Viewpro A30TR User manual

User Manual

A30TR AI 30x EO + IR Dual-Sensor Laser Rangefinder

Object Tracking Gimbal Camera

Standard Version

标准版 快拆版

Viewport Version

For more details please scan the QR code

or visit our website:

www.viewprotech.com

Disclaimer and Warning

Legends

1.1 Introduction

1.Product Introduction

1.

Important NoteWarning

A30TR is a 3-axis dual-sensor AI gimbal camera with laser rangefind-

er, which integrated with an AI object identification and tracking

module, features 30x optical zoom, 19mm 640*512 IR thermal and

1500m Laser rangefinder.

The highlight of A30TR is the AI object identification and tracking

module, with which A30TR can realize car, human automatic recogni-

tion and tracking, the simultaneous detection quantity of objects are

more than 10.

A30TR supports IR thermal and EO PIP switch, IR color palette switch,

Congratulations on purchasing your new Viewpro product. Please read

this entire document carefully. Failure to read or follow instructions and

warnings in this document may result in damage to your Viewpro prod-

uct. Disassemble the gimbal camera by user is not permitted, as which

may cause the camera does not work normally.

Viewpro accepts no liability for damage, injury or any legal responsibili-

ty incurred directly or indirectly from the use of this project. The user

shall observe safe and lawful practices including, but no limited to,

those set forth in the manual.

2.

photographing and video, target tracking, thermal digital zoom and so

on, also Geo-tagging is supported.

Features aluminum alloy housing and anti-interference, the 3 axis

gimbal can achieve stabilization in yaw, roll and pitch. The integrated

design of damping system can greatly reduce mechanical vibration.

A30TR is widely used in UAV industries of public security, electric

power, fire fighting, disaster prevention, emergency monitoring and in-

spection, search and rescue, zoom aerial photography and other in-

dustrial applications.

New Rich OSD Display

Simultaneous detection quantity≥ 10 targets

2.

1.2 In the Box

3..

A. Standard Version

B. Viewport Version

Gimbal Camera

x 1 pc

USB to TTL Cable

x 1 pc

Power Cable

x 1 pc

Gimbal Camera

x 1 pc

USB to TTL Cable

x 1 pc

M3 Screw

x 8 pcs

Copper Cylinder

x 4 pcs

Copper Cylinder

x 4 pcs

Power Cable

x 1 pc

PWM Control Cable

x 1 pc

M3 Screw

x 8 pcs

2.1 Overview

TTL / S.BUS Control

Cable x 1 pc

TTL Connect Cable

x 3 pcs

Ethernet Cable x 1 pc

4..

Viewport

Control Box Back Side

(Standard Version)

(Viewport Version)

[15]

2. Installation Instruction

[3]

[2]

[5]

[1]

[9]

[8]

[7

[11]

[10]

[4]

]

[6]

[14]

[13]

[12]

[12]

[13]

[14]

P W M P O WER

E T HERNET

U A R T

5.

[1] Control box

[2] Upper damping board

[3] Lower damping board

[4] FHD zoom camera

[7] Damping ball

[8] Yaw axis motor

[9] Roll axis motor

[10] TF card slot

[11] Pitch axis motor

[12] 3-6S power interface

[13] Micro HDMI interface

[15] Viewport unlock button

[14] Ethernet interface

[5] Infrared thermal camera

[6] laser rangefinder

2.2.1 Control Box Printing (Standard Version)

PITCH

Yellow Jumper Cap

TX

RX

GND

YAW

MODE

ZOOM

FOCUS

PIC/REC

MULTI

USB

AV

5V output

GND

123

Please ensure that there isn’t any obstacle while the

motor rotating.

Please remove the obstacle immediately if gimbal

camera is blocked during rotation.

Don't use laser ranging against glass within 5meters.

Don’t put the infrared thermal camera towards the sun,

magma, laser, etc. in case any burn to the camera.

The input voltage cannot be higher than 6S.

The pin insertion interface cannot be connected with

power supply.

The yellow jumper cap cannot be removed

Front Side

2.2.2 Control Box Printing (Viewport Version)

6.

Left Side

Right Side

HDMI

RX-

GND

5V

S.BUS

TTX

GND

RXD

TXD CVBS

GND

OUT

MULTI

FOCUS / PPM

ZOOM

MODE

YAW

PITCH

GND

3S~6S

PIC / REC

RX+

TX-

TX+

Unit: mm

2.3 Device Dimensions (Standard Version)

7.

