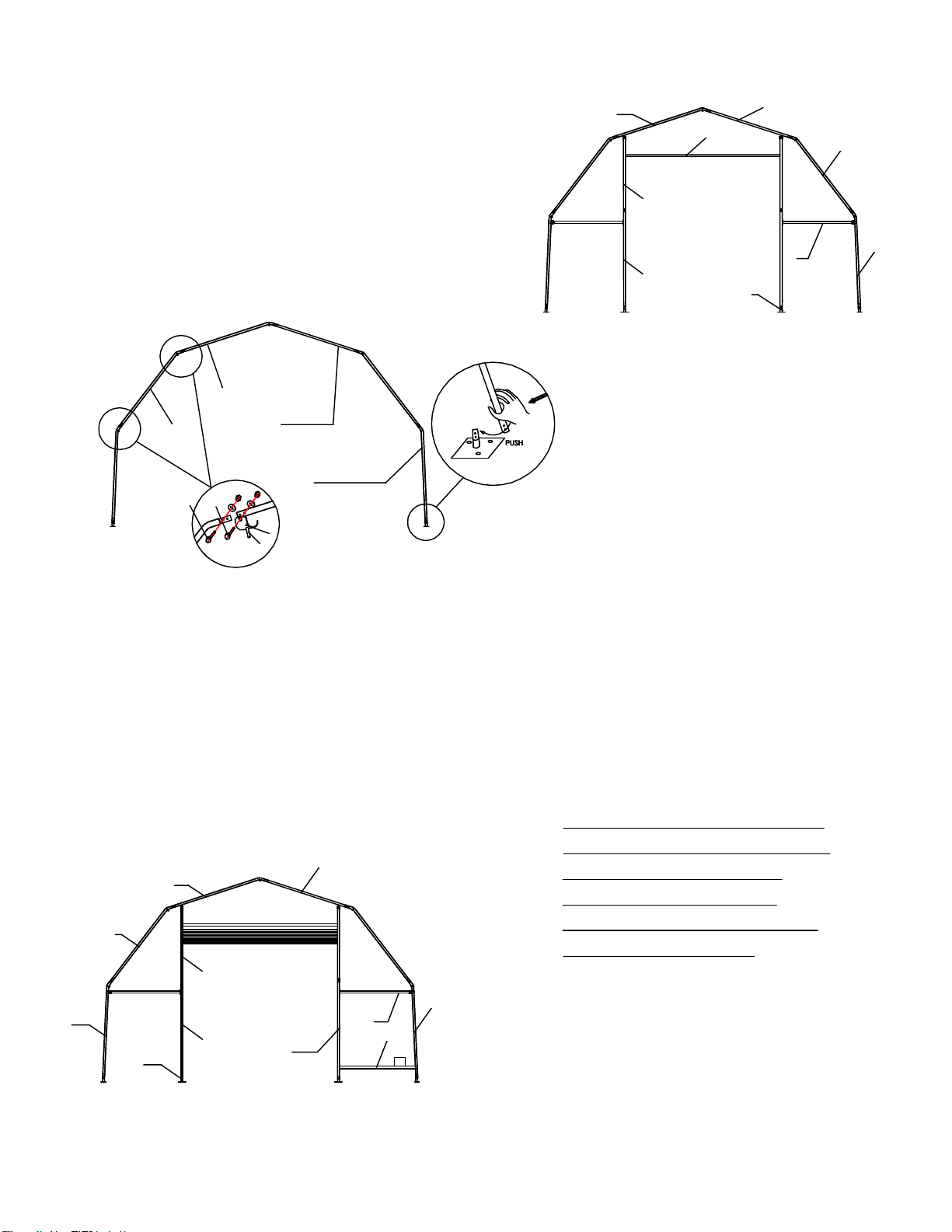

Congratulations on your purchase of our instant shelter. This unit is a combination of

excellent manufacturing and design. It is comprised of a rigid frame and a durable cover. For

easy assembly, we have marked all the parts with codes. With proper installation, use and

maintenance, your unit will provide many years of good and suitable service.

READALLTHE INSTRUCTIONS BEFOREASSEMBLY!

