Vizion TAP-42x Series User manual

TOTAL ASSURANCE

PACKAGE

TAP-42x Series

Owner’s Manual

P/N 1010976 Rev. G 03/12

Manufacturing

nuMbers:

9700800

9700801

9700810

9700811

Cartridge Tested and Certified by NSF

International against NSF/ANSI

Standard 42 and 53 for the reduction of:

Standard No. 42: Aesthetic Effects

Nominal Particulate Reduction Class I

Standard No. 53: Health Effects

Cyst Reduction

Turbidity Reduction.

TAP-421 shown

TAP-42X SERIES

2

A.J. Antunes & Co.

P/N 1010976 Rev. G 03/12

General

The TAP Series is an innovative filtration system that proprie-

tary multi-bore hollow fiber membranes as well as carbon ele-

ment to provide the latest innovation in filtration technology.

This manual provides the safety, installation and operating

procedures for the TAP-Series water filtration systems. We

recommend that all information contained in this manual be

read prior to installing and operating the system. Your TAP-

Series system is manufactured from the finest materials

available and is assembled to our strict quality standards.

This system has been tested at the factory to ensure depend-

able trouble-free operation.

OWNER INFORMATION

TABLE OF CONTENTS

IMPORTANT! Keep these instructions for future reference. If the system changes

ownership, be sure this manual accompanies the equipment.

Owner Information ...............................................................2

General............................................................................... 2

Warranty Information.......................................................... 2

Service/Technical Assistance ............................................. 3

Important Safety Information ..............................................3

Specifications .......................................................................5

Replacement Cartridges .................................................... 5

Operating Weights ............................................................. 5

Dimensions......................................................................... 5

Electrical Cord & Plug Configurations................................ 5

Performance Data Sheet......................................................7

Filter Cartridge Capacities.................................................. 7

System Capacities ............................................................. 7

Water Condition Equipment Guidelines.............................7

Performance Claims for Percent Reduction....................... 7

Installation.............................................................................8

Unpacking .......................................................................... 8

Equipment Setup................................................................ 8

Mounting the System ....................................................... 10

Drain Hose Connection.....................................................11

Rinse Hose Connection ....................................................11

System Inlet Connection ...................................................11

Filtered Water Permeate Outlet Connection .....................11

Starting the Smart Controller ........................................... 12

Rinsing the Ultra Filter Cartridge...................................... 12

Rinsing the Carbon Element and Plumbing

(TAP-421 units only)......................................................... 13

Sanitizing the System and Lines...................................... 14

Operation.......................................................................... 15

Manual Flushing............................................................... 15

System Power Loss ........................................................ 15

Operation.............................................................................15

Viewing Filtration Element Data....................................... 15

Viewing Sensor Readings ................................................ 15

Maintenance........................................................................16

Replacing the Ultra Filter Cartridge.................................. 16

Replacing the Carbon Element (TAP-421 ONLY) ............ 17

Resetting the Carbon Element Accumulated Total Value .... 18

System Sanitization.......................................................... 18

Troubleshooting .................................................................21

Wiring Diagram...................................................................22

Recommended Equipment Schematic.............................22

Replacement Parts .............................................................23

Limited Warranty ................................................................28

Warranty Information

Please read the full text of the Limited Warranty in this

manual.

If the system arrives damaged, contact the carrier immediate-

ly and file a damage claim with them. Save all packing materi-

als when filing a claim. Freight damage claims are the respon-

sibility of the purchaser and are not covered under warranty.

The warranty does NOT extend to:

improper use.

components.

any preset control or safety device.

TAP-42X SERIES

3

A.J. Antunes & Co.

P/N 1010976 Rev. G 03/12

Purchased From:

Date of Purchase:

Model No.:

Serial No.:

Mfg. No.:

IMPORTANT SAFETY INFORMATION

In addition to the warnings and cautions in this manual, use

the following guidelines to safely operate the system:

as described in this manual.

cord or plug; if it is not working properly, or if it has

been damaged or dropped.

-

nel only. Contact A.J. Antunes & Co. for repair.

water.

of Massachusetts Plumbing Code 248 CMR shall be

adhered to. The use of saddle valves are not permitted.

Please consult your local plumber.

The following warnings and cautions appear throughout this

manual and should be carefully observed.

service or maintenance on the unit.

local electrical codes and any other applicable codes.

Service/Technical Assistance

If you experience any problems with the installation or opera-

tion of your system, contact A.J. Antunes & Co. at 1-630-784-

1000, or toll free in the United States at 1-800-253-2991.

Fill in the information in the next column and have it handy

when calling for assistance. The serial number is on the

specification plate located on the system.

OWNER INFORMATION (continued)

IMPORTANT

A.J. Antunes and Company reserves the right to change specifications and product

design without notice. Such revisions do NOT entitle the buyer to corresponding

changes, improvements, additions or replacements for previously purchased equipment.

TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS INJURY OR DEATH.

- Do NOT modify the power supply cord plug. If it

does not fit the outlet, have a proper outlet installed

by a qualified electrician.

- Do NOT use an extension cord with this unit.

the manufacturer, its service agent, or a similarly quali-

fied person.

local plumbing code and any other applicable code.

To reduce water pressure, install a water pressure

regulator and set to suit the application.

the permeate water pressure) must not exceed 45 psi

(310 kPa).

installed on the circuit to this system.

electrical bonding jumper must be installed across the

inlet and outlet pipes serving this unit.

TAP-42X SERIES

4

A.J. Antunes & Co.

P/N 1010976 Rev. G 03/12

IMPORTANT SAFETY INFORMATION (continued)

Protect from becoming dry

If the membrane dries out, irreversible damage to the Ultra

Filter membrane may result. Protect the filter from becoming

dry by keeping it wet and sealed at all times.

Protect from freezing

If the Ultra Filter membrane freezes during operation or stor-

age, irreversible damage to the membrane and brittle cracking

of the cartridge or housing may result.

Protect from direct sunlight or other UV sources

Avoid long-term exposure to direct sunlight or other UV

sources. The Ultra Filter should be stored in a dark location.

Protect from high temperatures or abrupt variation in

temperature

The maximum operating temperature is 104°F (40°C). Avoid

abrupt variations in temperature. Any temperature variation

should be made slowly.

Protect from rough handling or dropping

Mechanical damage, external breakage, and/or internal break-

age of the filter can result if the system is dropped or bumped.

Handle with care at all times during transportation and instal-

lation.

