Tools needed (not supplied)

1. Philips screwdriver

2. Pair of pliers or a 5.5 mm spanner wrench

3. Small flathead screwdriver.

Figure 2 (Tools needed)

1. Disconnect the Cougar from the computer,

2. Disconnect the throttle from the stick base and set it aside.

3. Unscrew the stick from its mounting by unscrewing the big fastening nut.

4. On each of the corners on the bottom of the stick base you will locate a screw.

Unscrew them and put the screw away you we need these later again.

Take the bottom cover out of its position and lay it aside.

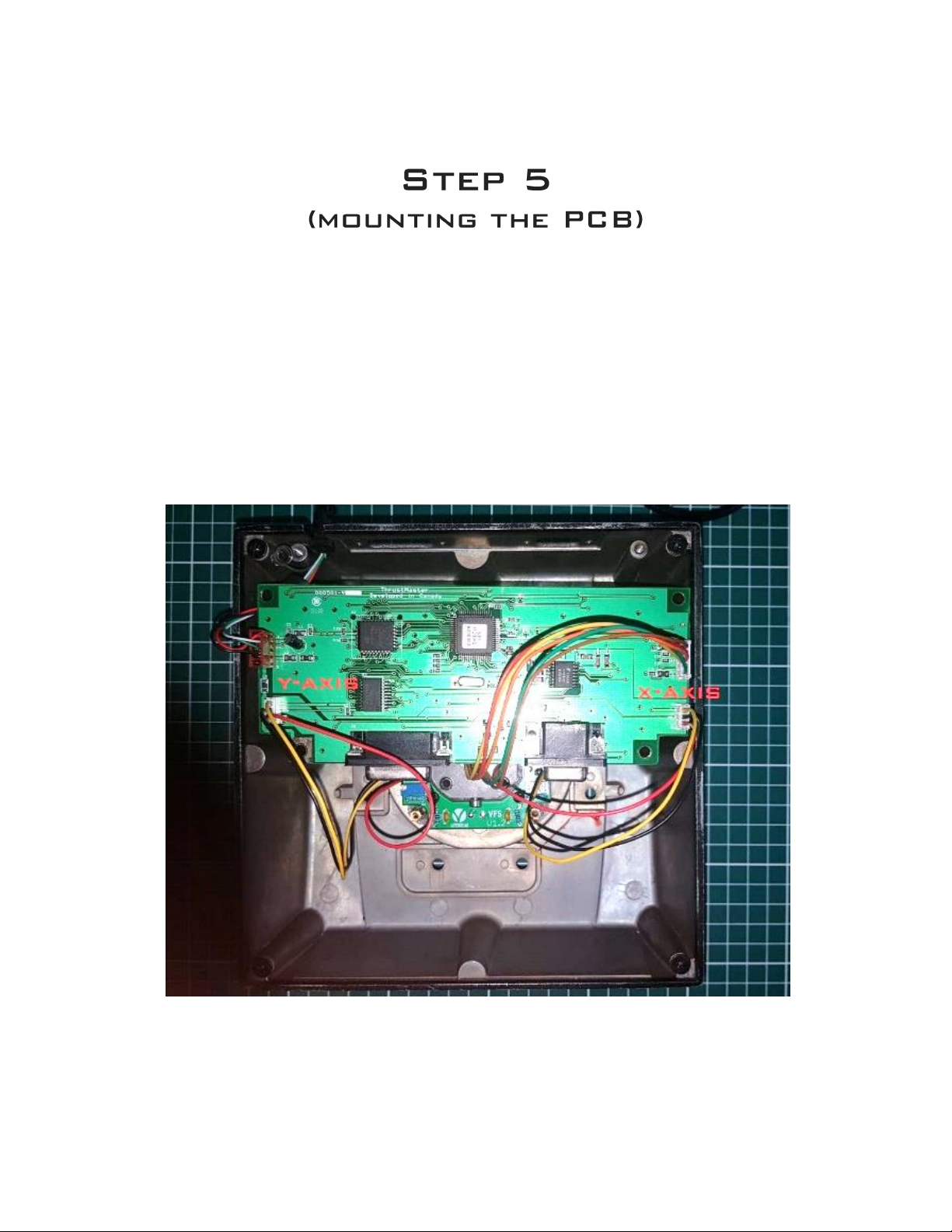

5. The printed circuit board (PCB) is now visible.

Again on each corner of the PCB there is a screw.

