VITECTOR FRABA RAY-LG 35 Series User manual

MANUAL (TRANSLATION)

RAY-LG 35XX

Page 1 RAY-LG 35XX Version: 1.0

Features

▪Type E Safety Device acc. EN 12453:2017

▪Safety Cat. 2, PL D according to EN ISO

13849-1:2008

▪Certified According to EN 12978: 2009

▪SIL 2 certified

▪Fulfils SIL 2 Without Testing (OSE Output)

▪TÜV –EC Type Examination Certified

▪Direct Mounting in Door Tracks with Blanking

▪Partial Opening Function

▪High Detection Capability Due to Cross Beams

▪Designed for Door Speeds up to 1.6 m/s

▪Selectable Transistor PNP/NPN or OSE Output

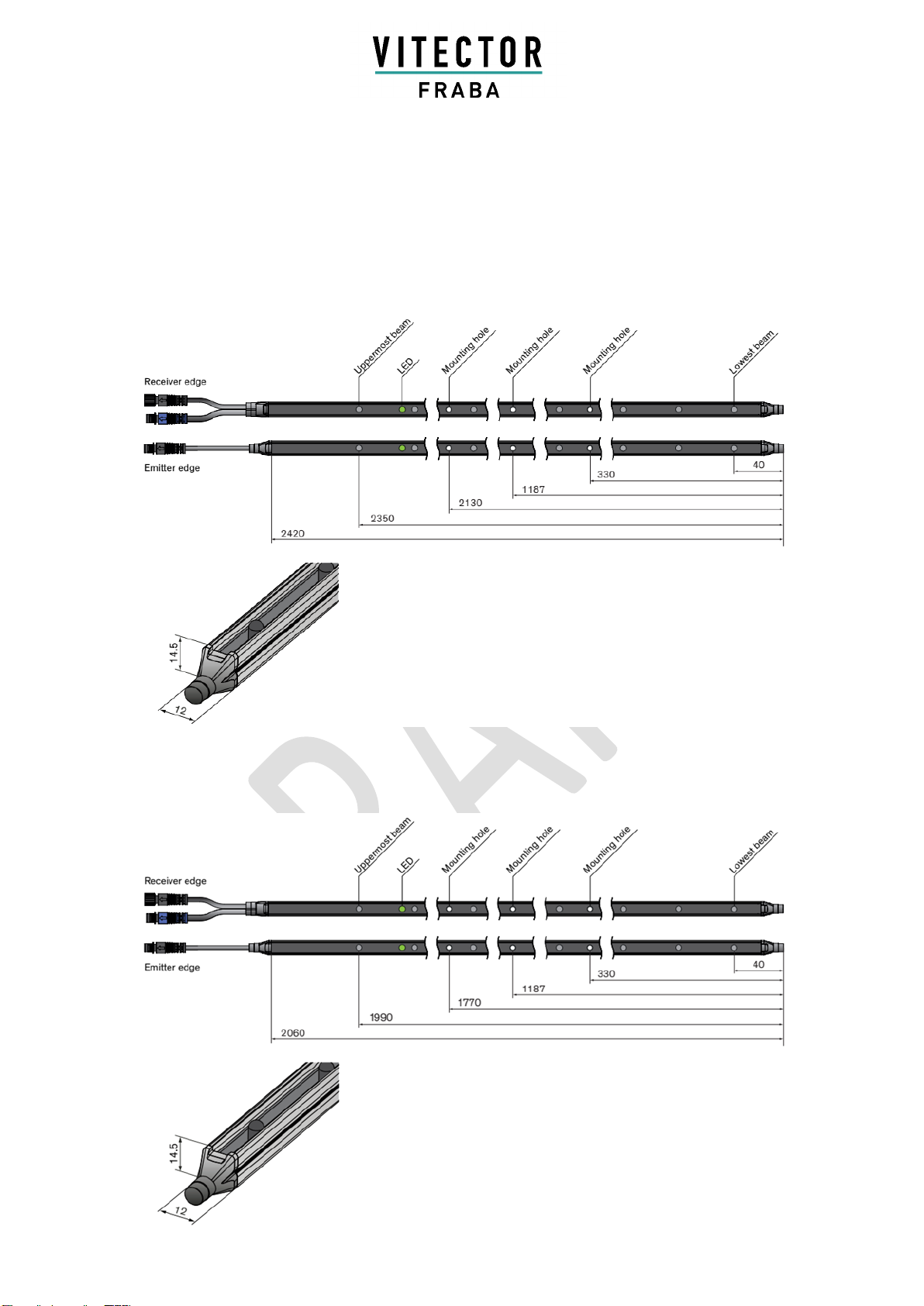

▪Cross Section of Only 12 mm × 14,5 mm

▪Easy Alignment

▪Ideal for Retrofit with OSE-C Control Unit

▪IP68 Waterproof Housing (Cable: IP67)

MANUAL (TRANSLATION)

RAY-LG 35XX

Page 2 RAY-LG 35XX Version: 1.0

Safety Information

The RAY-LG was developed and manufactured

using state-of-the-art systems and technologies.

However, injury and damage to the sensor can still

occur.

To ensure safe conditions:

▪Read all enclosed instructions and information.

▪Follow the instructions given in this manual

carefully.

▪Observe all warnings included in the

documentation and attached to the sensor.

▪Do not use the sensor if it is damaged in any

way.

▪Keep the instruction manual on site.

The RAY-LG should only be installed by authorized

and fully trained personnel! The installer or system

integrator is fully responsible for the safe integration

of the sensor. It is the sole responsibility of the

planner and/or installer and/or buyer to ensure that

this product is used according to all applicable

standards, laws and regulations in order to ensure

safe operation of the whole application.

Any alterations to the device by the buyer,

installer or user may result in unsafe operating

conditions. FRABA B.V. is not responsible for any

liability or warranty claim that results from such

manipulation.

Failure to follow instructions given in this manual

and/or other documents related to the RAY-LG may

cause customer complaints, product recalls,

damage, injury or death.

Non-intended Use

The RAY-LG must not be used for:

▪Equipment in explosive atmospheres

▪Equipment in radioactive environments

▪Protection of dangerous machine

Use only specific and approved safety devices for

such applications, otherwise serious injury or death

or damage to property may occur!

