Vizion UF-216 series User manual

WATER FILTRATION

SYSTEM

UF-216 Series

Owner’s Manual

P/N 1011078 Rev. B 03/12

Manufacturing

nuMbers:

9700435

UF-216 WATER FILTRATION SYSTEM

2

A.J. Antunes & Co.

P/N 1011078 Rev. B 03/12

General

VIZION, a division of A.J. Antunes & Co., has partnered

with companies from around the globe to produce the

UF-216 Series water filtration system. The UF-216

Series reduces cysts and turbidity that can enter a

typical water supply. This patented technology is now

available to you, sized for your particular application.

All filter configurations utilize NeoH capillary mem-

branes, providing the latest innovation in reusable sur-

face filtration technology.

This manual provides the safety, installation and

operating procedures for the UF-216 Series water

filtration system. We recommend that all information

contained in this manual be read prior to installing and

operating the unit.

Your UF-216 Series unit is manufactured from the finest

materials available and is assembled to VIZION’s strict

quality standards. This unit has been tested at the factory

to ensure dependable trouble-free operation.

OWNER INFORMATION

TABLE OF CONTENTS

IMPORTANT! Keep these instructions for future reference. If the unit changes

ownership, be sure this manual accompanies the equipment.

Warranty Information

Please read the full text of the Limited Warranty in this

manual.

If the unit arrives damaged, contact the carrier imme-

diately and file a damage claim with them. Save all

packing materials when filing a claim. Freight damage

claims are the responsibility of the purchaser and are

not covered under warranty.

The warranty does NOT extend to:

result of improper use.

components.

changing any preset control or safety device.

Owner Information .....................................................2

General......................................................................2

Warranty Information .................................................2

Service/Technical Assistance ....................................3

Important Safety Information ....................................4

Specifications .............................................................5

................................................................5

Replacement Cartridges............................................5

Ultra Filter Cartridge Capacities ................................5

Electrical Ratings.......................................................5

Electrical Cord & Plug Configurations .......................5

Overview......................................................................7

Overview....................................................................7

........................................................7

Installation...................................................................8

Unpacking..................................................................8

Equipment Setup.......................................................8

.................................................9

Inlet Water Plumbing .................................................9

Permeate Line Plumbing .........................................10

...........................................10

Starting the Controller .............................................10

Rinsing the Ultra Filter Cartridge.............................11

Sanitizing the System and Lines .............................11

Maintenance..............................................................12

Replacing the Ultra Filter Cartridge.........................12

System Sanitization.................................................12

Changing the Interval Setting..................................13

Resetting the Timer Program ..................................13

Troubleshooting .......................................................14

Replacement Parts ..................................................15

Limited Warranty ......................................Back Cover

UF-216 WATER FILTRATION SYSTEM

3

A.J. Antunes & Co.

P/N 1011078 Rev. B 03/12

Suggested replacement period for Ultra Filter Cartridge

is approximately 3 years.

For sales in the state of Iowa:

Service/Technical Assistance

If you experience any problems with the installation or

operation of your unit, contact us at 1-630-784-1000, or

toll free in the United States at 1-800-253-2991.

Fill in the information in the next column and have it

handy when calling for assistance. The serial number

is on the specification plate located on the unit.

Purchased From:

Serial No.:

OWNER INFORMATION (continued)

IMPORTANT

A.J. Antunes and Co. reserves the right to change specifications and product design without

notice. Such revisions do NOT entitle the buyer to corresponding changes, improvements,

additions or replacements for previously purchased equipment.

UF-216 WATER FILTRATION SYSTEM

4

A.J. Antunes & Co.

P/N 1011078 Rev. B 03/12

IMPORTANT SAFETY INFORMATION

In addition to the warnings and cautions in this manual,

use the following guidelines for safe operation of the unit:

corrosive chemicals in this equipment.

cord or plug; if it is not working properly, or if it has

been damaged or dropped.

-

sonnel only. Contact A.J. Antunes & Co. for repair.

The following warnings and cautions appear throughout

this manual and should be carefully observed:

service or maintenance on the unit.

with local electrical codes and any other applicable

codes.

FAILURE TO FOLLOW THESE INSTRUCTIONS

it does not fit the outlet, have a proper outlet

installed by a qualified electrician.

by the manufacturer or its service agent or a simi-

larly qualified person.

local plumbing code and any other applicable code.

kPa). To reduce water pressure, install a water

pressure regulator and set water pressure to suit

application.

-

sure minus the permeate water pressure) must not

valves are not permitted, please consult your local

plumber.

installed on the circuit to this system

sized electrical bonding jumper must be installed

across the inlet and outlet pipes serving this device.

UF-216 WATER FILTRATION SYSTEM

5

A.J. Antunes & Co.

