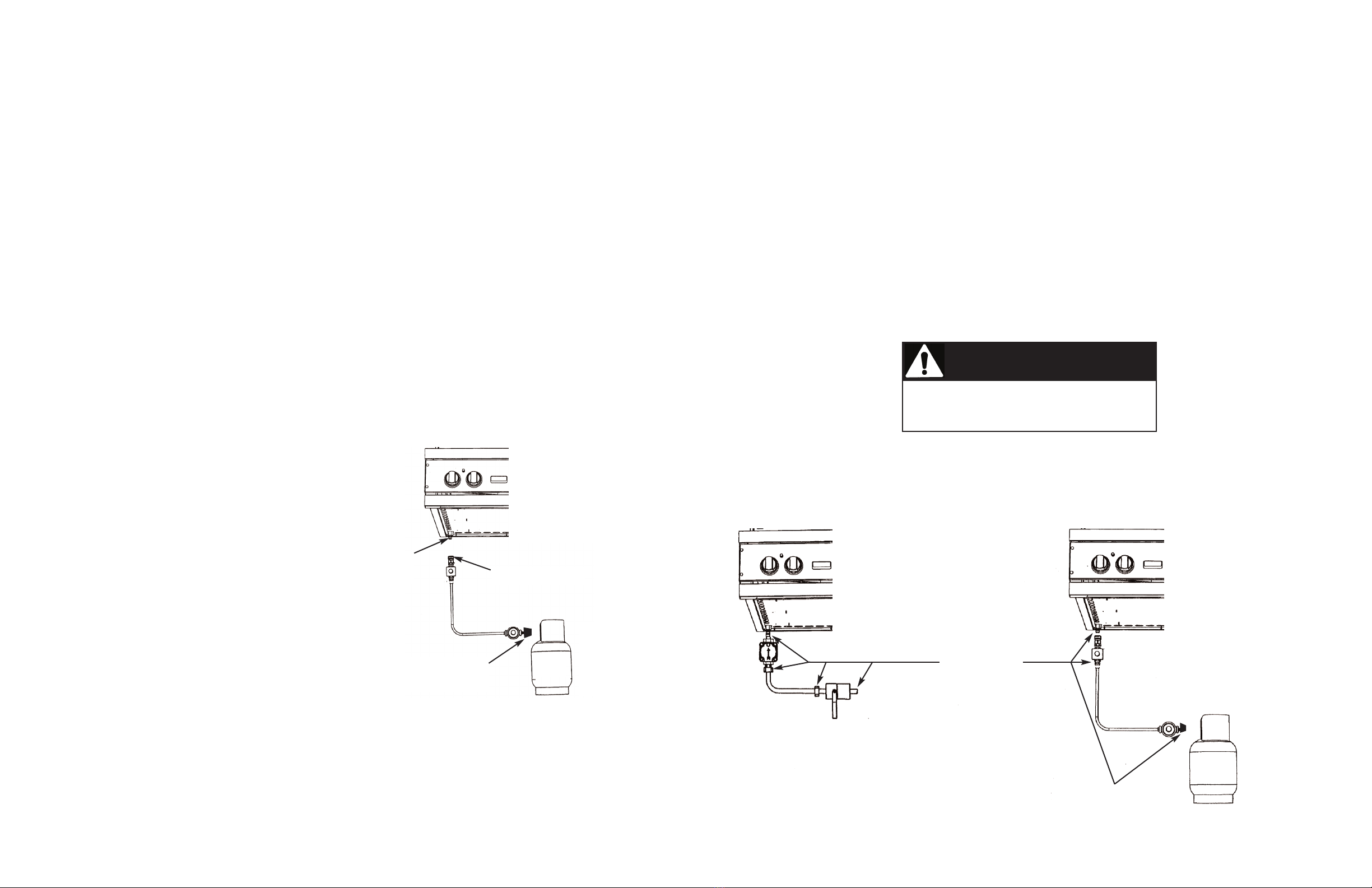

GAS CONNECTION

Verify the type of gas supply to be used, either natural or LP, and make sure the marking on the rating plate agrees

with that of the supply. Never connect an unregulated gas line to the appliance. An installer supplied gas shut-off

valve must be installed in an easily accessible location. All installer supplied parts must conform to local codes, or in

the absence of local codes, with the National electrical Code, ANSI/NFPA 70 and the National Fuel Code, ANSI

Z223.1. In Canada: Installation must be in accordance with the current CAN/CGA-B149.1, Natural Gas Installation

Code or CAN/CGA-B149.2, Propane Installation Code and/or local codes. All pipe sealants must be an approved type

and resistant to the actions of LP gas. Never use pipe sealant on flare fittings. All gas connections should be made by

a competent technician and in accordance with local codes and or ordinances. In the absence of codes, the installation

must comply with the National Fuel Gas Code ANSI Z223.1.