213.3

4*φ3.1

62.2

62.2

130

134.7

Unit: mm

8.

2.3 Device Dimensions (Viewport Version)

Control Box

78

4*φ3.1

78

130

219

134.7

43.2

34.3

46.2

48.4

56.2

51.2

P W M P O WER

E T HERNET

U A R T

2.4 Install Mounting Part

9.

(1) Find out the arrow on the gimbal which indicating the yaw heading

of the payload (i.e. the lens direction when the camera power on), and

synchronize with the direction specified by the UAV.

(2) Fix one end of the copper cylinder on the screw hole of lower damp-

ing board, and use M3 screw to fasten it.

(3) According to the provided screw hole dimension you can make suit-

able mounting holes on the UAV mounting board, and fixes the other

end of the copper cylinder on the mounting board of the UAV (Viewport

version is the same).

Front

2.5 Viewport Release Instruction

10.

1. Make sure the two white stripes indicated in above picture are

aligned with each other. (If the stripes are not aligned to each other,

please pinch the connector part and turn it to left manually)

×

11.

2. Align the white dot (unlock icon) to the red triangle (below unlock

button), push the gimbal into the Viewport completely and then rotate

the gimbal camera anticlockwise.

3. When you hear "click" sound (when red dot is aligned to the red tri-

angle) means the gimbal camera and Viewport has been locked.

4. To unlock the Viewport, you need to press on unlock button and

rotate the gimbal camera clockwise till the white dot align to the red tri-

angle. Then pull the gimbal out from the Viewport.

2.6 Install TF Card

2.7 Image Output Interface

12.

TF (Micro SD card): Install the TF card to the card slot (Re. 2.1 Over-

view). Support max 128GB. Request Class 10 (10m/s) transmission

speed or higher and FAT32 or exFAT format.

HDMI: Micro HDMI output, HD 1080P 60/30fps, 1080P 60fps as de-

fault. (Optional)

AV: no AV output

Ethernet: Ethernet/IP output interface, support RTSP/RTMP/UDP/ON-

VIF video streaming. Default: RTSP output, IP address: RTSP:

//192.168.2.119:554, output resolution: 1080P, frame rate: 30fps, bit

rate: 4M. (Optional)

Make sure device is power off when inserting the TF

card, hot plugging is not supported.

3.1 PWM Control

13.

Control the gimbal camera functions by the multiplex pulse width

modulation signal outputted by PWM channel of the remote control

receiver. The camera needs up to 6 control channels of PWM (to

expand tracking function use up to 7 PWM channels). You can choose

needed functions according to actual usage to reduce the required

number of PWM channels.

3.1.1 PWM Connection Diagram (Connect pitch chan-

nel as example)

3. Signal Control

Above output mode is optional. Please subject to

your actual product.

When using user interface software Viewlink for net-

work connection, the network of external device

(computer) should be the IP address: 192.168.2.2

(choose the last byte among 2~254, can not be 119

same as the gimbal), subnet mask: 255.255.255.0,

Default gateway: 192.168.2.1, and all firewalls of the

computer must be closed. Then enter the IP address

of the gimbal camera, Open Video, the video stream

can be outputted.

MULTI

PIC/REC

FOCUS

ZOOM

MODE

YAW

PITCH

14.

PWM IN

GND

5V OUTPUT

Remote Controller

Remote Controller

Connection Diagram

(Standard Version)

Connection Diagram

(Viewport Version)

Receiver

Receiver

3.1.2 PWM Control Operation Instruction

15.

1) Pitch (PWM Pitch channel in to control Pitch. Joystick, rotary knob

or 3-gear switch on remote control are optional. 3-gear switch as ex-

ample.)

2) Yaw (PWM Yaw channel in to control Yaw. Joystick, rotary knob or

3-gear switch on remote control are optional. 3-gear switch as exam-

ple.)

3) Mode (PWM Mode channel in to adjust speed control/one key to

Home position etc functions. Rotary knob or 3-gear switch on remote

control are optional. 3-gear switch as example.)

Low Gear

Pitch Up

Position 1

Middle Gear

Pitch Stop

Position 2

High Gear

Pitch Down

Position 3

Low Gear

Yaw Left

Position 1

Middle Gear

Yaw Stop

Position 2

High Gear

Yaw Right

Position 3

4) Function of continuous switching:

16.

