I-VICFLEX.AQD-M_4 REV_B

I-VICFLEX.AQD-M / Victaulic®VicFlex™Style AQD-M Bracket / Installation Instructions

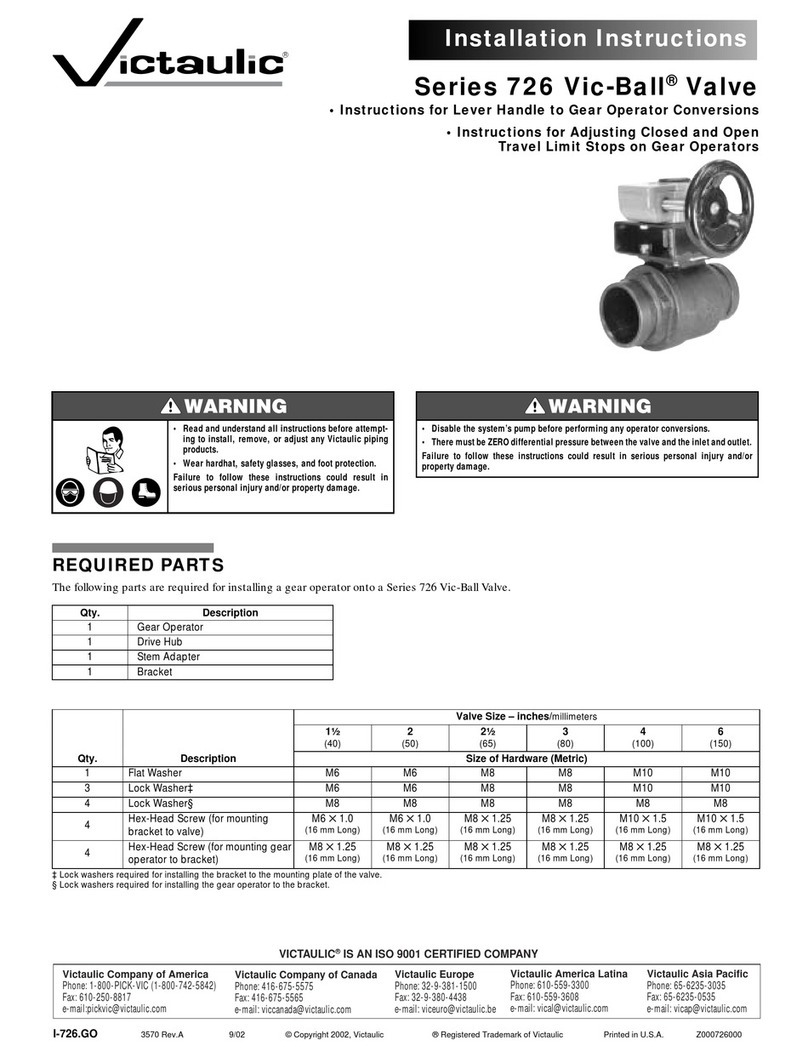

1-INCH/DN25 IGS CONNECTION TO THE

SPRINKLER PIPING USING A SERIES AH2-CC

FLEXIBLE HOSE

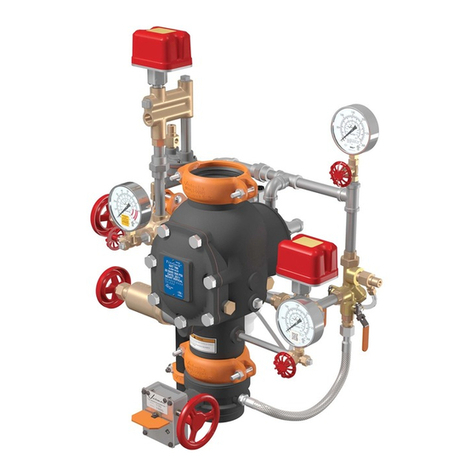

INCORRECT - Orignal Groove System (OGS) Groove Prole

CORRECT - IGS Groove Prole

Pipe and grooves are not shown to scale

The Style 108 Coupling of the Series AH2-CC shall be used ONLY

with sprinkler piping connections that are prepared to Victaulic IGS

proprietary groove specifications. DO NOT attempt to install the

coupling on sprinkler piping connections that are prepared to any other

groove specification. Refer to Victaulic publication 25.14 for the IGS

groove specification, which can be downloaded at victaulic.com.