Safety Message Categories

WARNING:

Serious Health Risks

Highlights critical information for the safe use of

the sensor. Disregarding these warnings can

result in serious injury or death

CAUTION:

Possible Health Risks

Highlights critical information for the safe use of

the sensor. Disregarding these warnings can

result in serious injury or death

NOTICE:

Risk of Damage

Disregarding these notices can lead to damage to

the sensor, the door controller and/or other

devices

MANUAL (TRANSLATION)

RAY-LG 35XX

Page 3 RAY-LG 35XX Version: 1.0

Product Description

The RAY-LG is a very reliable SIL 2 certified safety

light curtain. It was developed and designed to

safeguard all types of vertically opening industrial

doors such as sectional or highspeed doors. The

system is ideal for door openings up to 10 m width

and can handle door closure speed of 1.6 m/s. The

opening speed is up to 3 m/s. The emitter and

receiver are preferably installed directly inside the

guide rail. The RAY-LG has a selectable transistor

(NPN/PNP) or OSE output, so one system can

handle all relevant outputs. Selecting the OSE

output allows operation according to EN ISO

13849-1:2015 Cat. 2 without periodic testing of the

light curtain. This output is included in the TÜV

certification of the RAY-LG.

Functionality

The emitter and receiver edges create a grid of

infrared beams offering up to 2.5 m (8.2 ft) in

protection height.

When the infrared beams are interrupted, the

output sends a signal to the connected door

control unit. As soon as the detection area is clear

again, the output switches to indicate that the area

is "clear". The blanking system is designed to

mount directly into the guide rails. As the door

closes, the RAY-LG recognizes the door as such

and does not switch the output.

Once the door has arrived at the fully closed

position, the output signal will be switched off.

Intended use

RAY-LG is certified according to

EN ISO 13849-1:2015 and EN 12978:2009 if the

door is monitored over its full height up to 2.5 m

(8.2ft). It is designed and approved for mounting

and use in- and outside the side guides of

industrial doors and serves as E-device presence

detection according to EN 12978:2009 and

EN 12453:2017.

The RAY-LG 35XX fulfills the safety level up to

SIL 2 according to EN 61508:2010 and the

category 2 (cat. 2) / performance level d (PL d)

according to EN ISO 13849-1:2015.