Protect from organic solvents and concentrated acids

Prevent any and all contact of the membrane with strong sol-

vents, solvents containing chlorine, or concentrated acids. Do

NOT use strong solvents or concentrated acids on any plastic

parts of the filter system. Examples of some solvents to avoid:

acetone, methyl acetate (nail polish remover); hexane (spot

removers); turpentine, toluene (paint thinners); dry cleaning

solutions, insecticides.

Protect from abrasive material

The membranes must be protected from abrasive materials

like shavings left in a pipe. Abrasive materials in contact with

the membrane can cause irreversible damage to the mem-

brane. All pipes must be flushed clean before installing the fil-

ter. All plastic parts of the filter system must be protected from

sharp objects like knives, sand paper, or other tools. Cutting

or nicking a plastic part can weaken it and cause a leak. Do

NOT use abrasive cleansers on any plastic parts.

Protect from water hammer

The system must be protected from shock, pressure surges,

or pulsation that may occur inside water pipes. Water ham-

mer occurs in pipes when a valve or faucet shuts quickly.

Install a water hammer arrestor (pressure vessel containing

compressed air separated from the water by a diaphragm) to

reduce pressure shock.

CAUTION

This equipment is to be installed to comply with the

basic plumbing code of the Building Officials and Code

Administrators, Inc. (BOCA) and the Food Service

Sanitation Manual of the Food and Drug Administration

(FDA).

CAUTION

Water Flow Regulator Assemblies are NOT interchange-

able. Operating the system with the wrong Water Flow

Regulator or without a regulator can damage the sys-

tem, cause personal injury, and voids the warranty!

TAP-42X SERIES

5

A.J. Antunes & Co.

P/N 1010976 Rev. G 03/12

SPECIFICATIONS

Dimensions

CAUTION

All electrical connections must be in accordance with

local electrical codes and any other applicable codes.

Electrical Cord & Plug Configurations

A

B

C

(TAP-421 shown)

Replacement Cartridge Part Number

TAP-420 Ultra Filter L-420 7000411

TAP-421 Single pack Carbon 7000669

Replacement Cartridges

Kit Model

Number Description Configuration

0012146

DC Power Supply

100 - 240 VAC

Includes the

4 plug adaptors

below

US

NEMA 1-15 (2 pin)

or NEMA 5-15

(3 Pin)

Euro

CEE 7/16

3112

AUS

(2 Pin)

BS 1363

Model &

Mfg. No.

Width

(A)

Depth

(B)

Height

(C)

TAP-420

9700800

9700801

33”

(84 cm)

13”

(33 cm)

28”

(71 cm)

TAP-421

9700810

9700811

33”

(84 cm)

13”

(33 cm)

36”

(91 cm)

Model &

Mfg. No.

Operating

Weight

TAP-420

9700800

9700801

50 lbs.

(23 kg)

TAP-421

9700810

9700811

70 lbs.

(32 kg)

Operating Weights

NOTE: PLUG STYLE

M AY VAR Y

US

NEMA 1-15 (2 PIN)

or NEMA 5-15

(3 PIN)

BS 1363

UKUK

EURO

CEE 7/16

AS/NZS 3112

(2 PIN)

AUS

TAP-42X SERIES

6

A.J. Antunes & Co.

P/N 1010976 Rev. G 03/12

SPECIFICATIONS (continued)

Figure 1. System Components

Permeate

Tank

System

“SMART

Controller”

Differential Pressure

Sensor

UFL

Ultrafiltration

Cartridge

Carbon

Element

Housing

(TAP-421

units only)

System

Outlet

(Front)

Outlet

Ball Valve

(Manual)

Dual Check Valve

Assembly

with outlet

Pressure Gauge

Permeate Solenoid

Valve (Automatic)

Flow

Meter

DC Power

Supply

System

Outlet

Solenoid

Valve

(Automatic)

Inlet

Solenoid

Valve

(Automatic)

Inlet

Ball

Valve

(Manual)

INLET

Rinse

Ball Valve

(Manual)

DRAIN

Outlet

Ball Valve

(Manual)

Dual Check Valve

Assembly

with outlet

Pressure Gauge

Front View

Left-hand Side View Right-hand Side View

Carbon

Element

Housing

(TAP-421

units only)

Carbon

Element

Housing

(TAP-421

units only)

OUTLET

RINSE

System

Drain (Rear)

Rinse

(Rear)

System

Inlet

(Front)

TAP-42X SERIES

7

A.J. Antunes & Co.

P/N 1010976 Rev. G 03/12

PERFORMANCE DATA SHEET

Filter Cartridge Capacities

Maximum Operating Pressure 100 psig (690 kPa)

Maximum Operating Temp. 104°F (40°C)

Minimum Operating Temp. 40° F (4° C)

pH Range 3-10

MWCO 100 kD

System Capacities

Cartridge Tested and Certified by NSF

International against NSF/ANSI

Standard 42 and 53 for the reduction of:

Standard No. 42: Aesthetic Effects

Nominal Particulate Reduction Class I

Standard No. 53: Health Effects

Cyst Reduction

Turbidity Reduction

Cartridge has been tested according to NSF/ANSI Standard

42 and 53 for reduction of the substances listed below. The

concentration of the indicated substances in water enter-

ing the system was reduced to a concentration less than or

equal to the permissible limit for water leaving the system, as

specified in NSF/ANSI 42 or 53. While testing was performed

under standard laboratory conditions, actual performance may

vary.

Performance Claims for Percent Reduction

Substance Influent

Challenge

Concentration

Reduction

Requirement

cyst1minimum 50,000/L 99.95%

Turbidity 11+/1 NTU

Particulate Class I

Particles 0.5 to <

1µm

at least 10,000

particles /mL

85%

1based on the use of microspheres or Cryptosporium parvum oocysts

Model

Mfg. No.

Gal./Liters

Per Min.

(max)

Carbon

Element

Capacity

UF

Length

Number

of

Carbons

TAP-420

9700800

9700801 7.9 gal.

(30 liters)

0

20 in.

(51 cm)

0

TAP-421

9700810

9700811

60,000 gal.

(227,000 liters) 1

NOTE: The NSF Information provided above applies to

the TAP System’s Ultra-Filter Cartridge.

If your Inlet Turbidity (NTU) is... Then the Additional Equipment required or recommended is...

Less than 1 NTU Required: No additional equipment.

Recommended: Inlet Water Strainer (180 micron/80 mesh screen)

Greater than 1 NTU Required: Inlet Water Strainer (180 micron/80 mesh screen)

The following table describes the required or recommended equipment to be used with your filtration system based on the Inlet

Water Pressure and Inlet Turbidity.

