Vinotemp VT -WINEDRAW4 User manual

Other Vinotemp Beverage Dispenser manuals

Vinotemp

Vinotemp VT-WINED RAW4 User manual

Vinotemp

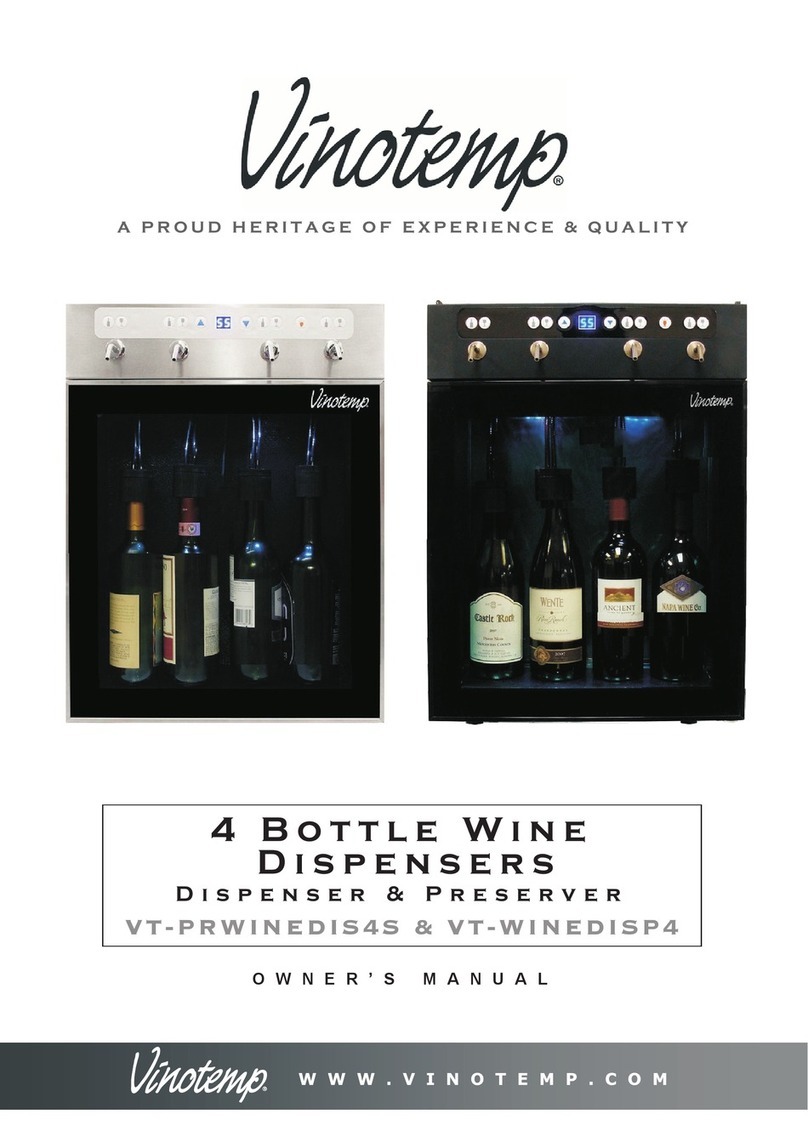

Vinotemp VT-WINEDISP4 User manual

Vinotemp

Vinotemp VT - PONYKEG User manual

Vinotemp

Vinotemp VT-WINEDISP4 User manual

Vinotemp

Vinotemp VT-WINEDISP4 User manual

Vinotemp

Vinotemp VT-WINEDISP2 User manual

Vinotemp

Vinotemp VT-WINEDISP2 User manual

Vinotemp

Vinotemp VT-WINEDISP2 User manual

Vinotemp

Vinotemp VT-WINEDISP4SS User manual

Vinotemp

Vinotemp Butler Series User manual

Popular Beverage Dispenser manuals by other brands

Marvel

Marvel ML24BN Series Installation, operation and maintenance instructions

Cecilware

Cecilware 2K-GB-LD Catalog

Sure Vend

Sure Vend 673 Setup guide

Cornelius

Cornelius 2 Flavor Post-Mix Cold Coffee Dispenser Quest... Technical specifications

Nostalgia Electrics

Nostalgia Electrics KEG7000SS instruction manual

Bunn

Bunn LCR-3 HV Installation & operating guide