Vitzro VITAC 200 User manual

VITAC 200

ATS Controller

www.vitzroem.com

Manual

VITAC 200

ATS Controller

Manual

4

Thank you for purchasing VITAC 200

▶

Please make sure to read all safety precautions thoroughly before using this product for proper use of the product.

▶

Please provide this user manual to end users and maintenance manager.

▶

Please keep this manual in a place where users can easily refer to at any time, after reading this manual.

▶

Please follow safety precautions to prevent any accidents or risks by using the

product safely and properly.

▶

Precautions are grouped into two types - “Warning” and “Caution”

1. Do not perform wiring work when power is supplied or the product is in operation.

2. There is always a dangerous level of voltage in the terminal that connects digital input, power,

and external I/O circuit power when operating normally.

3. Be sure to follow standard safety precautions while installing or maintaining the product.

4. General users should not access the terminal after product installation.

1. The product may be seriously damaged if the voltage/current that deviates from the power

supply input rating is applied.

2. Do not allow screws, metal objects, water, or oil to get inside the product.

3. Observe the rated load specifications of the input and output contacts.

4. Do not wire the cable at your own discretion.

5. Only qualified electricians are allowed to perform wiring, trial operation, and maintenance.

6. Do not run a withstand voltage test because all external terminals including the product power

plug are equipped with a withstand voltage protection device.

Safety Precautions

Warning

▶

In case severe injuries or death takes place when violating the instructions.

Warning

※

Please read this manual carefully before using the product to ensure that the functionality of this product is used fully and safely.

Caution

▶

In case minor injuries or product damage takes place when violating

the instructions.

Caution

5

▶

Warranty conditions

The warranty of the Vitzro product lasts 2 years and you can get support for the product

itself within that period.

▶

VITZRO shall not be liable for any warranty of the product damages caused by the followings.

•

If the product has been used without considering the installation information

(rated power, CT, DI, DO, communication), power supply, PT/CT, and digital I/O rating that are

specified in the product user guide.

•

If the product is damaged due to external artificial factors or product installation environment.

•

If the sealing sticker is not attached to the product or the product has been opened.

Warranty Information

The following is the warranty for the original Vitzro product purchaser.

Revision History

Version 1.0 2018. 03. 16

First Edition

4. 1 Measurement functions

··························

10

4. 2 ATS control function

·····························

10

4. 2. 1 Manual switchover function

·················

10

4. 2. 2 Automatic switchover function

···············

11

4. 2. 3 Automatic recovery function

·················

12

5. 1 Parameters related to switchover function setting

···

13

5. 2 Parameters related to system setting

··············

14

5. 3 How to set major parameters

·················

14-18

3. 1 Composition of the front unit

······················

8

3. 2 Composition of the rear unit

·······················

9

8. 1 ATS-W&WP Type connection wiring diagram

·······

20

8. 2 ATS-WN Type connection wiring diagram

···········

21

1. Overview

··············································

7

4. Major functions

································

10-12

3. Product composition

····························

8-9

2. Rating

··················································

7

5. Major parameters

·····························

13-18

6. Dimension

···········································

19

7. Installation

··········································

19

8. External connection wiring diagram

······

20-21

9. Test results

·········································

22

10. Guarantee

Contents

7

1. Overview

VITAC 200 is an electronic controller that controls the Automatic Transfer Switch (hereafter “ATS”),

and has the following characteristics.