WARNING

• The flexible hose shall not be bent or fluctuated up-and-down or

side-to-side when pressurized.

Failure to follow this instruction could cause improper sprinkler

operation, resulting in death or serious personal injury and property

damage.

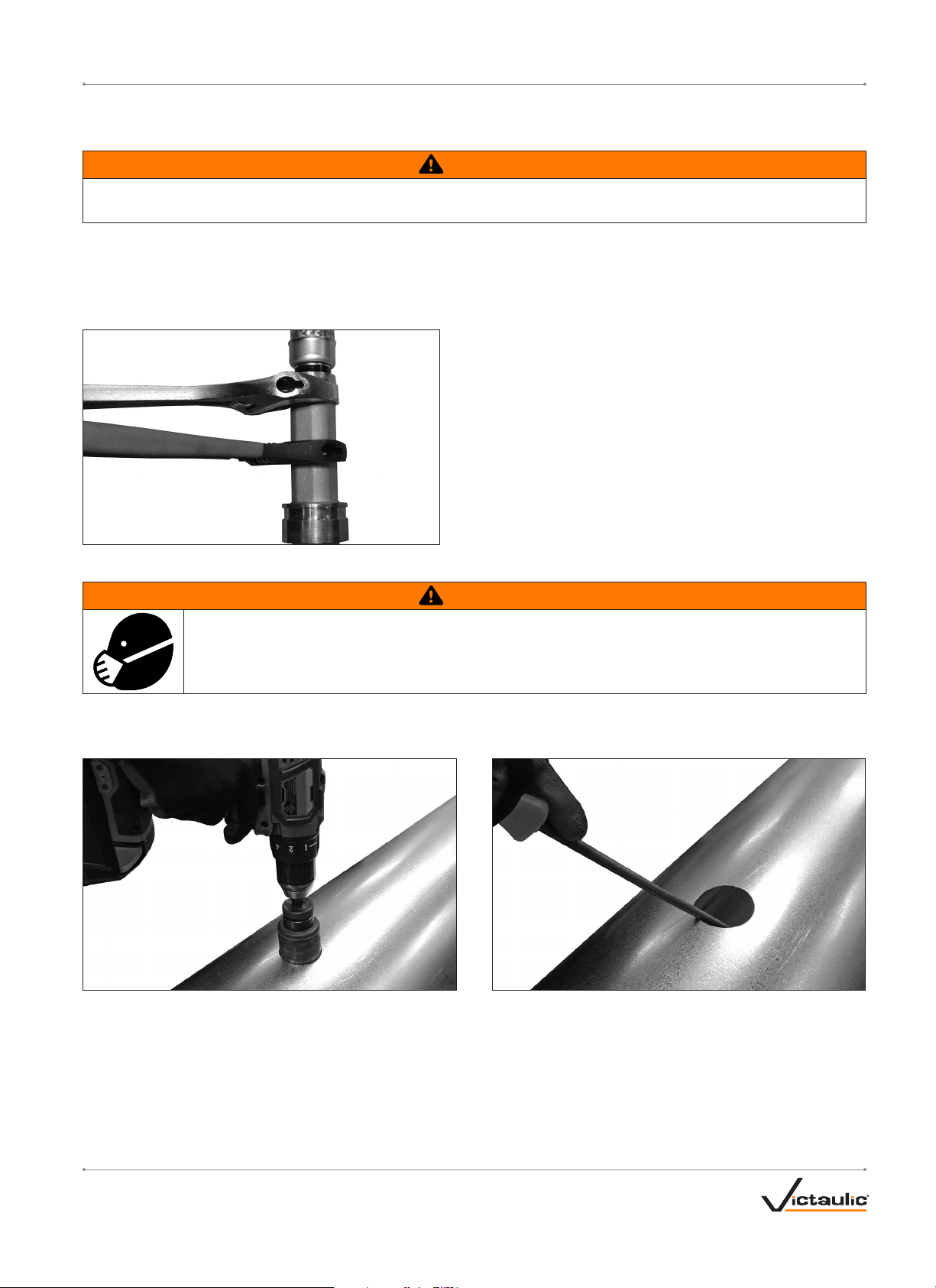

DO NOT REMOVE

NUT/BOLT/LINKAGE FOR

INITIAL INSTALLATION

1. DO NOT DISASSEMBLE THE COUPLING: The Style 108 Coupling

of the Series AH2-CC is designed so that the installer does not

need to remove the nut, bolt, or linkage for initial installation. This

facilitates installation by allowing the installer to directly insert the

sprinkler piping’s grooved end into the coupling.