3.1) Operate 1 time continuously and quickly, from position 2 - 3, to

Home position.

3.2) Operate 2 times continuously and quickly, from position 2 - 3 - 2

- 3, the camera lens looks vertically down.

3.3) Operate 3 times continuously and quickly, from position 2 - 3 - 2

- 3 - 2 - 3, to disable Follow Yaw Mode (gimbal yaw not follows by

frame)

3.4) Operate 4 times continuously and quickly, from position 2 - 3 - 2

- 3 - 2 - 3 - 2 - 3, to enable Follow Yaw Mode (gimbal yaw follows by

frame)

Position 1: Low speed mode, control pitch / yaw with this mode at

lowest speed

Position 2: Middle speed mode, control pitch / yaw with this mode at

middle speed

Position 3: High speed mode, control pitch / yaw with this mode at

highest speed

(If it is controlled by rotary knob, the speed will change according to

switch position)

Low Gear

Position 1

Middle Gear

Position 2

High Gear

Position 3

17.

5) Zoom (PWM Zoom channel in to control Zoom. Joystick, rotary

knob or 3-gear switch on remote control are optional. 3-gear switch as

example.)

6) Focus (PWM Focus channel is to control PIP, IR color palette

switch, 3-gear switch as example.)

7) Pic/Rec (PWM Pic/Rec channel in to control take picture and

record. Joystick, rotary knob or 3-gear switch on remote control are

optional. 3-gear switch as example.)

Switch from Position 2 to 1: Picture in Picture. EO+IR , IR+EO, EO

only, IR only. Switch from Position 2 to 3: IR color switching: white hot,

black hot, pseudo color

Low Gear

Zoom Out

Position 1

Middle Gear

Stop Zoom

Position 2

High Gear

Zoom In

Position 3

Low Gear

PIP switch

Position 1

Middle

Gear

Position 2

High Gear

IR color palette switch

Position 3

18.

Switch from Position 2 to 1: Take a picture

OSD display 'REC IMG' a second.

8) Multi: IR digital zoom / tracking control

Low Gear

Position 1

Middle Gear

Position 2

High Gear

Position 3

Low Gear

Position 1

Middle Gear

Position 2

High Gear

Position 3

Switch from Position 2 to 1: IR digital zoom, 1x~4x

Switch from Position 2 to 3:

Exit the tracking, display the cross cursor. Adjust the cross cursor to

lock target object and start tracking

Switch from Position 3 to 2:

Cancel tracking

Switch from Position 2 to 3: Start record / repeat operation to stop

record

Start record, the OSD display rec hh:mm:ss.

Stop record, the OSD display STBY.

3.2 Serial Port / TTL Control

Gimbal Camera Cable

19.

PC

PC

RX

GND

TX

GND

S.BUS

TTX

RXD

GND

TXD

RX-

RX+

TX+

TX-

GND

GANL

CANH

DC5V

RX (White)

TX

RX

GND

TX (Green)

GND (Black)

TTL communication requirements: TTL signal is 3.3V, baud rate:

115200, data bit 8, stop bit 1, no parity, HEX send and receive.

Control Box

Viewport Control Box

USB to TTL Cable

USB to TTL Cable

Connection Diagram Standard Version

Connection Diagram Viewport Version

Connection Diagram (PC - USB to TTL Cable- Gimbal Camera as

example):

Table of contents

Other Viewpro Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Critical Environment Technologies