P/N 1011078 Rev. B 03/12

SPECIFICATIONS

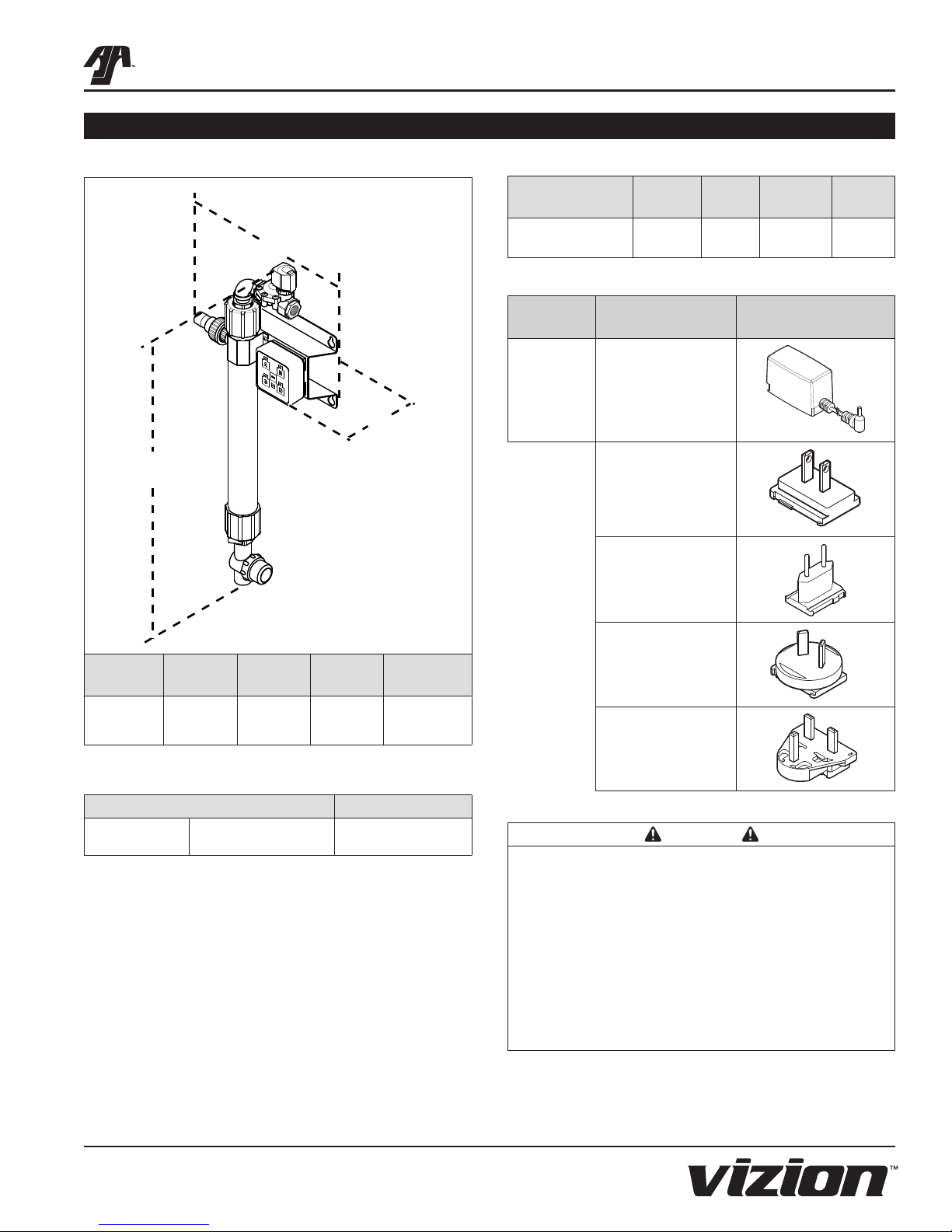

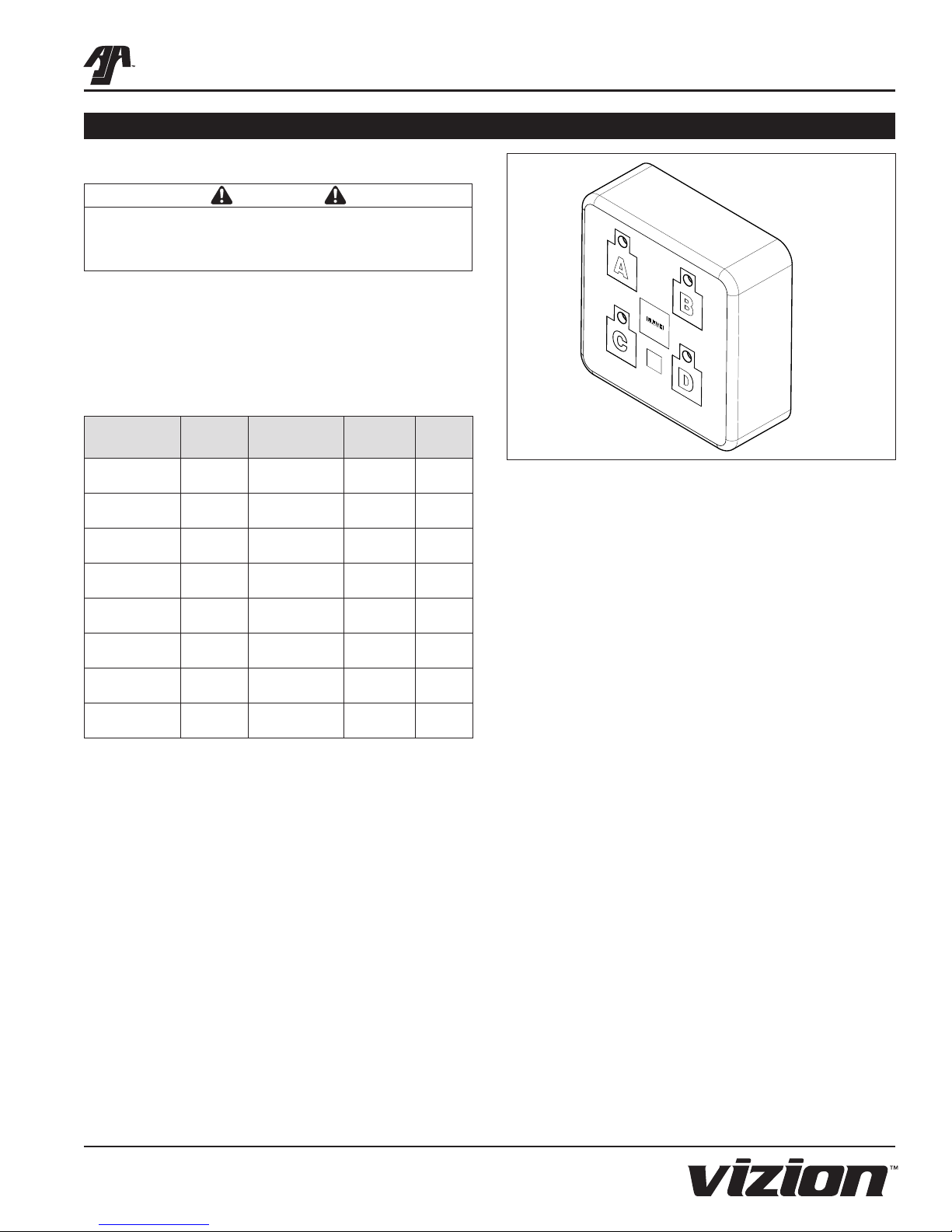

Electrical RatingsDimensions

CAUTION

All electrical connections must be in accordance

with local electrical codes and any other

applicable codes.

A ground fault circuit interrupter (GFCI) must be

installed on the circuit to this system.

When installed on metallic plumbing, a properly

sized electrical bonding jumper must be installed

across the inlet and outlet pipes serving this

device

A

C

B

Model &

Mfg. No. Voltage Watts Amps Hertz

UF-216

9700435 10 0.8 50/60

Model &

Mfg. No.

Width

(A)

Depth

(B)

Height

(C)

Operating

Weight

UF-216

9700435

11”

4”

26”

12 lbs.

Electrical Cord & Plug Configurations

Kit Model

Number Description Configuration

0012146

100 - 240 VAC

Includes the

4 plug adaptors

below NOTE: PLUG STYLE

M AY VAR Y

US

US

NEMA 1-15 (2 PIN)

or NEMA 5-15

(3 PIN)

Euro

CEE 7/16

EURO

CEE 7/16

AS/NZS

3112

AUS

AS/NZS 3112

(2 PIN)

AUS

BS 1363

BS 1363

UKUK

Replacement Cartridge Part No.

UF-216 Ultra Filter Cartridge 7000466

Replacement Cartridges

Ultra Filter Cartridge Capacities

pH Range 3-10

UF-216 WATER FILTRATION SYSTEM

6

A.J. Antunes & Co.

