4

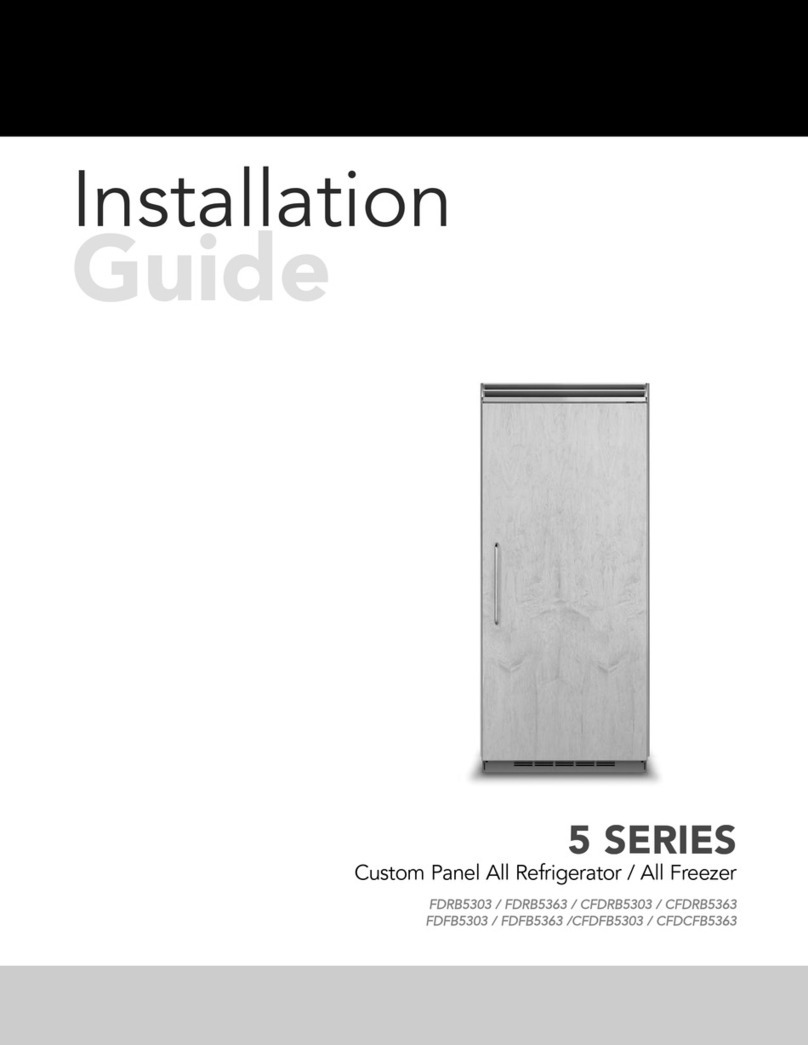

Door Swing Pin (Flush head, 1/8” allen drive)

Top Hinge

Bracket

Bottom Hinge

Bracket

Door Swing Pin

(Round head, Phillips)

Light Switch Activator

AREA REQUIREMENTS

UUnniittss CCeerrttiiffiieedd ffoorr nnddoooorr UUssee -- ((bbllaacckk oouutteerr ccaabbiinneett))

MUST BE NSTALLED N AN AREA PROTECTED FROM THE ELEMENTS, SUCH AS W ND, RA N, WATER (SPRAY OR

DR P).

1. Place unit so the front side will be completely unobstructed to provide proper air flow. The unit may be closed in

on the top and three sides, but the front MMUUSSTT BBEEunobstructed for air circulation and proper operation.

nstallation should be such that the cabinet can be moved for servicing if necessary.

2. Unit should be in a well ventilated area with temperature above 550F (130C) and below 1100F (430C). Best results

are obtained at temperatures between 650F (180C) and 800F (270C) for built-in products and 650F (180C) and 900F

(320C) for freestanding products.

3. Provisions for electricity should be determined before placing unit in proper place.

UUnniittss CCeerrttiiffiieedd ffoorr OOuuttddoooorr UUssee -- ((ssttaaiinnlleessss sstteeeell oouutteerr ccaabbiinneett))

1. Place unit so the front side will be completely unobstructed to provide proper air flow. The unit may be closed in

on the top and three sides, but the front MMUUSSTT BBEEunobstructed for air circulation and proper operation.

nstallation should be such that the cabinet can be moved for servicing if necessary.

2. Unit should be in a well ventilated area with temperature above 400F (4.40C) and below 1100F (430C). Best results

are obtained at temperatures between 600F (160C) and 1000F (380C).

3. Provisions for electricity should be determined before placing unit in proper place.

REVERSIBLE DOOR

Professional Series

(Glass Door Units Only)

You can change the door swing from right to left hinge very easily.

1. Simply unscrew the top hinge door swing pin with an 1/8”

allen drive unit and lift door off of the bottom hinge bracket.

Flip the door, remove the light switch activator and replace the

light switch activator on the other end of the door.

2. Remove the door swing pin from bottom right hinge. Move

the bottom, right hinge bracket to the upper, left side of the

cabinet and fasten it in place with its original mounting screws.

3. nstall the hinge door swing pin into the top right hinge bracket

and move the bracket to the lower left side of the cabinet.

Fasten it in place with its original screws.

4. Place the plastic washer over the bottom door swing pin on

the top surface of the bottom, left hinge.

5. Position the door on the bottom, left hinge pin and push the

door under the top, left hinge.

6. Line-up the top left hinge hole with the door bushing hole and

insert swing pin. Screw down the door swing pin with the

1/8” allen drive unit until its head is flush with the top surface

of the top, left hinge.

7. Reposition the logo. Your installation is now complete.

GENERAL INFORMATION

UUnnppaacckk

1. Remove banding from bottom of carton. Lift carton up and off of the unit.

2. Remove all tape and packaging material from the outside and inside of the cabinet.

3. Keep all carton packaging until your refrigerated beverage center has been thoroughly inspected and found to be in

good condition.