WATER CONDITION EQUIPMENT GUIDELINES

TAP-42X SERIES

8

A.J. Antunes & Co.

P/N 1010976 Rev. G 03/12

INSTALLATION

Unpacking

1. Open the large box. It should contain:

A. Plate mounted TAP-42x Series system with UFL

cartridge installed (Figure 2).

B. One 20-foot coil of flexible hose.

C. Accessory Box.

2. Open the Accessories box. It should contain:

A. Padded Envelope containing:

B. Carbon Element (TAP-421 units only).

C. Carbon Element Housing (TAP-421 units only).

D. Mounting Bracket.

3. Remove all packing materials and protective coverings

from the system.

4. Remove the information packet. To prevent any delay in

obtaining warranty coverage, fill out and mail the war-

ranty card.

NOTE: If any parts are damaged, contact A.J. Antunes &

Co. IMMEDIATELY at 1-800-253-2991 (toll free in the U.S.

and Canada) or 1-630-784-1000.

SUGGESTED TOOLS AND SUPPLIES FOR INSTALLATION

The following tools and supplies are suggested to make the

installation easier:

bleach

The TAP System uses the following connections (Figure 1):

System Inlet Male 3/4" NPT

System Outlet

(Product Water) Male 3/4" NPT

Drain 3/4" I.D. Hose Barb

Rinse Outlet 3/4" GHT (Garden Hose)

When making a plumbing connection to the system, use a

back-up wrench on the supporting plumbing. Always use a

quality, approved pipe sealant or thread seal tape on pipe

threads. Do not allow pipe sealant inside pipes.

Do NOT over tighten the connections. Use plastic fittings

when connecting to the plastic connections of the system.

If soldered plumbing is used, do NOT apply heat to, or near,

the filtration system. Use union (O-ring seal) connections for

ease of installation and future servicing.

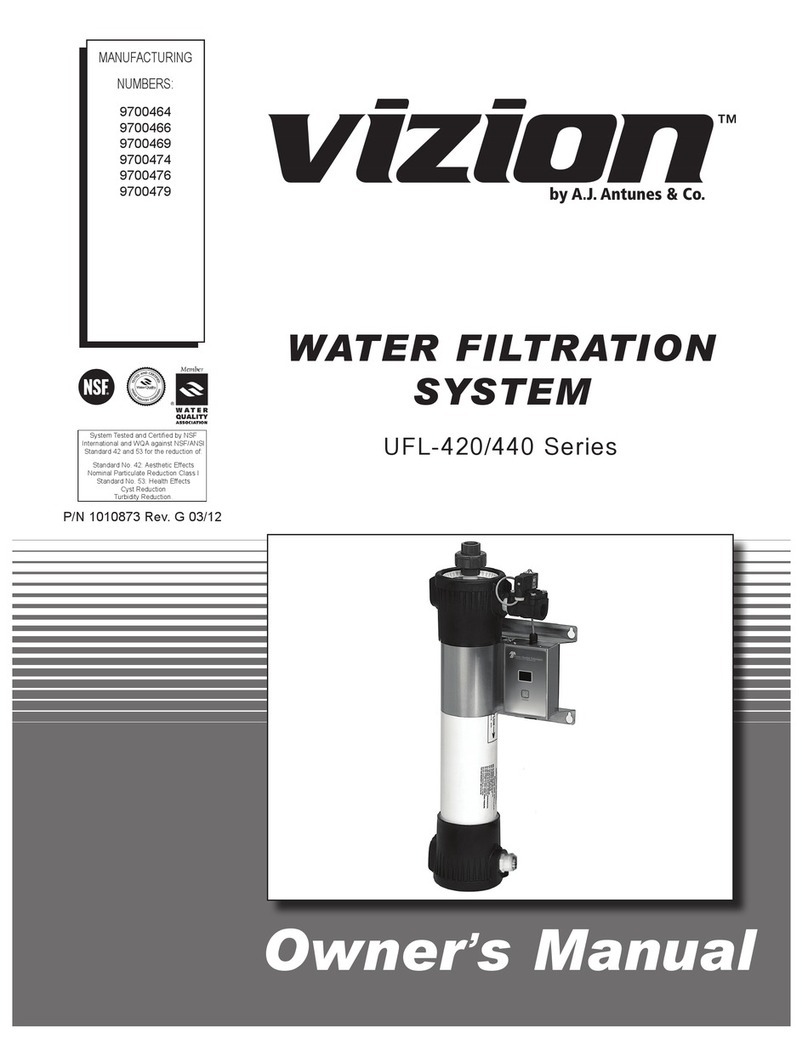

TAP-420 TAP-421

Figure 2. TAP-420 and TAP-421 Systems

Equipment Setup

GENERAL

When placing the system into service, pay attention to the

following guidelines:

ELECTRICAL

The line voltage must match the voltage on the specification

label. The plug on the power cord must match the appropriate

outlet. Do NOT connect the system to a switched electrical

outlet.

PLUMBING

NOTE: The system must be connected to the COLD water

line. Do not connect the system to the hot water line.

TAP-42X SERIES

9

A.J. Antunes & Co.

P/N 1010976 Rev. G 03/12

INSTALLATION (continued)

INLET WATER PLUMBING

If desired, a “T” or Cross Fitting with cap or plug can be

installed between the Inlet Valve and the System Inlet. This

fitting can be used for draining and sanitizing the system and

downstream plumbing.

The plumbing leading to the system must be flushed clear of

all debris before connecting to the system inlet. Hold a bucket

at the inlet water line and slowly open the inlet water valve.

Allow the pipe to flush until all debris is removed.

Figure 3. Proper Drain Plumbing

Figure 4. Smart Controller Inputs

2” (5.1 cm)

minimum

2” (5.1 cm)

minimum

Floor

Drain

Secure

End

Drain Line

from System

Drain Line

from System

Secure

End

Drain

Standpipe

DRAIN LINE PLUMBING

The drain line flushes particle buildup out of the system during

self cleaning and must be able to support the flow rate when

the system flushes.

The flow rate from the flush depends on the inlet water pres-

sure, inlet pipe size, and system selected. The drain opening

should be as large or larger than the inlet plumbing line.

The drain line leading out of the system should be as short as

possible, sloping downward without kinks or loops. Be sure

the drain used is not blocked or restricted.

