4 of 36 IM-HC 561174 1120 Basic Heating Control

Table of Contents

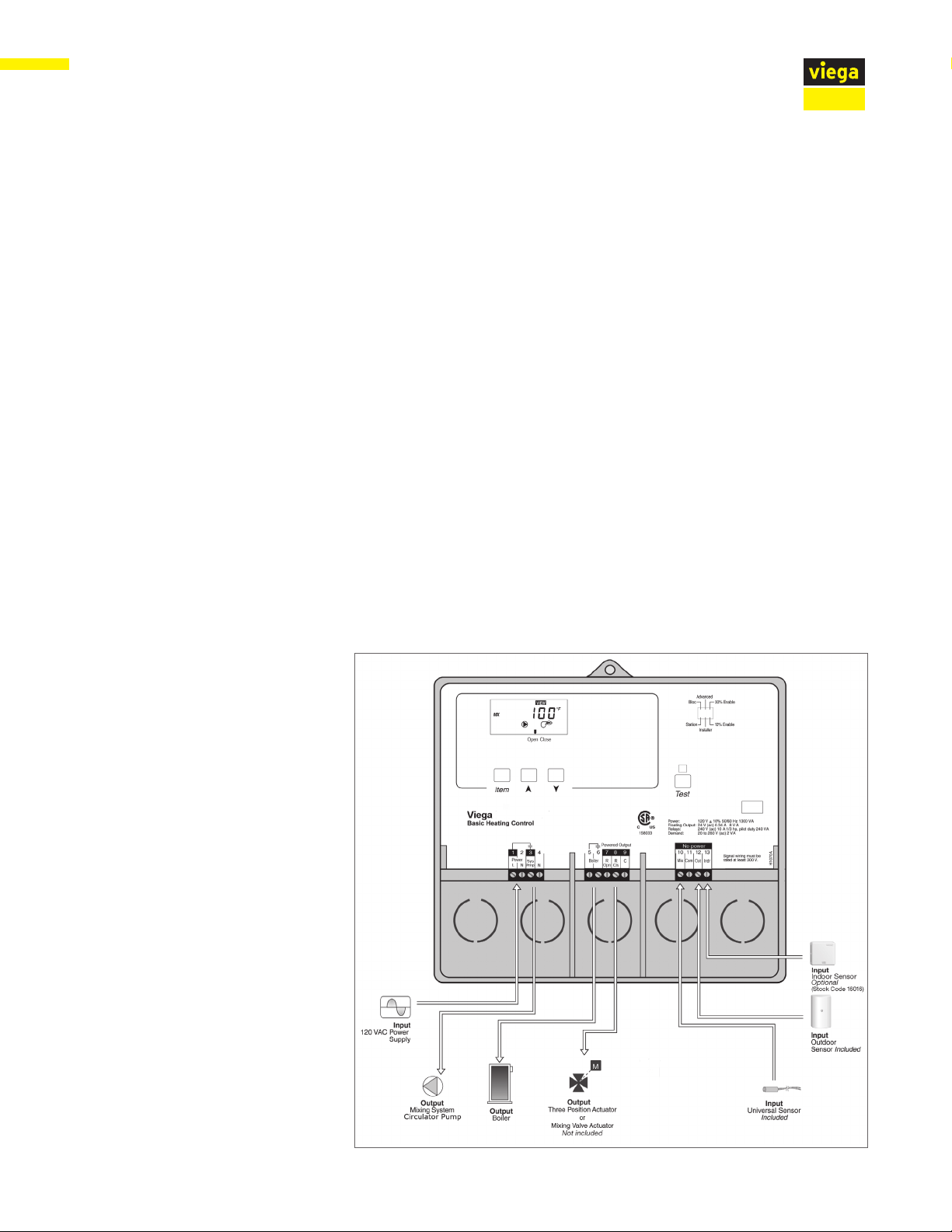

4.2.3 Sensor and Unpowered Input Connections _________ 19

4.2.3.1 Outdoor Sensor _________________________ 19

4.2.3.2 Supply Sensor __________________________ 19

4.2.3.3 Indoor Sensor ___________________________ 19

4.3 Testing the Wiring _____________________________________ 20

4.3.1 Testing the Sensors _____________________________ 20

4.3.2 Testing the Power Supply ________________________ 20

4.3.3 Testing the Outputs _____________________________ 21

4.3.3.1 System Circulator Pump (Sys Pmp) _________ 21

4.3.3.2 Boiler __________________________________ 21

4.3.4 Connecting the Control __________________________ 21

4.3.4.1 Mixing or Injection Valve Actuator __________ 21

4.4 DIP Switch Settings ___________________________________ 22

4.4.1 Advanced/Installer ______________________________ 22

4.4.2 Boiler Enable 30% - Boiler Enable 10% ____________ 22

4.4.3 Bloc / Station __________________________________ 22

4.5 View Menu Display Settings _____________________________ 23

4.5.1 OUTDR _______________________________________ 23

4.5.2 ROOM ________________________________________ 23

4.5.3 MIX __________________________________________ 23

4.5.4 MIX TARGET __________________________________ 23

4.6 Adjust Menu Display Settings ___________________________ 24

4.6.1 ROOM ________________________________________ 24

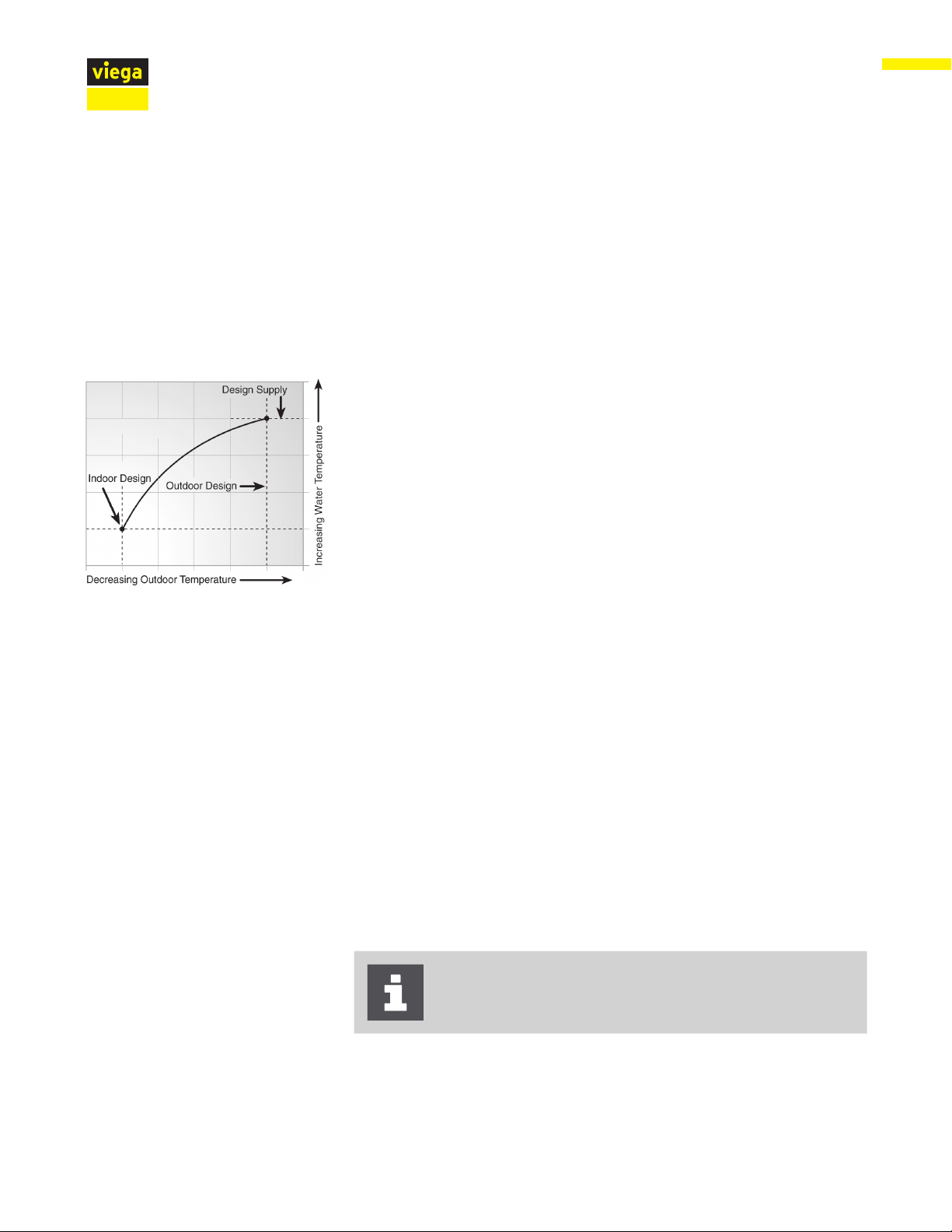

