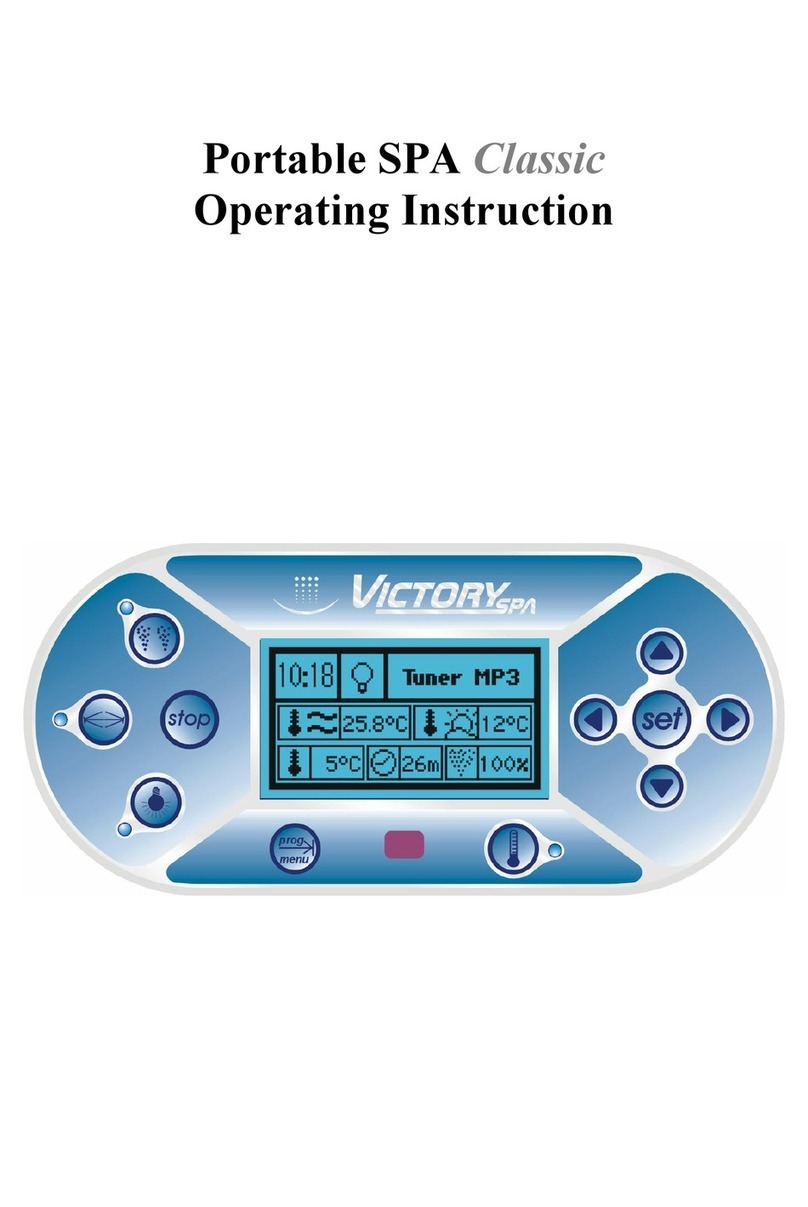

INDEX

1. Disinfection...................................................................................................................................3

2. Building over of the tub..................................................................................................................4

3. Replacement of remote control batteries........................................................................................5

4. Replacement of the bulb of the underwater light ............................................................................5

5. Whirlpools power connection........................................................................................................7

6. Transport safety plug....................................................................................................................12

7. Cabins outside installation connection......................................................................................... 13

8. Steam circulation.........................................................................................................................17

9. Mauritius Maxoutside installation connection ...........................................................................18

10. Main conditions to be satisfied by an object where installation of a spa bath

is planned.................................................................................................................................19

11. Availability of the exclusive systems in individual models of the Victory Spa baths..................60

12. Water pump motor power...........................................................................................................61

13. Whirlpools power consumption.................................................................................................62

14. R 64

15. Extras.........................................................................................................................................65

16. Whirlpools outside installation connection................................................................................67

17. Whirlpools electric diagrams.....................................................................................................84

18.Cabins electric diagrams...........................................................................................................101

19.Spas electric diagrams..............................................................................................................101

ecessed back jets......................................................................................................................

1

INHALTSVERZEICHNIS

1. Desinfektionsprogramm..............................................................................................................22

2. Bebauung der Badewanne............................................................................................................23

3. Batterie im Fernbedienungsgerät ersetzen....................................................................................24

4. Wechsel der Glühbirne in der Unterwasserbeleuchtung...............................................................24

5. Anschluss zum Netzwerk.............................................................................................................26

6. Sicherheitsverschluss des Luftgebläses.......................................................................................31

7.Anschluss von Kabinen................................................................................................................32

8. Dampfzirkulation in Duschkabinen.............................................................................................36

9. Anschluss Mauritius MAX..........................................................................................................37

10. Objektbedingungen für die Installation einer SPA-Anlage........................................................38

11. Das Vorhandensein von exklusiven Systemen in den einzelnen Modellen der

Wannen Victory Spa........................................................................................................................60

12. Leistung des Pumpenmotors......................................................................................................61

13. Leistungsaufnahme der Wannen................................................................................................62

14. Umwälzungen unter Düsen........................................................................................................64

15. Zubehör......................................................................................................................................65

16. Anschluss der Außerinstallationen.............................................................................................67

17. Schema des elektrischenAnschluss - Wannen............................................................................84

18. Schema des elektrischenAnschluss - Duschkabinen ................................................................101

19. Schema des elektrischenAnschluss - SPA................................................................................114

EN

DE