The gas side burner and its individual shut-off valve must be disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in excess of 1/2 PSIG (3.5 kPa). The unit must be isolated from the

gas supply piping system by closing its individual manual shut-off valve during any pressure testing of that system at

test pressures equal to or less than 1/2 psi (3.5 kPa).

Built-in installations must be plumbed using a fixed/hard line if the unit is going to be operated at a

distance exceeding 3 feet (0.91 meters) from the fuel supply per ANSI Z21.24.

3

BASIC SPECIFICATIONS

IMPORTANT:PLEASE READANDFOLLOW

1. Before beginning, please read these instructions completely and carefully.

2. Do not remove permanently affixed labels, warnings, or plates from product. This may void the warranty

3. Please observe all local and national codes and ordinances.

4. The installer should leave these instructions with the consumer who should retain for local inspector’s use and for

future reference

Installation must conform with local codes or in the absence of codes, the National Fuel Gas Code, ANSI Z223.1.

In Canada: Installation must be in accordance with the current CAN/CGA-B149.1, Natural Gas Installation Code or

CAN/CGA-B149.2, Propane Installation Code and/or local codes.

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. Open lid.

4. If odor continues, immediately call your gas supplier or your

fire department.

1. Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

2. Any LP cylinder not connected for use shall not be stored

in the vicinity of this or any other appliance.

If not installed, operated and maintained in

accordance with the manufacturer’s instructions, this

product could expose you to substances in fuel or

fuel combustion which can cause death or serious

illness and which are known to cause cancer, birth

defects or other reproductive harm.

For example, benzene is a chemical which is

part of the gas supplied to the cooking

product. It is consumed in the flame during

combustion. However, exposure to a small

amount of benzene is possible if a gas leak

occurs. Formaldehyde and soot are by-

products of incomplete combustion. Properly

adjusted burners with a bluish rather than

yellow flame minimize incomplete combustion.

2

FOR YOUR SAFETY WARNING

FOR YOUR SAFETY

GENERAL INFORMATION

WARNING:This outdoor gas side burner is not intended to be installed in or on recreational vehicles

and/or boats.

WARNING: Keep electrical supply cord and the fuel supply hose away from heated surfaces.

• Keep area clear and free from combustible materials, gasoline, and other flammable vapors.

• When the outdoor gas side burner or grill is not in use, the gas supply must be turned off at the LP gas supply

cylinder.

• The pressure regulator and hose assembly supplied with the unit must be used. Replacement pressure regulators

and hose assemblies must be those specified by the manufacturer.

• Finding a leak is not a “do-it-yourself” procedure. Some leaks can only be found with the burner control in the on

position and this must be done by a qualified technician.

• The LP supply cylinder to be used must be constructed and marked in accordance with the specifications for LP-

gas cylinders of the U.S. Department of Transportation (DOT) or the National Standard of Canada, CAN/CSA-

B339, Cylinders, Spheres, and Tubes for the Transportation of Dangerous Goods.

• Gas Manifold Pressure -

Natural gas - 4.0” W.C.P.

LP/Propane - 10.0” W.C.P.

• If the following instructions are not followed exactly, a fire causing death or serious injury may occur:

-Do not store a spare LP gas cylinder under or near this appliance.

-Never fill the cylinder beyond 80 percent full.

SAFETY TIPS

•Keep outdoor cooking appliance area free from combustible materials, gasoline and other flammable vapors and

liquids.

•Keep ventilation openings at the rear of the cart and cylinder free and clear to allow proper air flow. Do not obstruct

the flow of combustion and ventilation air.

•Spiders and insects can nest in the burners of the grill and block the gas and air flow to the burner ports. This may

cause a fire from behind the manifold cover. Inspect and clean burners periodically.