Protect the system from possible back contamination by

installing an air gap between the drain connection of the

system and the drain (Figure 3). This gap in the line, with no

physical contact between the system and drain, prevents con-

tamination of the system in the event of a backed-up drain.

NOTE: Make sure the end of the drain line is positioned

and secured at least 2 inches above the drain so that the

water flow is directed into the drain without splashing.

ATTACH THE SMART CONTROLLER AND WIRING

HARNESSES

1. Using the provided Velcro®fastener, connect the Smart

Controller to the system as shown in Figure 2.

2. Connect the two wiring harness connectors to the

appropriate points on the bottom of the Smart Controller

(Figure 4).

NOTE: Do NOT plug the power transformer into the

SMART controller at this time. Mount the system to the

wall first before attaching the power.

ULTRAFILTER

1

2

3

VIEW

CARBON

SYSTEM

NO FLUSH DURING PEAK

% REMAINING

ULTRAFILTER

CARBON

CHANGE

Wiring

Harness

Connection

Points

USB Port

(used for

downloading

saved data)

Power

Transformer

Connection

Point

TAP-42X SERIES

10

A.J. Antunes & Co.

P/N 1010976 Rev. G 03/12

CAUTION

Due to its weight and size, the TAP System MUST be

mounted with the provided Mounting Bracket. Read

the ENTIRE section on Mounting the System BEFORE

attempting to mount the TAP System. Use care when

lifting heavy objects.

Mounting the System

NOTE: Use caution when lifting and mounting the sys-

tem. The system MUST be mounted using the provided

Mounting Bracket.

INSTALLATION (continued)

Secure Mounting Bracket

to wall studs using

appropriate hardware

The System is

designed to “hang” from

the Mounting Bracket

Back Plate

(holes along bottom for

additional mounting stability)

Follow these steps to secure the Mounting Bracket to the wall

and seat the TAP System on the Mounting Bracket:

1. Use a level and a stud finder to attach the Mounting

Bracket securely to the wall with the appropriate mount-

ing hardware (Figure 5).

2. The Mounting Bracket is designed so that the TAP

System can be lifted and “hung” on the Mounting

Bracket. With assistance, lift the TAP System and seat

it onto the Mounting Bracket securely (Figure 5).

3. Secure the bottom portion of the TAP System to the

wall using the holes provided. Make sure the mounting

hardware secures the system into wall studs or use the

appropriate mounting hardware (Figure 5).

Figure 5. Mounting (TAP-421 Shown)

IMPORTANT

Allow 20 inches on either the left or right side of the

unit for cartridge replacement. For TAP-421 units,

allow 3-4 inches below the unit to remove the Carbon

Element Housing.

The TAP System comes with a Mounting Bracket (P/N

0505558) to assist in mounting the system securely (Figure 5)

Before mounting the system, consider these important points

when choosing a mounting location:

system should be mounted with 20 inches on either the

left or right side of the unit to allow proper access when

changing cartridges.

NOT ABOVE an

appropriate electrical outlet.

-

tion processes.

and hardware capable of supporting 70 lbs or more.

appropriate heavy duty mounting hardware.

The system is pre-assembled to a back plate. The back plate

has mounting holes across the bottom portion to secure the

bottom of the system to the wall. Some of the bottom mount-

ing holes may be obscured. Plan your mounting accordingly.

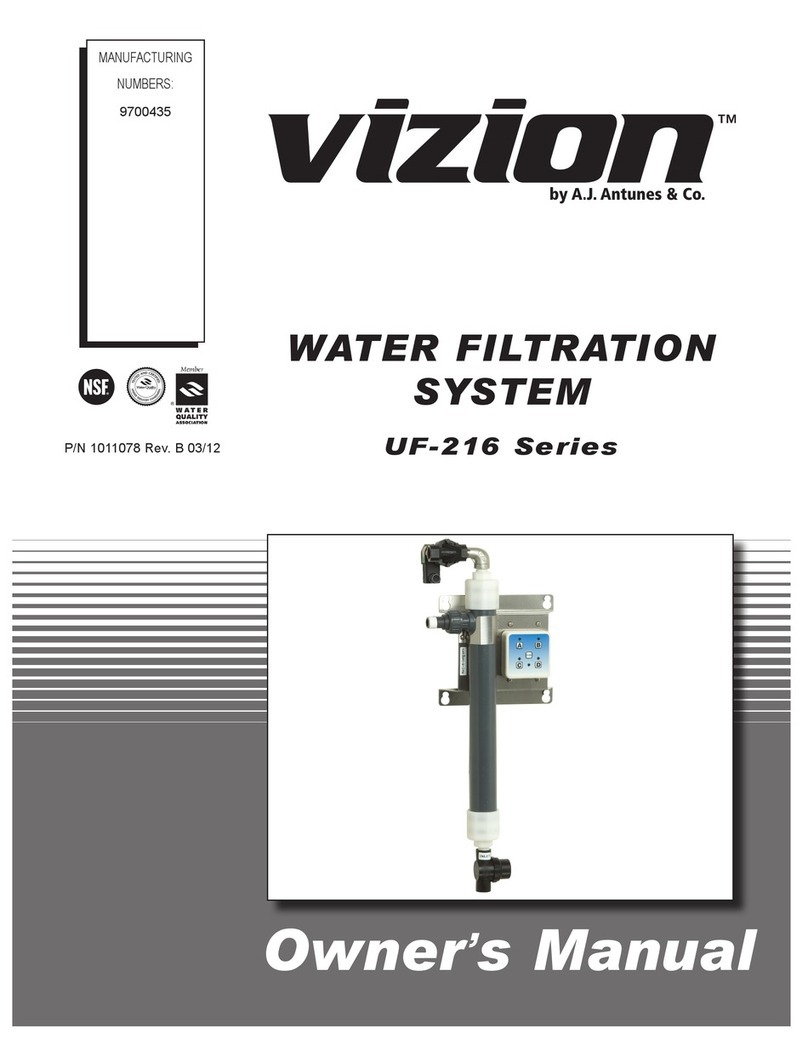

INSTALLING CARBON ELEMENT & HOUSING

(TAP-421 UNITS ONLY)

1. Insert the Carbon Element into the Carbon Element

Housing (Figure 6).

2. Screw the Carbon element Housing into the Carbon

Filter Head. Do NOT overtighten.

