VISTEK V1640A Owner's manual

29 October, 2003 v1640Aom_b.doc / B Page 1 of 11

V1640A

SDI VIDEO SYNCHRONISER

INSTALLATION and OPERATION

© Vistek Electronics Ltd

Filename: v1640om_b.doc

Issue B

October, 03

VISTEK Electronics Ltd

Wessex Rd

Bourne End

Buckinghamshire, SL8 5DT

ENGLAND

Tel. +44 1628 531221

Fax. +44 1628 530980

1 March, 2005 v1640Aom_b.doc / B Page 2 of 11

SDI VIDEO SYNCHRONISER

INSTALLATION AND OPERATION

1. DESCRIPTION

The V1640A SDI Video Synchroniser is a full broadcast specification Frame Synchroniser forming

part of the Vistek V1600 range of interface products. It is a 3U high module which can be fitted to

either the 1U V1601 or 3U V1603 chassis from which it receives its power. It replaces the existing

V1640 module with which it is fully compatible. The main improvements over its predecessor is that

local adjustment of the timing offsets is possible without removing the unit from the rack, and full

control over DART has been implemented. There are some other minor operational improvements

which are detailed later in this manual. Mechanically the unit has been improved since it is now built

on a single PCB, rather than using two.

When fitted in either the V1601 or the V1603 racks passive rear modules are required to interface to

the outside world. Different rear modules are required for the two chassis. The rear modules are

common to many other Vistek video modules.

The unit automatically operates in either 625/50 or 525/60 formats depending on the input signal.

Normally the Black and Burst reference will be of the same standard, but in the case of it being

different the unit will operate according to the SDI input and set itself to minimum delay. This has

been implemented for use in those areas where the input signal may originate in either standard,

and will be either synchronised or passed through a Standards Converter which will in itself

synchronise the signal.

There is a choice of action in the event of signal loss. The unit can either Freeze or cut to Black.

Provided a reference is connected the output timing is not affected by the loss of the input signal .

When operating in with 625/50 signals the unit works as a Line Synchroniser. This means that it

can handle cuts on the input signal with less picture disturbance than usual, provided the cut is done

on one of the designated switching lines, 6 or 7. The relative timing of the two signals on each side

of the cut should be within approximately 20 lines.

A TTL output is available which indicates the amount of delay being applied to the signal. This can

be used in a suitable tracking audio delay (such as the Vistek V1639) to ensure that video and audio

can stay timed correctly.

The front panel enables direct control of most functions within the unit. It is also used to switch

control from the front panel to the remote DART system. The unit contains non-volatile memory so

that when any parameters are set up locally they are still available after a power-down. Since the

timing offsets are often so important to an installation, an internal DIL switch is available to lock

them out. This prevents ‘accidental’ adjustments of the timing. Adjustment is always available over

DART, since the control system has its own built in safeguards.

The user may selectively pass or blank non-active video signals. Separate control is available over

the Vertical Blanking data, such as Teletext or Insertion Test Signals, and ancillary data, such as

embedded digital audio.

When operating in 525 mode later versions have the ability to selectively blank Line 21 on either

field to remove Closed Caption information. This can only be donelocally on a DIL switch.

The unit is fully controllable over the DART remote control system.

The output of the unit has full EDH signals applied, but there is no EDH detection on the input.

