2

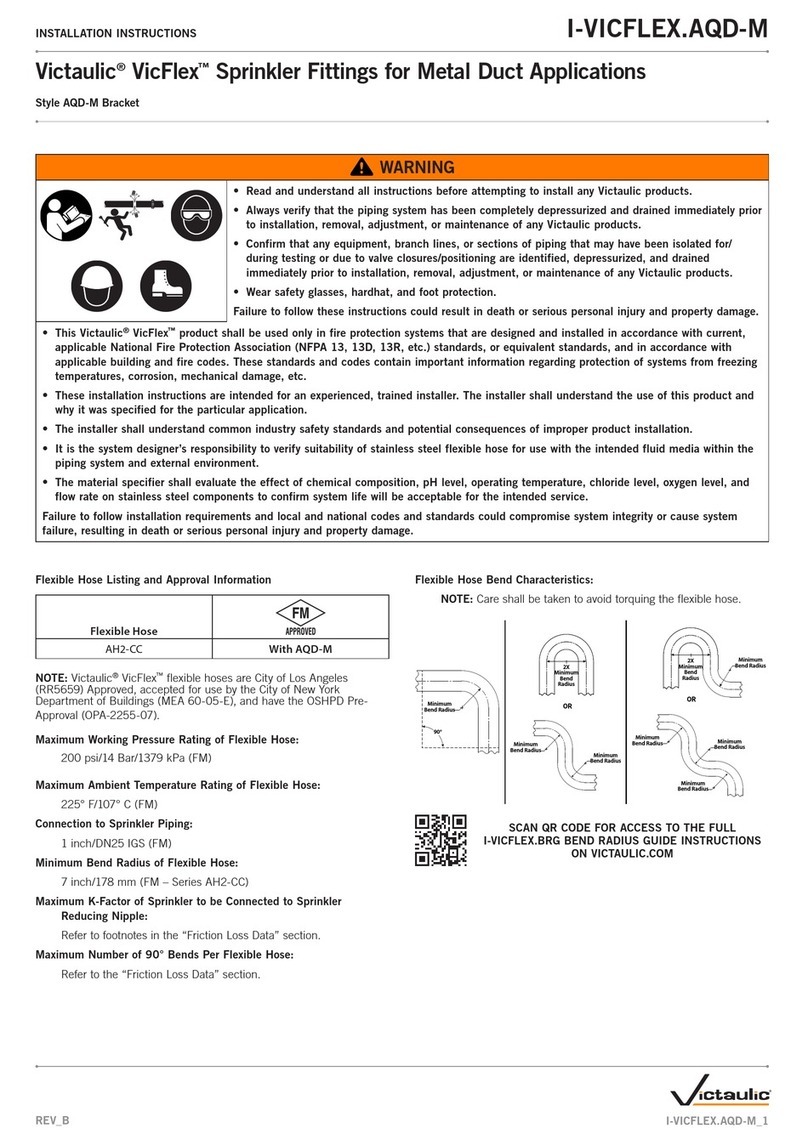

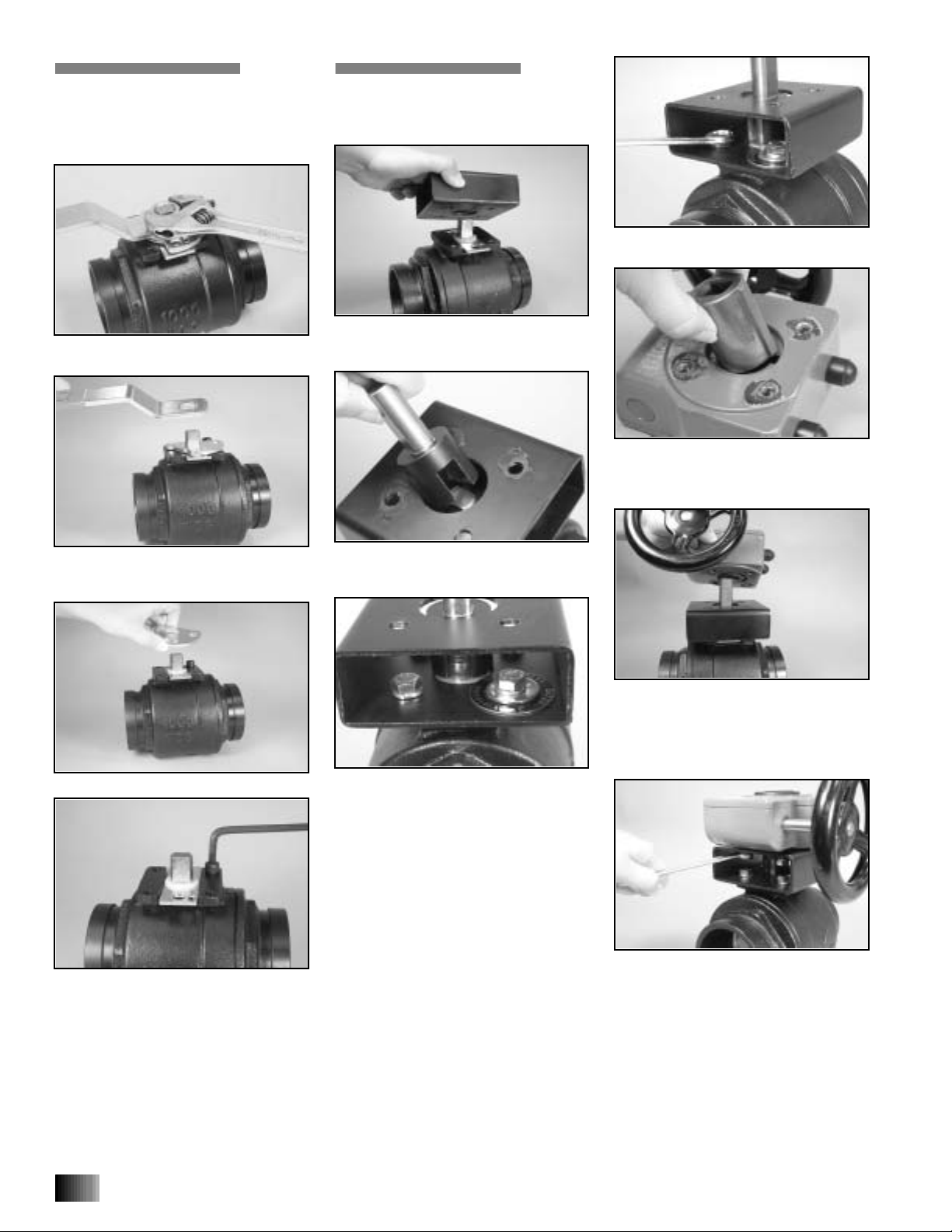

REMOVAL OF LEVER

HANDLE

To remove a lever handle for installation of a

gear operator, perform the following steps.

1.

Remove the handle assembly nut from the

lever handle, as shown above.

2.

Remove the identification tag and the

lever handle.

NOTE:

Keep the identification

tag for assembly onto the gear operator.

3.

Remove the locking plate from the valve.

4.

Using an allen wrench, remove the screw

from the mounting plate of the valve.