1. The proper erection and installation of this building requires a high level of care and safety.

We recommend the safety regulations be complied with during the installation. It includes

but is not limited to:

-Safety hats, protective eyewear and protective clothing

-Safety harnesses for all elevated workers

-Proper ladder, cage, and safety operation

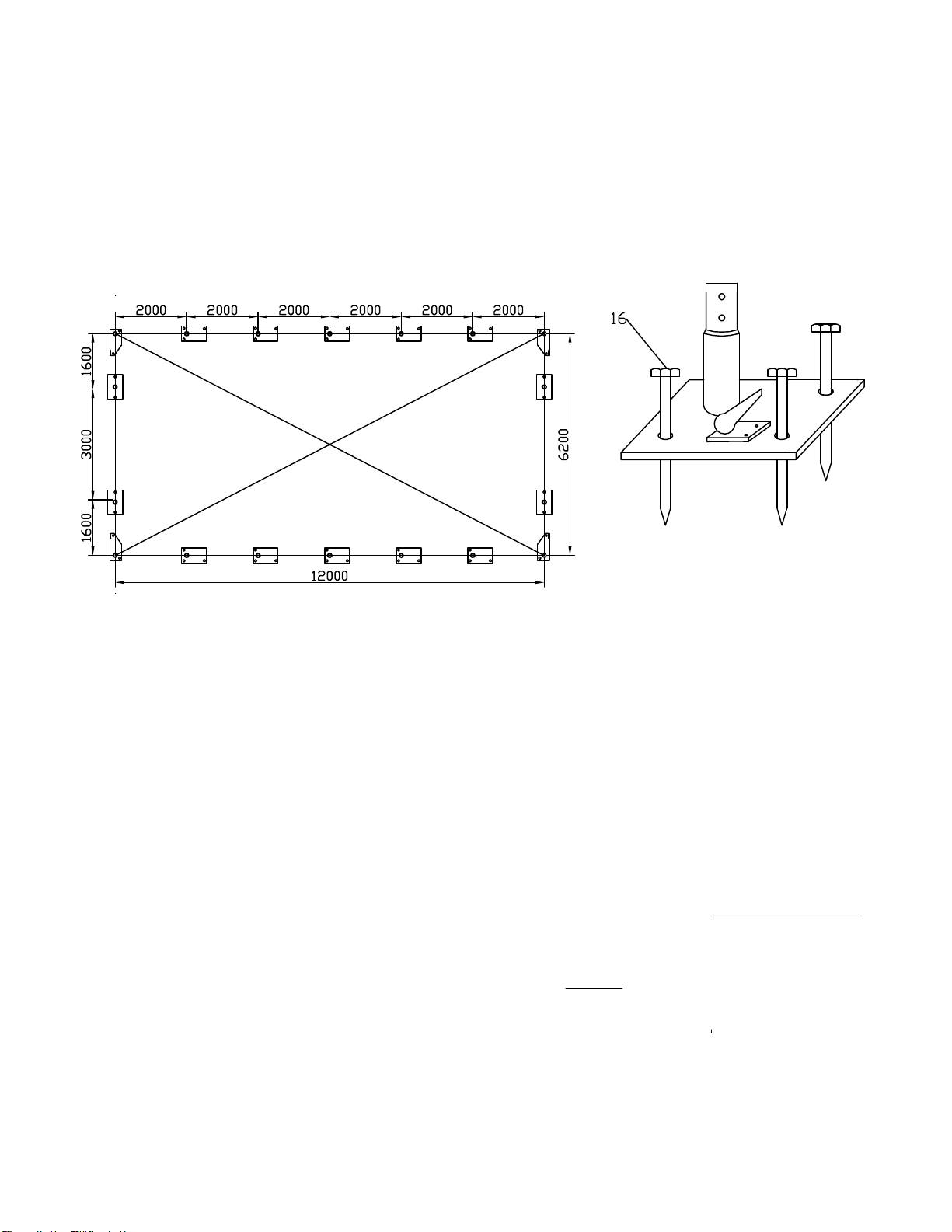

2. Site selection: Choose a solid level location for your building. Do not install the building

where the ground could not keep the building steady. Do not install the building where the

ground could not bear the weight of the building. Do not install the building in soft grass

ground or wetland.

3. Be cautious with the surroundings. Keep work area clean. Do not set up it near snow drifts, in

slippery places, or in wet location. The cover of the building will protect against normal

falling leaves and light debris, however, large, fast or sharp falling items etc. may cause a

puncture or tear in the cover material. So, keep the building away from such harmful things.

Be careful with power and heat sources. Don’t keep heat sources near the tarpaulin. Don’t

expose to open flame.

4. Chose a windless day to install the building. It is very difficult to attach the cover in heavy

wind.

5. All snow accumulation on the main cover should be removed as soon as possible. Otherwise,

when old snow on the roof becomes hard with new snow falling in, it will increase the

burden of the roof badly and will damage the roof.

6. Try to keep the building, especially its base, in a dry condition. This will help the building to

have a longer life than keeping it in a wet condition.

7. The user should be responsible for the parts missing or damage occurred during the

installation.

8. Don’t make alteration of the frame. Don’t hang anything besides included parts to the frame.

Damages, consequential damages, or injuries caused by improper installation, alteration,

improper use, or damages caused by snow, wind, or any acts of nature are owing to the user.

The building is not intended for occupancy for any length of time.