4

Safety and Warnings

Cleaning and Maintenance

CAUTION! Do not use solvent or oil-based cleaners,

abrasives or wire brushes to remove accumulations of

dirt as these damage the protective surfaces. To clean

mechanical surfaces, use only detergent-based cleaners

CAUTION! Do not use oil or grease on any exposed part

of the product. This is unnecessary and traps dirt which

acts as an abrasive

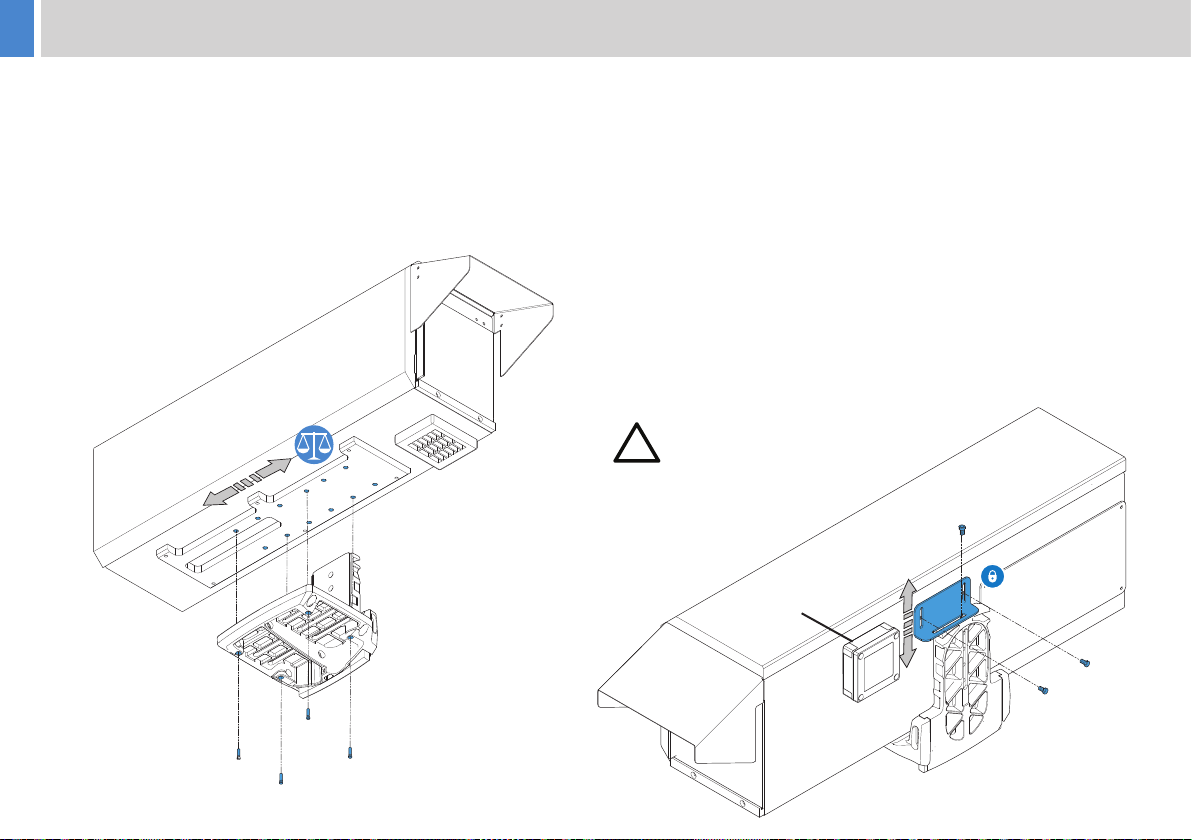

WARNING! The tilt lock MUST be engaged whenever

the head is lifted or transported and before installing or

adjusting the camera or payload. See head manual.

WARNING! Risk of electric shock. Always disconnect

and isolate the product from the power supply before

cleaning.

These are IP rated products. Any modication not

described in this manual could void IP rating warranty.