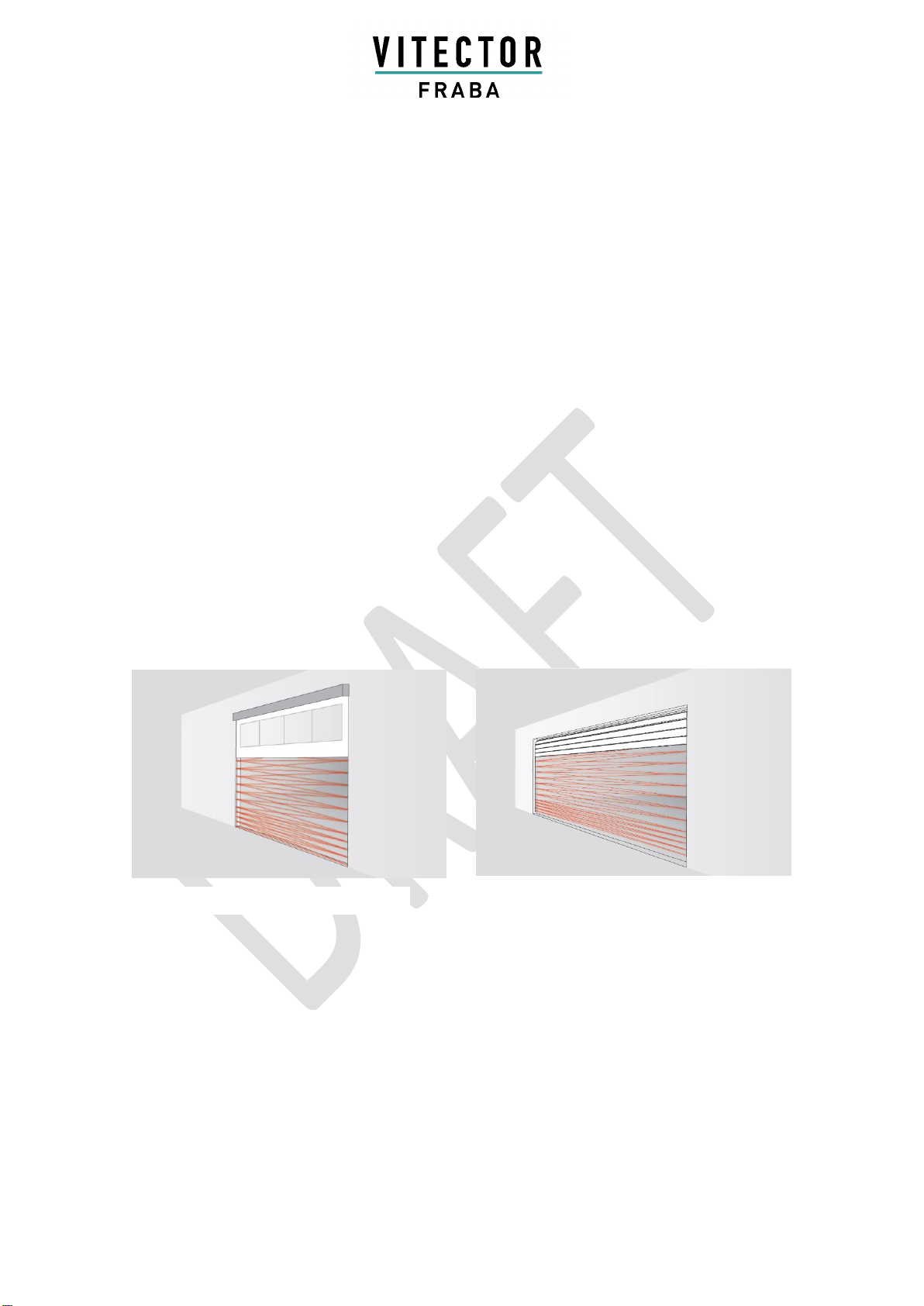

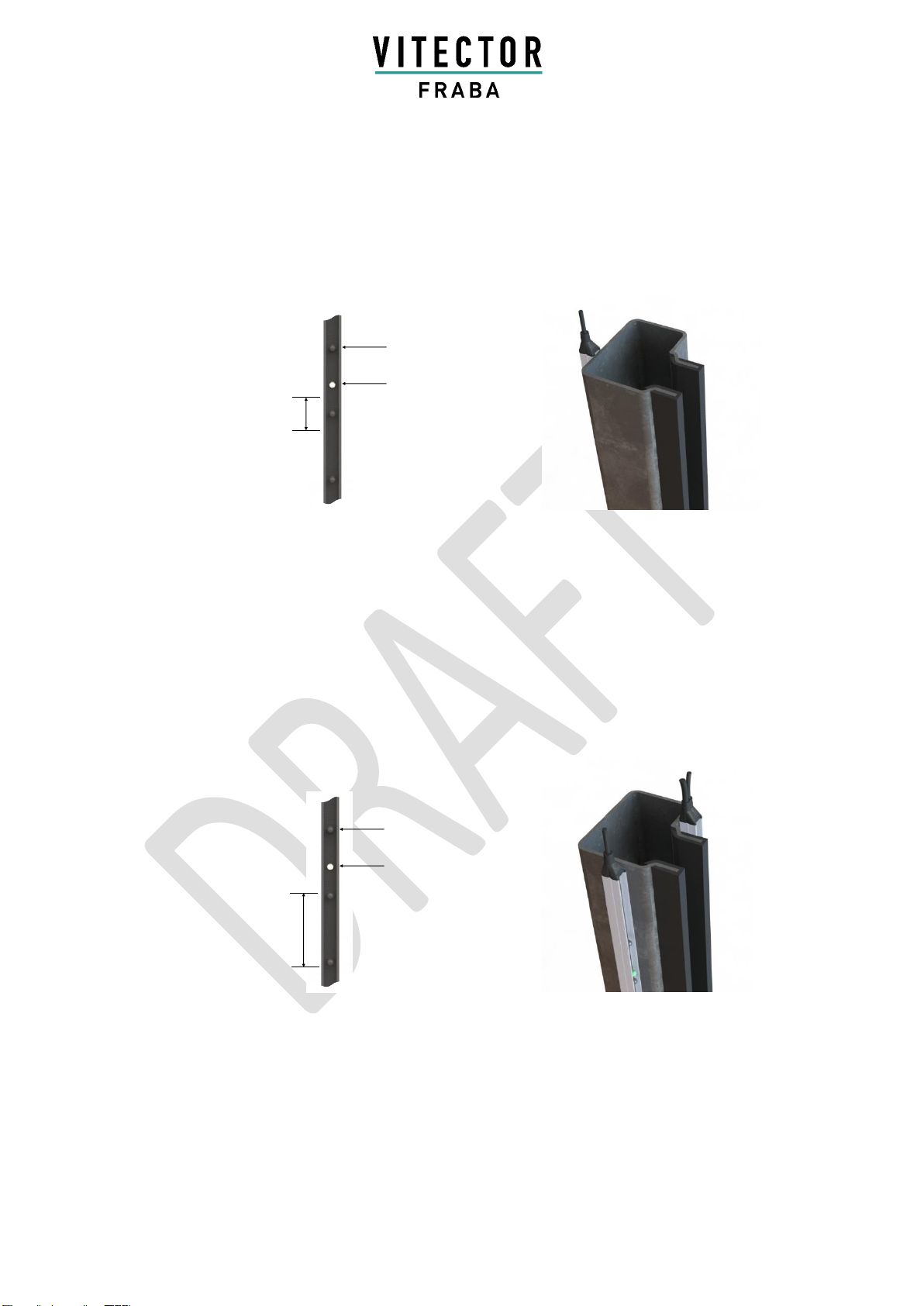

Figure 1: Rolling door with door blanking

Figure 2: Sectional door with door blanking

MANUAL (TRANSLATION)

RAY-LG 35XX

Page 4 RAY-LG 35XX Version: 1.0

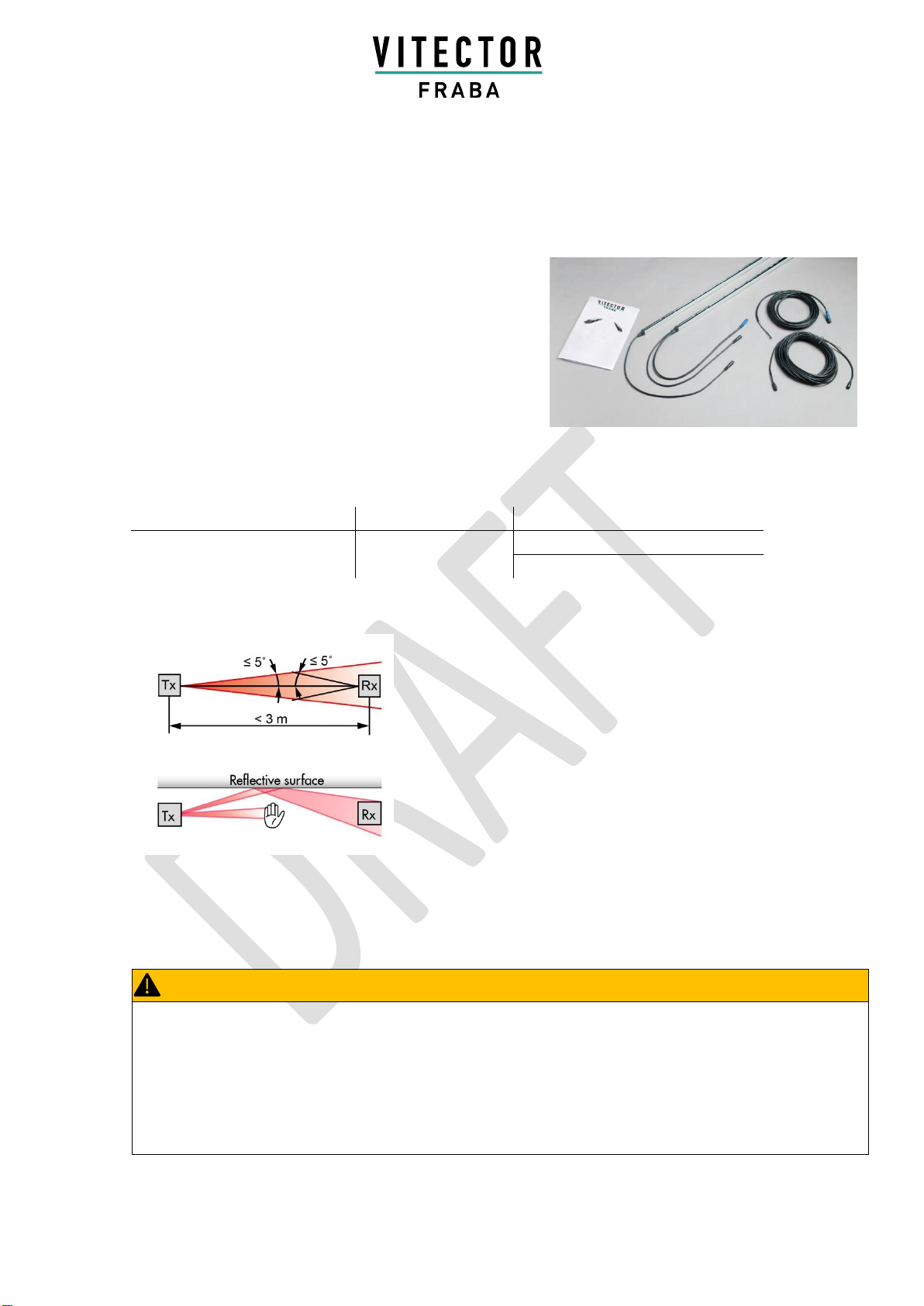

Delivery Set

RAY-LG comes with a customer-specific delivery package.