Critical Environment Technologies YES IMS Operation manual

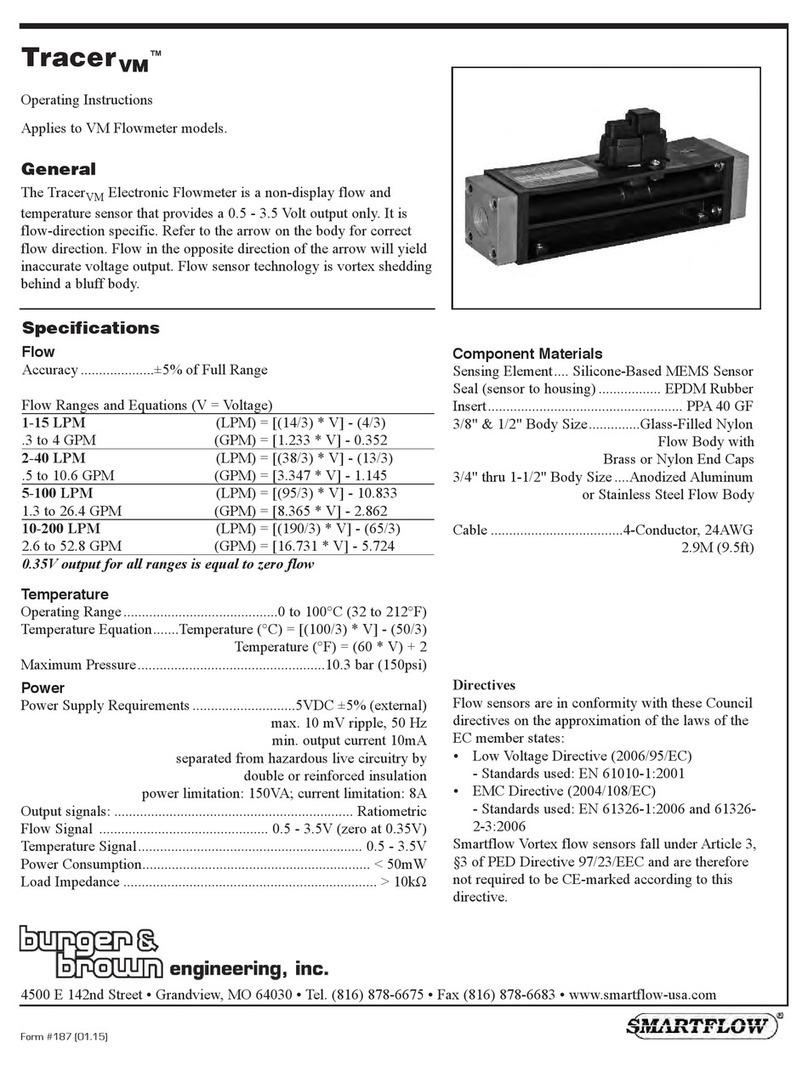

Smartflow

Smartflow Tracer VM Series operating instructions

BRONKHORST

BRONKHORST mini CORI-FLOW ML120 instruction manual

PeakTech

PeakTech 2705 Operation manual

Bushnell

Bushnell Hybrid Laser GPS user manual

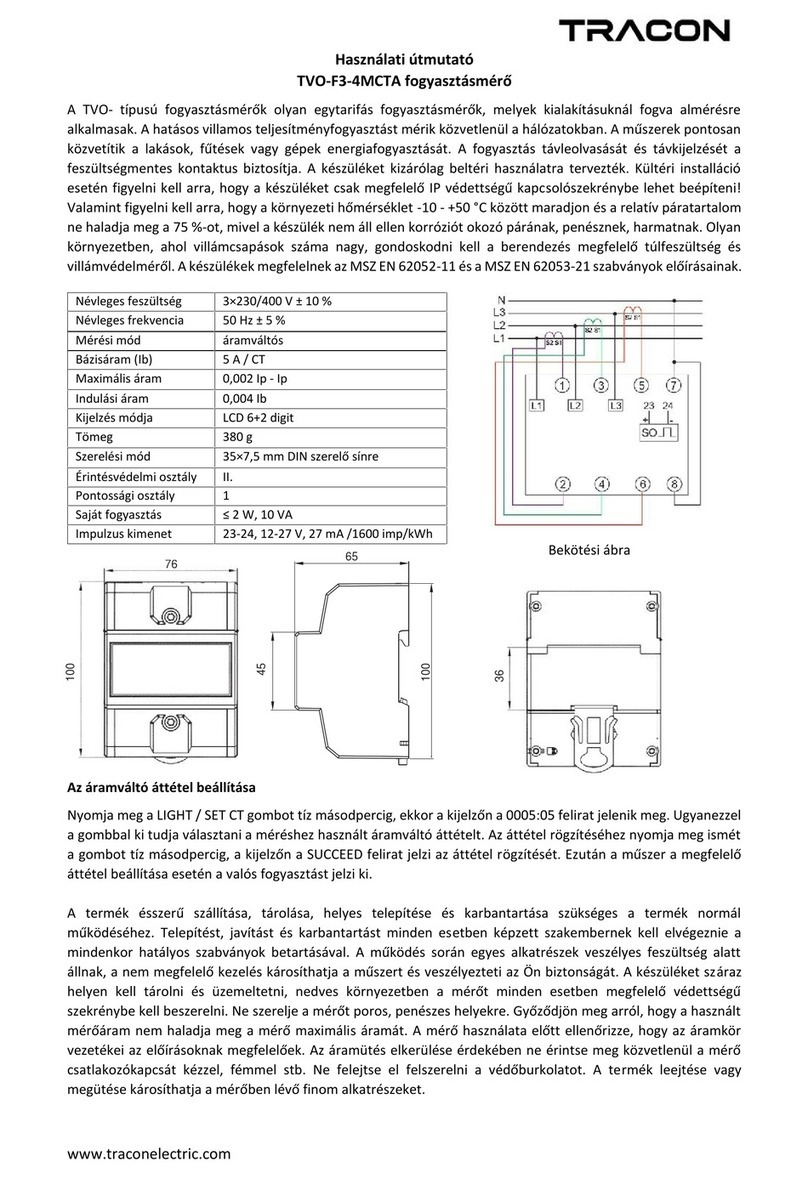

Tracon

Tracon TVO-F3-4MCTA user manual