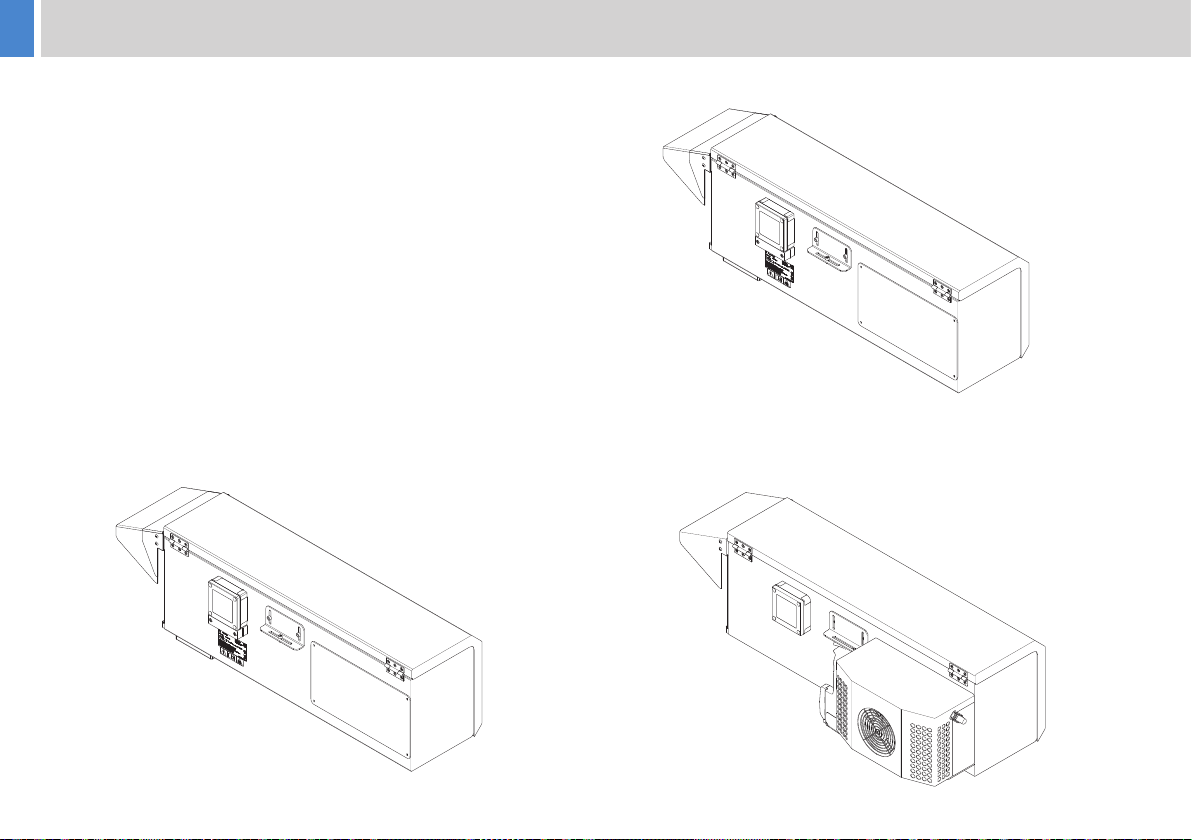

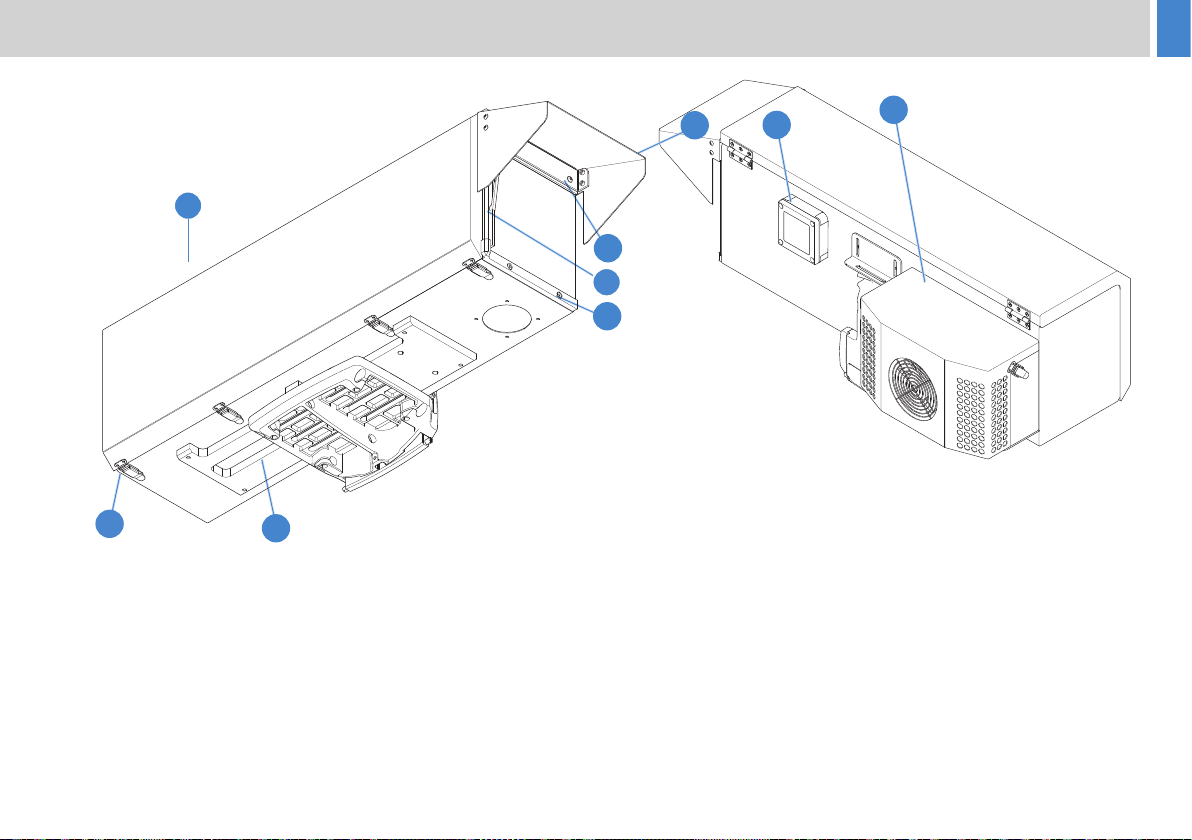

Mounting and Installation

WARNING! Always ensure that all power and auxiliary

communications cables are routed so that they do not

present any danger to personnel. Take care when routing

cables in areas where robotic equipment is in use.