P/N 1011078 Rev. B 03/12

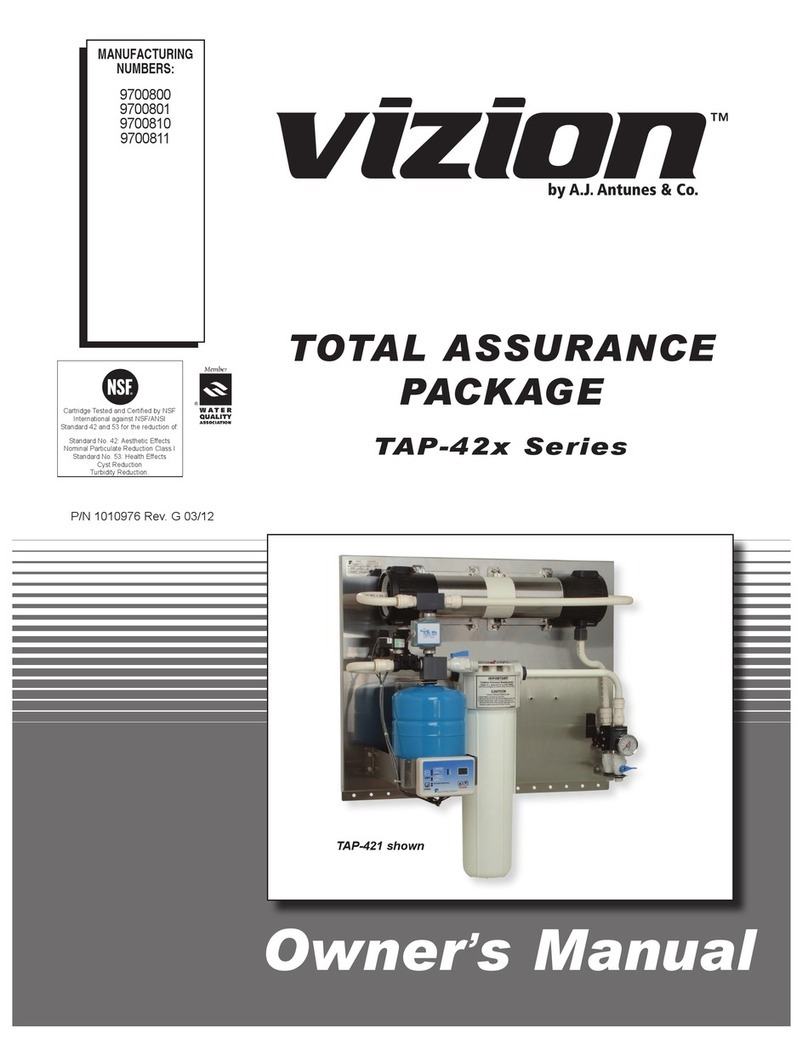

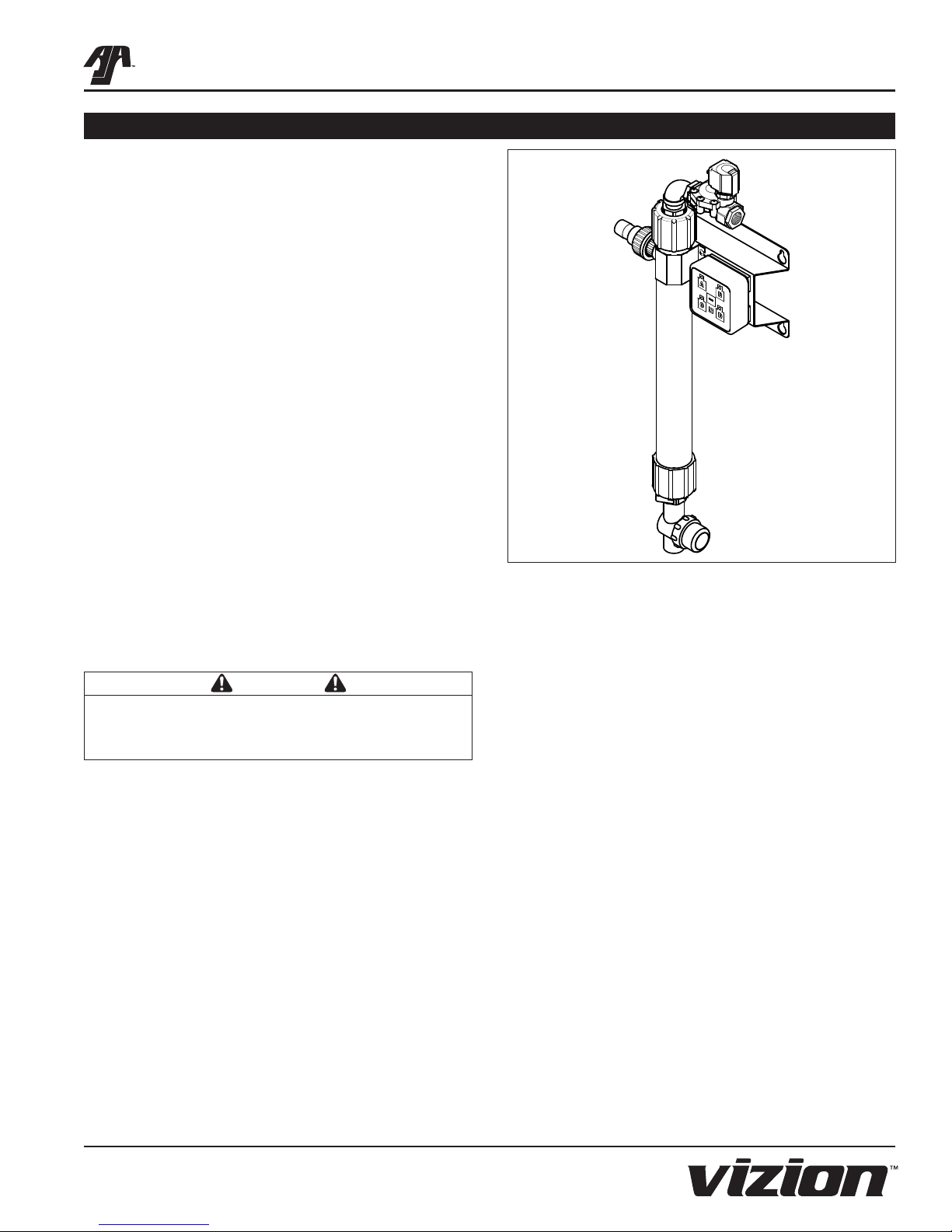

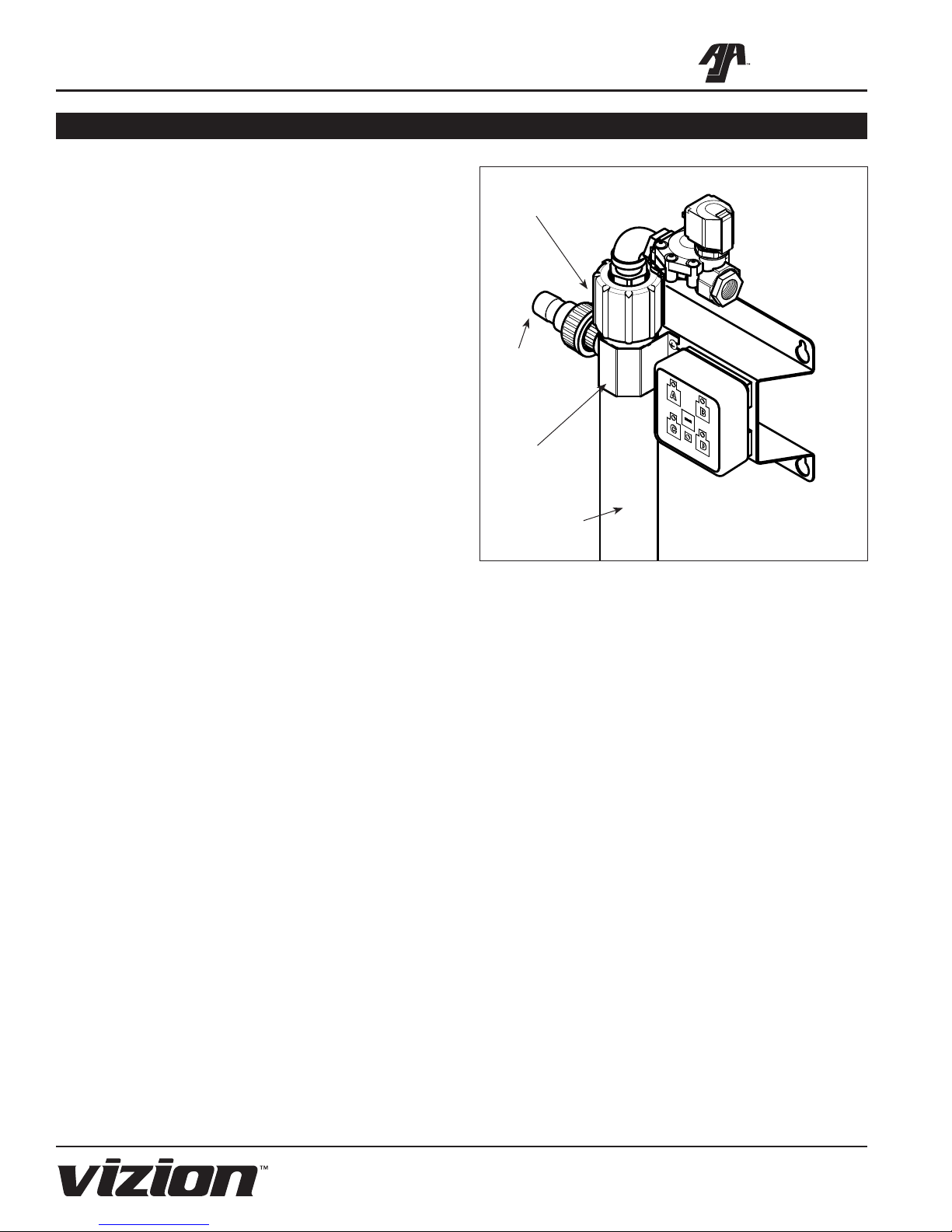

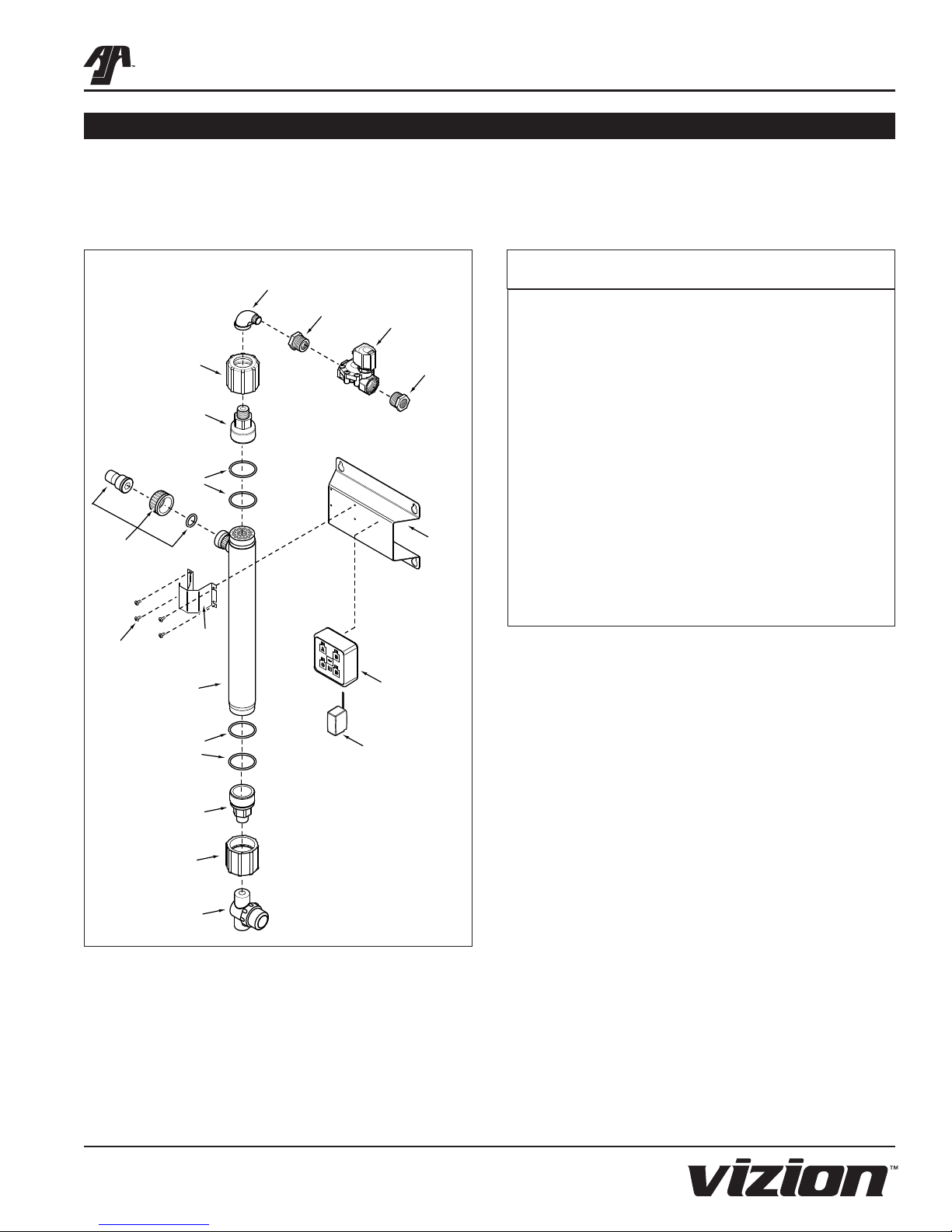

Drain

Pulse

Controller

SPECIFICATIONS (continued)

Flush Button

Filter

Housing

Figure 1. Components

Permeate

Outlet

Inlet

Mounting

Bracket

UF-216 WATER FILTRATION SYSTEM

7

A.J. Antunes & Co.

P/N 1011078 Rev. B 03/12

OVERVIEW

Overview

The UF-216 system operates in two modes:

and flows through the Ultra Filter before exiting the

Permeate Outlet as usable product water.

entering the Inlet flushes and cleans the Ultra Filter

membrane by removing any debris collecting on the

membrane wall.

NOTE: Do NOT unplug the power cord or turn off

the system during Flush Mode. If there is a power

outage or the system is unplugged, water will con-

tinue to be filtered but the system will NOT flush.

This could cause the Ultra Filter to plug premature-

ly and may void the warranty.

The flush is automated by the controller to last 10

seconds and take place in one hour intervals. This

Changing the Interval

Setting

Manual Flushing

A manual flush can be activated at any time by pressing

the FLUSH button.

When the FLUSH

NOTE: A manual flush will not affect the interval

flush setting.

CAUTION

Changing the flush interval can cause the Ultra

Filter to plug prematurely and may void the war-

ranty. Consult the factory for more information.

Figure 2. UF-216 System

UF-216 WATER FILTRATION SYSTEM

8

A.J. Antunes & Co.

P/N 1011078 Rev. B 03/12

Unpacking

1. Remove the system and all packing materials

from the shipping carton.

2. Remove all packing materials and protective

coverings from the system

3. Remove the information packet. To prevent any

delay in obtaining warranty coverage, fill out and

mail the warranty card.

NOTE: If any parts are damaged, contact A.J.

Antunes & Co. IMMEDIATELY at 1-800-253-2991 or

1-630-784-1000.

INSTALLATION

PLUMBING

NOTE: This unit is designed to use tap water not to

exceed 100°F (38°C) or 100 psig (690 kPa).

The UF-216 system uses the following connections

When making a plumbing connection to the system,

remember to use a back-up wrench on the supporting

plumbing. Always use a good quality, approved pipe

sealant or thread seal tape on pipe threads. Be careful

not to get the pipe sealant inside the pipe when making

the connections.

-

mended that plastic fittings be used when connecting to

the plastic connections of the system. This will reduce

the possibility of cracking the connections due to over-

tightening.