1 March, 2005 v1640Aom_b.doc / B Page 3 of 11

2. INSTALLATION

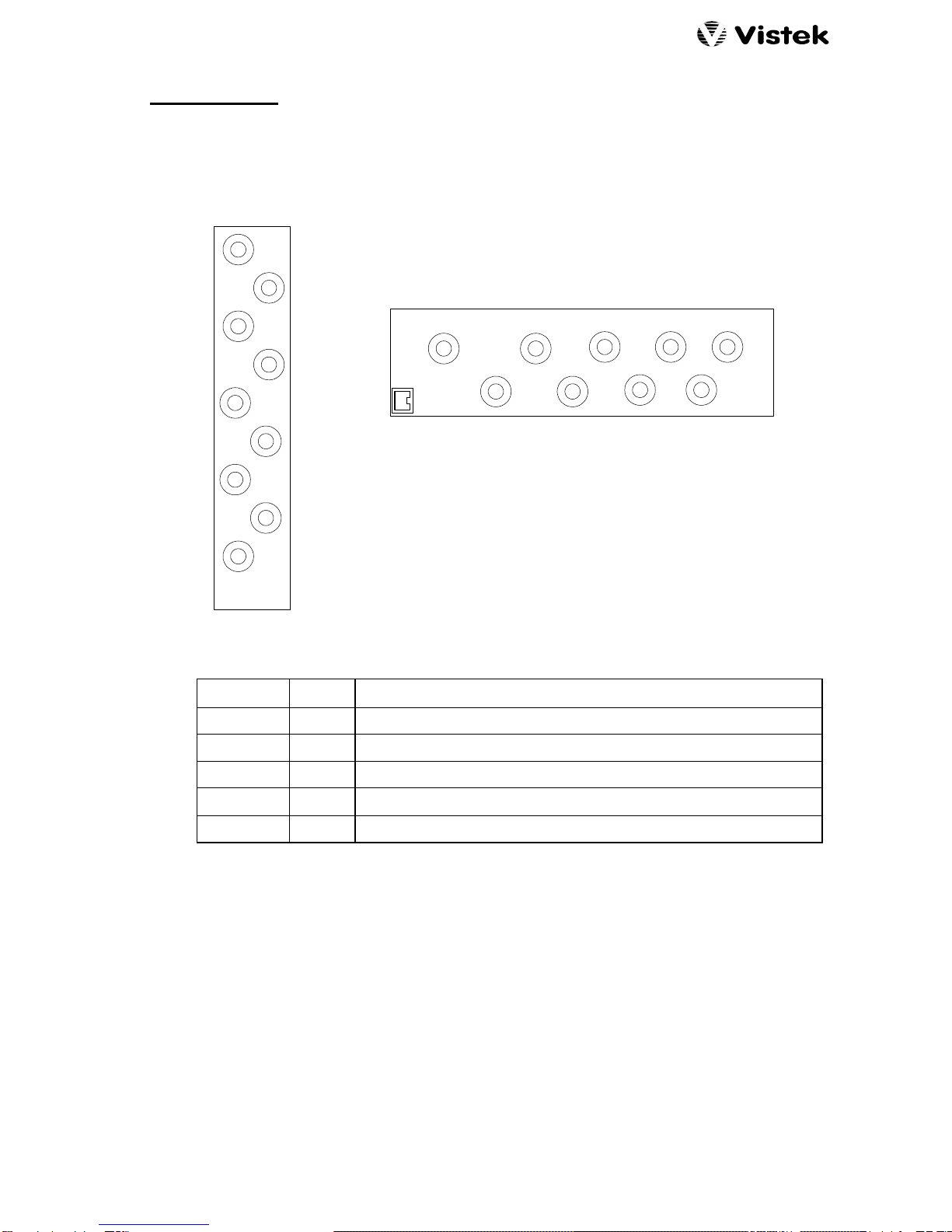

2.1 REAR PANEL

Two rear panels are available depending on the type of chassis into which the unit is fitted:

3U (V1603)

SDI

SDI1

SDI2

SDI3

VIDEO

REF

DELAY

1U (V1601)

SDI

IN

SDI1

SDI2

SDI3

VID. REF

DART

DELAY

2.2 REAR PANEL CONNECTIONS

SIGNAL CONN DESCRIPTION

SDI IN BNC SDI Video Input

SDI 1, 2, 3 BNC 3 off SDI Video Outputs

DELAY BNC TTL Delay Pulse

VID. REF BNC Video Reference Input. An internal switch enables 75Ωtermination.

DART RJ45 DARTNET connection. Only used in on position in 1U rack.

2.3 POWER CONSUMPTION

The V1640A power consumption is 6.5W

2.4 INSERTION DELAY

The insertion delay is, of course, variable over a frame. If the input and reference frame rates are

different then the delay will vary. At some stage there will be a frame drop or a frame repeat and

just before or just after there will be a point of minimum insertion delay. There is hysteresis in the

frame discontinuity, to avoid rapid toggling, so the minimum delay depends on the drift direction:

Minimum Delay (Increasing): 1.65µs

Minimum Delay (Decreasing): 1.05µs

The minimum delay, as set from the front panel or through DART, is 1.7µs.

