© 2018

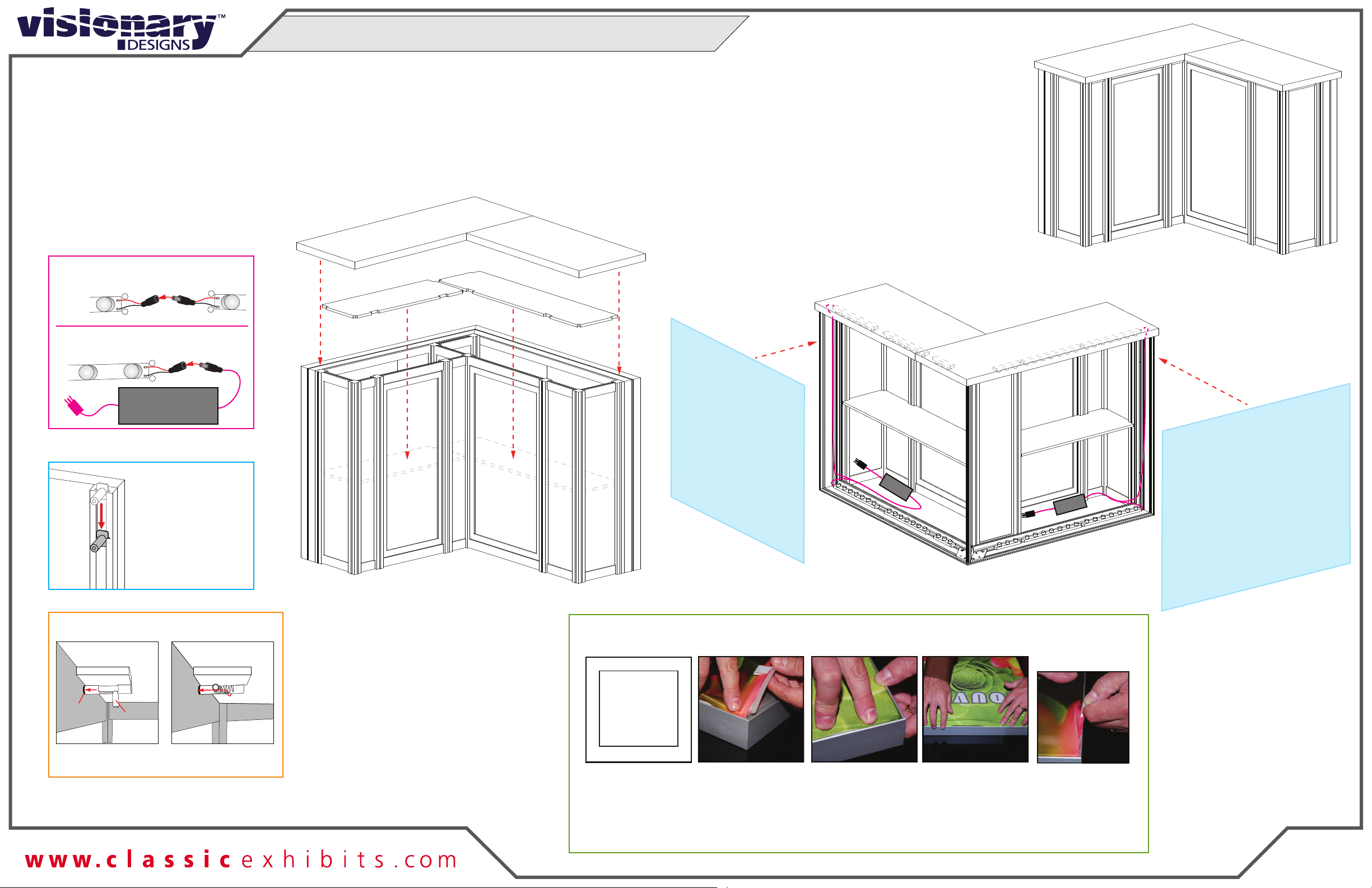

Step 3 of 3

Order #XXXXX

Completed Assembly

Back View

Counter Top

Counter Top

Shelf Shelf

Transformer Transformer

Steps:

1) Connect lighting power cords and attach

transformers. See Light to Light Connection

& Light to Transformer Connection details.

2) Place Shelves onto pins. See Shelf Pin detail.

3) Place Counter Top on top of assembed counter base.

See Counter Top Attachment detail.

4) Install SEG graphics to front of assembled frames.

See SEG Graphic Installation detail.

BACK VIEW FRONT VIEW

Graphic Removal

To remove the graphic from

the frame, locate the fabric

pull tab.Gently pull up on the

tab to remove the fabric.