If soldered plumbing is used, do NOT apply heat to,

seal) connections is highly recommended for ease of

installation and future servicing.

CAUTION

This equipment is to be installed to comply with

the basic plumbing code of the Building Officials

and Code Administrators, Inc. (BOCA) and the

Food Service Sanitation Manual of the Food and

Drug Administration (FDA).

CAUTION

Water pressure must not exceed 100 psig (690

kPa). To reduce water pressure, install a water

pressure regulator and set water pressure to suit

application. Note that the trans membrane pres-

sure must not exceed 45 psi (310 kPa).

Equipment Setup

GENERAL

When placing the unit into service, pay attention to the

following guidelines:

SUGGESTED TOOLS AND SUPPLIES FOR INSTALLATION

The following tools and supplies are suggested to make

the installation easier:

to 3” diameter)

bleach

ELECTRICAL

Ensure that the line voltage corresponds to the stated

the plug on the power cord from the system and the

outlet match. For proper operation, and to ensure the

highest quality water from the system, make sure that

the system is not connected to a switched electrical

outlet.

IMPORTANT

Commonwealth of Massachusetts Plumbing Code

248 CMR shall be adhered to. The use of saddle

valves are not permitted, please consult your local

plumber.

UF-216 WATER FILTRATION SYSTEM

9

A.J. Antunes & Co.

P/N 1011078 Rev. B 03/12

INSTALLATION (continued)

Mounting the System

mount the system securely. When mounting the system,

pay attention to the following guidelines:

an appropriate electrical outlet when choosing a

mounting location.

-

ate electrical outlet.

equipment or items that may be damaged if they

get wet.

-

tions.

filtration processes.

the appropriate heavy duty mounting hardware.

the bottom of the system to the wall.

Inlet Water Plumbing

The Inlet water plumbing line should be 3/4” NPT or

in the line leading to the system. The valve should be

mounted close to the system inlet and sized properly for

the inlet plumbing line.

An optional “T” or Cross Fitting with cap or plug can be

installed between the Inlet Valve and the System Inlet.

This fitting can be used for draining and sanitizing the

system and downstream plumbing.

The system should only be connected to the cold water

line.

Before connecting the fitting to the System Inlet, the

plumbing to the system must be flushed clear of all

debris. Hold a bucket at the inlet water line and slowly

open the Inlet Water Valve. Allow the pipe to flush until

all debris is removed.

UF-216 WATER FILTRATION SYSTEM

10

A.J. Antunes & Co.