1 March, 2005 v1640Aom_b.doc / B Page 4 of 11

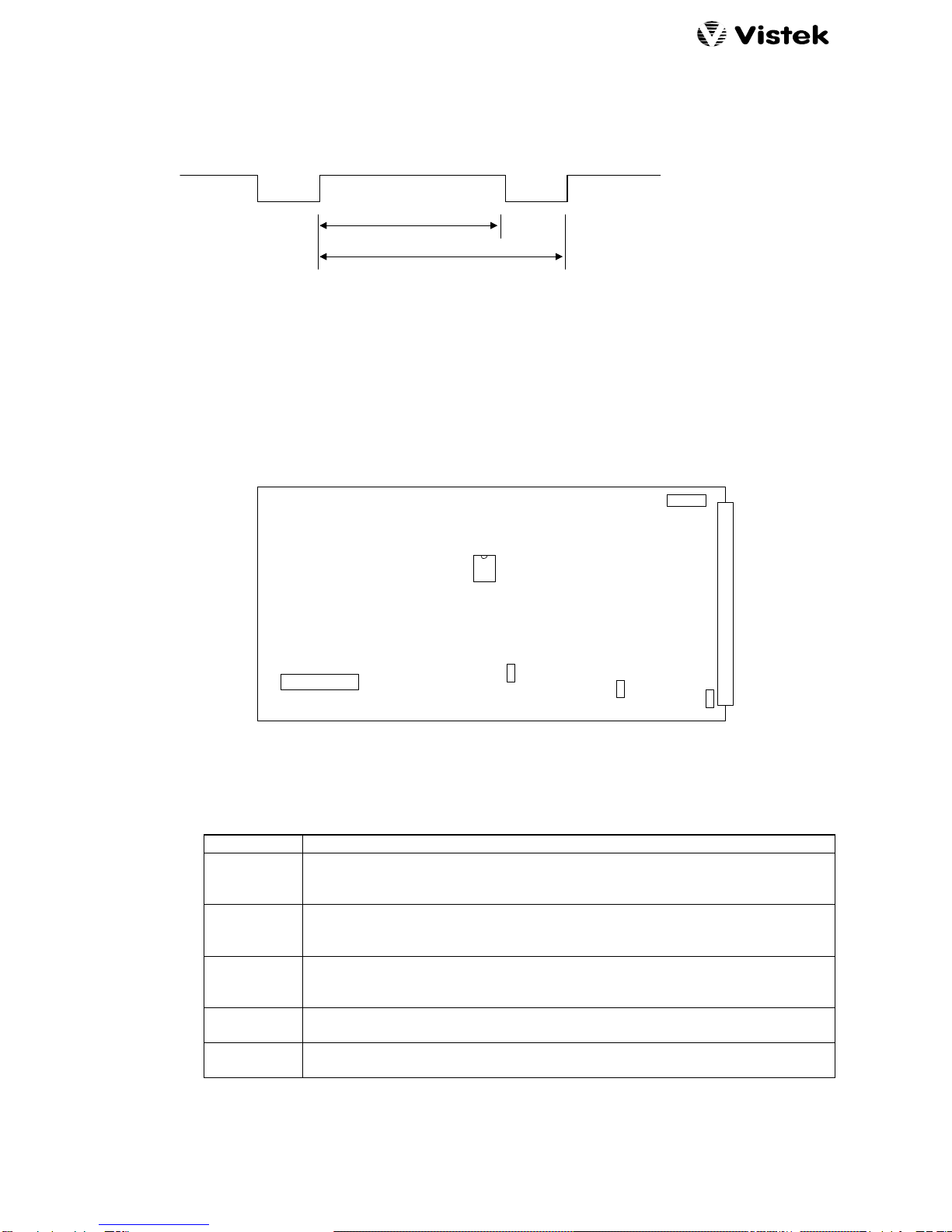

2.5 DELAY O/P

The Delay O/P signal is a TTL levels rectangular wave. The period is the same as the frame rate

(40ms for 625/50 and 33.3ms for 252/60) but the mark-space ratio varies according to the amount of

delay.

Frame

Delay

The minimum pulse width, either positive or negative, is 37ns.

2.6 INTERNAL HARDWARE

2.6.1 MAIN BOARD

FRONT PANEL

REAR CONNECTOR

PROM

DIL SWITCH

LK1

SW5

U15

FS1

18

VR1

VR2

The significant items on the main board are described here:

FS 1 Input power fuse, 3A.

SW 5 Internal configuration switches, S1 at the left. See section 3.11 for details.

Note that each switch is UP or DOWN. Ignore the ‘OFF; indication on the

switch block.

U15 The 8 pin DIL PROM that contains the firmware for the programmable device.

In the event of upgrades in the field it is most likely that this is the device that

will need to be changed.

LK 1 Enables termination of the video reference:

UP = Open

DOWN = Terminated

VR 1 Factory adjustment for reference standard select.

Adjust for 18ms on TP 49

VR 2 Factory adjustment for oscillator centre frequency.

Adjust for 27MHz on TP 39.

1 March, 2005 v1640Aom_b.doc / B Page 5 of 11

3. OPERATION

3.1 FRONT PANEL

REM +V

Local

Rem

V1640A

SDI Frame

Synchroniser

DART Control Access and Power indicators

REMOTE / LOCAL control selection

Input Format

I/P

Ref

525 625

H Adjust

V Adjust

FL Mode

Input

Min Delay

ANC & VI

Select

Normal

+

Reference Format

Adjust Horizontal Offset

Adjust vertical Offset

Set Input Fail Mode

Select Input Signal

Set Minimum Delay

Control VBI and Ancillary data handling

Control Select Button

'UP' Button

'DOWN' Button

Status LEDs

3.2 CONTROL

The V1640A can be controlled from either the front panel, shown above, or through the DART

remote control Network. If DART is used then any DART controller, with knowledge of the V1640A

can be used. Vistek can provide either the V1605 1U control panel or VIEWFIND which is a PC

based universal control system. Any DART controller can be used, provided it has ‘knowledge’ of

the V1640A.