A typical delivery package contains:

▪1 x RAY-LG transmitter bar (Tx)

▪1 x RAY-LG receiver bar (Rx)

▪1 x Synchronization cable 10 m (33 ft)

▪1 x Connection cable 5 m (16.5 ft)

▪1 x Installation and Operation Manual

Type Key

RAY-LG A B CD

A: Output

B: Aperture Angle

CD: Number of Optical Elements

A= 3: Semiconductor/OSE

B= 5: ±5°

CD = 20: 20 Elements (2060 mm)

CD = 22: 22 Elements (2420 mm)

Alignment and Calibration

The optical axis of the emitter (Tx) and the receiver edge (Rx) need to

be aligned towards each other to ensure the light curtain functions

reliably.

Reflective surfaces near to or parallel to the detection area can cause

reflections and interfere with the RAY-LG's functions. Keep a reasonable

distance between the sensor edges and any reflective surface.

A self-calibration on each optical beam is implemented. At the power- up

the ideal emitting strength will be detected and used. To reduce

interruption caused of dust the system checks the emitting power and

adapt a new higher or lower strength if necessary. After 45 s interruption

a self-reset of the system will be made.

CAUTION:

Damage to the Eye

Although the RAY-LG does not emit dangerous amounts of infrared light, long exposure to intense infrared light

sources can result in damage to the eyes.

- Never look directly into the active infrared emitter from a close distance

Possible health risks - Disregarding these warnings can result in injury

Figure 3: Typical RAY-LG delivery set

MANUAL (TRANSLATION)

RAY-LG 35XX

Page 5 RAY-LG 35XX Version: 1.0

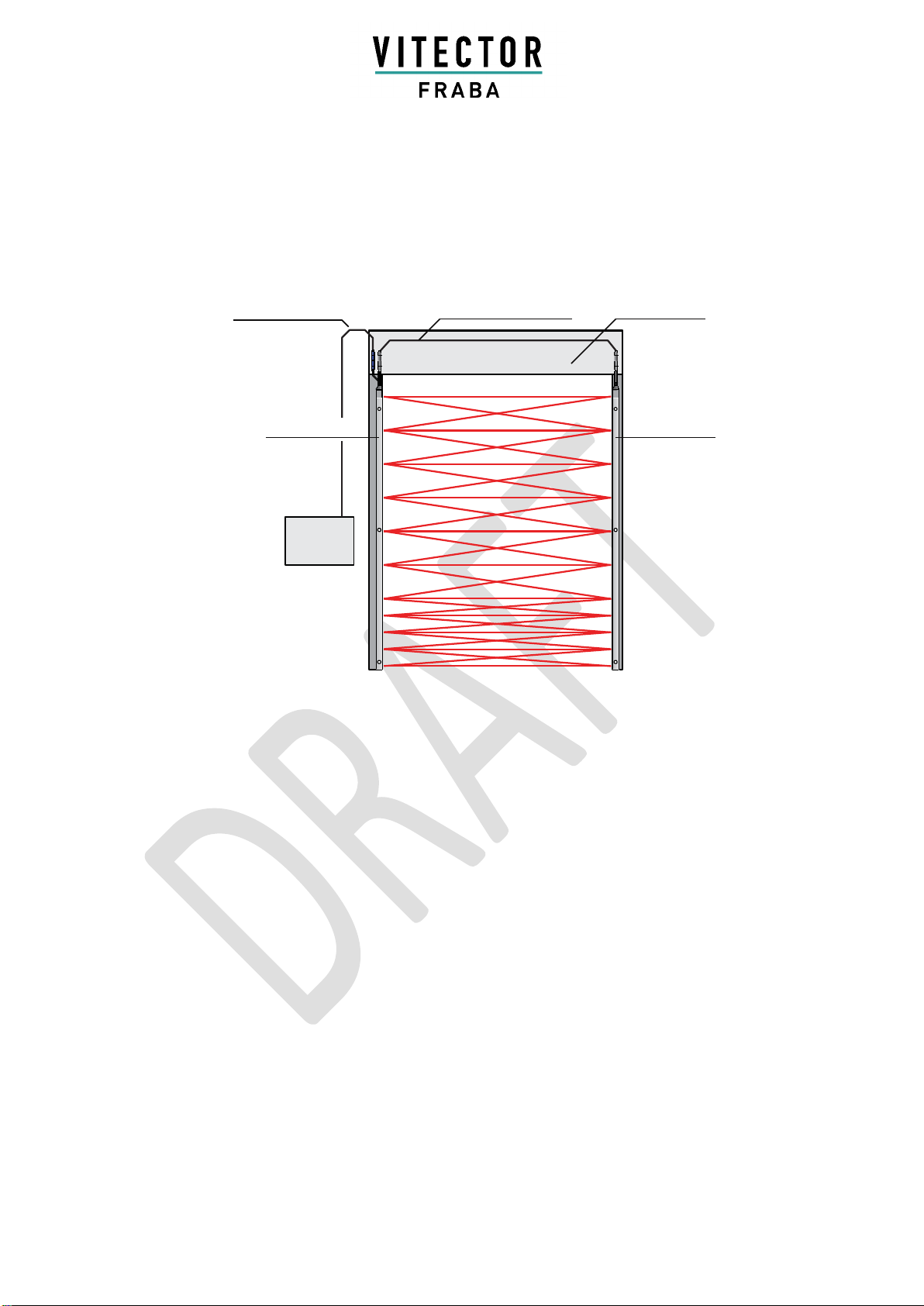

Application Overview

Door Blanking

The RAY-LG can differentiate between a light beam interruption caused by an object and a light beam

interruption caused by the closing door. The RAY-LG does this by analyzing the different interruption

patterns.

Blanking Routine during Door Closure:

The light beam interruption of a closing door starts at the topmost beam going downwards. There are two

ways to achieve blanking:

When the RAY-LG is integrated inside or, in this case matching holes need to be drilled, behind the side

guide, the door moves directly in front of the light curtain. The bottom section of the door needs to be solid

for at least 30 mm over the entire door width to ensure that at least one light element is completely

covered. Hollow extrusion profile may need to get clogged.

Door

Controller

Connection Cable

Synchronization Cable

Door Operator

Receiver

Emitter

Figure 4: RAY-LG application overview

MANUAL (TRANSLATION)

RAY-LG 35XX

Page 6 RAY-LG 35XX Version: 1.0

Optical element

Mounting hole

Min. height of the lower

end of the door

Optical element

Mounting hole

Min. distance

always covered

by the beam

blocker

When the installation of RAY-LG is not possible inside the side guide, it may also be mounted from the

back side (Figure 5.1). Holes of min Ø 10 mm must be drilled into the profile to allow the light to pass

through.