P/N 1011078 Rev. B 03/12

INSTALLATION (continued)

Drain Valve Connection

The drain line is for flushing particle buildup out of the

system during self cleaning. When connecting the drain

line, pay attention to the following guidelines:

flow rate whenever the system flushes. This flow

rate is dependent on the inlet water pressure, inlet

pipe size, and system.

as short as possible and slope downwards without

any kinks or loops.

3). This air gap protects the system from contami-

nation in the event of a backed-up drain.

the drain line plumbing.

Permeate Line Plumbing

To ensure the highest quality and safest water, it is

be installed in the water line after the permeate connec-

tion. This will help prevent possible contamination of the

filter system due to other equipment downstream. The

the system outlet, and sized properly for the plumbing

line. Check with local codes for the proper specification.

filtered water line leading from the system. The valve

should be mounted close to the system outlet and sized

properly for the plumbing line. This valve will allow for

easier servicing and future cartridge replacement.

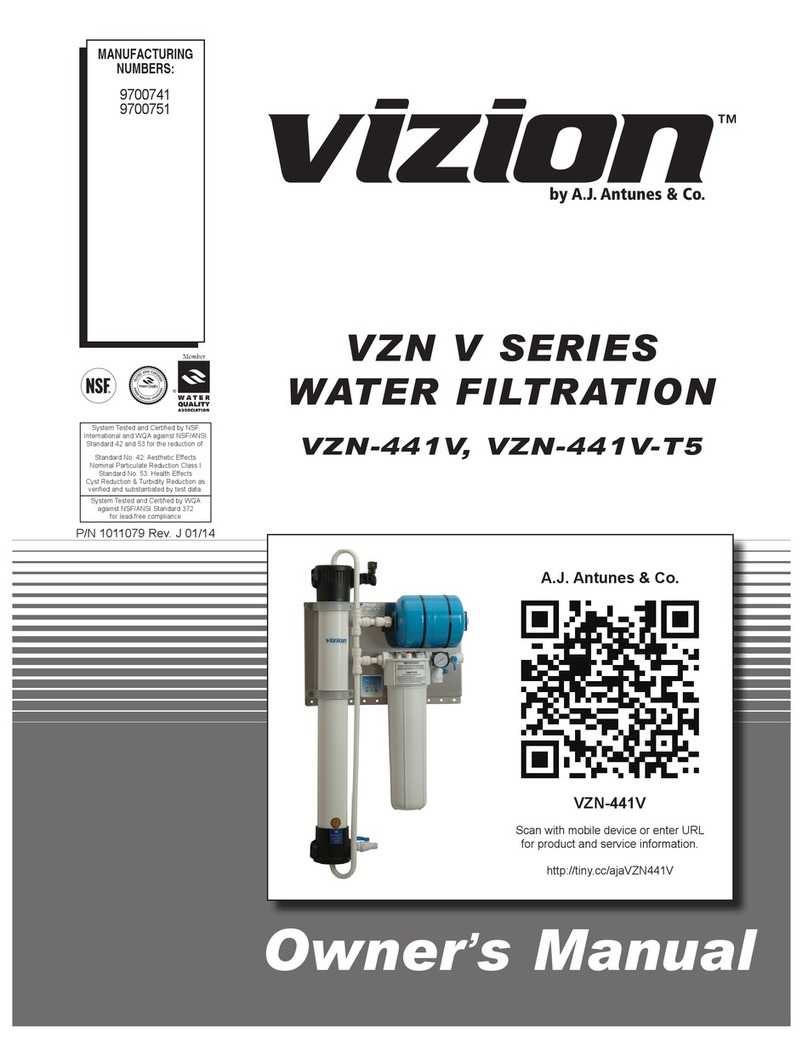

Figure 3. Proper Drain Plumbing

2” (5.1 cm)

minimum

2” (5.1 cm)

minimum

Floor

Drain

Secure

End

Drain Line

from System

Drain Line

from System

Secure

End

Drain

Standpipe

Starting the Controller

1. Select the proper AC plug for your electrical outlet

and install it onto the power supply.

2. Plug the appropriate end of the power cord into

the controller.

3. Plug the other end of the power cord into the electri-

indicating the unit has power and which interval is

selected in the controller.

UF-216 WATER FILTRATION SYSTEM

11

A.J. Antunes & Co.

P/N 1011078 Rev. B 03/12

INSTALLATION (continued)

Rinsing the Ultra Filter Cartridge

The Ultra Filter Cartridge must be rinsed before the sys-

tem is used to remove any air and protective solution.

NOTE: Ultra Filter Cartridge must be rinsed to drain

before use. Rinsing to drain removes storage solu-

tion and air. Do NOT rinse into carbon if present.

Carbon life and/or performance may be affected.

2. Open the tap or faucet closest downstream to the

filter system.

3. Slowly open the inlet water valve and allow water

to enter the system.

4. Press the FLUSH

open and air and water will come out of the drain

line. Repeat six times to ensure all air and stor-

age solution are flushed out of the Ultra Filter

Cartridge.

5. Allow water to continue to run through the system

and out the faucet for 15 minutes.

6. Inspect the unit for any leaks and repair as

needed.

7. After 15 minutes with water flow, close the tap or

faucet and let the system stand without water flow

for 15 minutes to allow trapped air to come out of

the hollow fibers of the Ultra Filter Cartridge.

8. After 15 minutes without water flow, open the tap

or faucet for five minutes to flush out the trapped

air.

9. Close the tap or faucet.

10. Press the FLUSH

Repeat six times to ensure any remaining air is

flushed out of the system.

Sanitizing the System and Lines

The plumbing must be sanitized to eliminate possible

contamination that may have occurred during the instal-

lation process.

used to sanitize the plumbing. The amount of bleach

needed depends on the system and the amount of

plumbing downstream of the system.

NOTE: Follow the handling and safety instructions

supplied with the bleach.

1. Follow the steps in the Rinsing the Ultra Filter

Cartridge in the Installation section of this manual.

2. Turn off the water to the system.

3. Open the faucet or tap closest downstream to the

system.

4. Close the Inlet Water Valve and allow the system

to depressurize.

5. Place a bucket under the “T” or cross fitting at the

inlet connection to the system. Open the inlet drain

valve or unscrew the cap to drain the system.

6. Press the FLUSH button to help drain the system.

7. When the water flow out of the inlet fitting stops,

close the inlet drain valve and pour the liquid

bleach into the inlet connection fitting. Be careful

not to spill bleach onto clothing or skin. You may

want to add the bleach using a cup. Reattach the

cap on the fitting.

8. Slowly open the inlet water valve and allow water

to flow out of the tap until the smell of bleach is

present.

9. Immediately close the tap and let the system

stand with no water flow for at least 15 minutes to

allow the bleach to sanitize the pipes.

10. After 15 minutes without water flow, open the tap

and flush until the presence of bleach is gone. All

other taps should be opened to flush any bleach

from the plumbing. Close the taps.

11. Press the FLUSH button to complete the flushing

process.

UF-216 WATER FILTRATION SYSTEM

12

A.J. Antunes & Co.

P/N 1011078 Rev. B 03/12

MAINTENANCE

System Sanitization

The system and downstream plumbing should be sani-

tized at least once a year. When necessary, follow the

procedure in Sanitizing the System and Lines in the

Installation section of this manual.

Replacing the Ultra Filter Cartridge

1. Open the faucet or tap closest downstream to the

filtration system.

2. Close the Inlet Water Valve and allow the system

to depressurize.

3. Place a bucket under the strainer at the inlet

connection to the system. Open the strainer by

unscrewing the cap. Water will flow out of the

strainer as the system drains.

4. Press the FLUSH button to help drain the system.

5. Reattach the cap on the strainer when the water

flow stops. Unplug the power cord.

the top and bottom End Caps yet.

8. Using a screwdriver, remove the screws from the

Cartridge Bracket and set the bracket and screws

aside.

9. Unscrew the End Caps from the cartridge.

10. Install a new cartridge to the system using the

cartridge bracket and screws from Step 8.