2. Rating

Item Specification

Control power

Voltage : AC 220 [V] (Input range : AC 130 [V] ~ 270 [V])

Type : Self-power using the power transformer

Power consumption

Constant switchover : Under 4W [5W]

Frequency

60 / 50 [Hz]

Voltage

Rating

AC 220 [V]

Number of channels (2ea)

A-phase voltage of the commercial power

A-phase voltage of the emergency power

Measurement scope

130 [V] ~ 270 [V] (measurement error: ±3 %)

Input contact

Type

Dry Contact

Number of channels (3ea)

Switch on state of the commercial power side

Switch on state of the emergency power side

Switchover interlock input state

Output contact

Type

For control : Wet contact (AC 220 [V]), NO (Normal Open)

For alarms : Dry contact, NO (Normal Open)

Contact point capacity

For control : AC 250V, 16A

For alarms : AC 250V, 5A

Number of channels (3ea)

For control : Switch on of the commercial power side,

switch on of the emergency power side

For alarms : Fault alarm

Communication

RS 232 serial communication (Modbus-RTU)

● Resumes power supply to load by controlling the ATS when power fails, by always monitoring the

commercial and emergency power.

● Reflects the power characteristics of the product installation site by setting the level of commercial and

emergency power monitoring.

● Supports automatic switchover to the commercial power when the commercial power returns to

normal level during emergency power operation.

● Controls the ATS of other companies as the output time of the ATS control signal can be set,

and the closing/trip coil damage of the ATS can be prevented.

● Guarantees product reliability using EMC test items and self-diagnosis function.

●

Checks the state of the product and modifies major setting values using the VITZRO’s VICOM Manager program

(Modbus-RTU, RS-232)

● Installing on panels with various thickness by applying the screw fastening method.

8

3. Product composition

3. 1 Composition of the front unit

1

2

5

10 9 8 7

3

6

4

No. Item Detailed description

①

Status, emergency

power status display LED

☞

Green lamp on :

Power on (normal power supply)

☞

Green lamp blinking :

Abnormal power (OVR, UVR, OFR, UFR)

☞

Lamp off : Power off, LED damage, product damage

②

Commercial, emergency

switch status display LED

☞

Green lamp on :

Open

☞

Red lamp on : On

☞

Green lamp blinking : In switching over (LED of the switched side blinks)

☞

Lamp off : Power off, LED damage, product damage

③

Commercial, emergency

switchover failure display LED

☞

Red lamp on : Switchover failure

1)

☞

Lamp off : Normal

④

Rotary switch to set the

commercial and emergency

switchover delay

☞

Rotary switch to set the commercial and emergency

switchover delay

Setting range : 0 ~ 45 seconds (setting in 5 seconds)

⑤

Switchover interlock

2)

input status LED

☞

Red lamp on : Input on

☞

Lamp off : Input off

⑥

Auto/Manual status displayed

LED

☞

Red lamp on :

Auto

☞

Green lamp on : Manual

☞

Lamp off : Power off, LED damage, product damage

⑦

Auto/Manual

selection button

☞

Operation in an Auto state :

Changes to Manual

☞

Operation in a Manual state :

Changes to Auto

⑧

Button to turn on the

commercial power side switch

☞

Turns on the commercial power side switch

⑨

Reset button

☞

S/W Reset

⑩

Button to turn on the

emergency power side switch

☞

Turns on the emergency power side switch

(Detailed description of the front unit)

1) Determined to be switchover failure only when switchover fails after making an attempt three times.

2) Switchover operation will not be performed even though the automatic switchover situation occurs, when inputting the switchover interlock.

*Precautions when manipulating buttons: Buttons will be activated only when pressed and held more than 1.5 seconds.

9

3. 2 Composition of the rear unit

No. Terminal name Name Description

①

a1

Alarm Output

Fault alarm contact output terminal

(Outputs when switchover fails or the controller is

abnormal.)

a2

②

UP

Utility Voltage

Commercial power input terminal

UN

③

A1

Operating Signal

Switch on contact output terminal at the use power side

A2

④

UTIL ON

Status Signal

Switch status input terminal at the commercial power side

EMG ON

Status input terminal at the emergency power side

Inter-Lock

Interlock status input terminal

COM

Input common terminal

⑤

B1

Operating Signal

Switch on contact output terminal at the emergency

power side

B2

⑥

EP

Emergency Voltage

Emergency power input terminal

EN

(Detailed description of the rear unit)

2 53 64

1

10

4. 1 Measurement functions

4. 2 ATS control functions

Type Display Range Precision

Commercial power voltage 130 ~ 270 V ± 3 %

Emergency power voltage 130 ~ 270 V ± 3 %

Commercial power frequency 40 ~ 70 Hz ± 0.2 Hz

Emergency power frequency 40 ~ 70 Hz ± 0.2 Hz

VITAC 200 provides measurement and ATS control functions, and major parameters related to ATS

control can be modified using engineering software.

