SM ENGLISH

Version 12/2017

1

ENGLISH

1. Introduction .....................................................................................................................................2

1.1. Before you start ...................................................................................................................2

1.2. Warranty................................................................................................................................2

1.3. Restrictions ..........................................................................................................................2

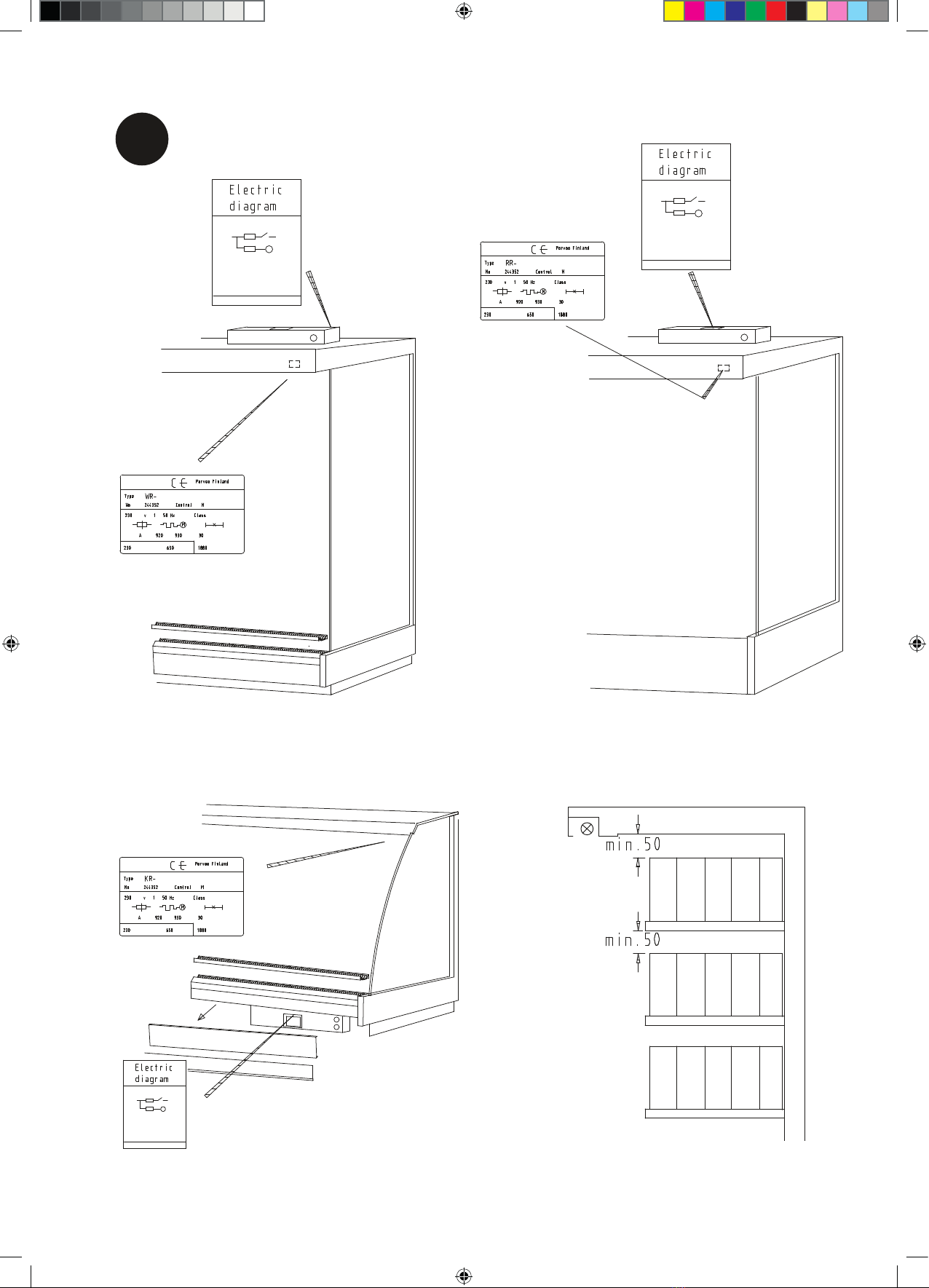

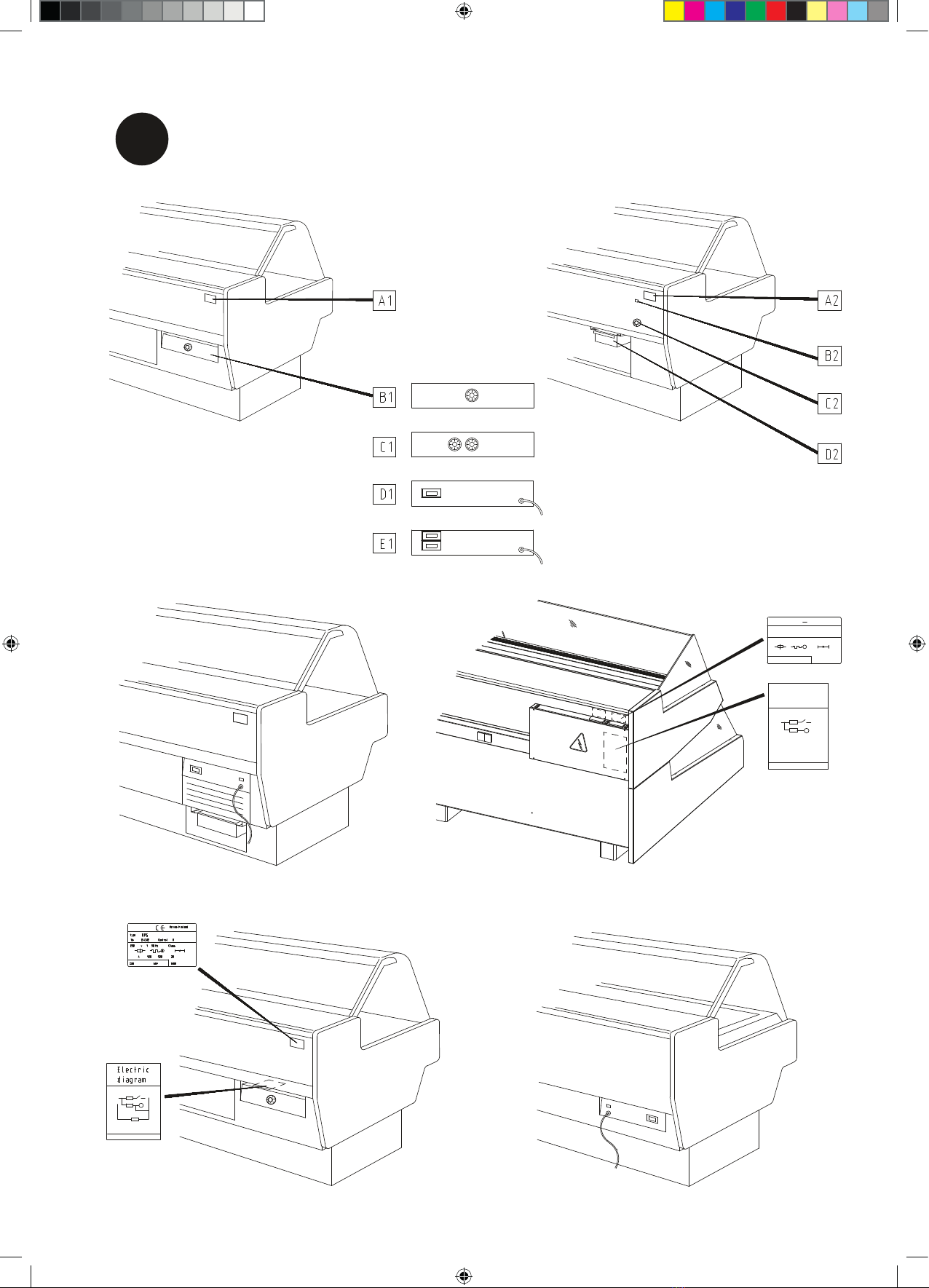

1.4. TectoDeck MD1 Spirit Plus, TectoDeck MD2 e-Novus, TectoDeck MD2 e-Ventus

and TectoDeck MD3 e-Visio, TectoDeck RI1 Intro and TectoDeck SV1 Inspi ................. 3

1.5. TectoFreeze IS1 Maxim........................................................................................................3

1.6. TectoFreeze VF1 Luxo.........................................................................................................3

1.7. TectoFreeze CF1 Nardo.......................................................................................................3

1.8. TectoFreeze SV1 Iconic.......................................................................................................3