11. Connect the Permeate Port Connection.

12. Inspect the O-rings to ensure they are clean and

not splitting or cut. For all O-rings, ensure they are

lubricated with an approved food grade lubricant

acceptable for drinking water use.

13. Screw each End Cap onto the cartridge. Tighten

with a strap wrench if necessary.

14. Plug in the power cord.

15. Open the Inlet Water Valve and allow the system

to pressurize.

16. Rinse the new Ultra Filter Cartridge before

placing the system back into operation. Follow

the Rinsing the Ultra Filter Cartridge and

Sanitizing the System and Lines procedures in

the Installation section of this manual to complete

the cartridge change.

17. When rinsing is complete, repressurize the

system.

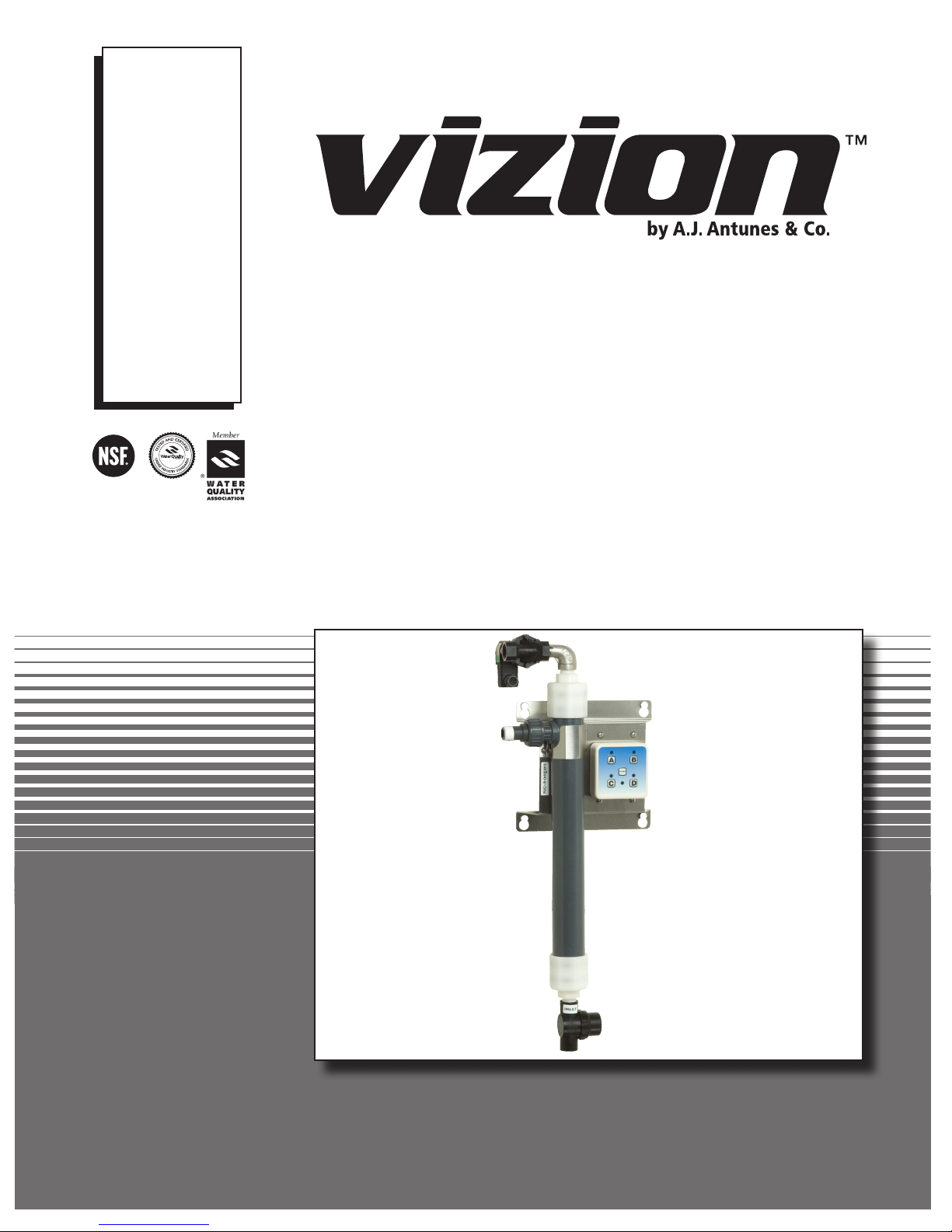

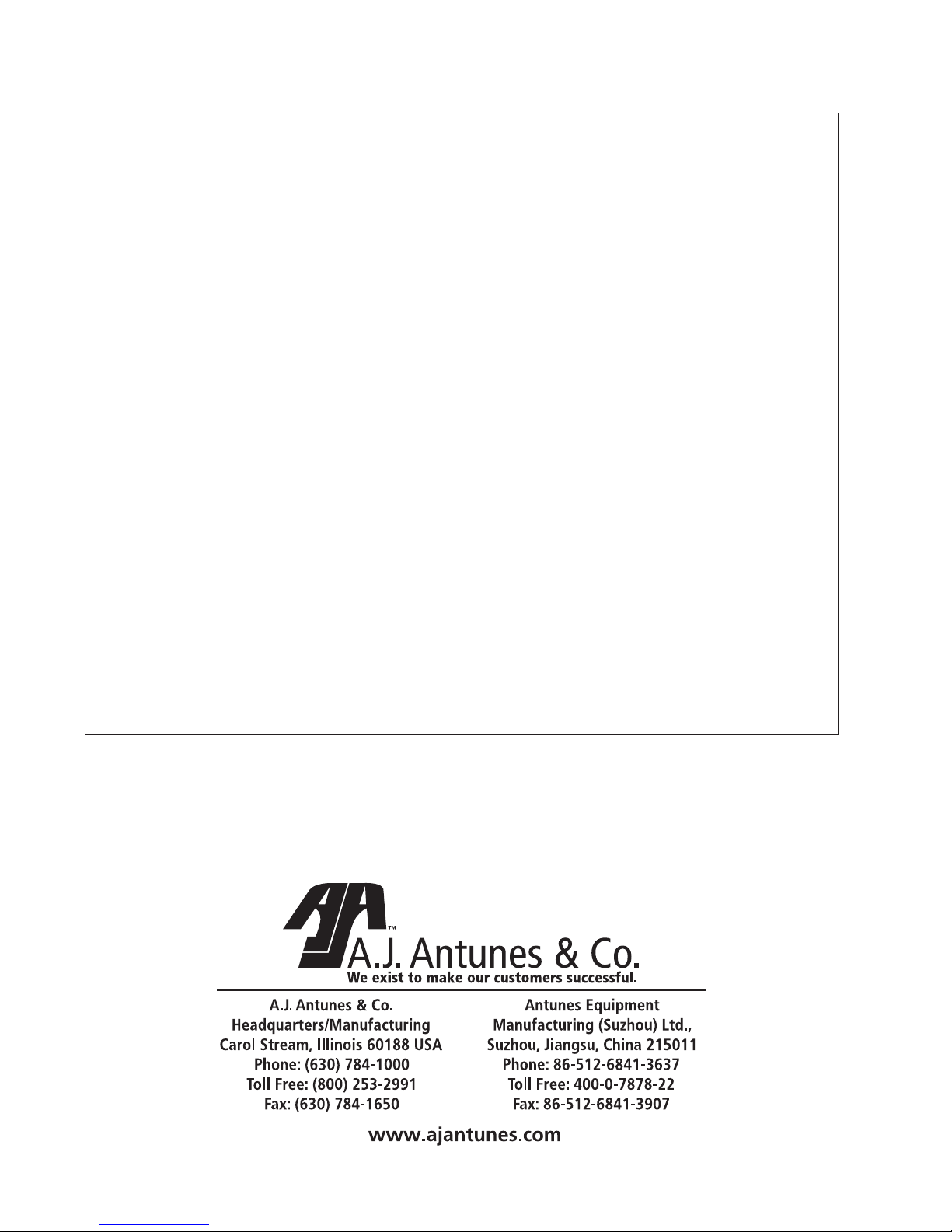

Figure 4. Replacing the Ultra Filter Cartridge

Cartridge

Bracket

Cartridge

End Cap

Permeate

Port

Connection

UF-216 WATER FILTRATION SYSTEM

13

A.J. Antunes & Co.