If two light curtains are installed parallel to, but not in line with the door panel in front of and behind the

guide rail, the descending door will not interrupt the active beams. (Figure 5.2) However, blanking may still

be required if any obstructing part of the door (e.g. strengthening bars, hinges, junction boxes) interrupt the

light curtain. A beam blocker can be employed to shade the diodes on one side, but it must be mounted so

that at least one element is continuously covered during door closure (Figure 5.2).

3 seconds after the last beam was interrupted by the now closed door, the output signal is interrupted.

Figure 5.1:Door blanking through door edge

Figure 5.2:Door blanking with two RAY-LG sets

MANUAL (TRANSLATION)

RAY-LG 35XX

Page 7 RAY-LG 35XX Version: 1.0

Blanking Routine during Door Opening / Partial Opening Function

The output signal will remain off during the opening of the door until the 11th beam is unobstructed (approx.

500 mm opening height). From this position onwards it will be possible to reverse and close the door in

automatic mode. Successively releasing additional light beams will increase this partial opening position

accordingly. During a later closing cycle, the monitored area and the smart blanking function will be limited

to the previously saved partial opening height, higher positioned light beams will remain blanked.

When the power supply of the RAY-LG is interrupted in a partial opening position, it is necessary to open

the door higher than the safeguarded area to allow the system to undergo an automatic initialization

routine.

Installation

WARNING:

Electrical and Mechanical Hazards

Electrical shock and unexpected door movement can cause serious injury or death.

▪Follow all applicable safety measures

▪Use only specific and approved tools

▪If the RAY-LG must be adjusted, the main power supply must be switched off and marked as “out

of service”.

Serious Health Risks - Disregarding these warnings can result in serious injury or death

▪Never scratch or paint the optical lenses because it

may obstruct the light path! Do not drill additional

holes into the profile. Unpack the profiles just before

installation in order to avoid damage.

▪Do not bend or twist the edges!

▪Oil can damage the cables. Contamination must

always be avoided!

▪Chemical can damage the profile and optical

characteristics. Contact must always be avoided!

NOTICE:

Mechanical Damage to the RAY-LG

▪Do not drill additional holes into the light curtain

▪Do not drill through mounting holes

▪Do not over-tighten the mounting screws

▪Mount the edges on a flat surface

Risk of damage - Disregarding this notice can lead to damage to the sensor, the door controller and / or

other devices

MANUAL (TRANSLATION)

RAY-LG 35XX

Page 8 RAY-LG 35XX Version: 1.0

▪Although the RAY-LG is not sensitive to direct sunlight,

avoid all unnecessary exposure if possible, especially

to the receiver.

▪Avoid interference from blinking lights or infrared light

sources such as photocells or other light curtains.

▪Do not install the RAY-LG in places where the emitter

and receiver edges are directly exposed to light

sources such as FL tubes or energy saving lamps.

▪Make sure to place the connection plugs for both the

emitter and receiver at the same end.

1. Switch off main power to the door control unit

and clearly mark that this system is out of

service before performing any work on the

system.

2. Mount the receiver on one side of the door

with better access to Door control unit for

easier cabling and only use the mounting

holes provided on the sensor bars (See

Figure 6.2).

3. In case of severe disturbances or direct

sunlight mount the receiver on the opposite

side

4. Mount the receiver bar into the guiding track

next to the door control unit (See Figure 5.1).

In order to fulfill EN 12978:2009 the lower end

of the edges must be at the level of the door

closed position (See Figure 6.1).

5. Mount the emitter across from the receiver. If

the receiver is mounted in the guiding track,

the emitter should be mounted in the guiding

track opposite the receiver. Make sure the

optical elements are facing each other (See

Figure 6.1).

6. Connect the emitter with the receiver using

the synchronization cable.

7. Plug the connection cable into the blue plug

on the receiver bar and connect it to the door

controller (See Electrical Connection, p. 9).

8. If using two RAY-LG on sides of the slide

guide rail (See figure 5.2) make sure that

both receiver bars are not mounted on the

same side of the door to avoid interference

between two sets.

Figure 6.1:Proper Mounting

Figure 6.2:Mounting Holes

MANUAL (TRANSLATION)