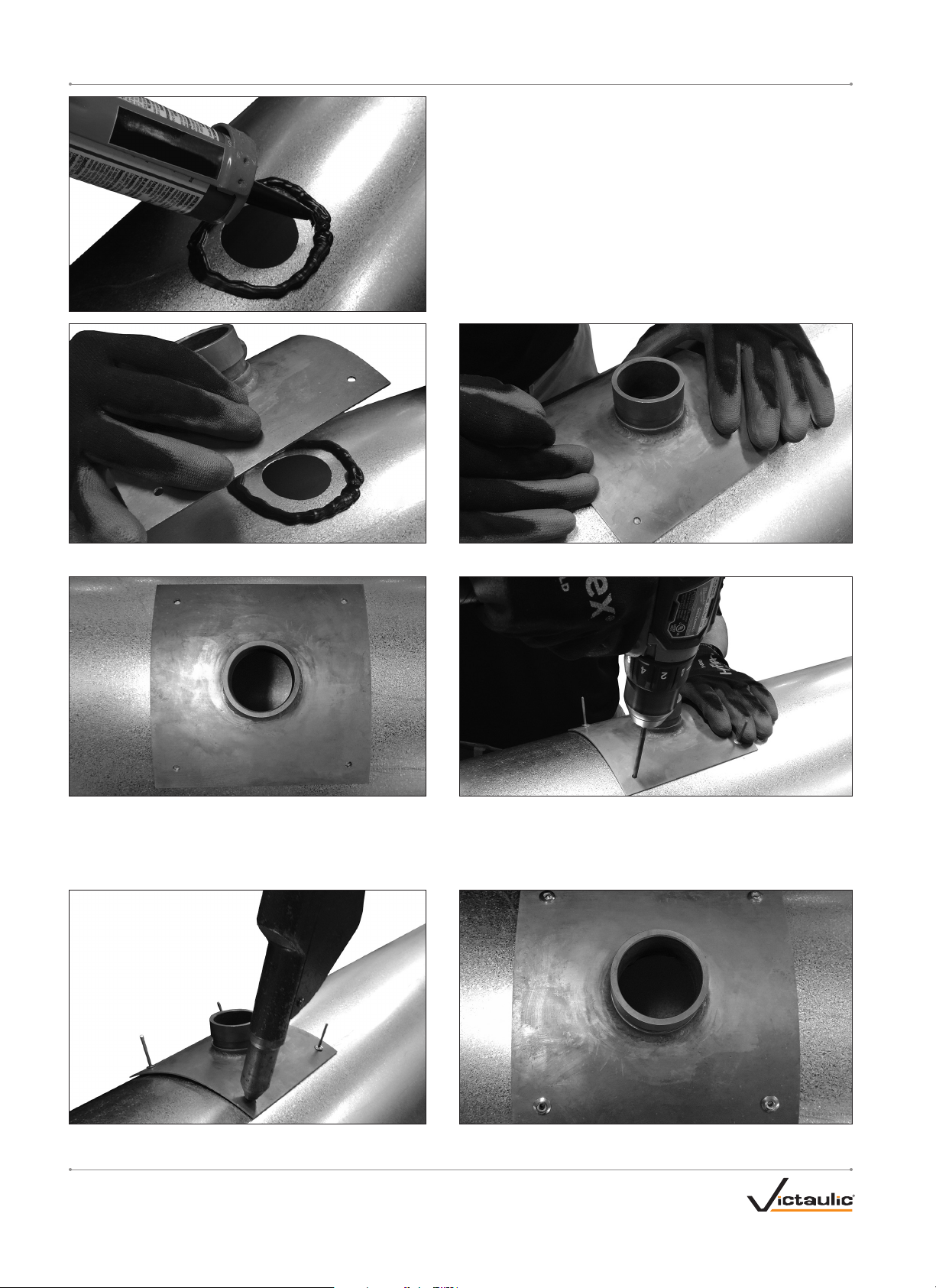

2. The outside surface of the sprinkler piping, between the groove

and the end of the sprinkler piping, shall be generally free from

indentations, projections, weld seam anomalies, and roll marks

to ensure a leak-tight seal. All oil, grease, loose paint, dirt, and

cutting particles shall be removed.

The sprinkler piping’s outside diameter (“OD”), groove dimensions,

and maximum allowable flare diameter shall be within the tolerances

published in current Victaulic IGS specifications, publication 25.14,

which can be downloaded at victaulic.com.

3. Check the gasket to verify that it is suitable for the intended

service. The color code identifies the material grade. Refer to

Victaulic publication 05.01 for the color code chart, which can

be downloaded at victaulic.com, and the “NOTICE” below for

important gasket information.

CAUTION

• If any conditions listed in the "NOTICE" below are met, a thin

coat of a compatible lubricant shall be applied only to the gasket

sealing lips to help prevent pinching, rolling, or tearing during

installation.

• DO NOT use excessive lubricant on the gasket sealing lips.

Failure to use a compatible lubricant may cause gasket damage,

resulting in joint leakage and property damage.

3a. If any conditions listed in the “NOTICE” below are met, apply a

thin coat of a compatible lubricant, such as Victaulic Lubricant

or an EPDM-compatible lubricant, only to the gasket sealing lips.

Silicone grease may be used (silicone spray is not a compatible

lubricant).

NOTICE

• Gaskets for Style 108 Coupling assemblies of AH2-CC Flexible

Hoses are pre-lubricated. Additional lubrication is not required