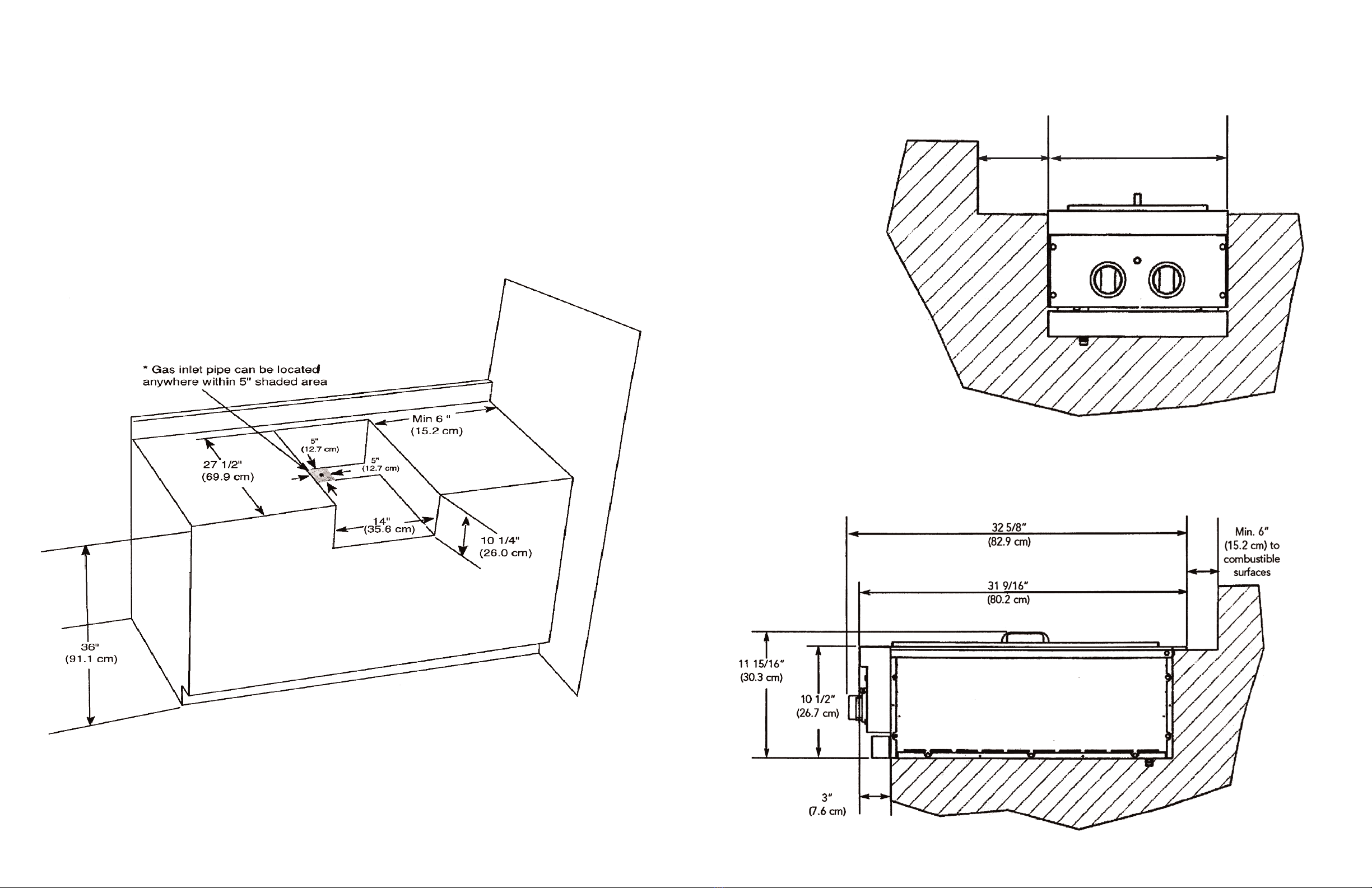

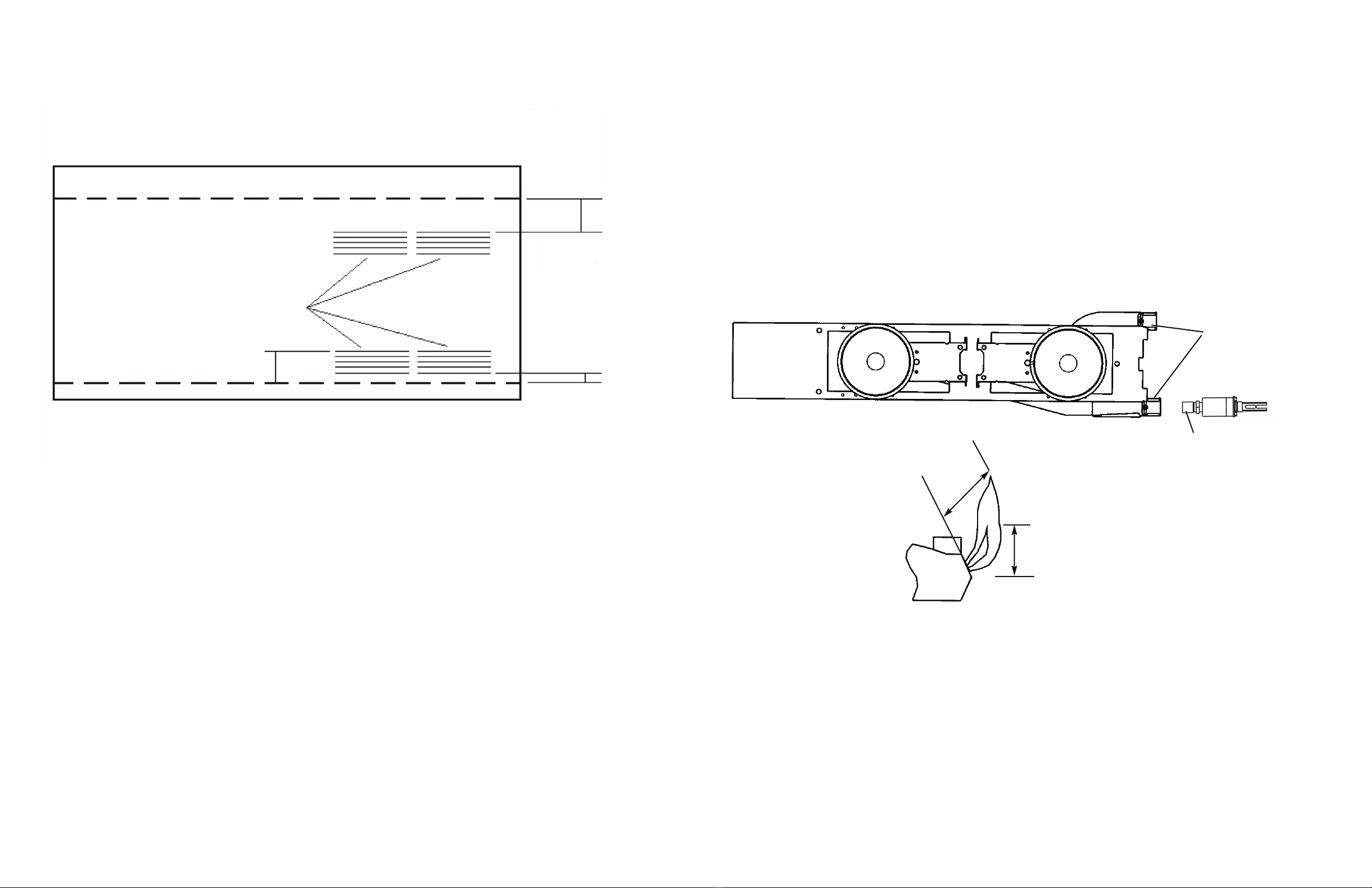

DescriptionVGSB5152

Overall Width 15-5/16” (38.9 cm)

Overall Depth To end of landing ledge 31-9/16” (80.2 cm)

To end of knobs 32-5/8” (82.9 cm)

Overall Height To cooking surface 10 1/2” (26.3 cm)

Cutout Width 14 ” (35.6 cm)

Cutout Depth 27-1/2” (69.9 cm)

Cutout Height 10-1/4” (26.0 cm)

Gas Requirements Natural: standard residential 1/2” (1.3 cm) ID gas service line.

LP/Propane: equipped with high capacity hose/regulator assembly for connection

to standard 5 gal, 20 lb. LP/Propane gas cylinder with Type 1, QCC-1

connection or standard residential 1/2” (1.3 cm) ID gas service line.

Side Burner Rating (2) - 15,000 BTU Nat./13,500 BTU LP

(4.4 kW Nat./4.0 kW LP)

Approximate Shipping Wt. 80 lbs. (36.3 kg) 55 lbs. (24.8 kg)