The control source, Local or Remote, is selected by the toggle switch on the front panel. The REM

LED does not indicate the selection of remote control, but ‘blips’ to show access by the Rack

Controller, if fitted. Only the position of the toggle switch indicates that remote control has been

selected.

When in Local control the front panel allows the user to set up all the parameters, and can show

how most of them are set. All the status LEDs on the front panel are active for Local or Remote

control so that they always show the operating conditions.

When under Remote Control the Parameter Select sequence is still active, although it is not

possible to change anything from the Local panel. This means that the user can still monitor the

state of the unit while under Remote Control.

1 March, 2005 v1640Aom_b.doc / B Page 6 of 11

3.3 INDICATIONS

3.3.1 POWER

The power LED, marked +V, indicates that the 5V VCC power rail is present on the board. This

shows not only that power has been applied to the rear, but also that the on board regulator is

functioning.

There is a fuse on the unit in series with the power input, and if this has ‘blown’ then the +V LED will

be OFF, as will the other LEDs.

There are other power rails on the unit (3.3V and ±5V) which are generated from the VCC, rather

than directly from the board supply. The +V LED may still be on even if these supplies have failed.

3.3.2 REM

This LED indicates that the unit is being accessed remotely by the DART system. It does NOT

reflect the position of the REM/LOC switch. The LED is not permanently ON, but blinks occasionally

when data is actually being transferred to or from the unit.

3.3.3 INPUT PRESENCE and FORMAT

This pair of LEDs indicate the presence and format of the input signal. The unit detects whether the

input is D1 525/60 or D1 625/50 and lights one of the LEDs accordingly. If there is no input signal

then neither LED is ON. This is the only panel indication of input signal fail.

3.3.4 REFERENCE PRESENCE and FORMAT

This pair of LEDs indicate the presence and format of the analogue reference signal. The unit

detects whether the input is 525/60 or 625/50 and lights one of the LEDs accordingly. If there is no

reference then neither LED is ON. This is the only panel indication of there being no reference.

It is quite possible to operate the unit with opposite formats on the input and reference. In this case

the unit will default to the input signal format, ignoring the reference completely, and set itself to

minimum insertion delay.

3.3.5 PARAMETERS

These LEDs indicate that one of the parameters has been selected for adjustment. Pressing the

SELECT button repeatedly selects each parameter in sequence. Only when a parameter has been

selected can it be adjusted by the sand tbuttons.

Note that there is one sequential position when no parameter is selected. This is the ‘idle’ state

where nothing can be affected by accident.

There is a time-out of either 68 secs (525/60) or 82 secs (625/50) so that if no adjustment is made

to a parameter within that time then it will return automatically to the ‘idle’ state. (Early units had a

shorter time-out of 34 and 41 seconds.)

Later sections discuss each of these adjustment parameters in more detail.

Under certain conditions it may not be possible to select the timing adjustment parameters; the

details are in section 3.4.