for the initial installation of wet pipe systems that are installed

at or continuously operating above 0°F/–18°C.

Supplemental lubrication is required only if any of the following

conditions exist. Apply a thin coat of a compatible lubricant to

the gasket sealing lips, as noted in step 3a on this page. It is

not necessary to remove the gasket from the housings to apply

additional lubricant to the gasket sealing lips.

• If the installation or continuous operating temperature is below

0°F/–18°C

• If the gasket has been exposed to fluids prior to installation

• If the surface of the gasket does not have a hazy appearance

• If the gasket is being installed into a dry pipe system

• If the system will be subjected to air tests prior to being filled

with water

• If the gasket was involved in a previous installation

Lubricated gaskets will not enhance sealing capabilities on

adverse sprinkler piping conditions. Sprinkler piping condition

and preparation shall conform to the requirements listed in these

product installation instructions.

WARNING

• Never leave a Style 108 Coupling of a Series AH2-CC partially

assembled on grooved sprinkler piping. ALWAYS TIGHTEN THE

HARDWARE IMMEDIATELY IN ACCORDANCE WITH THESE

INSTRUCTIONS. A partially assembled coupling poses a drop or

fall hazard during installation and a burst hazard during testing.

• Keep hands away from the grooved sprinkler piping and the

openings of the coupling when attempting to insert the grooved

sprinkler piping into the coupling.

• Keep hands away from coupling openings during tightening.

Failure to follow these instructions could result in death or serious

personal injury and property damage.