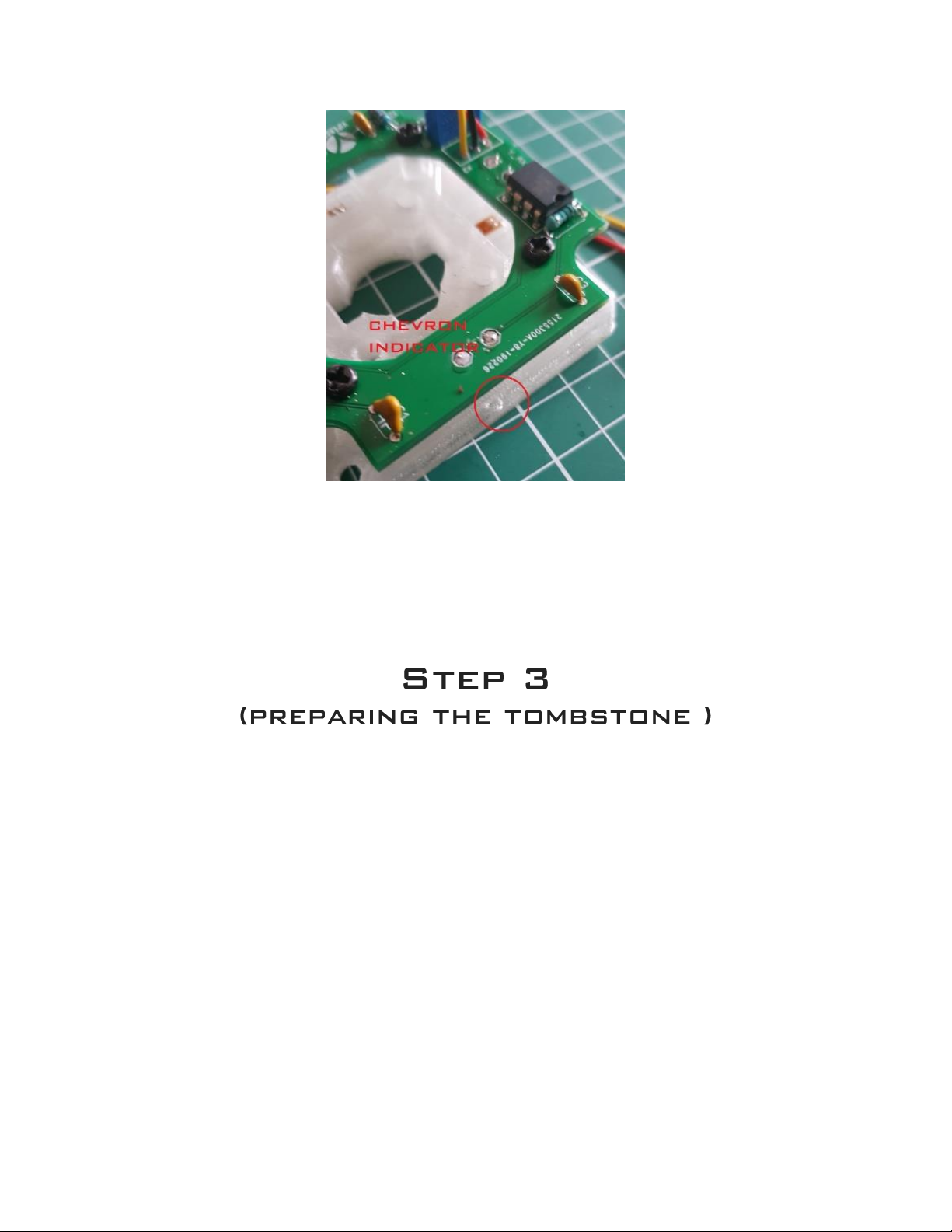

Unscrew and set the screws aside (figure 3).

6. Turn over the PCB and disconnect the two pot meter cable and the cable that comes out

of the stick.

You can leave the USB connector connected on the PCB, pull the USB cable out of the

Cougar stick base. Lay the PCB away.

7. The gimbals are screwed in there with eight screws, unscrew these.

Best way is to use the supplied 3/32 allen key and a pair of pliers to grab the nut on the

inside. Once the gimbal is unscrewed you need to wiggle it out of its place.

Best way to get the stick mount out of the base is to pull it out in an angle.

8. All we need from the gimbal is the threaded(stick mount) part in which the stick is placed.

(stick mount)

9. The rest of the gimbal can be stored somewhere safe.

To get the stick mount out of the gimbal gently pry of locking ring(figure,4) with a little