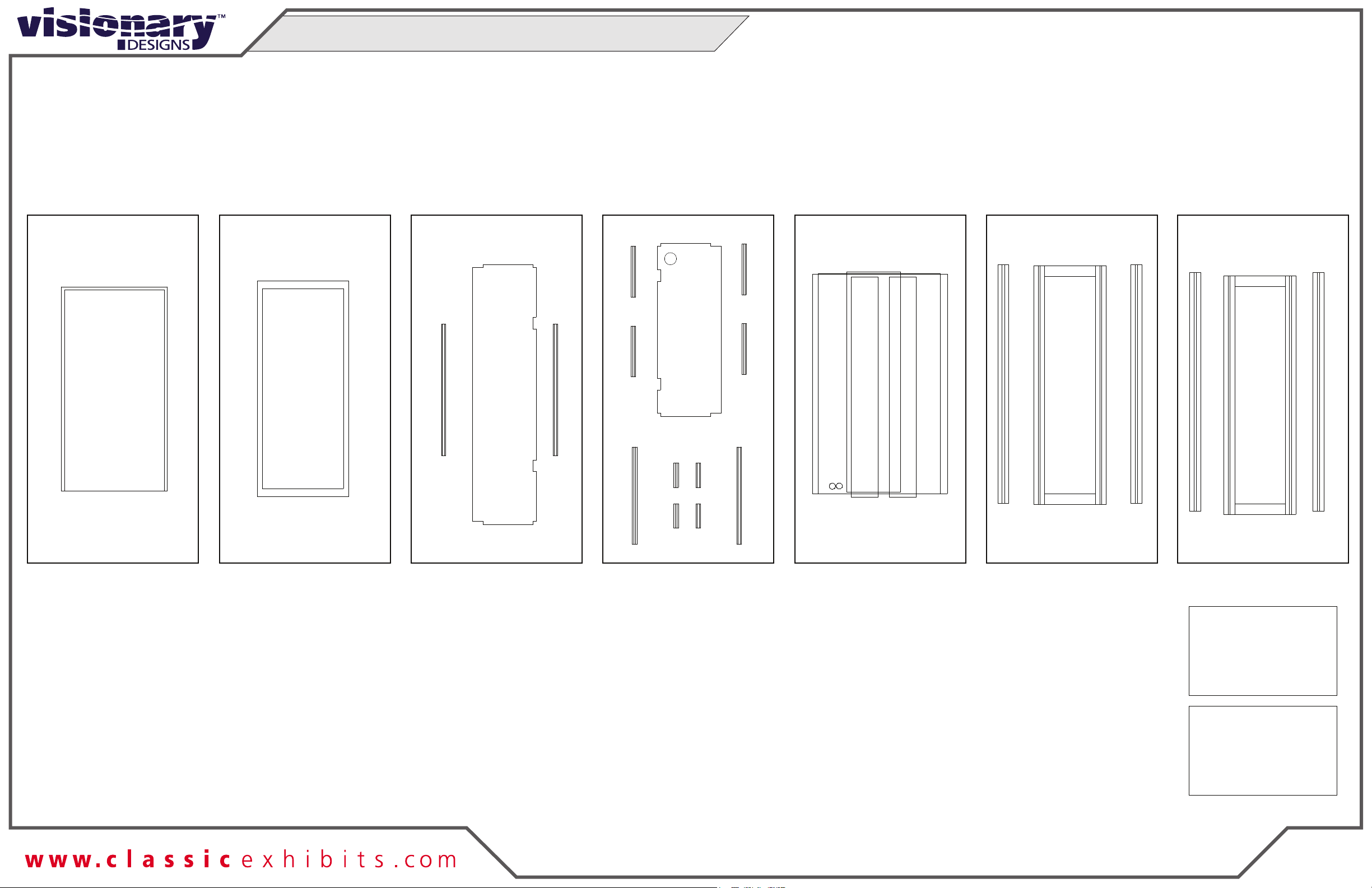

Step 1

Insert corner A. Turn edge of

graphic so silicon welt is

perpendicular to face of

graphic. Insert narrow side

of welt with fabric to outside

into the channel. Repeat for

other side of this corner.

Step 2

Repeat Step 1 for opposite

corner C, then insert corner

B, followed by corner D, to

complete the installation of

the corners.

Step 3

Once all corners are inserted,

press one silicon edge into

channel from corners and

work toward the center.

Make sure welt is fully inserted

into channel. Continue until

all sides are done. Smooth

out edges of graphic.

SEG Graphic Installation

It is important to first insert

graphic into each alternate

corner then to the sides of

the frame. If this is not done,

graphic will not fit into the

frame correctly.

