Maintenance schedule Visatron VN2020

By conducting regular maintenance, the product will have a long service life. If the maintenance intervals are not

observed, the oil mist detector may fail prematurely. It is essential that you follow the given sequence for the work.

NOTE: All maintenance steps should be performed while engine is stopped!

•M1 | Clean infrared sensors in measuring head

and replace seal on inspection cover.

•M2 | Exchange seal on connection box and

check bellows and suspension system between

measuring head and base plate for damage.

•M3 | Exchange filter in pressure regulator and

check negative pressure in measuring head.

•M4 | Clean suction/pipe system with

compressed air.

•M5 | Functional test with smoke test to be

carried out.

Every 6

months or

4 000

operating

hours.

(whatever

comes first)

Maintenance kit

for VN2020 -

small kit –Part

no.: 155003

Cleaning kit –

Part no.: 151482

Smoke test kit –

Part no.: 151780

Main two-year service (2 years) by authorized and

certified Schaller personnel only!

•Service and test of complete Oil Mist Detector

installation incl. software check and upgrade if

necessary.

•Replacement of mayor part kit for VN2020.

•Service certificate to be approved by authorized

personnel!

Please contact us for authorized personnel at:

Every 24

months or

16 000

operating

hours.

(whatever

comes first)

Maintenance kit

for VN2020 –

Part no.: 155004

Cleaning kit –

Part no.: 151482

Smoke test kit –

Part no.: 151780

Main two-year service (2 years) by authorized and

certified Schaller personnel only!

•Perform procedure 1 & procedure 2.

•Replace measuring head or complete oil mist

detector.

Please contact us for authorized personnel at:

Every 48

months or

32 000

operating

hours.

(whatever

comes first)

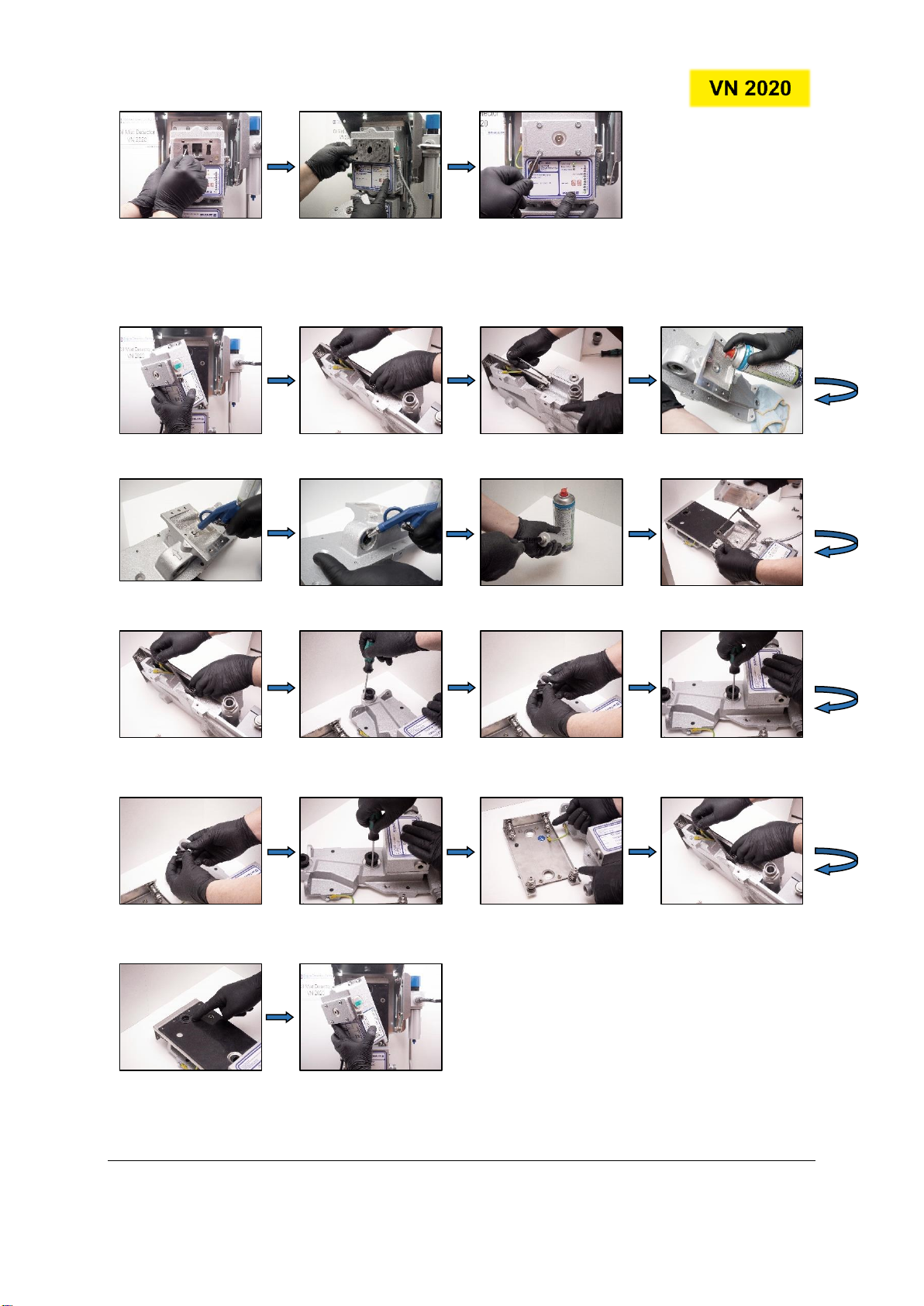

Procedure 1:

M1 | Clean infrared sensors in measuring head and replace seal on inspection cover.

1. Loosen the captive

screws on the inspection

cover.

2. Open the inspection

cover.

3. Use the cleaning fluid

and cotton sticks.

4. Clean the glass on the

transmitter diode on the

right side until it is clean.