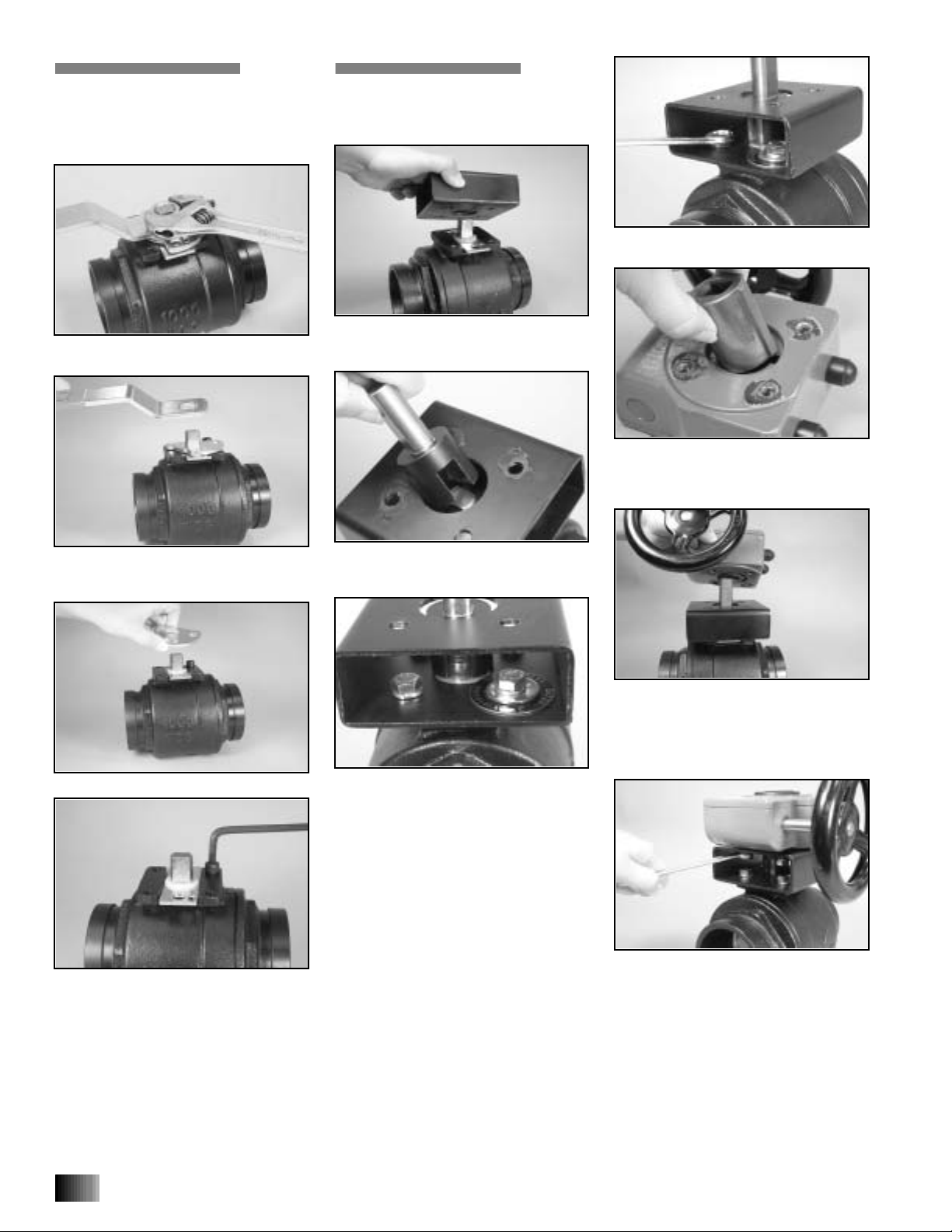

INSTALLATION OF

GEAR OPERATOR

ASSEMBLY

1.

Install the bracket onto the valve body by

aligning the holes of the bracket with the

holes in the mounting plate of the valve.

2.

Installthe stem adapter by positioningthe

flats of the stem adapter over the flats of the

valve stem, as shown above.

3.

Place a lock washer onto a hex-head

screw, and hand-tighten the screw into one

of the holes in the bracket and the mounting

plate of the valve. Repeat this procedure two

more times.

NOTE:

Refer to the “Required

Parts” chart on page 1 for the proper hex-

head screw size and lock washer size.

3a.

On the fourth hex-head screw, install a

flat washer, then the identification tag (with

lettering facing toward the hex head of the

screw). Hand-tighten this hex-head screw

into the final hole in the bracket and mount-

ing plate of the valve. Refer to the above

photo.

3b.

Tighten the four hex-head screws until

the lock washers are flattened.

4.

Insert the drive hub into the gear operator

by aligning the key of the drive hub with the

keyway in the gear operator, as shown

above.

5.

While supportingthe drive hub, install the

gear operator onto the stem adapter by posi-

tioning the flats of the drive hub over the

flats of the stem adapter. Make sure the indi-

cating arrow on top of the gear operator indi-

cates the correct disc position.

6.

Place a lock washer onto each of the four

hex-head screws, and hand-tighten the

screws into the holes in the bracket and the

gear operator.

NOTE:

Refer to the “Required

Parts” chart on page 1 for the proper hex-

head screw size and lock washer size.

6a.

Tighten the four hex-head screws until

the lock washers are flattened.

7.

Open and close the valve to ensure proper

operation of the gear operator.