1 March, 2005 v1640Aom_b.doc / B Page 7 of 11

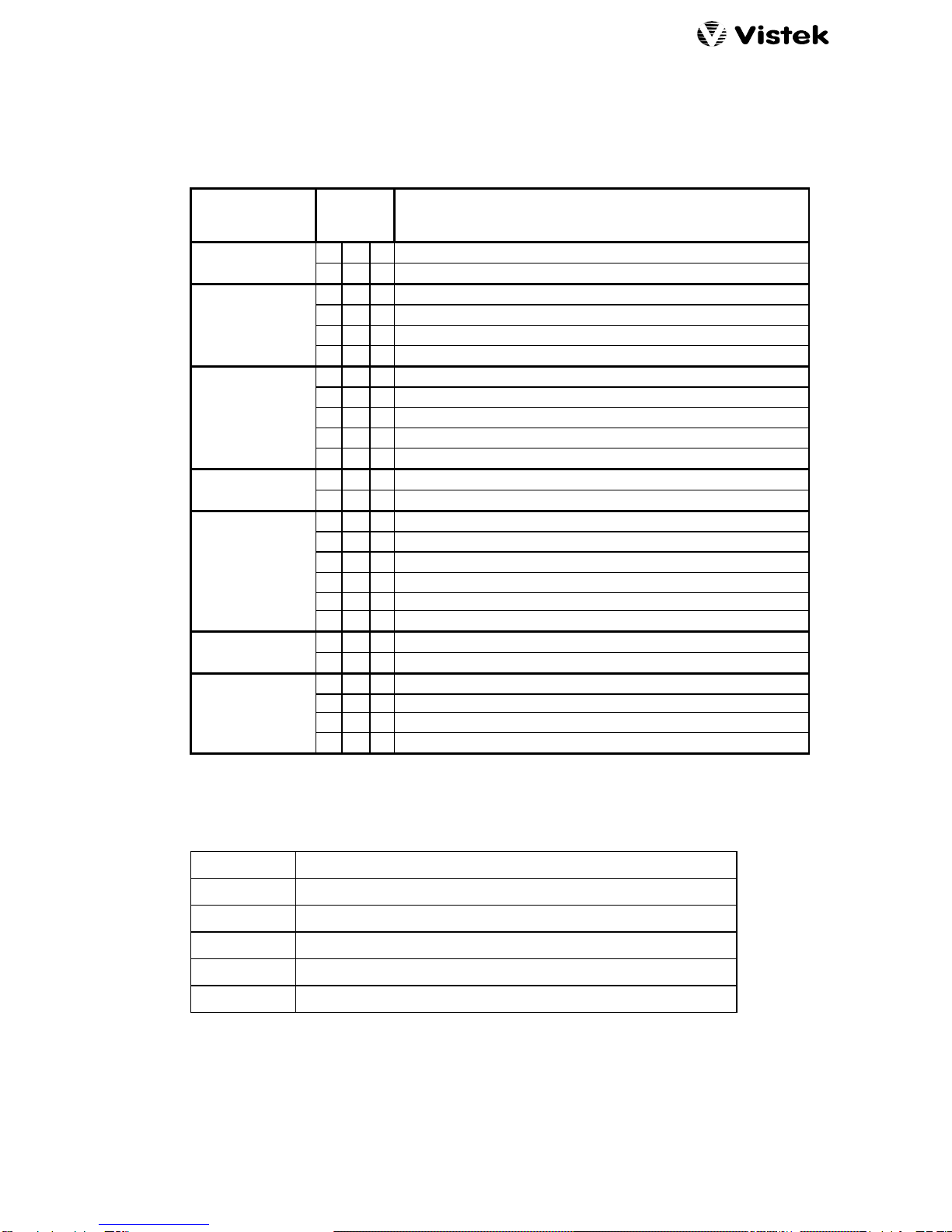

3.3.6 STATUS LEDs

These three LEDs give a guide as to the state of the variable parameters. It is clearly not possible

to give a full representation using only three LEDs but the following table shows how most of the

important information is conveyed.

LEDs

PARAMETER + N - DESCRIPTION

none (Idle) lWlNormal

WlWMinimum Delay is selected

WWlDelay >1 Field, Outside Hysteresis zone

WllDelay >1 Field, In Hysteresis zone

H Adjust llWDelay <1 Field, In Hysteresis zone

lWWDelay <1 Field, Outside Hysteresis zone

WllVertical Offset = +127 lines

WWl0 < Vertical Offset < +127 lines

V Adjust lWlZero offset

lWW-128 lines < Vertical Offset < 0

llWVertical Offset = -128 lines

FL Mode lWlFreeze field on Input Fail

WlWBlack on Input Fail

WlWFreeze Frame

llWFreeze on Field 2

Input WllFreeze on Field 1

lWlSDI Input signal

lllBlack

WlWInternal 100% Colour Bars (not broadcast quality)

Min Del lWlMinimum Delay OFF

WlWMinimum Delay SET

lWWPass VBI, Blank Ancillary

Anc & VI lllBlank Both

WlWPass Both

WllBlank VBI Pass Ancillary

3.4 LOCAL PARAMETER SELECTION

This table is a list of the local parameters that can be adjusted.

H Adjust Horizontal Offset Adjustment

V Adjust Vertical Offset Adjustment

FL Mode Signal Fail Mode

Input Input Source

Min Delay Minimum Delay

ANC & VI Ancillary Data and Vertical Interval data

There are two conditions during which it is not possible to select H Adjust and V Adjust. If

Min Delay is active then the output timing is not adjustable from the front panel, and there is a non-

standard display in the idle state. Secondly if the Lock-Adj DIL switch is set (S2 on SW 5) then

they will not be selected; see section 3.11.2. In either case the parameter selection will pass

straight from Idle to FL Mode.

1 March, 2005 v1640Aom_b.doc / B Page 8 of 11

3.5 SETTINGS MEMORY

All local parameter values are stored in a non-volatile memory, so they do not have to be set up

each time the unit is powered. When a value is changed it is only stored into the memory when the

parameter selection is changed. This means that if you alter a parameter and then remove the

power (or remove the unit from the chassis) before pressing SELECT or allowing the time-out to

happen, then the new value will not have been stored.