HBM

HBM FS22 SI user manual

National Instruments

National Instruments NI PXI-6541 Getting started guide

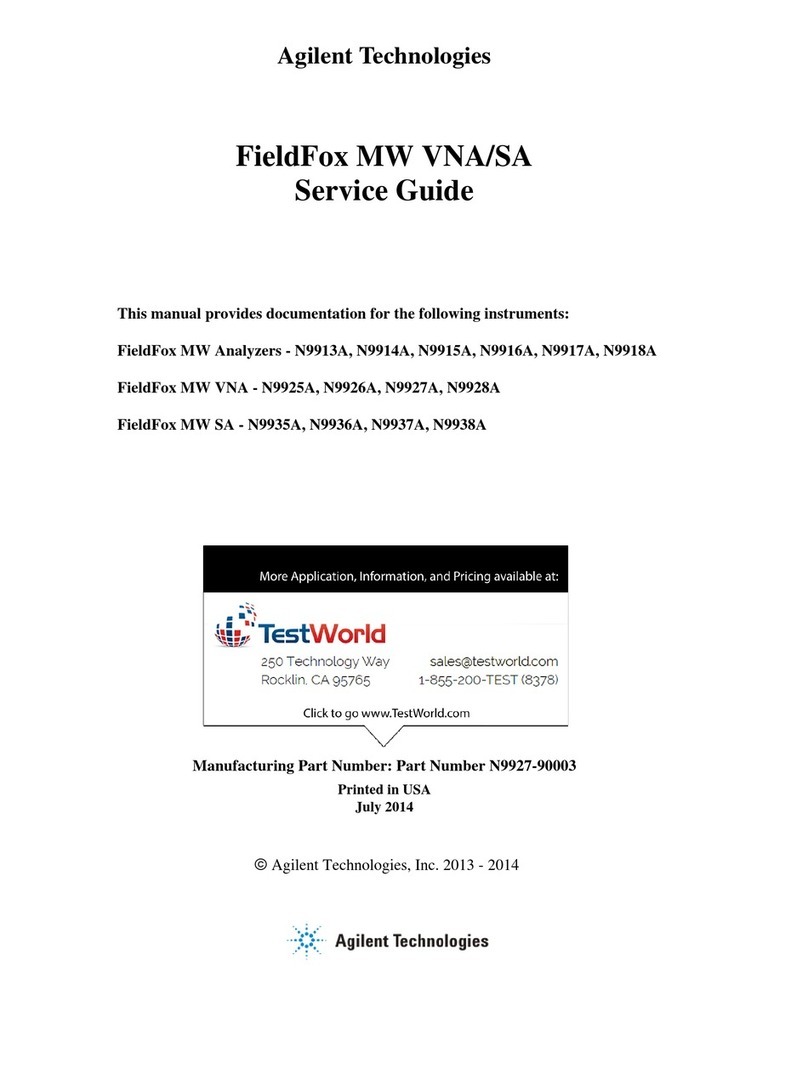

Agilent Technologies

Agilent Technologies FieldFox MW N9913A Service guide

Stocks AG

Stocks AG MM 117A Installation, Calibration and Operation

Thermo Scientific

Thermo Scientific Orion Star A111 reference guide

Topcon

Topcon ES-62 instruction manual