RAY-LG 35XX

Page 9 RAY-LG 35XX Version: 1.0

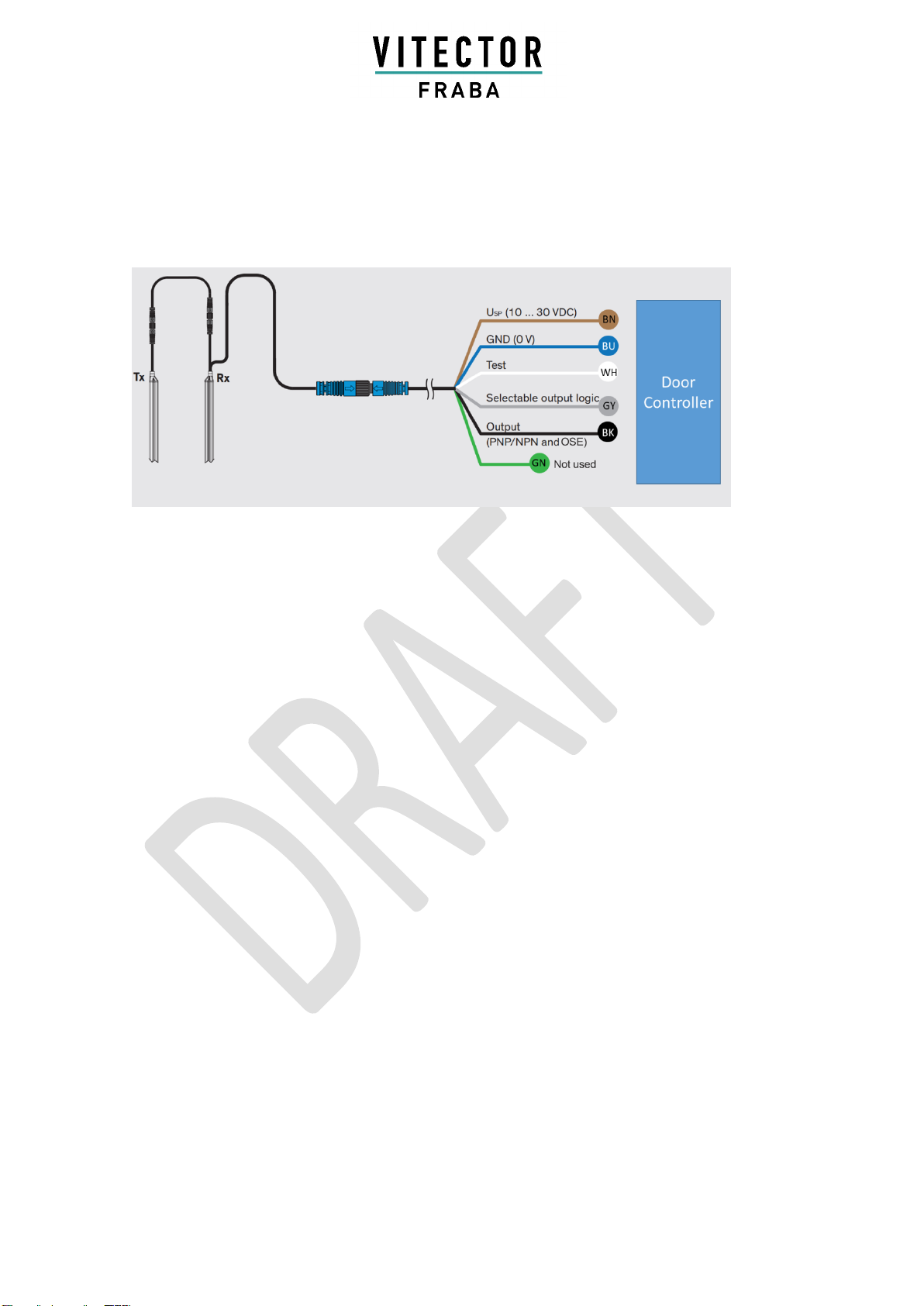

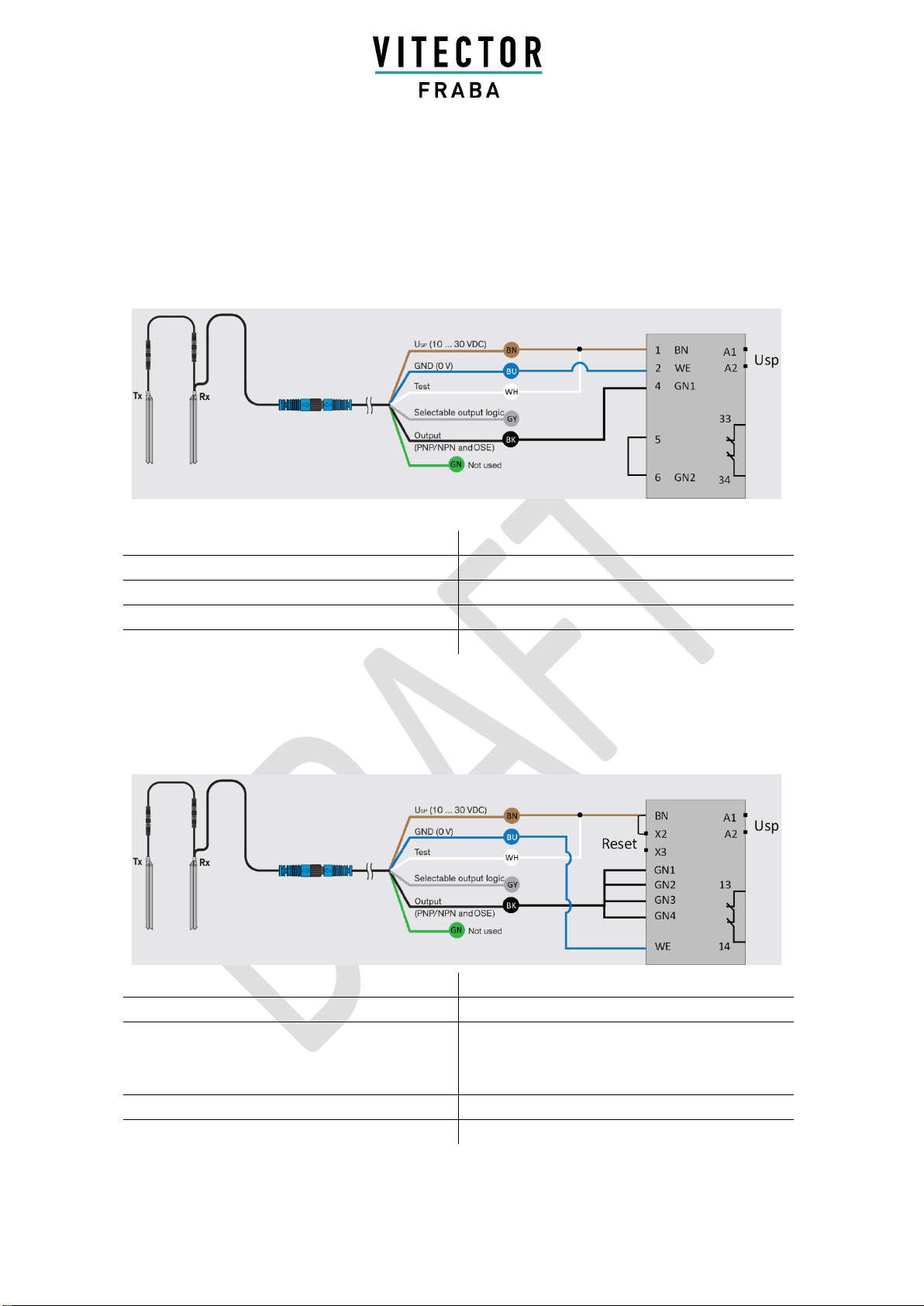

Electrical Connection

Figure 7: Connection diagram

Important: Any unconnected (not used) wire must be separated and isolated.

Output

When an obstruction is detected, (OBJECT

DETECTED) the RAY-LG output changes after

response time t2. When the object leaves the

surveillance area (NO OBJECT) the RAY-LG

output switches back after release time t3 (See

Timing Diagram, p. 11)

MANUAL (TRANSLATION)

RAY-LG 35XX

Page 10 RAY-LG 35XX Version: 1.0

Changing the output logic

Output (PNP/NPN) logic is set using the gray wire.

The default logic is LO (light-on) (See Timing

Diagram, p. 11).

The output logic is LO if the gray wire is connected

to GND (0 V). Connecting the gray wire to USP (10

to 30 VDC) changes the output logic to DO (dark-

on) (See Figure 9). If the gray wire is not

connected (floated), the output logic changes to

the OSE signal.

Gray wire Output logic

Not connected (floated) OSE

Connected to GND (0 V) LO

Connected to USP (10 to 30 VDC) DO

Table 1: Output (PNP/NPN) logic selection table

LO/DO selector not connected (floated)

LO/DO selector connected to USP

LO/DO selector connected to GND (0 V)

Figure 8: Output logic

MANUAL (TRANSLATION)

RAY-LG 35XX

Page 11 RAY-LG 35XX Version: 1.0

OSE Output

The OSE is a 1 kHz safety output allowing for

monitoring according to EN ISO 13849-1:2015,

without using a test signal. For the OSE version

the test input (white cable) of the light curtain has

to be connected to supply voltage (brown cable).