Carbon

Element

Housing

Carbon

Element

Head

Carbon

Filter

Element

Figure 6. Installing Carbon Element (TAP-421 ONLY)

NOTE: Mount the system to the wall BEFORE attaching the

Carbon Element and Carbon Element Housing (TAP-421 Only)

NOTE: Secure the bottom portion of the system to the wall

using the holes provided at the bottom of the Back Plate.

TAP-42X SERIES

11

A.J. Antunes & Co.

P/N 1010976 Rev. G 03/12

INSTALLATION (continued)

Drain Hose Connection

The TAP System is shipped with a coil of braided tubing (20

feet) designed to direct the Drain Valve Solenoid water to the

drain. Refer to Figure 7 and follow these steps:

1. If necessary, cut a length of braided tubing so that it

reaches the drain from the appropriate valve.

2. Connect one end of the hose to the Drain Valve

Solenoid and secure with a provided Worm Clamp.

3. Direct the other end of the hose to the drain.

NOTE: The drain MUST be able to accommodate a flow

up to 7.9 gpm. The drain hose MUST have an air gap

between the end of the hose and the drain.

Left-hand Side View

3/4”

Garden

Hose

Connection

3/4”

Garden Hose

(not supplied)

Direct hose

to Drain

Rinse Hose Connection

Figure 7. Attaching the Drain Hose

Figure 8. Attaching the Rinse Hose

CAUTION

Do NOT use the Rinse Valve connection for consumable

water. Because the Carbon Element is after the Rinse

Valve, the Rinse Valve water may have an objectionable

taste.

Rinse Hose Connection

The TAP System has a standard 3/4” garden hose connection

at the Rinse Valve (Figure 8).

1. Obtain a length of 3/4” garden hose long enough to

reach from the Rinse Valve connection to the drain.

2. Install a gasket in the end of the hose (non-drain end).

3. Connect the hose to the Rinse Valve fitting. Use a back-

up wrench on the fitting if required (Figure 8).

4. Direct the other end of the hose to the drain. Secure as

necessary (Figure 8).

NOTE: The drain MUST accommodate a flow of up to 7.9

gpm.

System Inlet Connection

The System Inlet (Figure 9) has a 3/4” NPT male thread at

the Inlet Valve. Do NOT overtighten fittings. The plastic ball

valve can crack due to over-tightening.

Use plastic fittings and a pipe thread sealant approved for use

on PVC fittings when making connections.

Filtered Water Permeate Outlet Connection

The system outlet (Figure 9) has a 3/4” NPT male thread at

the Outlet Valve. Do NOT overtighten a fittings. The plastic

ball valve can crack due to overtightening.

Use plastic fittings and a pipe thread sealant approved for use

on PVC fittings when making connections.

Right-hand Side View

Drain Hose Connection

Secure Hose

with Worm

Clamp

Direct Hose

to Drain

System

Inlet

Drain

Connection

Permeate

Outlet

Figure 9. TAP-42X Inlet and Outlet Connections

Right Side View Left Side View

TAP-42X SERIES

12

A.J. Antunes & Co.

P/N 1010976 Rev. G 03/12

INSTALLATION (continued)

NOTE: The system is designed to supply water even with

the power off. However, with power off, the system will

not flush or monitor any usage.

SETTING THE INTERNAL CLOCK

After setting the Product Type, the Display flashes "CL" indi-

cating that the Internal Clock must be set before any other

action can take place. The unit beeps as a reminder to set

this value. To set the clock:

1. Press and hold (in order) the VIEW

the red System LED illuminates and “ -- “ appears on

the display.

2. Release all buttons.

01.

4. Press the FLUSH button. The Clock Set program uses

the following format for date and time:

YY; MM; DD; HH (0-23); MM

time.

NOTE: The system uses military time. If the local time is

3:45 PM on July 2, 2008, the clock would be set as 08; 07;

02; 15; 45.

Rinsing the Ultra Filter Cartridge

The Ultra Filter Cartridge is pre-installed with the TAP System

before shipment. This cartridge must be rinsed before placing

the system into operation to remove air and the shipping solu-

tion from the Ultra Filter Cartridge.

Follow these steps to rinse the Ultra Filter Cartridge.

1. Manually close the Inlet Valve (Figure 11).

2. Make sure a drain hose is connected to the Rinse

Valve. Direct this hose to a drain.

Starting the Smart Controller

NOTE: Make sure that ALL ball valves are closed before

starting the system.

Follow these steps to power up the system:

1. After the system is mounted, connect the power supply

to the bottom right of the Smart Controller (Figure 4).

2. Select the appropriate adaptor for your power outlet

and attach the adapter to the transformer.

3. Plug the transformer into the appropriate outlet that has

power to it at all times.

NOTE: Do NOT plug the power transformer into an outlet

that will be switched off. Failure to supply power to the

system at all times may result in short cartridge life or

bad tasting water.

ULTRAFILTER 1

2

3

VIEW

CARBON

SYSTEM

NO FLUSH DURING PEAK

% REMAINING

ULTRAFILTER

CARBON

CHANGE

Figure 10. TAP System Control Panel

System

Display

3. Manually open the Rinse Valve (Figure 11).

4. Enter the 06 program. Press and hold (in order) the

VIEWSYSTEM LED illumi-

nates and “ -- ” appears on the display (Figure10).

NOTE: Ultra Filter Cartridge must be rinsed to drain

before use. Rinsing to drain removes storage solution

and air. Do NOT rinse into carbon if present. Carbon life

and/or performance may be affected.

06” and press the

FLUSH button to start the rinse program. The system

displays d3 and begins to depressurize.

6. Manually open the Inlet Valve. Press the FLUSH

button to start the r1 stage.

7. Wait until the display flashes r1 (approximately 1

minute). The system beeps.

8. Press the FLUSH button. The system starts the r2

stage.

9. Wait until the display flashes r2 (approximately 15

minutes) The system beeps.

10. Manually close the Rinse Valve.

11. Press the FLUSH button to start the r3 stage.

TAP-42X SERIES

13

A.J. Antunes & Co.

P/N 1010976 Rev. G 03/12

12. Wait until the display flashes r3 (approximately 15

minutes). The system beeps.

13. Manually open the Rinse Valve.

14. Press the FLUSH button to start the r4 stage (Rinse

Flow stage).

15. Wait until the display flashes r4 (approximately 5

minutes). The system beeps.

16. Manually close the Rinse Valve.

17. Press the FLUSH button to start the r5 stage.

18. Wait for 1 minute. Water flows through the UFL housing

and out of the Drain Solenoid Valve.

19. The system begins the r6 stage. The system completes

depressurization and displays d3.

