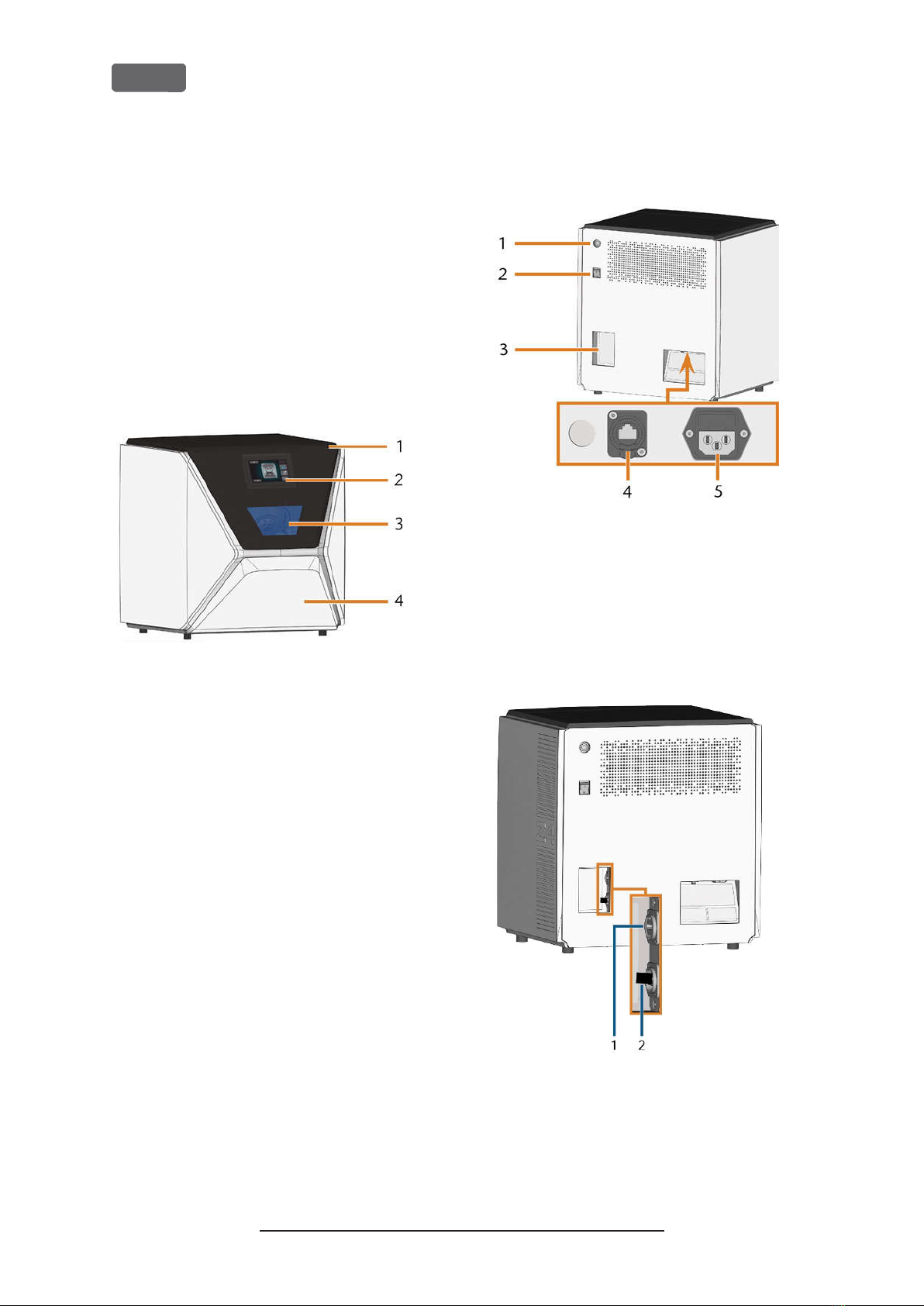

Controlling the machine through software

You control the machine through specially designed

applications which are supplied with the machine.

Always use the latest program version that officially

supports your machine.

Before installing or operating the machine, read

the documentation for the applications.

Ensure that your CAM computer meets all system

requirements.

Maintenance and cleaning

Maintenance and cleaning is part of standard machine

usage.

Clean and maintain the machine as required. Only

then can the machine reach a long service life.

Spindle

The spindle of your machine is a high-precision instru-

ment.

Do not use unbalanced tools at high rotational

speeds. Such an imbalance puts a great strain on

the spindle’s ball bearings, which can cause the

bearings to be damaged.

When working in the working chamber, do not

apply manual pressure against the spindle.

Unattended operation

If the machine runs unattended, the risk of material

damage is increased.

Only allow unattended operation of the machine

to occur if the following conditions are met:

nThe national and local laws allow it.

nThe working chamber of the machine is com-

pletely clean.

nUnauthorized users cannot access the machine.

nThe room in which the machine is located has an

automatic fire detection system.

Original Operating Instructions:Z4

Version: 12/5/2018

Z4 – Operating regulations

EN 8