P/N 1011078 Rev. B 03/12

MAINTENANCE (continued)

Changing the Interval Setting

Resetting the Timer Program

according to the set interval. It is possible the system

will flush at a time of high water use. If this poses a

problem, the controller can be reset. Unplug the power

supply, wait for 5 seconds, and then plug the power

supply in. When power is restored to the controller, it

then begin timing from the point when power is restored

based on the interval setting selected.

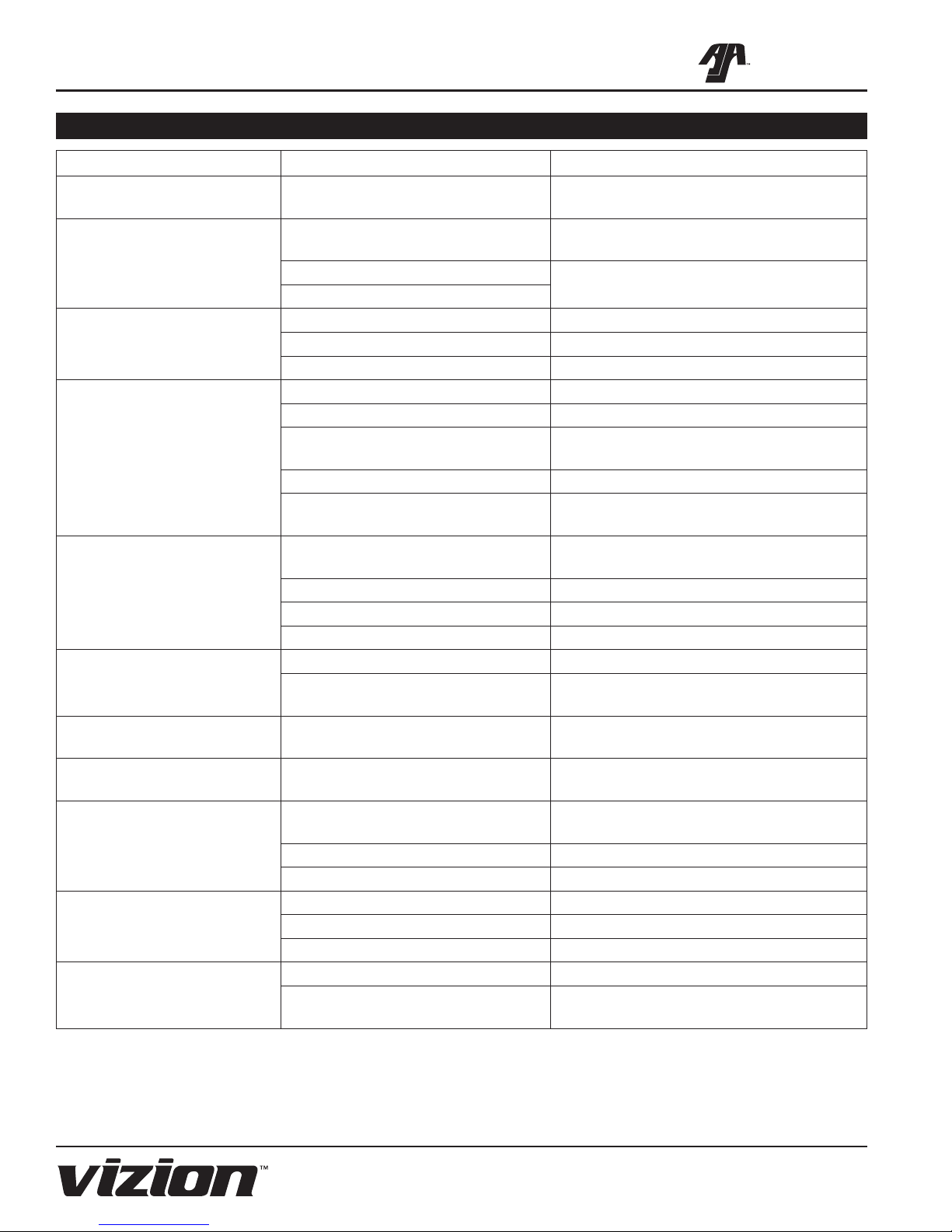

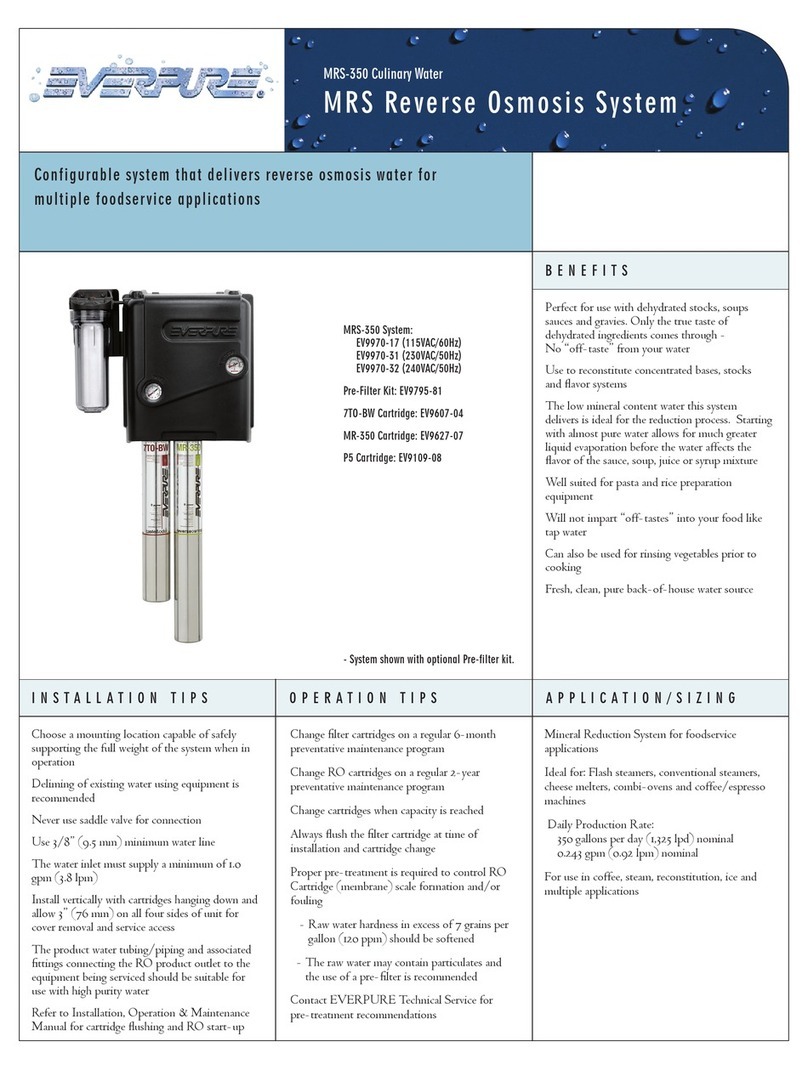

Figure 5. Controller

Flush

Interval Button Hold Time Button

LED

Flush

LED

15 minutes A10 seconds On On

30 minutes B10 seconds On On

45 minutes C10 seconds On On

1 hour A5 seconds On Off

4 hour B5 seconds On Off

6 hours C5 seconds On Off

12 hours 5 seconds On Off

24 hours 10 seconds On On

CAUTION

Changing the flush interval can cause the Ultra

Filter to plug prematurely and may void the war-

ranty. Consult the factory for more information.

Though not recommended, the Interval Setting on the

controller can be changed. If the setting must be

changed, use the chart below. Press and hold the cor-

on.

UF-216 WATER FILTRATION SYSTEM

14

A.J. Antunes & Co.

P/N 1011078 Rev. B 03/12

TROUBLESHOOTING

Problem Possible Cause Corrective Action

Unit does not have power. The power cord is not correctly

plugged in.

Plug power cord in correctly.

The power cord is not correctly

plugged in.