4.6.2 OUTDR DSGN _________________________________ 24

4.6.3 MIX DSGN ____________________________________ 24

4.6.4 MIX INDR _____________________________________ 24

4.6.5 MIX MAX ______________________________________ 25

4.6.6 WWSD _______________________________________ 25

4.6.7 UNITS ________________________________________ 25

4.7 Testing the Control ____________________________________ 26

4.7.1 Test Sequence _________________________________ 26

4.7.2 Testing Sensors ________________________________ 26

5 Troubleshooting __________________________________________ 28

5.1 Underheating _________________________________________ 29

5.2 Overheating __________________________________________ 29

5.3 Error Messages _______________________________________ 30

5.3.1 E01 __________________________________________ 30

5.3.2 Shr (OUTDR ___________________________________ 30

5.3.3 OPn (OUTDR)__________________________________ 30

5.3.4 Shr (MIX ______________________________________ 30

5.3.5 OPn (MIX) _____________________________________ 31

5.3.6 Shr (ROOM) ___________________________________ 31

5.3.7 OPn (ROOM) __________________________________ 31

6 Mechanical and Electrical Diagrams _______________________ 32

6.1 Mechanical Schematic _________________________________ 32

6.2 Electrical Schematic ___________________________________ 32

7 Technical Data ___________________________________________ 33

8 Limited Warranty _________________________________________ 34