STOCKS AG –MICROMETER APPLICATOR CONTROL SYSTEM

7

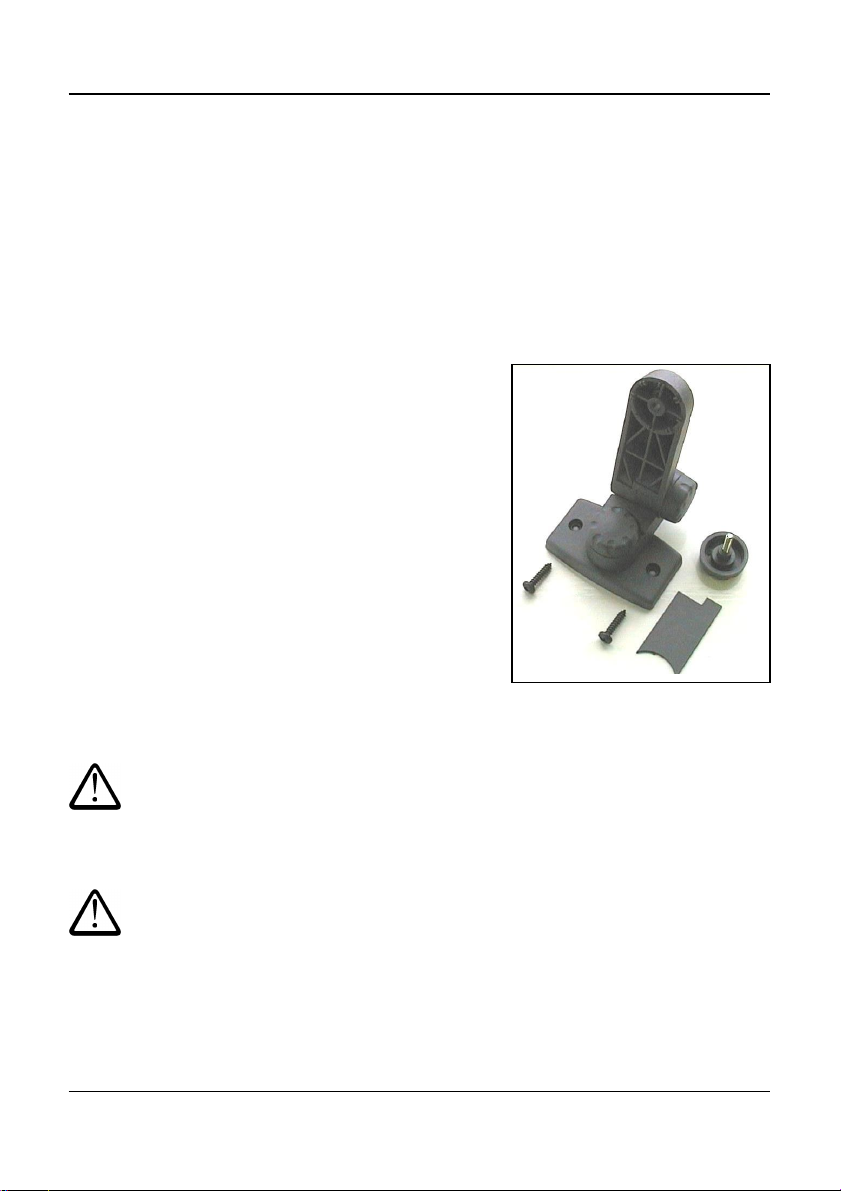

2.2 The Head Unit

Confirm with the operator on where to mount the head unit in the cab. It must

not restrict the view out of the cab, nor impede the use of the controls. The

head unit is fitted with a 1-metre flying lead terminating with an 8/10-way IDC

type connector, ready for connection into the "Terminator" junction box.

The head unit is supplied with mounting kit ref: TJ235 comprising the following

parts (fig. 2):

1 Long Bracket

1 Short Bracket

3 Clamping Knobs

1 Cover Plate

1 Mounting Plate

2 Self Tapping Screws

1. Snap the cover plate into the recess of the

long bracket (it only fits one way).

2. The instrument mount is designed to offer

maximum flexibility in positioning the

head unit, either from the right hand side

of the cab, from the dashboard or from an

overhead position.

Assemble the two brackets, and mounting

plate with clamping knobs, and attach to

the head unit.

NOTE: Either the long or short bracket can be

attached to the head unit, whichever gives

the most suitable orientation.

Having established the orientation for the

bracket, fix the mounting plate to the cab

with the self-tapping screws provided.

Do not drill into a ROPS or FOPS frame.

If you are fixing the mounting plate to plastic e.g. the dashboard or other cab

moulding, it is recommended to use M4 screws with mudwing washers to

strengthen the mounting point.

Do not attempt to adjust the mounting bracket assembly without first

slackening off the clamping knobs sufficiently. You will only succeed in

damaging the bracket otherwise.

Figure 2 : Head Unit Mounting Kit