20. Repressurize the system using the 08 program.

Press and hold the VIEW

SYSTEM LED illuminates and “ -- ” appears on the dis-

play.

08”.

22. Press the FLUSH button to start the Pressurize System

program.

The system repressurizes and makes water available through

the system.

INSTALLATION (continued)

Rinsing the Carbon Element and Plumbing

(TAP-421 units only)

The Carbon Element is used on TAP-421 units only. The

Carbon Element must be rinsed before using the system the

first time and after replacing the Carbon Element.

1. Direct water from the System Outlet to a drain.

2. Turn on the water to the system.

3. Allow water to flow through the Carbon Element and

Carbon Element Housing to flush out trapped air and

any debris that may be present.

4. To help remove trapped air from the Carbon Element

Housing, press the red button on the top of the housing

until water just begins to come out of the button.

5. Flush the Carbon Element for at least 5 minutes.

NOTE: Do NOT consume water used during this process.

6. When the Carbon Element flushing is complete, turn off

the water to the system.

7. Reconnect the water to service. The system is now

ready for use.

8. For new piping installations: After making the con-

nection to the System Outlet:

a. Open the faucet or tap closest to the filter system

b. Slowly open the Inlet Valve.

c. Allow the pipe to flush until all debris is removed.

Figure 11. Manual Valve Locations (TAP-420/421)

Inlet

Ball

Valve

(Manual)

Rinse

Ball

Valve

(Manual)

Outlet

Ball Valve

(Manual)

Front View

Left-hand Side View

TAP-42X SERIES

14

A.J. Antunes & Co.

P/N 1010976 Rev. G 03/12

INSTALLATION (continued)

Sanitizing the System and Lines

NOTE: If installed, remove the Carbon Element from the

system BEFORE Sanitizing.

The plumbing must be sanitized to eliminate possible contam-

ination that may have occurred during the installation process.

One ounce (30 ml) of liquid chlorine bleach (regular bleach,

unscented 6 % sodium hypochlorite) can be used to sanitize

the plumbing. The amount of bleach to use depends on the

system installed and the amount of plumbing downstream of

the TAP System.

NOTE: Follow the handling and safety instructions

supplied with the bleach.

1. Follow the procedures in the Rinsing the Ultra Filter

Cartridge section of this manual.

2. Remove the Carbon Element from the system

(TAP-421 systems only).

3. Turn off the water to the system.

4. Open the faucet closest downstream to the system.

5. Allow the system and plumbing to drain.

6. If an inlet sanitation fitting is installed, remove the plug

or disconnect the water line at the inlet of the system.

Allow the water to drain out of the system.

7. Pour the bleach into the inlet sanitation fitting or inlet

water line using a cup or funnel. Be careful not to spill

bleach onto clothing or skin.

8. Reattach the plug on the sanitation fitting or inlet

water line.

9. Slowly turn on the water supply to the system.

10. Allow water to flow through the system and out of the

open faucet until the smell of bleach is present.

11. Close the faucet.

12. Let the system stand without water flow for at least 15

minutes to allow the bleach to sanitize the pipes.

13. After 15 minutes without water flow, open the faucet.

14. Allow water to flow through the system until the

presence of bleach is gone.

15. Open all other faucets in line with the system to flush

any bleach from the plumbing.

16. Close all open faucets.

17. If your system uses Carbon Element (TAP-421 sys-

tems only) and you removed them in step 2, follow the

steps in the Replacing the Carbon Element in the

Maintenance section of this manual.

18. If necessary, reinstall the Carbon Element or install a

new Carbon Element.

19. Repressurize the system using the 08 program.

Press and hold the VIEW

SYSTEM LED illuminates and “ -- ” appears on the

display.

08”.

21. Press the FLUSH button to start the Pressurize System

program.

The system repressurizes and makes water available through

the system. Sanitation is complete.

TAP-42X SERIES

15

A.J. Antunes & Co.

P/N 1010976 Rev. G 03/12

CAUTION

The system continues to filter water even after a power

loss but it will NOT flush. Therefore, running the system

without power may shorten the life of the filtration ele-

ments. Make sure the system always has power.

Operation

The TAP System is designed to operate with little to no user

intervention. The system monitors and flushes itself automati-

cally.

Manual Flushing

The TAP System is designed to automatically flush but can

also be manually flushed when desired. To manually flush the

system:

1. Press and hold the FLUSH button for 3 to 4

seconds.

2. The system enters the FLUSH program and automati-

cally performs the following stages while displaying the

stage code on the display throughout the process:

F1 (Close Permeate Solenoid Valve stage)

F2 (Close Inlet Solenoid Valve stage)

F3 (Open Drain Solenoid Valve stage)

F4 (Open Inlet Solenoid Valve stage)

F5 (Close Drain Solenoid Valve stage)

F6 (Open Permeate Solenoid Valve stage)

NOTE: The system automatically performs these stages

3. Flushing is complete once the system completes the

F6 stage of the FLUSH program.

System Power Loss

The TAP System is designed to run with constant power.

Thus, the power cord should always be plugged into an

appropriate power outlet that will not be switched off.

In the event of a power loss, the TAP System:

1. Aborts any active valve program.

2. Resets the valves to normal operation (pressurized/

water available).

3. Sounds an alert to notify the operator of the power loss.

4. Records the time of the power loss into the controller

memory.

5. Displays the EV-20 event code (indicating a loss of

power).

6. The system beeps 4 times every 10 seconds for

approximately 2 minutes. Then it beeps once every 30

seconds.

NOTE: Be sure to restore power to the system. The sys-

tem displays the EV-21 code when power is restored to

the system.

Viewing Filtration Element Data

The TAP System monitors the lifespan of the filtration ele-

ments and can display the percent-of-life remaining for the

selected component. Follow these steps to view the Filtration

Element Data:

1. Press the VIEW button to cycle through the Ultra Filter

and Carbon LEDs.

2. Pressing the VIEW button again steps to the next

component.

3. The system displays the percent-of-life remaining for

the selected component in the display.

Viewing Sensor Readings

The TAP System uses the Flow Meter and Differential

Pressure Sensor to monitor the Flow Rate and Differential

Water Pressure respectively.

The system also uses measurements to determine when to

automatically flush and monitors the effectiveness of the flush

operations. To view this data:

1. Press and hold both the VIEW

Red SYSTEM LED illuminates.

2. Press the VIEW button to scroll through the green LEDs

(numbered 1, 2, and 3 - Figure 12) which indicate the

following data:

LED 1 (top): Used to determine when the system

automatically flushes and measures the effectiveness

of flush operations.