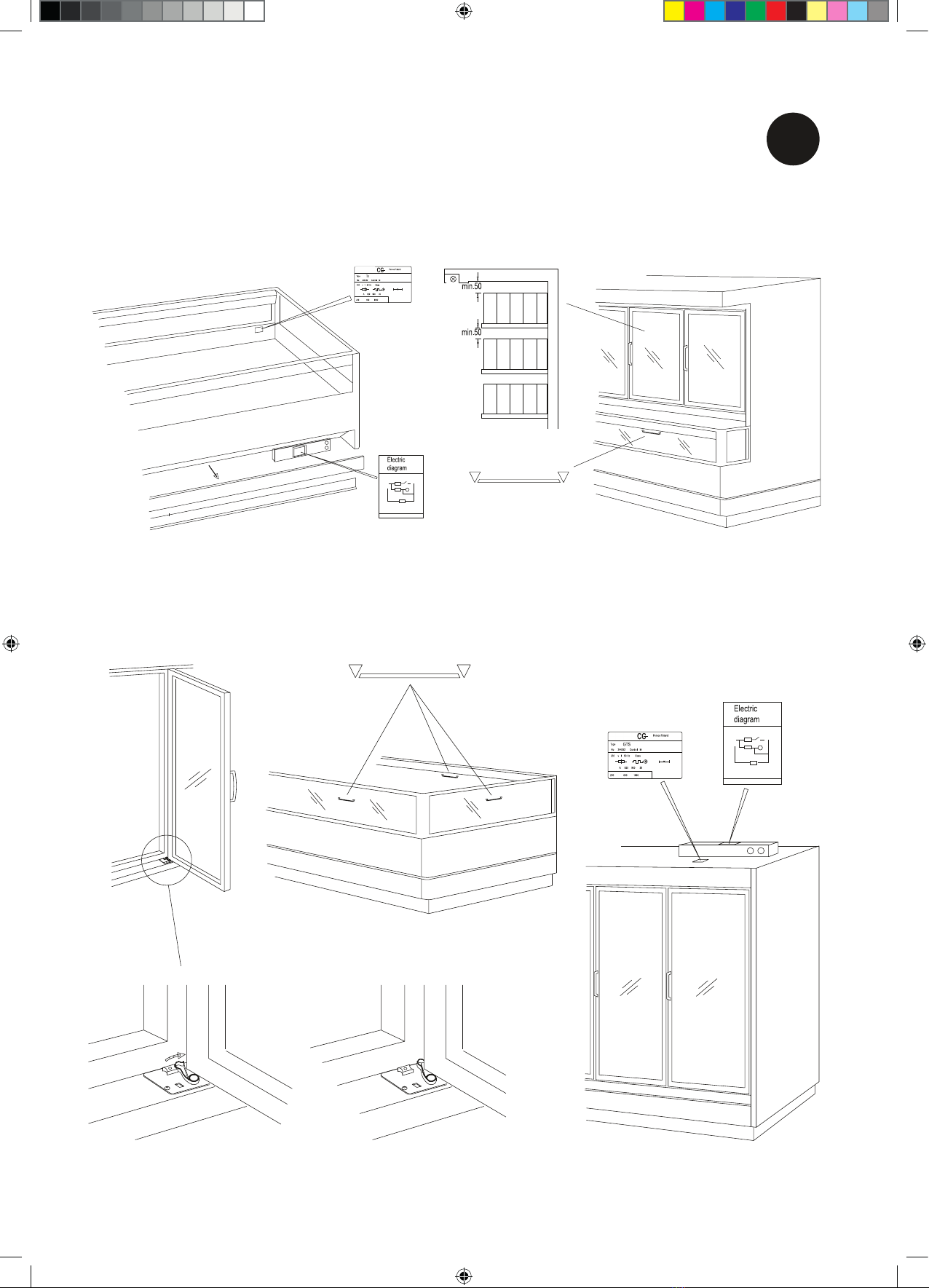

1.9. TectoServe SL1 Gusto.........................................................................................................4

1.10.TectoServeDC1Soe..........................................................................................................5

1.11.TectoServe DC1 Emilie........................................................................................................5

1.12.Night covers, glass lids and doors ....................................................................................6

2. Preparations ....................................................................................................................................7

2.1. Package ................................................................................................................................7

2.2. Transport damage................................................................................................................7

2.3. Installation............................................................................................................................7

2.4. Cleaning before use.............................................................................................................8

2.5. Electrical connections.........................................................................................................8

3. Operation .........................................................................................................................................8

3.1. Start-up .................................................................................................................................8

3.2. Operating thermostat ..........................................................................................................9

3.2.1. Machine Status menu................................................................................................9

3.2.2. Programming menu ...................................................................................................9

3.2.3. Manual activation of defrosting cycle.......................................................................10

3.2.4. LED..........................................................................................................................10

3.3. Automatic defrosting.........................................................................................................10

3.4. Loading cabinet ................................................................................................................. 11

3.5. Fan speed control..............................................................................................................12

4. Maintenance ..................................................................................................................................12

4.1. Cleaning..............................................................................................................................12

4.2. Troubleshooting.................................................................................................................13

4.3. Interruption in mains supply.............................................................................................13

4.4. Servicing and spare parts.................................................................................................13

4.5. Disposal of equipment ......................................................................................................14