As long as the monitored area is free, the OSE

output sends a 1 kHz signal. When an object

enters the monitored area (OBJECT DETECTED)

the OSE output switches to LOW/GND (0V). When

the object leaves the monitored area (NO

OBJECT) the frequency starts again (See Timing

Diagram, p. 11).

Test Input

To fulfill EN ISO 13849-1:2015, the RAY-LG with

PNP/NPN output must be tested by the door

controller before each door closing cycle. The

RAY-LG is available with test active LOW.

Important: When the OSE output is used, using

the test input is not necessary to achieve

monitoring according to EN ISO 13849-1:2015. In

this case, the white wire must be connected to the

USP.

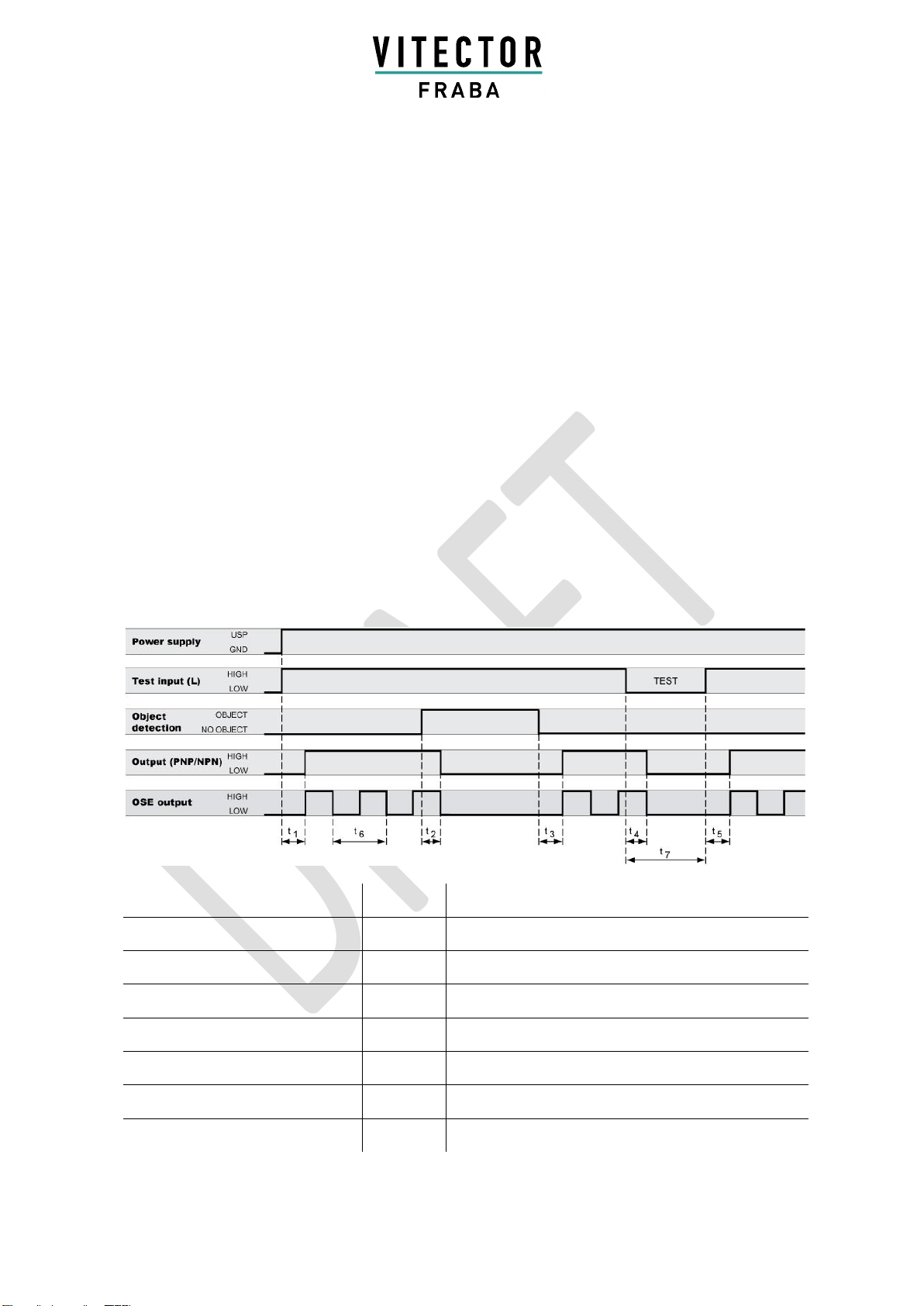

Timing Diagram

Figure 9: General timing diagram

Time

Value

Power up time

t1

max. 1,700 ms

Response time with 22 elements

t2

typ. 40 ms / max. 80 ms

Release time

t3

max. 50 ms

Test response time

t4

max. 80 ms

Restart time

t5

max. 200 ms

OSE sequence time

t6

1 ms

Test time

t7

>100 ms

Table 2: General timing table

MANUAL (TRANSLATION)

RAY-LG 35XX

Page 12 RAY-LG 35XX Version: 1.0

PNP / NPN

Power supply USP

10…30 VDC

Power supply GND

0 V

Test input HIGH

> 10 VDC

Test input LOW

< 2 VDC

Output HIGH

> USP - 2 VDC

Output LOW

< 2 VDC

OSE output HIGH

3.4…4.2 VDC

OSE Output LOW

< 1 VDC

Table 3: General value table

Start-up

1. The door must be opened completely, and

the monitored area must be unobstructed.

2. Switch on main power supply and power up

the door control unit. The LEDs blink during

power up.

3. Check the LED on both sensor bars (power,

status).

4. Test if the system is working correctly by

letting the door open and close, interrupting

the light during the opening and closing

process.

LED Status Description Receiver Edge

green LED

red LED

Sensor status

Light curtain free

Light curtain interrupted

Start-Up (slow blinking)

Internal Malfunction (fast

blinking)

No Power or light curtain

defective

LED on LED off LED blinking

Table 4: LED status description receiver edge

LED Status Description Emitter Edge

green LED

Sensor status

Power ok

No Power or not within the limits or

edge is defective

LED on LED off

Table 5: LED status description emitter edge

MANUAL (TRANSLATION)

RAY-LG 35XX

Page 13 RAY-LG 35XX Version: 1.0

Troubleshooting

Emitter (Tx)

Receiver (Rx)

Action

LED off

LED off

▪Check electrical connections.

▪Check supply voltage of the door controller.

LED off

LED red

▪Check the connection of the synchronization cable.