LED 2 (middle): Flow Rate, in gallons per

minute (gpm)

LED 3 (bottom): Differential Water Pressure, in

pounds per square inch (psi)

3. To exit, press and hold the FLUSH button until the red

SYSTEM LED turns off.

OPERATION

Figure 12. TAP System Control Panel

LEDs

1, 2, and 3

ULTRAFILTER 1

2

3

VIEW

CARBON

SYSTEM

NO FLUSH DURING PEAK

% REMAINING

ULTRAFILTER

CARBON

CHANGE

TAP-42X SERIES

16

A.J. Antunes & Co.

P/N 1010976 Rev. G 03/12

MAINTENANCE

Snap

Ring End

Cap

Ultra Filter

Housing

Ultra Filter

Cartridge

End Cap

O-rings

Cartridge

O-ring

Cartridge

O-ring

End Cap

O-rings

Snap

Ring

End

Cap

Remove the Elbow

from this point

on either side

of the system to

access the

UF Cartridge

Figure 13. Replacing the Ultra Filter Element

Replacing the Ultra Filter Cartridge

NOTE: Always install a new Carbon Element after replacing

the UFL cartridge.

This procedure involves depressurizing the system, replacing

the UFL cartridge, and then repressurizing the system.

DEPRESSURIZE THE SYSTEM

1. Depressurize the system using the 07 program.

Simultaneously press the VIEW

system LED illuminates and the system displays “ -- “

on the display.

07.

3. Press the FLUSH button.

The system performs the 07 program, which consists of

the following stages:

d1 (Close Inlet Valve stage)

d2 (Open Drain Valve stage)

d3 (Close Permeate Valve stage)

4. When the 07 program completes, place a bucket under

one end of the Ultra Filter Cartridge Housing.

5. Refer to Figure 13 (and inset). Locate the elbow fitting

on the desired side of the cartridge and push the collet

squarely in against the face of the fitting. With the collet

held in this position, the fitting can be removed from the

tubing. Water drains into the bucket. Discard this water.

NOTE: Make sure there is enough room next to the system

to remove the cartridge.

6. Remove the Snap Ring from the Ultra Filter housing.

Grab the raised lug with a pair of pliers and pull towards

the center of the end cap and away. The ring should lift

out of its groove.

7. Remove the End Cap, End Cap O-ring, and Cartridge

from the housing (Figure 13).

NOTE: If the cartridge does not easily come out of the

housing, remove the opposite End Cap for assistance

during Step 4.

8. Inspect the cartridge O-rings and end cap O-ring for

nicks or cuts. Replace as needed.

9. Lubricate all O-rings with a food-grade silicone lubri-

cant. Apply a light coating of lubricant to the inside

center tube at both ends of the new cartridge.

10. Record the serial number of the new cartridge. The

cartridge serial number is engraved on one end of the

11. Install the End Cap O-ring on the End Cap and insert

the End Cap into the end of the new cartridge.

12. Position the new cartridge and End Cap at the housing

and gently insert into the housing.

13. Press the End Cap into position until it is fully seated

and the Snap Ring groove is visible.

TAP-42X SERIES

17

A.J. Antunes & Co.

P/N 1010976 Rev. G 03/12

Replacing the Carbon Element (TAP-421 ONLY)

The life of a Carbon Element depends on the overall quality

of the water in the area. Follow these steps to replace the

Carbon Element:

1. Turn off water to the system by closing the Inlet valve

and the Outlet valve.

2. Run the 03 program. Press and hold the VIEW and

-- “

appears on the display.

03.

4. Press the FLUSH button.

The system performs the 03 program, which consists of

the following stages:

C1 (Close Inlet Valve stage)

C2 (Open Drain Valve stage)

C3 (Open Permeate Valve stage)

5. When the 03 program completes, press and hold the

RED Pressure Relief Button on the top of the Carbon

Element Housing (Figure 14) to lower the water level

inside the housing by 2 to 3 inches.

6. Remove the Carbon Element Housing.

O-Ring

Carbon

Element

Housing

Carbon

Filter

Element

Carbon

Element

Head

RED Pressure

Relief Button

Figure 14. Replacing the TAP Carbon Element

MAINTENANCE (continued)

14. Install the Snap Ring by guiding the non-lugged end

into the groove first, pushing outward and working

around the ring until it snaps into place.

NOTE: Make sure that the Snap Ring is fully seated

before turning the water on.

15. Re-attach the elbow fitting that was disconnected in

Step 5 (Figure 13 and inset). Push the fitting onto the

tubing until it comes into contact with the internal tubing

stop. Rotating the fitting slightly during installation helps

make the connection slide past the O-ring seal.

NOTE: Make sure the fitting is completely inserted onto

the tubing past the O-ring. A loose connection results in

leaking at the point of connection.

16. Rinse the new Ultra Filter cartridge before placing the

system back into operation. Follow the Rinsing the

Ultra Filter Cartridge and Sanitizing the System

and Lines procedures in the Installation section of this

manual to complete the cartridge change.

17. When rinsing is complete, repressurize the system.

08” and press the

FLUSH button to start the Pressurize program.

7. Empty any water into a drain and discard the old

Carbon Element. See Figure 14.

8. Inspect the O-ring on the Carbon Element Housing.

Replace the O-ring if it is cracked, twisted, or missing.

9. Lubricate the O-ring with an approved food grade lubri-

cant and install into the Carbon Element Housing.

10. Install the new Carbon Element into the Carbon

Element Housing.

NOTE: Make sure the End Seal gaskets are in place on

both ends of the Carbon Element. The gasket is retained

on the end of the element in the recessed groove. Be

careful that the gasket does not fall off the element while

placing the element into the bowl.

11. Screw the Carbon Element Housing (containing the

Carbon Element) into place. Tighten the Carbon

Element Housing until it stops. The housing will come to

a hard stop at the end of the thread. Use a filter wrench

if necessary.

12. Direct the outlet of the system to drain.

NOTE: It is important to direct the system outlet to drain

as the water resulting from Steps 13 through 17 should

NOT be used.

13. Next, repressurize the system using the “08"program.

To enter the program, press and hold (in order) the

VIEWSYSTEM LED illumi-

nates and “ -- “ appears on the display.

08”.

TAP-42X SERIES

18

A.J. Antunes & Co.