CAUTION! Perform a risk assesment before mounting

or adjusting the enclosure. Where possible move or

adjust the enclosure with 2 people. Adjustments should

only be made by trained personnel.

CAUTION! Only install this equipment on a support

system rated for the load. Ensure support structures (such

as scaolding, cranes or building elements) are suciently

strong for the whole system and all weather conditions,

access for tting and maintenance is safe and secure.

CAUTION! Use the tilt lock provided when working on the

enclosure, and release it when leaving the site.

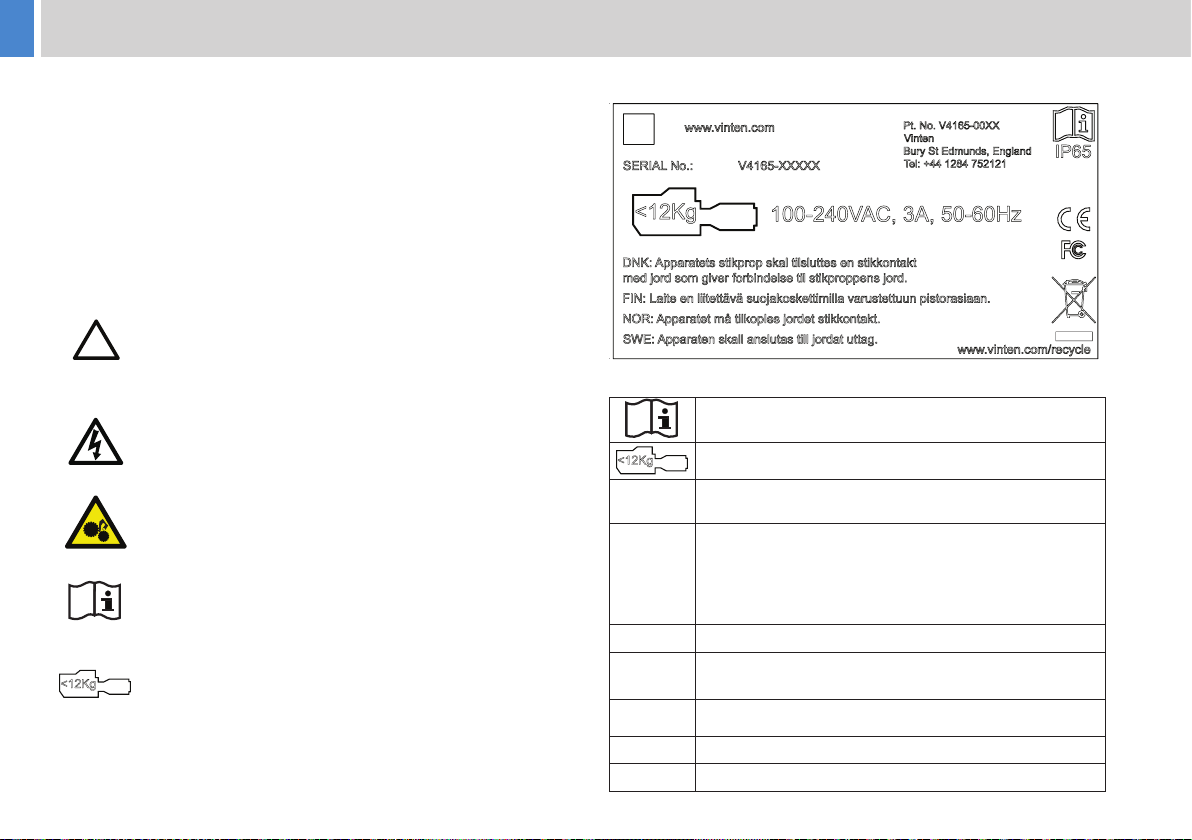

CAUTION! Enclosure Mass 23Kg, Enclosure Payload:

12Kg Maximum, Total mass with payload 35Kg.

CAUTION! The enclosure is only to be used with the

xing plate underneath the assembly (lid to the top), never

upside down.

WARNING! Open the lid fully so it rests on the top of the

cradle area and secure. If closed by the wind or by gravity

it may cause injury to ngers, be damaged, or cause the

user to fall.

CAUTION! The glass window is fragile. Avoid tapping the

edges of the glass with hard objects.

CAUTION! Tilt range from horizontal (horizon), glass

towards the ground 90˚, avoid pointing lens towards the

sky as much as possible. Do not direct the glass directly

towards the sun.

WARNING! When mounted at height it is recommended

that secondary protection against falling is installed, such

as a net below the product or securing cables. These

should be suitable of supporting the weight of the product

and its payload should the primarily mounting method fail.