The single-phase voltage and frequency of the commercial and emergency power can be measured.

The following table shows the measurement range and precision.

VITAC 200 supports the W-Type and WN-Type ATS of VITZRO and various ATS of other suppliers.

If VITAC 200 is used with the 3Position ATS (as the WN-Type ATS of VITZRO), use the same wiring

method with the WN-Type of VITZRO.

4. Major functions

4. 2. 1. Manual switchover function

Switchover is performed manually using buttons located in the front. Please take the following

steps to perform switchover.

Step 1. Set manual mode

Check the “Auto/Manual status display LED”. If the mode is Auto (red lamp on), press and hold the

“Auto/Manual selection” button until the mode is changed to Manual (green lamp on).

Step 2. Perform manual switchover

①

Manual switchover from the emergency power to the commercial power

Press and hold the “Emergency power side switch on” button more than 1.5 seconds to change over

to the emergency power side.

However, switchover operation will be performed only when the emergency power is normal

(green lamp on the emergency power status display LED) and the LED status will be changed as follows.

- Switch status LED at the commercial power side: Changes from green to red.

- Switch status LED at the emergency power side: Changes from red to green.

②

Manual switchover from the commercial power to the emergency power

Press and hold the “Commercial power side switch on” button more than 1.5 seconds to change over

to the commercial power side.

However, switchover operation will be performed only when the commercial power is normal

(green lamp on the commercial power status display LED) and the LED status will be changed as follows.

- Switch status LED at the commercial power side: Changes from red to green.

- Switch status LED at the emergency power side: Changes from green to red.

11

4. 2. 2. Automatic switchover function

If a power error is detected while monitoring the state of the commercial power and emergency power,

the power is automatically changed over, in order to resume power supply to load. If the controller is

in Auto mode (“Auto/Manual status display LED” red is on), the following switchover operation will be

performed.

If switchover is not performed normally, switchover will be attempted again three times. If switchover

still fails, it will be recognized as an ATS problem and the switchover failure LED will turn on.

Automatic switchover from the commercial power to the emergency power

If the emergency power is normal 3) when a problem occurs at the commercial power (abnormal power

4)

or non-supply

5)

while running with the commercial power, automatic switchover to the emergency power

side will be performed after the time specified in the “emergency switchover delay time setting”.

Performing automatic switchover can be checked using the “switch status display LED at the emergency

power side”, and LED changes as follows, depending on the switchover progress.

-

Switchover in progress :

The “switch status display LED at the emergency power side” blinks in green.

- Successful switchover

﹡

Switch status LED at the commercial power side : Changes from red to green.

﹡

Switch status LED at the emergency power side : Changes from green to red.

- Switchover failure

﹡

Switch status LED at the commercial power side : Keeps the red lamp on.

﹡

Switch status LED at the emergency power side : Keeps the greed lamp on.

﹡

Switchover failure LED at the commercial power side : Turns the red lamp on.

Automatic switchover from the emergency power to the commercial power

If the commercial power is normal when a problem occurs at the emergency power (abnormal power or

non-supply) while running with the emergency power, automatic switchover to the commercial power

side will be performed after the time specified in the “commercial switchover delay time setting”.

Performing automatic switchover can be checked using the “switch status display LED at the commercial

power side”, and LED changes as follows, depending on the switchover progress.

- Switchover in progress:

The “switch status display LED at the commercial power side” blinks in green.