Corner A

Corner D

Corner B

Corner C

***

**

*

**

SE

G Gra

p

h

i

c

S

E

G

G

raph

ic

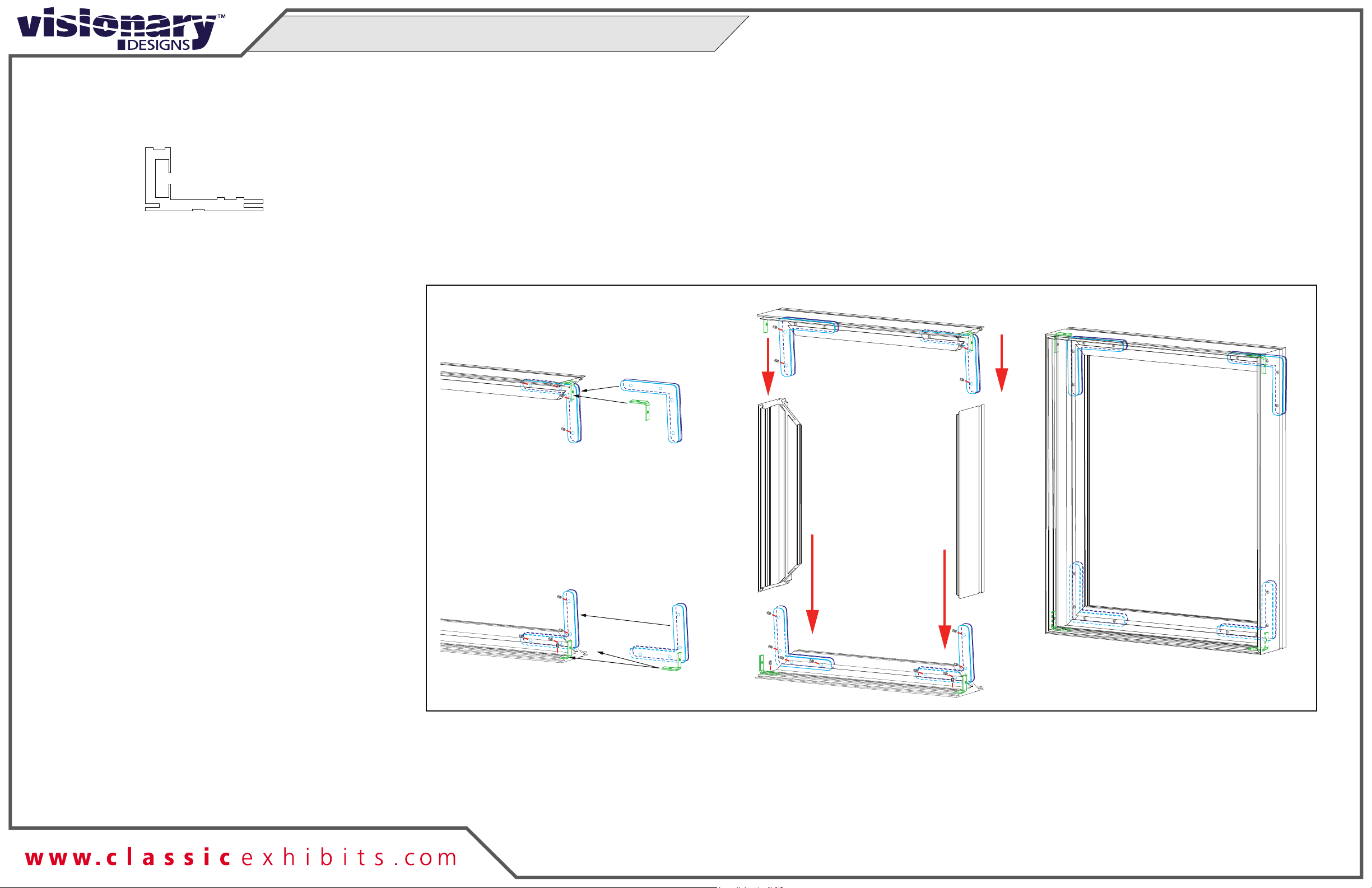

Shelf Pin

1) Slide pin into groove

of Vertical Extrusion.

2) Use hex tool to

tighten pin in place.

Pin

*

Align hole with pin Rotate pin. Spring

will push pin into hole.

Counter Top Attachment

12

*

Pin

Hole

++

+

-

-

-

to power

Lights

Male

Male

Female

Female

Transformer

Light to Light Connection

Light to Tranformer Connection

Counter Attachments (Cont’d)