3.6 OFFSET ADJUSTMENTS

The output timing can be offset from the reference using two parameters. The first allows horizontal

adjustment over a full line, while the second allows vertical adjustment over -128 to +127 lines. The

reference will be either the external analogue video signal, or the D1 input itself. This means the

unit may be used as delay line.

The status LEDs give some indication during horizontal adjustment as shown in section 3.3.6, and

during vertical adjustment show which direction the offset is, and whether it is at its maximum.

If the unit has Min Delay or Lock-Adj set then the timings cannot be adjusted.

3.7 I/P FAIL MODES

The V1640A has sophisticated monitoring on the SDI input, so it handles intermittent signals in a

‘user-friendly’ manner. Minor disturbances to the TRS data (roughly equivalent to the Sync pulses

in an analogue video signal) cause short freezes of the data. However if the input fails completely,

which is defined by either a loss of the input 270MHz or a sequence of erroneous TRS signal then

the unit goes into its Fail mode.

This Fail mode can be either a freeze to the last ‘good’ field that has been stored, or a cut to black,

as set on the FL Mode parameter. The normal operation is to freeze the picture, but sometimes this

can be a disadvantage when installing or setting up a system when the user might actually want to

know that the input has failed.

3.8 INPUT

Although titled Input, this parameter selects the signal source that is passed out of the V1640A.

There are five options as follows:

Freeze Frame

Freeze Field 2

Freeze Field 1

SDI Input

Digitally Generated Black

100% Colour Bars

Any of the Freeze functions actually cause a whole frame to be frozen, and if a Field Freeze is

chosen then the output processing ensures that only one of the fields is displayed. Under these

conditions a single input field will be displayed on both output fields. This will reduce any blurr

caused by motion at the point of freezing, but the vertical resolution will also be reduced.

Since the whole frame is frozen all three freeze options are available without having to re-freeze the

input signal.

The Digital Black and Colour Bars are generated on the output side of the V1640A but the input

processing and front panel indications are still active. The Colour Bars are so-called ‘hard’ bars in

that they have no transition edge shaping. This means that they contain very high frequencies and

will produce ringing on all transition after a DAC.

1 March, 2005 v1640Aom_b.doc / B Page 9 of 11

3.9 MINIMUM DELAY

The unit can be set into a Minimum Delay mode without having to actually adjust the timings, which

would lose their settings. The actual minimum delay for both formats is as defined above in

section 2.4. The main advantage of the Minimum Delay is to ignore the reference even though it is

still connected.

Because the timing adjustments have no effect when Min Del is active, it is not possible to select

them as a parameter. It is also indicated on the Idle menu by both the +and -LEDs being on.

3.10 ANC. DATA AND VBI

In some installations it may be desirable to blank either the Vertical Blanking Interval data and/or the

Ancillary data. The VBI often contains Teletext or Insertion Test signals which occupy the active

video portions of the vertical interval; they may be passed through the V1640A.

An SDI signal may contain Ancillary data in the horizontal blanking between the EAV and SAV TRS

signals. Often this data is embedded digital audio, and should be removed from the V1640A output.

This is because the any Frame Synchroniser, including the V1640A, can introduce discontinuities in

the frame sequence when the input and reference signals are not synchronous which will cause a

major disturbance to digital audio.

The ‘normal’ setting for the V1640A is to pass the VBI data, but to blank the Ancillary data.

If the Ancillary data is set to blank then ALL information between the EAV and SAV is removed, not

just audio data.