- Successful switchover

﹡

Switch status LED at the commercial power side : Changes from green to red.

﹡

Switch status LED at the emergency power side : Changes from red to green.

- Switchover failure

﹡

Switch status LED at the commercial power side : Keeps the greed lamp on.

﹡

Switch status LED at the emergency power side : Keeps the red lamp on.

﹡

Switchover failure LED at the emergency power side : Turns the red lamp on.

3) Normal power: When no overvoltage, low voltage, over-frequency, or low-frequency problem occurred.

4) Abnormal power: When the overvoltage, low voltage, over-frequency, or low-frequency problem occurred.

5) No power supply: When 0 [V] voltage is measured because no power is supplied.

12

4. 2. 3 Automatic recovery function

The function of changing over to the high priority power automatically even though the currently

supplied power is normal, if the power with higher priority becomes normal.

This function will be enabled only when the “automatic recovery function” is activated.

Please refer to Chapter 5 “Major parameters” regarding “automatic recovery function setting” and

“power priority setting”.

If the commercial power has higher priority than the emergency power.

Automatically changes over to the commercial power side after the time set in “commercial switchover

delay time setting” according to power supply priority, when the commercial power becomes normal

while running with the emergency power.

Performing automatic switchover can be checked using the “switch status display LED at the

commercial power side”, and LED changes as follows, depending on the switchover progress.

-Switchover in progress :

The “switch status display LED at the commercial power side” blinks in green.

- Successful switchover

﹡

Switch status LED at the commercial power side : Changes from green to red.

﹡

Switch status LED at the emergency power side : Changes from red to green.

- Switchover failure

﹡

Switch status LED at the commercial power side : Keeps the greed lamp on.

﹡

Switch status LED at the emergency power side : Keeps the red lamp on.

﹡

Switchover failure LED at the commercial power side : Turns the red lamp on.

If the emergency power has higher priority than the commercial power.

Automatically changes over to the emergency power side after the time set in “emergency switchover

delay time setting” according to power supply priority, when the emergency power becomes normal

while running with the commercial power.

Performing automatic switchover can be checked using the “switch status display LED at the emergency

power side”, and LED changes as follows, depending on the switchover progress.

- Switchover in progress :

The “switch status display LED at the emergency power side” blinks in green.

- Successful switchover

﹡

Switch status LED at the commercial power side : Changes from red to green.

﹡

Switch status LED at the emergency power side : Changes from green to red.

- Switchover failure

﹡

Switch status LED at the commercial power side : Keeps the red lamp on.

﹡

Switch status LED at the emergency power side : Keeps the greed lamp on.

﹡

Switchover failure LED at the commercial power side : Turns the red lamp on.