LED green

LED always green

(also, when

interrupted)

▪Make sure the sensor edges are not mounted

close to any shiny or reflective surface.

▪Restart the system.

LED on/off

LED on/off

(flickering red)

▪Check power supply.

▪Check connections.

LED green

LED on/off, min. 100ms

off (red, slow blinking)

▪Make sure the protective field is clear of interruption

▪Check the alignment of the light curtain

▪Clean elements.

LED on

LED switching

between red

(interrupted) and

green (free), sporadically

flickering

▪Make sure the protective field is clear of interruption

▪Clean the elements

▪Make sure that the cables and sensor bars are located

away from sources of electromagnetic interference.

▪Ensure that the emitter and receiver are correctly

aligned and remain so during door closure (e.g. that

vibrations do not cause edges to become misaligned).

▪Restart the system.

LED green

LED always red

▪Make sure the protective field is clear of interruption.

▪Reopen the door completely.

▪Clean the elements.

▪Check the alignment of the light curtain.

▪Check that the test input is connected to the test output

signal of the door control unit and that the signal level

and logic (HIGH/LOW) are correct. If the test input is not

used, connect it permanently to USP.

▪Measure the USP voltage.

▪Restart the system.

LED off

LED on/off, min. 100ms

off (red, slow blinking)

▪Check the connection of the synchronization cable.

LED green

LED on/off (red, fast

blinking, 5 Hz)

▪Internal error occurred

▪Restart the system.

▪Replace Rx edge.

MANUAL (TRANSLATION)

RAY-LG 35XX

Page 14 RAY-LG 35XX Version: 1.0

Important: Whenever a parameter is changed, the system must be restarted. If a problem persists, please

contact your local FRABA VITECTOR representative. Visit www.vitector.eu for contact data.

Maintenance

Although the RAY-LG does not need regular maintenance, a periodic functional check is strongly

recommended:

▪Make sure the optical elements are clear of dirt and dust. If necessary, clean the front surface with a

soft towel.

▪Make sure the profiles are securely fastened.

▪Check the mounting position, cable routing, and connection of the sensor.

Disposal

Disposal should be done using the most up-to-date recycling technology according to local regulations and

laws. There are no harmful materials used in the design and manufacture of the sensor. Traces of such

dangerous materials may be found in the electronic components but not in quantities that are harmful.

NOTICE:

Damage to the optical elements

▪Never use any solvents, cleaners or mechanically abrasive towels or high-pressure water to clean

the sensor

▪Avoid scratching the optical elements while cleaning

MANUAL (TRANSLATION)

RAY-LG 35XX

Page 15 RAY-LG 35XX Version: 1.0

Technical Data of RAY-LG 35xx

Optical

Operating range

1…10 m (3ft…33 ft)

Number of

elements

20, 22

Max. ambient

light

100,000 Lux

Max. protection

height

2,500 mm (98.5 in)

Mechanical

Cross section

12 mm × 14.5 mm (0.47 in ×

0.57 in)

Housing material

Natural anodized aluminum

Enclosure rating

IP68 (Cable: IP67)

Temperature

range

−40 °C…+60 °C (−40

°F…+140 °F)

Electrical

Supply voltage

USP

10…30 VDC

Current

Consumption with

22 elements at 24

VDC

50 mA

Output

PNP/NPN (push-pull) and

OSE

Output load

100 mA, 100 nF

Typ. response time

with 22 elements

40 ms

Max. response time

with 22 elements

80 ms

Max. door speed

closing speed

1.6 m/s (5.3 ft/s)

Max. door speed

opening speed

> 3 m/s

Status LED Rx:

Object detected: red

No object detected: green

Power LED Tx:

Power OK: green

MANUAL (TRANSLATION)

RAY-LG 35XX

Page 16 RAY-LG 35XX Version: 1.0

General

EMC emission

EN 61000-6-3:2007

EN 12015:2014

EMC immunity

EN 61000-6-2:2005

EN 12016:2013

Vibration

EN 60068-2-6:2007

Shock

IEC 60068-2-27:2008

RoHS

2011/65/EU

Certificates

CE, TÜV

Safety category

EN 12978:2009

EN 61508:2010, SIL 2

EN ISO 13849-1:2015, Cat.

2, PL D

EN 12453:2017, E Device

Applicable

standards

UL 325:2012

Synchronization and electrical connection

Extention cable

Length

10 m (33 ft)

Connector

M8, 4 pins, A-coded

Diameter

Ø 3.5 mm (Ø 0.14 in)

Material

PVC, black

Plug color

Black

Wires:

brown

blue

black

white

AWG26

USP

GND (0 V)

Communication

Not used

Connection Cable

Length

5 m (16.5 ft)

Connector

M8, 6 pins, A-coded

Diameter

Ø 4.2 mm (Ø 0.14 in)

Material

PVC, black

Plug color

Blue

Wires

brown

blue

black

white

gray

green

AWG26

USP

GND (0 V)

Output (PNP/NPN and OSE)

Test input

LO/DO selector

Not used

MANUAL (TRANSLATION)

RAY-LG 35XX

Page 17 RAY-LG 35XX Version: 1.0

Dimensions

Measurements for 22 elements (all dimensions in mm)

Figure 10: RAY-LG 3522 Dimensions (mm)

Measurements for 20 elements (all dimensions in mm)

Figure 11: RAY-LG 3520 Dimensions (mm)

MANUAL (TRANSLATION)

RAY-LG 35XX

Page 18 RAY-LG 35XX Version: 1.0

Control Unit OSE-C 2300 or OSE-C 2301 / OSE-C 2323 or OSE-C 2324

Supply Voltage USP

24 VDC or 230 VAC

Dimensions

123 x 83 x 61 mm

Enclosure Rating

IP56

Safety Category of the Control Unit

3 acc. EN 13849-1:2008

Performance Level of the Control Unit

c acc. EN 13849-1:2008

Please pay attention to the operating manual of the control unit!

Control Unit OSE-C 5024

Supply Voltage USP

24VAC/DC

Dimensions

22.5 x 100 x 120 mm

Enclosure Rating

- Housing

- Terminal

IP40

IP20

Safety Category of the Control Unit

3 acc. EN 13849-1:2008

Performance Level of the Control Unit

d acc. EN 13849-1:2008

Please pay attention to the operating manual of the control unit!

MANUAL (TRANSLATION)

RAY-LG 35XX

Page 19 RAY-LG 35XX Version: 1.0

Product Label

Lot No.:

yymmdd: year (2 digits), month, day

mmmmmmmm: manufacturing job number

eeeee: employee number responsible for final test

cccccc: incremental number

Technical Instruction valid from year of manufacture 2019

Disclaimer

© FRABA B.V. all rights reserved. We do not assume responsibility for technical inaccuracies or

omissions. Specifications are subject to change without notice.