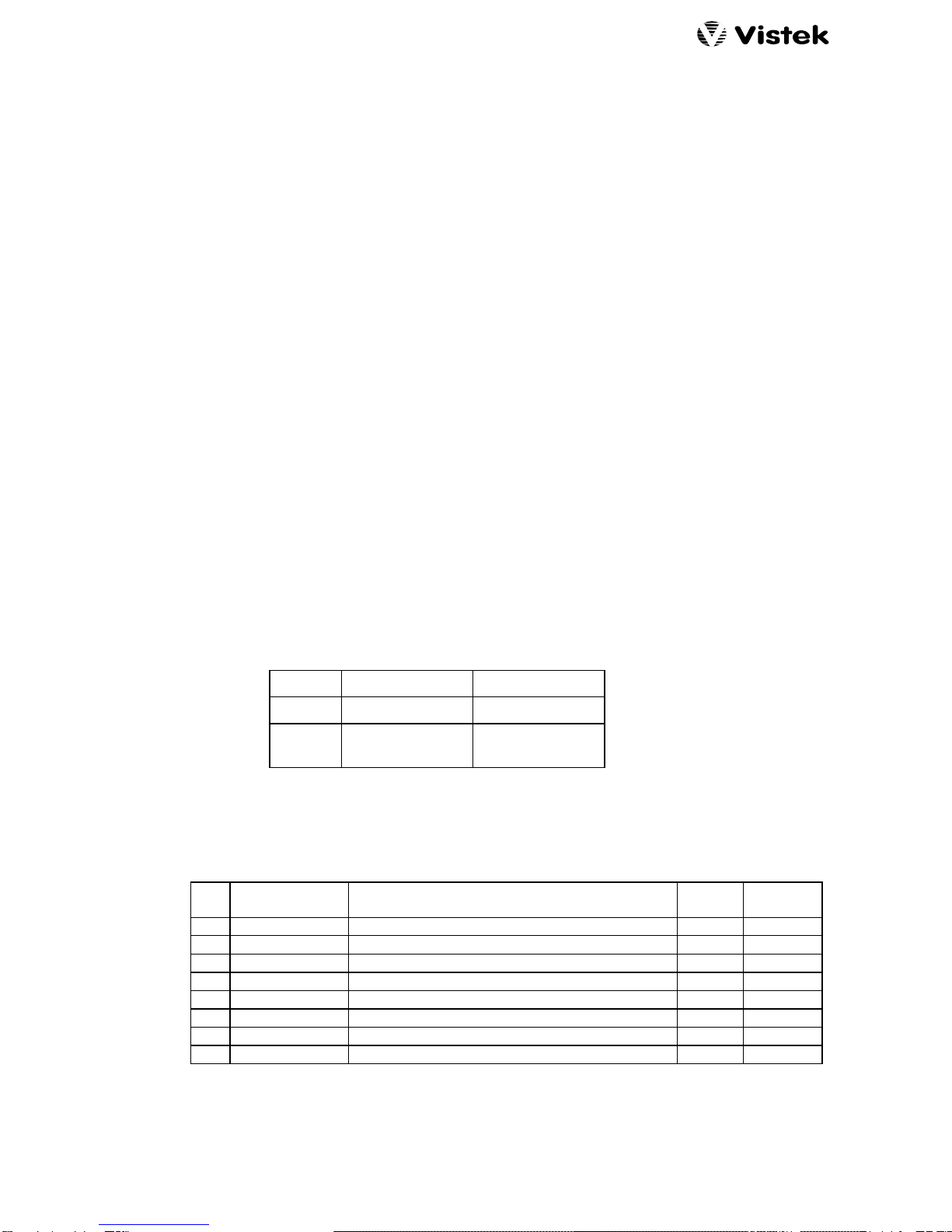

If the VBI is set to be blanked then the active portions of the following lines are removed depending

on the standard:

625/50 525/60

Field 1 9 - 22 12 - 20

Field 2 321 - 335 274 - 282

(11 - 19)

3.11 INTERNAL SETTINGS

An eight way DIL switch on the PCB (SW 5) is used to set up some internal parameters as shown

here:

S Title Description UP Down

(= OFF)

1 DEF STD Default Standard (used when no I/P and no Ref) 625/50 525/60

2 LOCK ADJ Lock local control of timing adjustments Free LOCKED

3 REF FL MODE Reference Fail Mode Norm Min delay

4 Field 1 Line 21 Selectively blank this line in 525 mode only Pass Blank

5 Field 2 Line 21 Selectively blank this line in 525 mode only Pass Blank

6 reserved

7 reserved

8 reserved

For normal operation all switches should be set to UP.

1 March, 2005 v1640Aom_b.doc / B Page 10 of 11

3.11.1 DEFAULT STANDARD

This switch sets the operating standard when there is no input or reference. This can be useful

during system installation when an output SDI signal may be needed of the correct format with no

input or reference. For example the non broadcast quality colour bars may be used.

The unit does ‘remember’ which standard it is operating on even after the SDI input and reference

have been removed, so this setting is only really used when the unit is powered up without any

signals.

3.11.2 ADJUSTMENT LOCK OUT

To avoid accidental adjustment of the timing values this switch should be set down. Make sure that

the values you want are properly stored in the non-volatile memory before removing the unit from

the chassis (see section 3.5).

When the Adjustment Lockout is active it is not possible to select the H Adjust and V Adjust

positions.

The DART remote control system can still change the timing values independently of this switch

setting.

3.11.3 REFERENCE FAIL MODE

This switch changes the output when the reference fails. Normally the unit will switch its locking

reference to the SDI input signal (if present) and continue to provide an output and the adjustment

offsets are still applied. If this switch is set DOWN then the unit will go into minimum delay and the

adjustment parameters will have no effect.

In either case if there is no input either, when the reference fails, then the output will free-run from its

internal crystal oscillator. The unit will operate in the same standard that was last applied.

3.12 EDH

The unit contains an EDH (Error Detection and Handling) chip on its output stages. This is

permanently set to generate mode, so it produces correct EDH data whatever the state of the input

signal.