13

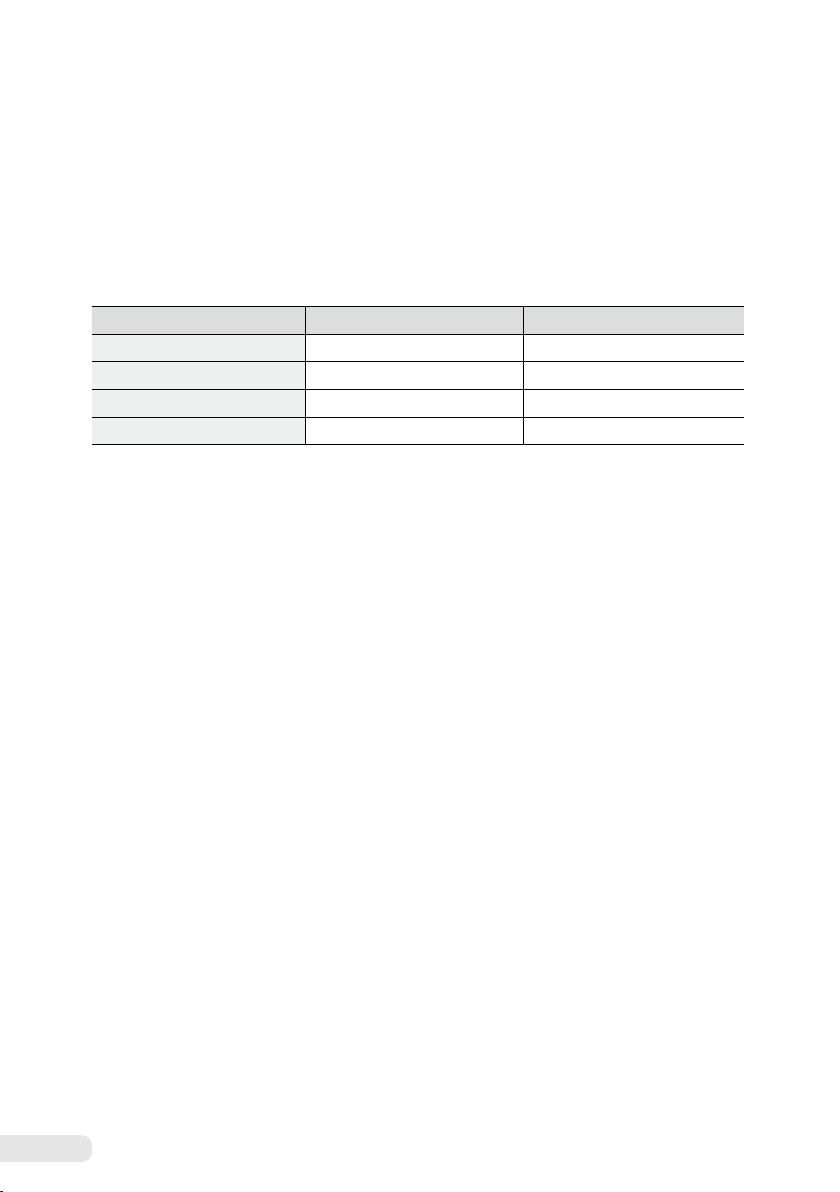

5. 1 Parameters related to switchover function setting

Item Setting range Description

Default value

Compression

voltage setting

[low voltage]

Operation

setting Enable / Disable

Sets automatic switchover when the low

voltage occurs. (Enable : Switchover,

Disable : No switchover)

Enable

Pick Up 150.0 ~ 210.0 [V]

Low voltage setting

176 [V]

Time Delay 0.0 ~ 99.9 [S]

Sets the time of keeping the low voltage.

(Performing switchover if the low voltage is

kept for the specified period of time.)

1 [S]

Compression

voltage setting

[Over voltage]

Operation

setting Enable / Disable

Sets automatic switchover when the

overvoltage occurs. (Enable : Switchover,

Disable : No switchover)

Enable

Pick Up 230.0 ~ 245.0 [V]

Overvoltage setting

242 [V]

Time Delay 0.0 ~ 99.9 [S]

Sets the time of keeping the overvoltage.

(Performing switchover if the low voltage is

kept for the specified period of time.)

1 [S]

Switching

frequency setting

[the low frequency]

Operation

setting Enable / Disable

Sets automatic switchover when the low

frequency occurs. (Enable : Switchover,

Disable : No switchover)

Enable

Pick Up 58.0 ~ 60.0 [Hz]

Low frequency setting

59 [Hz]

Time Delay 0.0 ~ 99.9 [S]

Sets the time of keeping the low frequency.

(Performing switchover if the low voltage is

kept for the specified period of time.)

1 [S]

Switching

frequency setting

[the over frequency]

Operation

setting Enable / Disable

Sets automatic switchover when the over-

frequency occurs. (Enable : Switchover,

Disable : No switchover)

Enable

Pick Up 60.0 ~ 62.0 [Hz]

Over-frequency setting

61 [Hz]

Time Delay 0.0 ~ 99.9 [S]

Sets the time of keeping the over-frequency.

(Performing switchover if the low voltage is

kept for the specified period of time.)