Plug power cord in correctly.

Control Board is inoperable. Contact your maintenance person or

Authorized Service agency.

Transformer is inoperable.

No water comes out of the fil-

ter system

Inlet Valve closed Open the Inlet Valve

Inlet Strainer is plugged Clean/replace Inlet Strainer

End of the capillaries plugged Clean/replace Ultra Filter Cartridge

Low water flow/pressure out

of system

See above. See above.

The system may be in a flush cycle. Wait for the flush cycle to end.

Flushing program not set correctly

for water conditions.

Operation section of this manual).

The inlet water pressure is too low. Boost the inlet water pressure/replace

pipes.

Water tastes bad. Storage/shipping solution not com-

pletely rinsed out of system.

Rinse system for a longer period of time.

Biological growth in pipes. Sanitize plumbing.

Water conditions changed. Consider installing taste and odor filtration.

Broken capillary in Filter Cartridge. Replace Filter Cartridge.

Flush runs continuously.

Controller sending continuous signal

to valve.

Replace the controller.

Flush occurs at time of high

water usage.

The Flush Interval is set to interfere

with water use.

Change Flush Interval. Unplug unit and

plug in at a time of lower water usage.

Water splashes at drain dur-

ing flush.

Reposition the end of the drain line.

Water leaks at the ends of the

Filter Cartridge after changing

cartridges.

Cartridge end connections are not

tight enough.

Tighten with wrench if necessary.

O-rings not lubricated. Lubricate O-rings with food-grade lubricant.

O-rings are split, cut, or twisted Replace O-rings.

Water leaks from Permeate

port.

Permeate port is not tight enough Tighten, with wrench if necessary.

O-ring not lubricated. Lubricate O-ring with food-grade lubricant.

O-ring split, cut, or twisted. Replace O-ring.

Water leaks from system fit-

ting or connection.

Fitting broken or loose. Retighten or replace the fitting.

Not enough pipe thread sealant

used.

Redo the fitting with the proper amount of

sealant.

UF-216 WATER FILTRATION SYSTEM

15

A.J. Antunes & Co.

P/N 1011078 Rev. B 03/12

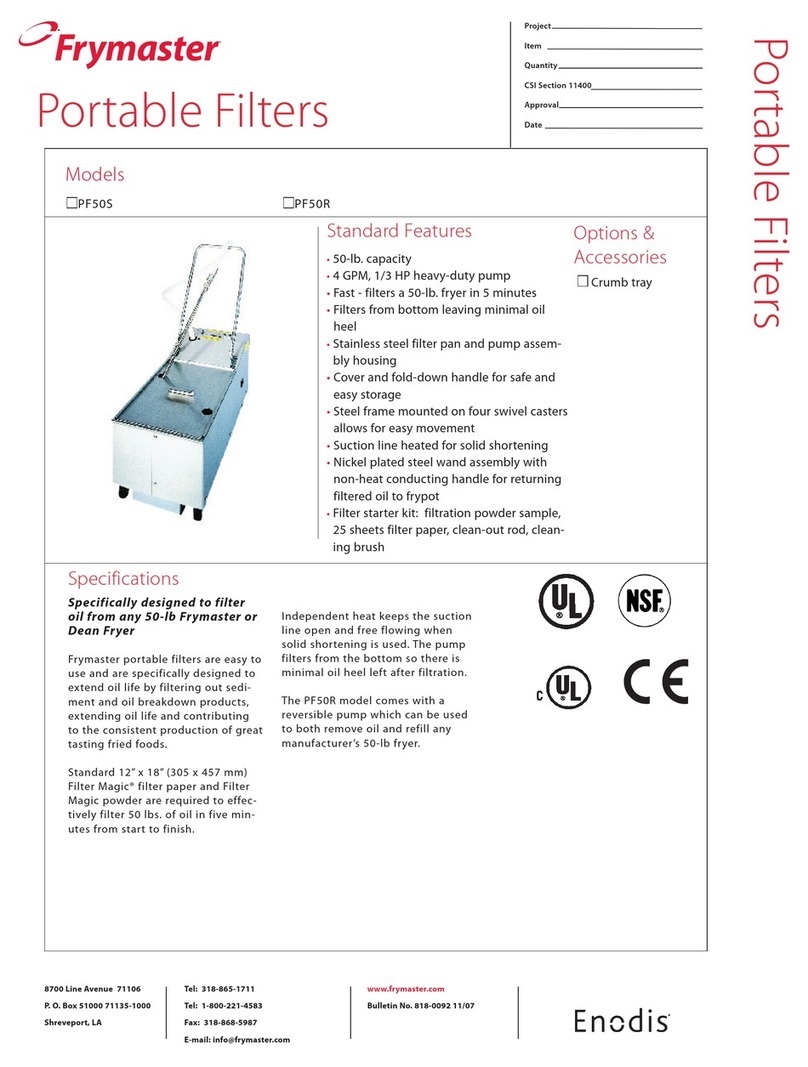

REPLACEMENT PARTS

14

13

12

11

10

16

9

2

3

4

8

7

5

4

3

2

1

6

Replacement Parts can be purchased from an authorized dealer. Contact

A.J. Antunes & Co. at 1-630-754-1000 or toll free in the United States at 1-800-253-2991.

1 2190133 Strainer, Tee 1/2” NPT 1

2 2180177 End Cap Filter, 2” 2

3 2180173 Slide Connector, 2” 2

4 0200219 O-ring, 2” 4

5 2090120 Cartridge Filter 2” x 16” 1

6 0503981 Filter Clamp, 2”

8 7000360 Permeate Assembly 1

10 2070132 Reducer Bushing 1

3/4” NPT to 1/2” NPT

13 0012357 Universal Pulse Controller 1

14 0012146 Power Adapter 1

16 2190169 Reducer Bushing 1

3/4” NPT to 1/2” NPT

Item Part Description Qty.

No.

LIMITED WARRANTY

Equipment manufactured by A.J. Antunes & Co. has been constructed of the finest materials avail-

able and manufactured to high quality standards. These units are warranted to be free from defects

in materials and workmanship for a period of one year from date of purchase under normal use and

service, and when installed in accordance with manufacturer’s recommendations*. The ultra filtration

membrane cartridge is warranted under the same terms and conditions on a prorated basis for 24

months from date of purchase.

*To ensure continued proper operation of the units, follow the maintenance procedure outlined in the

1. This warranty does not cover failures due to improper system installation, defects caused by improper

storage or handling prior to placing of the equipment into service. This warranty does not include

overtime charges or work done by unauthorized service agencies or personnel. This warranty does

not cover normal maintenance, calibration, or regular adjustments as specified in operating and main-

tenance instructions of this manual, and/or labor involved in moving adjacent objects to gain access to

the Equipment.

2. A.J. Antunes & Co. reserves the right to make changes in design or add any improvements on any

product. The right is always reserved to modify equipment because of factors beyond our control and

government regulations. Changes to update equipment do not constitute a warranty charge.

3.

If shipment is damaged in transit, the purchaser should make a claim directly upon the carrier.

Careful inspection should be made of the shipment as soon as it arrives and visible damage should

be noted upon the carrier’s documentation. Damage should be reported to the carrier. This damage

is not covered under this warranty.

4.

-

Prices and specifications are subject to change without notice.

This manual suits for next models

1

Table of contents

Other Vizion Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Everpure

Everpure MRS-350 quick start guide

GRE

GRE FAQ200 instruction manual

Frymaster

Frymaster Enodis PF50R Specifications

GE

GE Profile PNRQ15FBL Owner's manual and installation

Manitowoc

Manitowoc ArcticPure AR-10000 Installation, operation and maintenance manual

Monarch Water

Monarch Water PRISM COFFEE 10 install guide

Donaldson

Donaldson BOFA DentalPRO 250 user manual

Antunes

Antunes WATER WRO-50-R owner's manual

Brita

Brita Stream user guide

Watts

Watts OneFlow OF1260-30TM Installation, operation and maintenance manual

Omnifilter

Omnifilter U25 Series E installation instructions

Industrial Separation Systems

Industrial Separation Systems VGS Technical manual