1 March, 2005 v1640Aom_b.doc / B Page 11 of 11

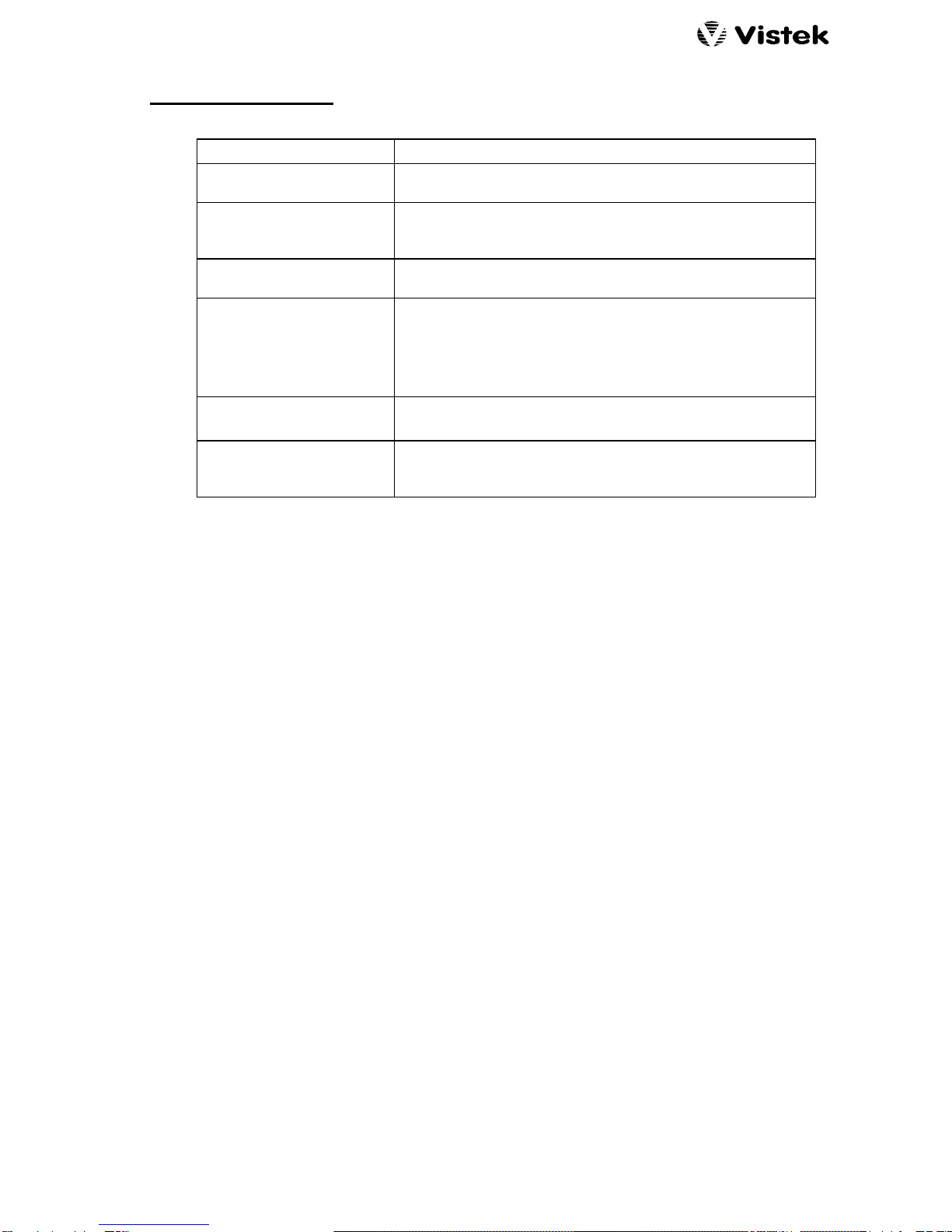

4. TROUBLE SHOOTING

SYMPTOM POSSIBLE CAUSE AND CURES

Cannot select any

parameter on Front Panel. Is power applied? Observe the +5V LED.

Cannot select Hadj or Vadj

parameters, but others are

OK.

Min Del parameter is set. Section 3.9.

Lock-Adj is set. Section 3.11.2.

Changing Hadj and Vadj

has no effect. No reference and REF FL MODE is DOWN so setting

minimum delay. Section 3.11.3.

Not Synchronising Check that a reference is applied.

Check that the reference is the same format as the SDI input,

otherwise the unit tracks the SDI input.

Check that the measurement apparatus is connected in a

suitable manner.

O/P Black No I/P, and FL Mode set to Cut to Black. Section 3.7

Input Selection set to Black

Can select a parameter, but

cannot change anything. The unit is probably in REMOTE mode. You can still select a

parameter to see how it has been set over DART, but cannot

change anything unless you are in LOCAL mode.

Table of contents