1 [S]

Normal voltage

range setting

Maximum

voltage 231.0 ~ 240.0 [V] Sets the maximum normal voltage value. 235 [V]

Minimum

voltage 150.0 ~ 215.0 [V] Sets the minimum normal voltage value. 181 [V]

Normal frequency

range setting

Maximum

frequency 60.0 ~ 62.0 [Hz]

Sets the maximum normal frequency value.

60.5 [Hz]

Minimum

frequency 58.0 ~ 60.0 [Hz]

Sets the minimum normal frequency value.

59.5 [Hz]

VITAC 200 provides the following parameters to reflect the power characteristics of the product

installation site and control the ATS smoothly.

5. Major parameters

14

5. 2 Parameters related to system setting

5. 3 How to set major parameters

VITAC 200 may malfunction if you change major parameters at your own discretion.

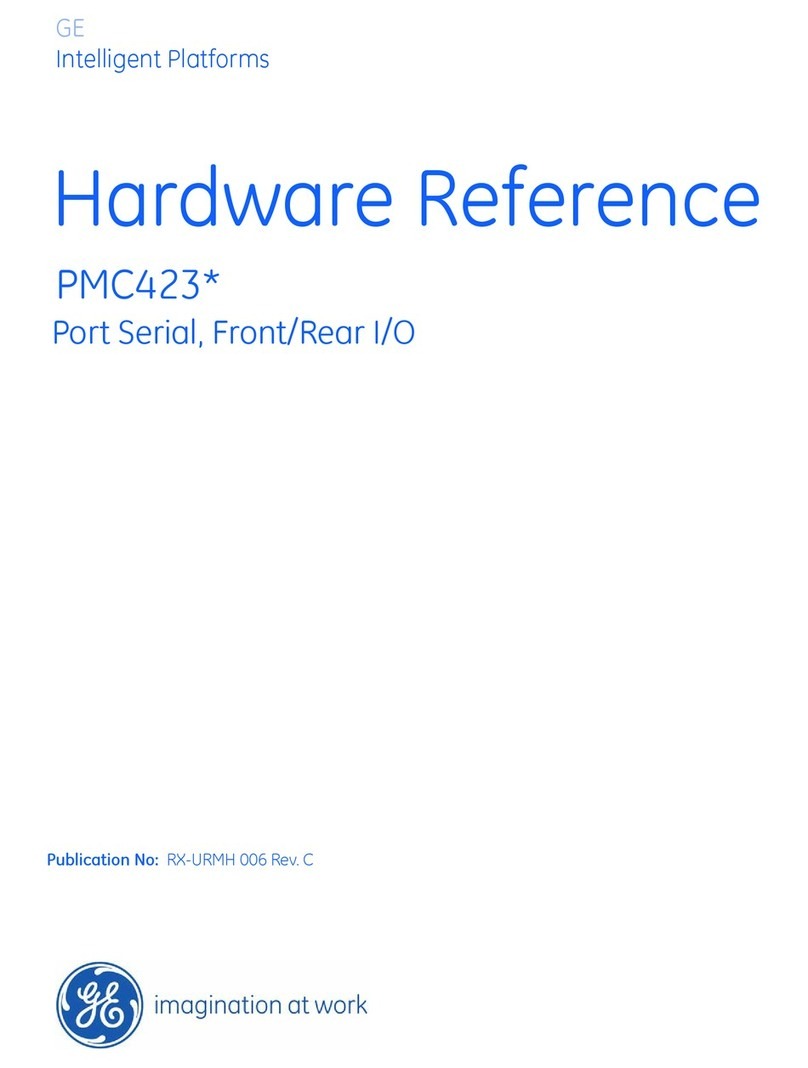

1) Communication environment configuration

①

Connect the “Micro-B USB to D-sub” cable to the “Micro-B USB” port of VITAC 200.

②

Connect the “Micro-B USB to D-sub” cable and “USB to Serial” cable.