P/N 1010976 Rev. G 03/12

MAINTENANCE (continued)

Resetting the Carbon Element Accumulated

Total Value

The TAP System uses the Carbon Element Accumulated Total

feature to measure the lifespan of the Carbon Element.

After installing the Carbon Element, the Carbon Element

Accumulated Total value must be reset. This ensures that

system maximizes the life of the Carbon Element.

1. Reset the Carbon Element Accumulated Total using

the 04 program. Simultaneously press the VIEW and

SYSTEM LED illuminates and “ -- “

appears on the display.

04.

3. Press the FLUSH button to start the program. The

system automatically resets the Carbon Element

Accumulated Total. The display returns to “ -- “.

4. Press the FLUSH button again to return the system to

normal operation.

15. Press the FLUSH button to start the Pressurize System

program. This allows the system to pressurize when the

Inlet valve is opened and make water available to the

Carbon Element.

16. Turn on the water to the system by opening the Inlet

Valve and allow water to flow through the Carbon

Element and Housing to rinse out trapped air and any

carbon fines that may be present.

To help remove trapped air from the Carbon Element

Housing, press the red button on the top of the housing

until water just begins to come out of the button.

17. Rinse the Carbon Element for at least 5 minutes.

NOTE: Do not consume the water used for rinsing the

Carbon Element.

18. When the Carbon Element rinsing completes, manually

close the Inlet Valve and reconnect the water to service.

19. When the system is reconnected, turn on the water by

manually opening the Inlet Valve and Outlet Valve. The

system is ready for use. System Sanitization

The system and downstream plumbing should be sanitized at

least once a year.

When necessary, follow the Sanitizing the System and

Lines procedure in the Installation section of this manual.

TAP-42X SERIES

19

A.J. Antunes & Co.

P/N 1010976 Rev. G 03/12

MAINTENANCE (continued)

NOTE: The system beeps every time a button is pressed.

NOTE: When in normal operating mode, pressing both the ▲ and ▼ buttons displays the current software version.

POWER LOSS TO SYSTEM (SYSTEM UNPLUGGED OR SUPPLY INTERRUPTED)

FLUSH (BUTTON)

Press and hold to run a Flush cycle. The system automatically performs the following stages:

VIEW (BUTTON) Normal Operating Mode

Toggles between UFL cartridge % of life and Carbon Element % of life

VIEW (BUTTON) – SENSOR READINGS

1. Press and hold (in order): VIEW

2. The red System LED illuminates.

3. Press the VIEW

4. To exit Sensor Readings, press the FLUSH button until red LED turns off.

ERROR CODE DESCRIPTIONS

EC-01

Flow Rate is greater than 0 gpm

EC-08

less than ½ of the discharge amount)

EC-02 - Differential Pressure is greater than 45 psid

EC-09 - Memory data re-initialized

EC-03 - Differential Pressure is greater than 0 psid,

EC-10

EC-06 - Flush Flow is less than 0.75 gallon EC-11

EC-07 - Flow is greater than 10 gpm EC-12 - Flow switches erratic

EC-13 - EEPROM bad

EVENT CODE DESCRIPTIONS

TAP-42X SERIES

20

A.J. Antunes & Co.

P/N 1010976 Rev. G 03/12

MAINTENANCE (continued)

SERVICE MENU ACCESS

Press and hold in order, the VIEW

1. The red SYSTEM LED illuminates and the “--” appears in the display.

2. Release all buttons. The system displays “--”.

FLUSH button

4. To exit the Service Menu, press the FLUSH button until the red LED turns off.

“--” - Exit Service Level 2 13 - Set Differential Pressure Sensor to 0 psi

01 - Set Clock (Year; Month; Day; Hour 0-23; Minute) 14

02 - Set Flush Time Hour and Minute (Hour 0-23; Minute) 15 - Clear Displayed Error Codes (Data stays in memory)

03 - Change Carbon Element 20 - Set Valve Times (Factory use only)

04 - Reset Carbon Element Accumulated Total 21 - Set Forward Flush Time (Factory use only)

05 - Set Maximum Gallons for Carbon

Element (x 10,000)

22 - Set Maximum VER Value (Factory use only)

06 - Rinse New UFL Membrane and reset UFL Total 23 - Set Flush Trigger Point (VER Value) (Factory use only)

07 - Depressurize UFL System 24 - Reset to Factory Values

08 - Pressurize System 25

09 - Toggle Valves (Green LED illuminated when valve is

26

10 - Dump User Data out USB (serial) port 27 - Set VER Factor (Factory use only)

11 - Dump Events out USB (serial) port 28

buttons.

Note: Items 25 & 26 are in versions 2.3 AC and 3.3 DC. Items 27 & 28 are in version 2.4 & 3.4 (as of 8-10-07 not released).

PROGRAM DESCRIPTIONS

03 - (Change Carbon Element)

06 - (Rinse New UFL Membrane)

06 program (See Service Menu Access above)

07 - (Depressurize UFL System) program (see below)

d3. When the system beeps, operator opens both the Rinse Ball Valve and the Inlet Ball Valve.

Press FLUSH.

r1 stage. Operator - wait for 1 minute. The system beeps. Press FLUSH

r2 stage: Operator - wait for 15 minutes. The system beeps. Manually close the Rinse Ball Valve. Press FLUSH.

r3 stage: Operator - wait for 15 minutes. The system beeps. Manually open the Rinse Ball Valve. Press FLUSH.

r4 stage: Operator - wait for 5 minutes. The system beeps. Manually close the Rinse Ball Valve. Press FLUSH.

r5 stage: Operator - wait for 1 minute as the system automatically opens the Drain Valve.

r6 stage: The system closes the Inlet Valve - the system is depressurized.

07 - (Depressurize UFL System)

08 - (Pressurize System)

This manual suits for next models

2

Table of contents

Other Vizion Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Conel

Conel CLEAR STOP operating instructions

Judo

Judo JHF-T Installation and operating instructions

Wen

Wen 3410 Replacement guide

Dennerle

Dennerle CarboSTART E200 + Special Edition operating instructions

Simple Water Service

Simple Water Service 7QCRO Installation, operation & service

Quooker

Quooker CUBE installation guide

kent marine

kent marine MAXXIMA MAX24 instructions

GE

GE GNULQ installation instructions

BRUEL & KJAER

BRUEL & KJAER 1623 instruction manual

Ferplast

Ferplast BLUWATERFALL user manual

Fresh Water Systems

Fresh Water Systems GTS-550S installation instructions

entegris

entegris Optimizer ST2 Installation and use manual