③

Connect the USB terminal of the “USB to Serial” cable to the PC in which VICOM-Manager is installed.

※ The “USB to Serial” cable and “USB to Serial” cable for communication are not provided. Therefore, you need to purchase separately.

Micro-B USB Port

Micro-B USB to D-sub Cable USB to Serial cable

PC with VICOM installed

Item Setting range Description

Default value

Rated frequency 50 / 60 [Hz] Sets the rated frequency 60 [Hz]

Automatic recovery Enable / Disable Sets automatic recovery activation according

to power priority Enable

Switchover interlock Enable / Disable Sets the activation of the switchover interlock

function Enable

Power priority A Side / B Side Sets power priority A Side

Input/Open signal

output time 50 ~ 5000 [ms] Input/Open signal output time 500 [ms]

Number of retry times 0 ~ 10 [times] Number of retry times 3 [times]

Retry times 1 ~ 99 [S] Sets the waiting time to try switchover again 3 [S]

① ②

③

15

2) Installing VICOM-Manager

Run the VICOM-Manager installation file to install software at the desired folder.

3) Running VICOM-Manager

Run the VICOM-Manager icon on the desktop or in the software installation folder.

①

Logging into VICOM Manager

Input the user ID and password and then, press the Proceed button.

※ For more information on installation, please refer to the VICOM-Manager user manual.

※ The user ID and password are provided to the engineer only. For more information, please contact the manufacturer.

Proceed button

16

②

Selecting a VITAC 200 project

Select “VITAC_Series” from the recent project. If you cannot find “VITAC_Series” in the recent project,

click “Create a new project”.

※ For more information on new project creation, please refer to the VICOM-Manager user manual.

③

Setting communication

Select the “Project” tab for communication setting. Set the “communication information” on the

right side of the screen as follows.

- Map type :

MODBUS_RS232

- Type :

RS232

- Device ID :

1

- COM port :

Apply the Com port value set in the PC. (Check in Device Manager of the PC)

- Baud rate :

9600

17

④

Establishing communication

Select the “Device” tab to establish communication. Click “Establish communication” on the left

side of the device screen to start communication with VITAC 200.

<

Before establishing communication

>

<

After establishing communication

>

18

⑤

Checking and modifying major parameters

You can check the information or modify the setting value by selecting a menu item located at the

left side of VICOM-Manager.

- Measurement :

You can check the voltage and frequency of the commercial and emergency power.

- Status monitoring tab :

You can check the status of the commercial and emergency power,

and switch on/open status.

- Settings tab :

You can check the current value of major parameters. To change the setting value,

input the value to change and click the “Apply to IED” button.

19

6. Dimension

Appearance and dimension : 180(W) x 120(H) x 56.6(D) (mm)

The following figure shows how to install the VITAC 200 and the installation conditions.

7. Installation

※ VITAC 200 penetrates into the panel when installed. M4×L12 bolts are used (based on 3t panel thickness).

20

8. 1 ATS-W&WP Type connection wiring diagram

8. External connection wiring diagram

Table of contents

Popular Controllers manuals by other brands

LS

LS Smart I/O datasheet

Wulfsberg

Wulfsberg FLEXCOMM II C-5000 installation manual

Sun Yeh Electrical

Sun Yeh Electrical OM Series Operation manual

Philips

Philips Dynalite DMRC210DA-RJ12 installation instructions

KE2

KE2 Evaporator Efficiency Condensed Quick Start Guide

GE

GE PMC423 Series Hardware reference

Leroy-Somer

Leroy-Somer UMV 2301 AS Series Installation and Maintenance

Solcon

Solcon RVS-BX Series instruction manual

RC4 Wireless

RC4 Wireless LumenDim4 quick start guide

Titan Controls

Titan Controls Mercury 3 Easy guide

Trane

Trane TCONTCCMHCM04A Installation and operation manual

Desoutter

Desoutter CVIL II Operator's manual